Abstract

The synthesis of cobalt, nitrogen and sulfur co doped carbon quantum dots (Co-NS-CQDs) has become a subject of significant research interest. These CQDs were produced using a single-step microwave method, which is considered environmentally friendly, and the entire process was completed in just 90 seconds. In this synthesis, citric acid was utilized as the carbon source, methionine served as the source for both nitrogen and sulfur, and cobaltous acetate was used to introduce cobalt ions into the CQDs structure. The synthesized carbon quantum dots (CQDs) exhibit a narrow size distribution and a high quantum yield of 51.5%, which is notably superior to non-metal-doped CQDs with a yield of 38%. Characterization of these CQDs was performed using different techniques such as transmission electron microscopy (TEM), high-resolution TEM (HRTEM), Fourier transformation infrared spectroscopy (FTIR), energy dispersive X-ray analysis (EDX), X-ray diffraction (XRD) and X-ray photoelectron spectroscopy (XPS). The developed CQDs have blue luminescence at emission wavelength 438 nm after excitation at 350 nm. Different factors affecting the CQDs synthesis including dialysis duration, reaction time and reaction temperature. These CQDs were utilized as a probe for the detection of monosodium glutamate (MSG) in various food products. The intensity of the fluorescence of the CQDs showed a direct and linear increase with the concentration of MSG within the range of 25–250 µg/mL. The detection and quantitation limits for MSG were 2.78 µg/mL and 8.44 µg/mL, respectively. Additionally, the developed method is environmentally friendly, as confirmed by assessments using the analytical Eco scale, Green Analytical Procedure Index (GAPI), and Analytical Greenness calculator (Agree). The proposed method presents several advantages over other reported methods in terms of convenience, rapid response, and attainment of accurate and precise results.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Photoluminescent carbon quantum dots (CQDs) possess a range of advantageous characteristics, including chemical stability, ease of synthesis, low cytotoxicity, unique optical properties, robust stability, biocompatibility, and environmental friendliness (Gulati et al. 2023). Consequently, CQDs find increasing applications in various fields (Shilpi and Thakur 2023), including bioimaging, biosensing (Pourmadadi et al. 2023), catalysis (Yadav et al. 2023), and chemical sensors (Zhu et al. 2023; Salih Ajaj and Sadiq 2023; Wang et al. 2023b). Several methods have been employed for CQDs synthesis, such as hydrothermal (John et al. 2023; Zhang et al. 2023; Sun et al. 2023), pyrolysis (Kostromin et al. 2023), microwave (De et al. 2023; Kim et al. 2023), solvothermal (Wang et al. 2023a; Palacio-Vergara et al. 2023), laser ablation, and arc discharge (Yang et al. 2023). However, these methods often involve multiple steps, consume substantial energy, and require sophisticated conditions. The microwave method, on the other hand, offers a solution by being both rapid and energy-efficient (Elshenawy et al. 2022, 2023; El-Malla et al. 2022). To further enhance the utility of CQDs, surface functionalization and heteroatom doping have emerged as effective strategies (Shanmugasundaram et al. 2023; Cui and Zhang 2023; Anthony et al. 2023; Mondal et al. 2023). These approaches were applied to improve photoluminescent properties and broaden the range of applications for CQDs (El-Malla et al. 2021). Chemical heteroatom doping involves the introduction of non-metal atoms (Mohandoss et al. 2023; Abdella et al. 2024) and metal ions (Rajabi and Farsi 2015; Dewangan et al. 2022) into CQDs, altering their electronic structures and energy gaps. Among non-metallic atoms, nitrogen and sulfur are commonly used, as they have similar radius to carbon atoms and they reduce the energy gap (Ahmed Abdel Hamid et al. 2023; Ambade et al. 2023). Transition metal ions have more electrons and unoccupied orbitals. Thus they can readily form chelates with amino and carboxyl groups on CQDs surfaces during chemical reactions. The inclusion of such metal ions can introduce new physicochemical properties to CQDs, such as catalytic capabilities (Lin et al. 2018). CQDs doped with non-metallic atoms like nitrogen and sulfur, in combination with cobaltous ions, exhibit exceptionally bright fluorescence, excellent surface passivation, resistance to photobleaching, and ultra-high photoluminescence quantum yields. This is primarily due to excitation energy traps.

In this study, non-metal and metal ion-doped CQDs were successfully synthesized through a one-step microwave method in only 1.5 minutes. The synthesis involved the use of citric acid and methionine as a non-metal dopant, along with cobaltous acetate as a metal dopant. All factors affecting the fluorescence intensity including the reaction time, reaction temperature and excitation wavelength were investigated carefully. These CQDs were utilized as a probe for the routine analysis of MSG in food products. Traditional methods for determination of MSG such as UV–visible spectroscopy (Rachma and Saptawati 2021; Elattar et al. 2023), spectrofluorometry (Kamal et al. 2023; Kumar Vashistha et al. 2023), chromatography (Krishna Veni et al. 2010; Demirhan et al. 2015; Soyseven and Arli 2021) and potentiometry (Md Isa and Ab Ghani 2008; Anirudhan and Alexander 2015), do offer advantages in terms of sensitivity and selectivity. However, they have inherent drawbacks, including complex sample preparation, the need for expensive equipment, and long analysis durations. Hence, there is a pressing need for a rapid, straightforward, and eco-friendly method for MSG analysis in food products.

Experimental Section

Materials

The starting materials citric acid and methionine were obtained from Sigma Aldrich (99%, Missouri, USA). Hydrochloric acid and sulfuric acid were purchased from Advent Chembio (Maharashtra, India). Potassium iodide (99%), sodium hydroxide (98.9%) and cobalt acetate (98%) were of laboratory grade (ISO-Chem, Vert-le-petit, France). Quinine sulfate (99%) (reference for the quantum yield measurements) was purchased from Alpha chemika (Maharashtra, India). Instant noodles and chicken cubes were purchased from local market.

Apparatus

Fluorescence measurements were conducted using JASCO FP-6300 spectrofluorimeter (Tokyo, Japan) with a slit width of 5.0 nm at a scanning speed of 1000 nm/min equipped with Spectra Manager software (V1.53.01). For UV data spectra processing and manipulation, Shimadzu UV-1800 double beam spectrophotometer (Kyoto, Japan) with a UV Probe 2.33 software, was employed. X-ray photoelectron spectroscopy XPS was collected on K-ALPHA (Thermo Fisher Scientific, USA) with monochromatic X-ray Al K-alpha radiation -10 to 1350 eV with a spot size of 400 µm at pressure 10–9 mbar with full spectrum pass energy 200 eV and at narrow spectrum 50 eV. X-ray diffraction pattern XRD was performed using X-ray diffractometer (Bruker Co, D8 Discover, Germany) using Cu Kα radiation line with a wavelength of 1.54 A. Tornado Microwave oven (1000W) model MOM-C36BBE-S with frequency of 50 HZ was used for the synthesis of CQDs. The pH measurements were conducted using HANNA pH-meter with double junction glass electrode calibrated by standard buffers. Digital balance (Sartorius, Germany) were utilized for sample preparation. Jasco FT/IR-4100 spectrophotometer (USA) was utilized to measure FTIR spectra. Dialysis membrane has molecular cut off 10 KDa and a mean pore size of 2–5 nm was used for CQDs synthesis.

Synthesis of Co-NS-CQDs

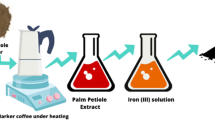

In a 10 mL flask, citric acid (0.5 g), methionine (0.3 g), and cobaltous acetate (0.06 g) were dissolved in distilled water, and the solution was brought up to the mark. This solution was thoroughly mixed and sonicated for 5 minutes until it turned into a red solution. Subsequently, the mixture was transferred to a crucible and placed inside a microwave oven for 1.5 minutes until the formation of a viscous bluish-yellow layer of Co-NS-CQDs. After this step, the Co-NS-CQDs were allowed to cool, and 5.0 mL of distilled water was added. To separate any remaining particles, a dialyzing membrane was employed. Finally, fluorescence intensities were measured at an emission wavelength of 438 nm following excitation at 350 nm. Figure 1 summarizes the steps of Co-NS-CQDs synthesis and characterization.

Quantum Yield Measurement

The quantum yield QY was determined using quinine sulfate as a reference in 0.1 M H2SO4 (Qst = 0.54), employing the following equation:

where Fu/Fst represents the fluorescence ratio of CQDs to quinine sulfate after excitation at 350 nm. While Au and Ast correspond to the absorbance of CQDs and quinine sulfate respectively and η refers to the refractive index of the solvents (η = 1.33 for aqueous solvents).

Determination of MSG

To prepare a stock solution of MSG (1 mg/mL), 0.01 g of MSG was precisely weighed and diluted up to 10 mL with distilled water in 10 mL flask. For the preparation of the working solution within the range of 25–250 µg/mL, various volumes of the MSG solution (ranging from 250 µL to 2500 µL) were added to 500 µL of carbon quantum dots (CQDs) in a series of 10 mL flask. Then these CQDs were diluted with distilled water and were thoroughly mixed to obtain the desired working solution concentrations. Subsequently, the fluorescence intensities were measured at 438 nm following the excitation at 350 nm versus the blank. The blank was prepared by the addition of 500 µL of CQDs in 10 mL flask and completed with distilled water to the mark.

Assay of Food Products

Chicken Cubes

A 0.5 g portion of chicken cubes was crushed using a mortar and pestle and then transferred to a 100 mL flask where it was dissolved in distilled water. The resulting solution was sonicated and subsequently filtered to generate the stock solution. To create the working solution, 500 µL of this stock solution was mixed with 500 µL of Co-NS-CQDs and diluted further with distilled water until reaching a final volume of 10 mL. The fluorescence intensities of this solution were then measured, and the amount of monosodium glutamate (MSG) present in the sample (99.05 µg/mL) was determined using standard addition method. Different volumes (250 µL, 500 µL, 1000 µL) of a 1.0 mg/mL MSG standard solution were added to 500 µL of the stock solution and 500 µL of CQDs in separate 10 mL flasks. After dilution with distilled water, the respective fluorescence intensities of these solutions were measured.

Instant Noodles

Each packet of instant noodles contains a powder sachet weighing 4.588 grams. To prepare the stock solution of the noodles, 0.5 grams of the powder were accurately weighed and dissolved in distilled water in a 100 mL flask. The solution was then sonicated for 10 minutes and subsequently filtered using a filter membrane. Following this, 250 µL of the stock solution of noodles were added to 500 µL of Co-NS-CQDs and the volume was adjusted to the mark with distilled water in a 10 mL flask. The fluorescence intensities of this solution were measured at 438 nm after excitation at 350 nm. The amount of MSG in the noodles was determined to be 76.37 µg/mL using the calibration curve obtained through the standard addition method. This involved adding different volumes (250 µL, 500 µL, 1000 µL) of a 1 mg/mL MSG standard solution to 250 µL of the noodles' stock solution and 500 µL of Co-NS-CQDs in separate 10 mL flasks, followed by the measurement of their fluorescence intensities.

Results and Discussion

Synthesis and Characterization of Co-NS-CQDs

The highly water-soluble carbon quantum dots (CQDs) were efficiently synthesized using an environmentally friendly microwave-assisted method in 90 seconds as illustrated in Fig. 1. This microwave-based approach offers notable advantages over other synthesis methods due to its speed, reduced energy consumption, and enhanced reaction rates. The resulting CQDs exhibit blue luminescence when exposed to UV light, with a high quantum yield of 51.5%. To examine the morphology and microstructure of the prepared CQDs, they were subjected to TEM and HR-TEM analysis. The TEM image in Fig. 2A shows that these CQDs are nano-sized, with dimensions up to 8 nm and are uniformly distributed quasi-spherical particles, without evident aggregation. Figure S1 illustrates the size distribution of CQDs. The HRTEM image in Fig. 2B further reveals that these CQDs are highly crystalline, with a d-spacing of 0.31 nm. On the other hand, XRD was used as a non-destructive technique to study the crystal structure of the CQDs. Figure S2 showed narrow diffraction peaks, which can be ascribed to the crystalline structure of carbon that was observed in the XRD pattern of the as-prepared CQDs. To determine their elemental composition, EDX-TEM analysis was performed (Fig. 2C). The results indicated the presence of carbon (33.56%), oxygen (42.20%), nitrogen (11.10%), sulfur (1.77%), and cobalt (11.38%), confirming successful doping. The surface functional groups of the CQDs were analyzed using FTIR (Fig. 2D), revealing various peaks. These include N–H and O–H (3300–3453 cm−1, broad), S–H (2370 cm−1), which contribute to the hydrophilicity of the CQDs. Additional peaks at 1637 cm−1 (C = O and C = C) suggest the presence of carboxylic acid and oxygen-containing groups. The bending vibration of N–H (1590 cm−1) indicates the existence of amino-containing functional groups. A broad band at 664 cm−1 is attributed to = C–H stretching, while the peak at 1397 cm−1 confirms the presence of C = S.

The surface functional groups and chemical composition of the synthetized CQDs were also investigated using XPS. Figure S3A shows five typical peaks at 285.86, 532.98, 401.52, 164.43 and 797.8 eV, which correspond to the characteristic C1s, O1s, N1s, S2p and Co2p, respectively (Hu et al. 2014). The high resolution C1s spectrum showed three peaks at 284.07, 285.84 and 287.53 eV, which can be assigned to C = C, C–O and C = O, respectively as shown in Figure S3B. The high resolution O1s spectrum (Figure S3C) displayed three peaks at 531.19, 531.77 and 533.5 eV, which can be ascribed to O-C = O, C = O and C–OH, respectively. Figure S3D showed the high resolution N1s spectrum containing two peaks at 399.21 and 400.69 eV, which refer to amine groups NH and N(-C = O)-O respectively. The high resolution spectrum of S2p (Figure S3E) showed two Gaussian peaks at 163.4 and 165.1 eV, which correspond to the presence of C-S-C. The high resolution spectrum of Co2p (Figure S3F) exhibited two peaks at 795.5 and 799.5 eV, which can be assigned to Co3+ and Co2+ respectively (Zhang et al. 2018). The fluorescence of the CQDs depends on the excitation wavelength. When the excitation wavelength was varied from 300 to 390 nm, as shown in Figure S4, the strongest emission was observed at 438 nm after excitation at 350 nm.

Factors Affecting the Synthesis of CQDs

Several metal ions were evaluated for their potential use as dopants during the synthesis of CQDs, including silver nitrate, copper sulfate, cobaltous acetate, and ferric chloride. However, each metal ion shows specific limitations. For instance, silver nitrate was insoluble in water, resulting in a suspension that hindered CQDs' formation. Although copper sulfate is soluble in distilled water, it presented a challenge in terms of reaction time. Ferric chloride had a negative impact on the native fluorescence of CQDs. This decrease in fluorescence can be attributed to the quenching effect of FeCl3 on the fluorescence properties of CQDs. In contrast, cobaltous acetate proved to be the most promising choice. It facilitated rapid CQDs' formation with a notably high quantum yield, compared to those derived from citric acid and methionine, as illustrated in Fig. S5.

Other factors such as the reaction time and reaction temperature were studied. The reaction time and temperature play an important role in the synthesis process of CQDs which affect the intensities. It was found that the optimum incubation time is 1.5 min at 800 watt. On increasing the time above 1.5 min, the CQDs were charred while incubation time less than 1.5 minutes did not provide sufficient time for the formation of CQDs. Figure 3 shows an overlay of excitation and emission spectra of Co-NS-CQDs before and after the addition of MSG.

Response optimization

Effect of Reaction Time

The impact of reaction time was assessed by continuously measuring the fluorescence intensity at 438 nm as a function of time following the addition of MSG. This assessment was carried out over a 15minutes period with 1minute intervals. Notably, there was no observable alteration in fluorescence intensity over time (Figure S6). This observation suggests that the interaction between MSG and CQDs takes place instantaneously, without the need for prolonged waiting periods.

Effect of Co-NS-CQDs Volume

The study investigated the impact of varying the volume of Co-NS-CQDs on the fluorescence within a range of 500–2500 µL. It was observed that increasing the amount of Co-NS-CQDs led to a reduction in the fluorescence ratio. Specifically, as the volume of CQDs increased, both the blank and MSG fluorescence intensities increased. However, the increase in blank fluorescence was not comparable to the increase in MSG fluorescence. Consequently, this resulted in a decrease in the fluorescence ratio. Figure S7 illustrates that the optimal volume of Co-NS-CQDs is 500 µL, as it provides the optimal fluorescence response.

Effect of Ionic Strength

The influence of ionic strength on the interaction between monosodium glutamate (MSG) and Co-NS-CQDs was investigated, considering the potential presence of charged functional groups on the surface of CQDs. This effect was studied by introducing different volumes of potassium iodide (KI) at a concentration of 1 mg/mL, as shown in Figure S8. The results indicated that the fluorescence of Co-NS-CQDs remained unaffected. This observation may be attributed to the absence of charged groups on the surface of CQDs. If CQDs possessed positive charges, they would likely attract the negative charge of iodide ions, potentially leading to aggregation and altering the intensity of CQDs. On the other hand, if CQDs had negative charges, they might interact electrostatically with the positive charge of potassium ions, leading also to the aggregation of CQDs. However, in this case, the fluorescence of Co-NS-CQDs remained stable, suggesting a lack of charged groups on their surface.

Effect of pH

The impact of the pH on the intensity of the fluorescence Co-NS-CQDs was thoroughly investigated. It was observed that at low pH levels, the fluorescence intensity was diminished. This phenomenon can be attributed to the aggregation of Co-NS-CQDs in acidic conditions due to the protonation of the CQDs' surface, leading to their self-assembly into larger particles through the formation of hydrogen bonds between surface oxygen-related groups of the CQDs. As the pH level increased, the fluorescence intensity was notably increased until it became stable within the pH range of 5 to 8. This behavior is shown in Figure S9. Ultimately, the optimum pH for the determination of MSG was identified as pH = 7.

Method Validation

The proposed fluorimetric method was validated as recommended by ICH guidelines. The obtained results were found to be analytically acceptable. The parameters assessed in the validation procedures were linearity, range, limit of detection, limit of quantitation, accuracy, precision and robustness.

Linearity and Range

A calibration curve was generated by plotting MSG concentrations against fluorescence intensity, as shown in Figure S10. This curve demonstrated linearity within the range of 25–250 µg/mL (Fig. 4). The resulting regression equation has a correlation coefficient r of 0.996. The proximity of this value to 1 indicates an excellent correlation, indicating that this analytical method is suitable and reliable for MSG determination.

Limit of Detection (LOD) and Limit of Quantification (LOQ)

The LOD and LOQ were determined using the regression line (Table 1). These values were calculated as LOD = 3.3 × (σ/S) and LOQ = 10 × (σ/S), where σ represents the standard deviation of the intercept, and S is the slope of the calibration line. The obtained LOD and LOQ values were found to be 2.78 and 8.44 μg/mL, respectively. The LOQ value is typically expected to be approximately three times higher than the LOD value. In this analysis, the achieved LOD and LOQ values align well with this expectation, confirming the sensitivity of the method.

The Accuracy

To assess the accuracy of the proposed method, it was applied to the analysis of pure samples of MSG. Three different concentrations (50, 150, and 250 μg/mL) were selected for this purpose. The measurements were carried out in triplicate, and the mean % recovery along with the standard deviation were calculated (Table S1). The resulting mean % recovery values were found to be close to 100%, indicating that the proposed method is highly accurate and provides reliable results for MSG determination.

The Precision

The precision of the proposed method was evaluated through both intra-day and inter-day reproducibility assessments. For intra-day precision, three different concentrations within the linearity range were measured through triplicate analyses on the same day. On the other hand, for inter-day precision, these same concentrations were examined over three successive days, with triplicate measurements each day. The results, as presented in Table 2, demonstrate that the proposed method exhibited high precision, with relative standard deviations consistently below 2%.

Robustness

The robustness was validated by introducing minor variations in optimization parameters, such as pH (7 ± 0.2), emission wavelength (438 ± 2 nm), excitation wavelength (350 ± 2 nm), and incubation time (1 minute). These slight alterations, which could occur during routine experimentation, were found to have no significant impact on fluorescence intensities. The relative standard deviation values, as shown in Table 3, consistently remained below 2.0%.

Application in Food Analysis

The developed method was effectively employed for determining MSG) in chicken cubes and instant noodles. The standard addition method was applied to cancel the influence of matrix components. The results in Table 4, showed mean % recovery values ranging from 98 to 102%. These results indicate the suitability of the proposed method for accurately assessing MSG content in food products, with % recovery values falling within an acceptable range.

Greenness Assessment of the Developed Method

The greenness of the developed method was evaluated using three common metrics including Analytical Eco Scale, GAPI and AGREE (Moema et al. 2023; Soyseven et al. 2023) in comparison with a reported HPLC method (Soyseven et al. 2021). An analytical eco scale is a quantitative tool for greenness evaluation by assigning numerical values or scores after considering a range of environmental aspects (Rizk et al. 2023). The developed method was found to be excellent green as the score is 90 while the reported method scored 50, which is considered acceptable (Table 5). The GAPI metric employs a pictogram with a color scale, for evaluation for each stage within the analytical method (Hammouda et al. 2023). Figure 5 shows the GAPI representations for the developed and reported method. It is clear that the developed method has a higher density of green, indicating its lower environmental impact compared to the HPLC method. AGREE metrics are simple and open source. The results are represented as pictogram with a final score from 0–1 in the center indicating the environmental impact of the analytical procedure based on the 12 principles of green analytical chemistry GAC (Sharaf et al. 2023). The AGREE calculations for the developed method achieve a total score of 0.75 while the reported method gives a score of 0.47 indicating that the developed method is more environmentally friendly (Fig. 6).

Comparison with Previously Published Fluorimetric Methods

Direct spectrofluorometric determination of MSG is not feasible due to the absence of fluorophore. Therefore, developing a simple and rapid analysis method for MSG is a challenge. Most reported fluorimetric methods rely on derivatizing agents in multistep reactions. While sensitive, these methods require expensive reagents and special conditions. Table 6 compares the developed method with other reported fluorimetric methods, showing that the developed method is simple, time and cost effective, and environmentally friendly, requiring no sample preparation.

Conclusion

In this study, we have successfully synthesized Cobalt, Nitrogen, and Sulfur co-doped Carbon Quantum Dots (Co-NS-CQDs) using a one-step microwave assisted method. This green and efficient synthesis method, completed in just 90 seconds, utilizing citric acid as a carbon source, methionine as a nitrogen and sulfur source, and cobaltous acetate as a cobalt metal ion source. The resulting Co-NS-CQDs exhibited several remarkable properties, including a narrow size distribution and a high quantum yield (51.5%), outperforming non-metal-doped CQDs (38%). The Co-NS-CQDs, with their exceptional photoluminescent properties and surface functionalization, were employed as a probe for the determination of MSG in food products. Our method demonstrated several advantages over reported methods, including convenience, rapid response, and sensitivity.

Data Availability

The data used in this study are available from the corresponding author on reasonable request.

References

Abdella AA, Zaki AM, Hammad S, Mansour FR (2024) Rapid environmentally benign label free detection of heparin using highly fluorescent N, S-CDs sensing probe through a turn-on mechanism. Spectrochim Acta Part A Mol Biomol Spectrosc 306:123609. https://doi.org/10.1016/j.saa.2023.123609

Ahmed Abdel Hamid M, Elagamy SH, Gamal A, Mansour FR (2023) Microwave prepared nitrogen and sulfur co-doped carbon quantum dots for rapid determination of ascorbic acid through a turn off–on strategy. Spectrochim Acta Part A Mol Biomol Spectrosc 293:122440. https://doi.org/10.1016/j.saa.2023.122440

Ambade RB, Ali M, Lee KH et al (2023) Nitrogen and sulfur co-doped carbon quantum dot-engineered TiO 2 graphene on carbon fabric for photocatalysis applications. ACS Appl Nano Mater 6:15782–15794. https://doi.org/10.1021/acsanm.3c02661

Anirudhan TS, Alexander S (2015) Selective determination of monosodium glutamate (Ajinomoto) in food samples using a potentiometric method with a modified multiwalled carbon nanotube based molecularly imprinted polymer. RSC Adv 5:96840–96850. https://doi.org/10.1039/C5RA17885A

Anthony AM, Pandurangan P, Abbas S (2023) Ligand engineering with heterocyclic aromatic thiol doped carbon quantum dots. Carbon N Y 211:118086. https://doi.org/10.1016/j.carbon.2023.118086

Cui P, Zhang J (2023) Photovoltaic performance of heteroatom-doped boron nitride quantum dots in quantum dot photovoltaic cells. Catal Commun 174:106590. https://doi.org/10.1016/j.catcom.2022.106590

De R, Jo KW, Lee BH et al (2023) Microwave-assisted rapid synthesis of nitrogen-enriched amphibious carbon quantum dots for sensitive detection of ROS and multiple other applications. J Mater Chem B 11:6024–6043. https://doi.org/10.1039/D3TB00614J

Demirhan BE, Demirhan B, Sönmez C et al (2015) Monosodium glutamate in chicken and beef stock cubes using high-performance liquid chromatography. Food Addit Contam Part B 8:63–66. https://doi.org/10.1080/19393210.2014.991355

Dewangan L, Chawre Y, Korram J et al (2022) N-doped, silver, and cerium co-doped carbon quantum dots based sensor for detection of Hg2+ and captopril. Microchem J 182:107867. https://doi.org/10.1016/j.microc.2022.107867

El-Malla SF, Elshenawy EA, Hammad SF, Mansour FR (2022) Rapid microwave synthesis of N, S-doped carbon quantum dots as a novel turn off-on sensor for label-free determination of copper and etidronate disodium. Anal Chim Acta 1197:339491. https://doi.org/10.1016/j.aca.2022.339491

El-Malla SF, Elshenawy EA, Hammad SF, Mansour FR (2021) N-doped carbon dots as a fluorescent nanosensor for determination of colchicine based on inner filter effect. J Fluoresc 31:675–684. https://doi.org/10.1007/s10895-021-02698-0

Elattar RH, Kamal AH, Mansour FR, El-Malla SF (2023) Spectrophotometric determination of monosodium glutamate in instant noodles’ seasonings and Chinese salt by ligand exchange complexation. J Food Compos Anal 121:105404. https://doi.org/10.1016/j.jfca.2023.105404

Elshenawy EA, El-Malla SF, Hammad SF, Mansour FR (2022) Innovative spectrofluorimetric determination of vildagliptin based on a “switch off/on” NS-doped carbon dot nanosensor. RSC Adv 12:25815–25821. https://doi.org/10.1039/D2RA04991K

Elshenawy EA, El-Malla SF, Hammad SF, Mansour FR (2023) Green microwave-prepared N and S Co-doped carbon dots as a new fluorescent nano-probe for tilmicosin detection. Talanta 265:124853. https://doi.org/10.1016/j.talanta.2023.124853

Graham LT, Aprison MH (1966) Fluorometric determination of aspartate, glutamate, and γ-aminobutyrate in nerve tissue using enzymic method. Anal Biochem 15:487–497. https://doi.org/10.1016/0003-2697(66)90110-2

Gulati S, Baul A, Amar A et al (2023) Eco-friendly and sustainable pathways to photoluminescent carbon quantum dots (CQDs). Nanomaterials 13:554. https://doi.org/10.3390/nano13030554

Hammouda MEA, Salem YA, El-Ashry SM, Abu El-Enin MA (2023) Inclusive study for sustainable enantioseparation of racemic chlorpheniramine and caffeine by HPLC using dual cyclodextrin system as chiral mobile phase additive: assessment with AGREE and Complex-GAPI approaches. Sustain Chem Pharm 35:101201. https://doi.org/10.1016/j.scp.2023.101201

Hnin-Pwint Aung UP (2016) In-capillary derivatization with o-phthalaldehyde in the presence of 3-mercaptopropionic acid for the simultaneous determination of monosodium glutamate, benzoic acid, and sorbic acid in food samples via capillary electrophoresis with ultraviolet detectio. J Chromatogr A 1449:156–165. https://doi.org/10.1016/j.chroma.2016.04.033

Hu Q, Paau MC, Zhang Y et al (2014) Green synthesis of fluorescent nitrogen/sulfur-doped carbon dots and investigation of their properties by HPLC coupled with mass spectrometry. RSC Adv 4:18065–18073. https://doi.org/10.1039/C4RA02170C

John BK, Mathew S, John N et al (2023) Hydrothermal synthesis of N, S-doped carbon quantum dots as a dual mode sensor for azo dye tartrazine and fluorescent ink applications. J Photochem Photobiol A Chem 436:114386. https://doi.org/10.1016/j.jphotochem.2022.114386

Kamal AH, El-Malla SF, Elattar RH, Mansour FR (2023) Determination of monosodium glutamate in noodles using a simple spectrofluorometric method based on an emission turn-on approach. J Fluoresc 33:1337–1346. https://doi.org/10.1007/s10895-023-03143-0

Kim B-S, Oh G-H, Song Y et al (2023) Acid catalyzed microwave-assisted production of full-color light emissive carbon quantum dots for CCT-tunable WLEDs. Appl Surf Sci 640:158301. https://doi.org/10.1016/j.apsusc.2023.158301

Kostromin S, Borodina A, Podshivalov A et al (2023) Characterization of carbon quantum dots obtained through citric acid pyrolysis. Fullerenes, Nanotub Carbon Nanostructures 31:931–939. https://doi.org/10.1080/1536383X.2023.2224467

Krishna Veni N, Karthika D, Surya Devi M et al (2010) Analysis of monosodium l-glutamate in food products by high-performance thin layer chromatography. J Young Pharm 2:297–300. https://doi.org/10.4103/0975-1483.66795

Kumar Vashistha V, Bala R, VSR Pullabhotla R (2023) Derivatizing agents for spectrophotometric and spectrofluorimetric determination of pharmaceuticals: a review. J Taibah Univ Sci. https://doi.org/10.1080/16583655.2023.2206363

Lin L, Luo Y, Tsai P et al (2018) Metal ions doped carbon quantum dots: Synthesis, physicochemical properties, and their applications. TrAC Trends Anal Chem 103:87–101. https://doi.org/10.1016/j.trac.2018.03.015

Md Isa I, Ab Ghani S (2008) Heterogeneous membrane and coated wire type electrode with chitosan as ionophore in the potentiometric determination of glutamate: comparative study. Electroanalysis 20:1782–1787. https://doi.org/10.1002/elan.200804243

Moema D, Makwakwa TA, Gebreyohannes BE et al (2023) Hollow fiber liquid phase microextraction of fluoroquinolones in chicken livers followed by high pressure liquid chromatography: Greenness assessment using National Environmental Methods Index Label (NEMI), green analytical procedure index (GAPI), Analyti. J Food Compos Anal 117:105131. https://doi.org/10.1016/j.jfca.2023.105131

Mohandoss S, Ahmad N, Velu KS et al (2023) Synthesis of photoluminescent carbon dots using hibiscus tea waste and heteroatom doping for multi-metal ion sensing: applications in cell imaging and environmental samples. Chemosensors 11:474. https://doi.org/10.3390/chemosensors11090474

Mondal TK, Kapuria A, Miah M, Saha SK (2023) Solubility tuning of alkyl amine functionalized carbon quantum dots for selective detection of nitroexplosive. Carbon N Y 209:117972. https://doi.org/10.1016/j.carbon.2023.03.047

Palacio-Vergara M, Álvarez-Gómez M, Gallego J, López D (2023) Biomass solvothermal treatment methodologies to obtain carbon quantum dots: A systematic review. Talanta Open 8:100244. https://doi.org/10.1016/j.talo.2023.100244

Pourmadadi M, Rahmani E, Rajabzadeh-Khosroshahi M et al (2023) Properties and application of carbon quantum dots (CQDs) in biosensors for disease detection: A comprehensive review. J Drug Deliv Sci Technol 80:104156. https://doi.org/10.1016/j.jddst.2023.104156

Rachma FA, Saptawati T (2021) Analysis tolerance of monosodium glutamate (MSG) in instant noodles with Uv-Vis spectrophotometry. J Sci Technol Res Pharm 1:20–24. https://doi.org/10.15294/jstrp.v1i1.43568

Rajabi HR, Farsi M (2015) Effect of transition metal ion doping on the photocatalytic activity of ZnS quantum dots: Synthesis, characterization, and application for dye decolorization. J Mol Catal A Chem 399:53–61. https://doi.org/10.1016/j.molcata.2015.01.029

Rizk M, Abou El-Alamin MM, Abd Elkhalek O, Shallan AI (2023) Validated and selective potentiometric analysis of anti-coagulant edoxaban via a screen-printed electrode: green assessment by Eco-Scale and Complex-GAPI. J Iran Chem Soc 20:2319–2327. https://doi.org/10.1007/s13738-023-02842-6

SalihAjaj C, Sadiq D (2023) Mulberry juice-derived carbon quantum dots as a Cu2+ ion sensor: investigating the influence of fruit ripeness on the optical properties. Nanomater Nanotechnol 2023:1–11. https://doi.org/10.1155/2023/9980479

Sánchez FG, Gallardo AA (1992) Liquid chromatographic and spectrofluorimetric determination of aspartame and glutamate in foodstuffs following fluorescamine fluorigenic labelling. Anal Chim Acta 270:45–53. https://doi.org/10.1016/0003-2670(92)80090-T

Shanmugasundaram E, Ganesan V, Narayanan V et al (2023) Heteroatom (boron, nitrogen, and fluorine) quantum dot-doped polyaniline-photoactive film preparation and characterization for organic solar cell applications. New J Chem 47:13127–13137. https://doi.org/10.1039/D3NJ02435K

Sharaf YA, Ibrahim AE, El Deeb S, Sayed RA (2023) Green chemometric determination of cefotaxime sodium in the presence of its degradation impurities using different multivariate data processing tools; GAPI and AGREE greenness evaluation. Molecules 28:2187. https://doi.org/10.3390/molecules28052187

Shilpi S, Thakur A (2023) A review of the application of carbon quantum dots. In: AIP Conference Proceedings, vol 2535, No. 1. AIP Publishing. https://doi.org/10.1063/5.0111342

Soyseven M, Aboul-Enein HY, Arli G (2021) Development of a HPLC method combined with ultraviolet/diode array detection for determination of monosodium glutamate in various food samples. Int J Food Sci Technol 56:461–467. https://doi.org/10.1111/ijfs.14661

Soyseven M, Arli G (2021) Method validation and rapid determination of monosodium glutamate in various food products by HPLC–fluorescence detection and method optimization of HPLC–evaporative light scattering detection approach without derivatization. J Chromatogr Sci 60:760–769. https://doi.org/10.1093/chromsci/bmab122

Soyseven M, Sezgin B, Arli G (2023) The development and validation of a novel, green, sustainable and eco-friendly HPLC-ELSD method approach for the simultaneous determination of seven artificial sweeteners in various food products: an assessment of the greenness profile of the developed me. Microchem J 193:109225. https://doi.org/10.1016/j.microc.2023.109225

Sun X-H, Ma M, Tian R et al (2023) One-pot hydrothermal method preparation of cerium–nitrogen-codoped carbon quantum dots from waste Longan nucleus as a fluorescent sensor for sensing drug rifampicin. ACS Omega. https://doi.org/10.1021/acsomega.3c04242

Wang L, Lu Y, Xu J et al (2023a) Solvothermal synthesis of g-C3N4 nanosheets modified carbon quantum dots for enhanced photocatalytic degradation. Solid State Sci 143:107271. https://doi.org/10.1016/j.solidstatesciences.2023.107271

Wang W, Bai X, Zhou H et al (2023b) Energy-efficient, room-temperature, and facile synthesis of carbon quantum dots from interstitial compound TiC for the selective detection of Fe(III). ACS Sustain Chem Eng. https://doi.org/10.1021/acssuschemeng.3c03625

Yadav PK, Chandra S, Kumar V et al (2023) Carbon quantum dots: synthesis, structure, properties, and catalytic applications for organic synthesis. Catalysts 13:422. https://doi.org/10.3390/catal13020422

Yang H-L, Bai L-F, Geng Z-R et al (2023) Carbon quantum dots: preparation, optical properties, and biomedical applications. Mater Today Adv 18:100376. https://doi.org/10.1016/j.mtadv.2023.100376

Zhang S-Y, Li T-T, Zhu H-L, Zheng Y-Q (2018) Co3O4 polyhedrons with enhanced electric conductivity as efficient water oxidation electrocatalysts in alkaline medium. J Mater Sci 53:4323–4333. https://doi.org/10.1007/s10853-017-1855-2

Zhang Y, Li P, Yan H et al (2023) Green synthesis and multifunctional applications of nitrogen-doped carbon quantum dots via one-step hydrothermal carbonization of Curcuma zedoaria. Anal Bioanal Chem 415:1917–1931. https://doi.org/10.1007/s00216-023-04603-z

Zhu X, Qi W, Wang M et al (2023) Microfluidic steam-based synthesis of luminescent carbon quantum dots as sensing probes for nitrite detection. Green Process Synth. https://doi.org/10.1515/gps-2022-8144

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

AG conducted the practical work and prepared the initial draft of the manuscript. MAA supervised the work, and participated in manuscript revision. SHE supervised the work, and participated in manuscript revision. FRM supervised the work and participated in manuscript preparation, revision and submission.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hamid, M.A.A., Elagamy, S.H., Gamal, A. et al. One-pot Microwave Synthesis of Cobalt, Nitrogen, and Sulfur Co-Doped Carbon Quantum Dots for Efficient Monosodium Glutamate Determination in Food Samples. Food Anal. Methods 17, 739–750 (2024). https://doi.org/10.1007/s12161-024-02609-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-024-02609-6