Abstract

Traditional methods used to determine oil purity like fatty acids and sterols are time consuming and chemically wasteful; standards that utilize these methods require a large set of samples to cover natural variables to establish upper and/or lower limits for each compound. Due to this, it can be challenging to determine the purity of newer products on the market, like avocado oil, when standards have not yet been fully developed. Triacylglycerol analysis in tandem with principal component analysis (PCA) differs from these tradition methods; standard ranges for each triacylglycerol are not needed to determine purity. This study built on our earlier work on olive oil but used laboratory-made avocado oils accounting for a wide range of natural variables to measure avocado oil triacylglycerols and apply PCA to detect adulteration in avocado oil. This method had the same purity determination accuracy as traditional fatty acid and sterol methods, while being less time consuming, producing less chemical waste, easier to perform than the original methods with the added advantage that it can be utilized immediately by industry while official standards are still being developed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

There is an urgent need to detect adulterations in avocado oil. Standard development is underway, primarily by CODEX Alimentarius, an international food standards and regulation agency (Codex Alimentarius Commission 2021). However, this process takes time and significant data input from industry members of producing countries, academics, and the government. Fatty acid profile (FAP) and sterols are currently the two purity parameters being included in CODEX standards on fats and oils (Codex Alimentarius Commission 2021), with each of their own advantages and disadvantages. Sterols require significantly more sample preparation than FAP, but it is often seen as necessary to perform both of these analyses; it is possible for adulterated samples to pass as pure, or fit into the according to only their fatty acid profile, but adulteration is revealed upon analysis of sterols, and vice versa.

In 2020, our research group analyzed 22 avocado oils on the market in the USA to evaluate their quality (e.g., free fatty acidity, peroxide value, UV absorbances, vitamin E) and purity (e.g., fatty acids, sterols, triacylglycerols) and found quality issues and adulterations in many of the samples (Green and Wang 2020). Aside from the typical, standard tests, other methods have been developed to detect the presence of seed oils in avocado oil. Fourier transform infrared spectroscopy (FTIR) has been the most popular analytical tool for adulteration detection in avocado oil and has been used in multiple studies including Quiñones-Islas et al. (2013) and Jiménez-Sotelo et al. (2016) where it was combined with SIMCA and partial least squares analysis (PLS) to detect the presence of sunflower, soybean, and canola oils in avocado oils. Lumakso et al. (2015) also utilized FTIR with PLS and to differentiate avocado oil from grapeseed and sesame oil, while Rohman et al. (2016) used it with PLS and principal component regression (PCR). These FTIR applications have the advantage of being fast with no sample pretreatment; however, some of the chemometric approaches could be difficult to implement in a wide-scale industrial setting. In addition, for method prediction to be accurate, it is necessary to have a breadth of samples encompassing how avocado oil varies with time, region, and other variables, and it has not yet been assessed if these methods have the same level of accuracy when using this breadth of samples. Nuclear magnetic resonance (NMR) in Tang et al. (2021) and Jin et al. (2022) can also be used as an adulteration detection tool. Like FTIR, NMR also requires minimal to no sample preparation. It can be seen as a more rapid approach to detecting fatty acids, which are already used in purity determination. It has the added advantage that it could also detect minor components and oil quality with one analysis; however, cost and sample variety is a barrier to widespread use.

Since our first study, we have been working on collecting FAP and sterols of authentic avocado oil samples as these methods require an acceptable range for each fatty acid and sterol to be developed for avocado oil standards. At the same time, the rapid method our group developed using triacylglycerols in combination with multivariate analysis to detect adulteration in olive oil (Green et al. 2020) has significant potential for the avocado oil industry. In brief, triacylglycerols (TAGs) are the primary constituents that make up oils. Determining purity directly using these compounds is convenient because the resources and time for sample prep are minimized. By using principal component analysis (PCA) to analyze the TAGs, a sample can simply be put on the PCA plot, and its purity can be determined by visualization. Comparing to FAP or sterols, this eliminates the need to establish upper and/or lower limits for individual fatty acid or sterol and is more accessible for personnel who may not be familiar with the fatty acid and sterol ranges of avocado oil and common adulterants. This study applies our previously developed method for olive oil, with some modifications, in a way that can directly and immediately benefit the avocado oil industry while acceptable FAP and sterols ranges are still determined. In addition, it can continue to be used as a screening tool for adulteration in the place of fatty acids and sterols to reduce resources used with the traditional purity methods.

Materials and Methods

Oil Samples

Authentic avocado oils and potential avocado oil adulterants were used in this study. The potential adulterant oils included high oleic sunflower, high oleic safflower, soybean, and canola oil. Ten samples from each adulterant oil were purchased from grocery stores and online, were confirmed to be pure via fatty acid profile, then used for this study. The pure avocado samples (n = 68) used in this study were previously descried in Green and Wang (2023). Briefly, two different experimental designs were used to account for a variety of natural factors that can impact the chemical composition of avocado oil. The first design included region harvested (California and Mexico), harvest time, grade of fruit used, and using whole fruit or flesh to make the oil. These oils were cold-pressed and extracted mechanically. The second design accounted for region harvested (two locations within California), harvest time, cultivar, and using whole fruit or flesh to make oil. The oils from this design were solvent extracted using n-hexane. Test samples used for this method were pure oils sent from producers in different countries (n = 3) and oils of unknown purity purchased from different regions in the USA (n = 25).

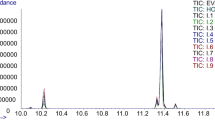

TAG Analysis

The method described in Green et al. (2020) was used for TAG analysis. In brief, oil samples were diluted by 100 with methanol/chloroform (50:50, v/v) to make the final concentration of 1% before being placed in a vial and injected in a Vanquish™ Flex UHPLC-CAD system (Thermo Fisher Scientific, Waltham, MA, USA) using a Thermo Scientific™ Accucore™ C18 column (100 mm × 2.1 mm; 2.6 μm) for TAG separation. The injection volume was 1 μL and the flow rate was 0.5 mL/min. Mobile phase A was acetonitrile and mobile phase B was isopropanol. The solvent gradient conditions were as follows: from start, 10% B; 2 min, 10% B; 25 min, 40% B; 30 min, 60% B; 35 min, 90% B; 40 min, 50% B and 45 min 10% B. The sample chamber was maintained at 25 °C and column temperature at 50 °C. Thirteen TAGs were chosen because they either are the primary components in avocado oil or were important for distinguishing avocado oil from other potential adulterant oils. Peaks were identified with analytical standards and by comparing to previous samples analyzed with this method. Peak area ratios were used for statistical analysis. The ratios were calculated for the TAGs in each sample by comparing each peak area to the total TAG area. All samples were analyzed in duplicate.

Fatty Acid Profile

The fatty acid profile analysis was carried out as Green and Wang (2023) described and according to the International Olive Council (IOC) official method for the determination of the fatty acid methyl esters by gas chromatography (COI/T.20/ Doc. No 33/Rev.1, 2017). In brief, approximately 20 µL of oil was mixed with 3 mL of n-hexane. Then, 200 µL of 2 M methanolic KOH was added and vigorously mixed for 1 min. Samples were left until the top solution was clear, and the organic layer was filtered using 0.2-micron PTFE filters. Samples were analyzed in duplicate. The GC-FID analysis was conducted on an Agilent 7890A GC using a 90 m × 250 μm × 0.25 μm DB-FastFAME capillary column (Agilent J&W). The injection volume was 1.0 μL, and helium was used as a carrier gas at a flow rate of 1.9 mL/min. The injector temperature was held at 260 °C at a split ratio of 30. The GC oven program was initially held at 35 °C for 1 min, then ramped at 65 °C/min to 200 °C and held for 14 min, followed by a ramp of at 2.5 °C/min to 210 °C, which was held for 5 min. The last ramp was at 12 °C/min to 230 °C and held for 20 min, giving a total run time of 49.2 min. The FID temperature was 260 °C. The detector gas consisted of hydrogen (flow rate: 40 mL/min), air (flow rate: 400 mL/min) and helium make up gas (flow rate: 25 mL/min). Peak identification was performed using a FAME 37-component reference standard mix (MilliporeSigma).

Sterol Profile

Sterol content was analyzed as described in Green and Wang (2023). The unsaponifiable fraction was prepared by drying 20 µL of internal standard 0.2% α-cholestanol ethyl acetate solution before adding 200 mg of oil followed by 1.5 mL of 2 M KOH in 95% ethanol. The mixture was heated at 80 °C for 25 min, mixed and heated for a second 25 min. Then, 13.5 mL DI water was added before loading onto a Phenomenex Strata DE SLE cartridge, 60 cc tube, followed by two 1-mL rinses. The extract was eluted with five, 15-mL portions of diethyl ether after 15 min. Eluent was passed through a syringe packed with sodium sulfate then dried using a rotary evaporator and placed in an oven at 100 °C for 10 min to remove the remaining water. Dried extracts were reconstituted with 5 mL n-hexane. Next, the silica SPE columns (6 mL, 1 g sorbent, Agilent brand) were conditioned using two, 6-mL n-hexane rinses followed by 1 mL of 0.2 M KOH in 98% ethanol, which was followed by an additional 5 mL n-hexane rinse. Each sample was then loaded onto the SPE cartridge then the cartridges were washed with 85 mL of n-hexane/diethyl ether (98:2, v/v) at 2 mL/min. The sterol fraction was eluted using 5 mL of n-hexane: diethyl ether (80:20, v/v) followed by 5 mL of n-hexane/diethyl ether (60:40, v/v). Extracts were dried in a rotary evaporator and if needed placed in an oven at 100 °C for 5–10 min to remove remaining water before adding 250 μL of the silylation reagent (pyridine/hexamethyl disilazane/trimethylchlorosilane, 9:3:1, v/v/v) to prepare the sample for GC injection. The GC-FID analysis was carried out on an Agilent 7890A GC using a 30-m × 0.25-mm × 0.25-μm DB-5 capillary column (Agilent Technologies) with an injection volume of 1.0 μL and helium as the carrier gas at a flow rate of 1.2 mL/min. The injector temperature was held at 280 °C at a split ratio of 5. The GC oven program was held isothermally at 150 °C for 8 min, then ramped at 20 °C/min to 290 °C and held for 20 min to obtain a total run time of 37.33 min. The FID temperature was 300 °C. The detector gas consisted of hydrogen (flow rate: 30 mL/min), air (flow rate: 400 mL/min), and helium make up gas (flow rate: 25 mL/min). Peak identification was carried out with both analytical standards campesterol, stigmasterol, and β-sitosterol (MilliporeSigma) and by comparing against the sample chromatograms provided in the IOC official method and their relative retention times. Quantification was performed using the peak area and concentration of the internal standard.

Statistical Analysis

Principal component analysis was performed using Originlab Corporation software version “OriginPro 2016 Sr2.” Confidence ellipses and principal component scores were computed by Originlab.

Results and Discussion

Constructing TAG-PCA Plots

The first step in applying the original method to be used for avocado oil was to analyze the TAG profile of authentic samples and then plot them using PCA. Figure 1 shows the PCA plot developed using TAGs as variables. The separation of avocado oil from the common adulterants currently used is promising in this method’s ability to differentiate pure and adulterated oils. The four common avocado adulterants are in clusters below the x-axis. High oleic safflower and sunflower oils are highly correlated with oleic-containing TAGs and soybean with linoleic-containing TAGs, which is consistent with their fatty acid profiles. The avocado oil cluster is in black, above the x-axis. It was necessary to not only analyze a group of pure avocado oils, but samples that accounted for a variety of variables as it has been documented that the fatty acid profile, and thereby triacylglycerols, can change depending on harvest time (Slater et al. 1975; Ozdemir and Topuz 2004), fruit growing region (Tan et al. 2017), and cultivar (Jorge et al. 2015; Fernandes et al. 2018; Yanty et al. 2011).

Principal component analysis using TAGs as variables showing avocado oil compared to potential adulterant oils. Each oil type is shown in a cluster of dots, surrounded by a 95% confidence ellipse with avocado oil in black, canola in orange, high oleic (HO) safflower oil in in blue-green, high oleic (HO) sunflower oil in dark blue, and soybean oil in light blue

The avocado oils in this study accounted for harvest times from early to late season from two growing regions: California and Mexico. Two cultivars were included: Hass, the most common cultivar used to make oil, and Carmen. The oil was extracted in two different ways: using the whole fruit, including flesh, skin, and pits, and just the flesh (Green and Wang 2023). The impact of these variables on purity parameters such as fatty acids and sterols was previously described in Green and Wang (2023). Inclusion of oils with this breadth of natural variation to form the avocado oil cluster in Fig. 1 helps to improve method accuracy, as the power and accuracy of this method is related to the diversity and number of available samples.

Using the TAG-PCA Plot to Test Commercial Sample Purity

One utility of this method is it can be used as a screening tool for avocado oil purity to minimize the number of samples that need both fatty acid profile and sterols analysis. This method can be implemented by plotting an unknown oil onto Fig. 1, and if it is inside the 95% confidence ellipse for avocado oil, it is considered “pure”; if it is just outside the ellipse, further testing (fatty acid profile and sterols analysis) is needed to confirm purity. If the sample is close to another one of the adulterant oil clusters on the PCA, then it is likely adulterated with high amounts of that oil.

A set of known, single-origin, and pure avocado oils were collected from producers around the world and tested using this method. Each sample was from producing regions of New Zealand, Kenya, or South Africa. Figure 2 shows the Kenya and South Africa samples are located within the avocado cluster and thus are considered pure. The sample from New Zealand is located next to two other pure avocado oils from this study, which are just outside the 95% confidence ellipse for avocado oil. In this case, the New Zealand sample would need to go through FAP and/or sterol testing to confirm purity. The fatty acids and sterol profile of this sample, which confirmed its purity, and all others tested are in SI Tables 1 and 2, respectively. As this method is used, verified pure avocado oils can be added to the avocado oil cluster, bolstering its accuracy, which will be particularly important for new regions and cultivars.

Principal component analysis showing the same plot as Fig. 1 with three pure test-avocado oils also plotted on the PCA from different regions (New Zealand in light grey, South Africa in brown, Kenya in dark yellow). Each oil type is shown in a cluster of dots, surrounded by a 95% confidence ellipse with avocado oil in black, canola in orange, high oleic (HO) safflower oil in in blue-green, high oleic (HO) sunflower oil in dark blue, and soybean oil in light blue

An additional set of 25 avocado oils on the market (either pure or adulterated) were tested using this TAGs method and results confirmed with traditional methods. Figure 3 shows these 25 samples on the original Fig. 1 PCA plot and labeled according to whether they were determined pure, not pure, or maybe pure according to the TAG method. These results were then compared to fatty acids and sterol results, listed in Tables S1 and S2. Three samples were considered pure (sample 4, Fig. 3(a); sample 11, Fig. 3(b); sample 24, Fig. 3(d)) because they were located inside the avocado oil cluster. One sample 23, shown in light grey in Fig. 3(d), was just outside the avocado oil cluster and was labeled as “maybe.” This sample was confirmed to be pure upon fatty acid and sterol comparison.

Principal component analysis using the same clusters as Fig. 1 with the addition of 25 unknown samples to determine their purity. (a) displays unknowns 1–6; (b) displays unknowns 7–12; (c) displays unknowns 13–18; (d) displays unknowns 19–25. Oils are color-coded according to whether they are pure according to the TAG method (dark yellow), maybe pure (light grey), or not pure (brown). Each oil type is shown in a cluster of dots, surrounded by a 95% confidence ellipse with avocado oil in black, canola in orange, high oleic (HO) safflower oil in in blue-green, high oleic (HO) sunflower oil in dark blue, and soybean oil in light blue

Figure 3 shows that in many cases of adulteration, it was clear that a sample was not only far from the avocado oil cluster, but near an adulterant oil cluster. For example, samples 13–17 in Fig. 3(c) are all near the high oleic safflower and high oleic sunflower oil clusters. They likely either contain nearly 100% high oleic safflower oil or because the high oleic sunflower oils are in between the safflower and avocado oil clusters, these samples could also be adulterated with high oleic sunflower oil and levels of around 75% (an approximation based on the proximity between the clusters, discussed in Green et al. 2020). In total, 21 out of the 25 test samples were considered not pure according to the TAGs method, and in all cases, the results were corroborated by fatty acids and sterols.

There were no samples tested using this method that were pure according to TAGs but were not pure according to fatty acids and sterols. There were a couple cases shown in Figs. 2 (New Zealand sample) and 3(d) (sample 23) in which a pure sample can lie just outside the avocado oil cluster. In these ambiguous cases, it will still be necessary to utilize traditional methods for purity confirmation. However, the consistency of the results of this method with the traditional methods lend it to be an effective screening tool particularly since this is a rapid, simpler, and less wasteful method. The commercial samples tested in this study indicate that current adulteration of avocado oil is often happening at high levels where most commercial samples are far from the avocado oil cluster and easily identified as being adulterated. In the case of low levels of adulteration, particularly with high oleic seed oils, which could go undetected using TAGs, also cannot be detected using traditional methods, which was described in Green and Wang (2022). These risks should continue to be investigated while improving the accuracy of this method with more verified pure avocado oil and its potential adulterants.

Conclusions

This study applied the previously developed method for olive oil to detect adulteration in avocado oil. The TAG-PCA tandem method is as accurate as using both fatty acids and sterols, indicating the promise for it to be used as a simple and effective screening tool for avocado oil adulteration since it uses less time and resources than the traditional methods. Based on the results of this work, this approach is ready to be utilized in the immediate future for the avocado oil industry and could be included in testing methods for certifications to help consumers gain confidence in the authenticity of the products.

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Codex Alimentarius Commission (2021) REP22/FO, October 2021. Report of the 27th Session of the Codex committee on fats and oils. Proposed draft revision to the Standard for Named Vegetable Oils (CXS 210–1999) –Inclusion of avocado oil, for adoption at Step 5 by CAC45. p 46–82

Fernandes GD, Gómez-Coca RB, Pérez-Camino MC, Moreda W, Barrera-Arellano D (2018) Chemical characterization of commercial and single-variety avocado oils. Grasas y Aceites 69(2). https://doi.org/10.3989/gya.0110181

Green HS, Li X, De Pra M, Lovejoy K, Steiner F, Acworth IN, Wang SC (2020) A rapid detection approach for extra virgin olive oil adulteration using UHPLC-CAD profiling of triacylglycerols and PCA. Food Control 107:106773. https://doi.org/10.1016/j.foodcont.2019.106773

Green HS, Wang SC (2020) First report on quality and purity evaluations of avocado oil sold in the US. Food Control 116. https://doi.org/10.1016/j.foodcont.2020.107328

Green HS, Wang SC (2022) Cis-vaccenic acid: new marker to detect seed oil adulteration in avocado oil. Food Chem Adv 1. https://doi.org/10.1016/j.focha.2022.100107

Green HS, Wang SC (2023) Evaluation of proposed Codex purity standards for avocado oil. Food Control 143. https://doi.org/10.1016/j.foodcont.2022.109277

International Olive Council (IOC) (2017). COI/T.20/ Doc. No 33/Rev.1, 2017. Determination of the fatty acid methyl esters by gas chromatography, Madrid, Spain

Jiménez-Sotelo P, Hernández-Martínez M, Osorio-Revilla G, Meza-Márquez OG, García-Ochoa F, Gallardo-Velázquez T (2016) Use of ATR-FTIR spectroscopy coupled with chemometrics for the authentication of avocado oil in ternary mixtures with sunflower and soybean oils. Food Addit Contam: Part A 33(7):1105–1115. https://doi.org/10.1080/19440049.2016.1203073

Jin H, Wang Y, Lv B, Zhang K, Zhu Z, Zhao D, Li C (2022) Rapid detection of avocado oil adulteration using low-field nuclear magnetic resonance. Foods 11:1134. https://doi.org/10.3390/foods11081134

Jorge TS, Polachini TC, Dias LS, Jorge N, Telis-Romero J (2015) Physiochemical and rheological characterization of avocado oils. Ciênc Agrotec Lavras 39:390–400. https://doi.org/10.5772/32596

Lumakso FA, Riyanto S, Ahmad SAS, Rosman AS, Yusoff FM, Rohman A (2015) Application of chemometrics in combination with Fourier transform mid infrared spectroscopy for authentication of avocado oil. J Food Pharm Sci 3(1):12–17

Ozdemir F, Topuz A (2004) Changes in dry matter, oil content and fatty acids composition of avocado during harvesting time and post-harvesting ripening period. Food Chem 86(1):79–83. https://doi.org/10.1016/j.foodchem.2003.08.012

Quiñones-Islas N, Meza-Márquez OG, Osorio-Revilla G, Gallardo-Velazquez T (2013) Detection of adulterants in avocado oil by mid-ftir spectroscopy and multivariate analysis. Food Res Int 51:148–154. https://doi.org/10.1016/j.foodres.2012.11.037

Rohman A, Windarsih A, Riyanto S, Sudjadi, Shuhel Ahmad SA, Rosman AS, Yusoff FM (2016) Fourier transform infrared spectroscopy combined with multivariate calibrations for the authentication of avocado oil. Int J Food Prop 19:680–687. https://doi.org/10.1080/10942912.2015.1039029

Slater GG, Shankman S, Shepherd JS, Alfin-Slater RB (1975) Seasonal variation in the composition of California avocados. J Agric Food Chem 23(3):468–474

Tan CX, Tan SS, Tan ST (2017) Influence of geographical origins on the physicochemical properties of Hass avocado oil. JAOCS J Am Oil Chem Soc 94(12):1431–1437. https://doi.org/10.1007/s11746-017-3042-7

Tang F, Green HS, Wang SC, Hatzakis E (2021) Analysis and authentication of avocado oil using high resolution NMR spectroscopy. Molecules 26(2):310. https://doi.org/10.3390/molecules26020310

Yanty NAM, Marikkar JMN, Long K (2011) Effect of varietal differences on composition and thermal characteristics of avocado oil. J Am Oil Chem Soc 88(12):1997–2003. https://doi.org/10.1007/s11746-011-1877-x

Acknowledgements

Former and current lab members Sarah Chen, Amber Sun, and Gavin Sou helped to complete the chemical analyses for this project. H.G. is thankful for the ARCS Fellowship and Berta Fellowship to support her work on this by providing graduate student researcher stipend.

Author information

Authors and Affiliations

Contributions

Hilary S. Green: conceptualization, methodology, software, validation, formal analysis, data curation, investigation, writing-original draft preparation, writing-reviewing and editing, visualization. funding acquisition. Selina C. Wang: conceptualization, methodology, investigation, resources, supervision, writing-reviewing and editing, project administration, funding acquisition.

Corresponding author

Ethics declarations

Competing Interests

Hilary S. Green declares no competing interests. Selina C. Wang declares no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Green, H.S., Wang, S.C. Tandem Triacylglycerol (TAG) and PCA Adulteration Detection Approach for Avocado Oil. Food Anal. Methods 16, 850–856 (2023). https://doi.org/10.1007/s12161-023-02468-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-023-02468-7