Abstract

Improving plant characteristics for better environmental resilience and more cost-effective transformation to fuels and chemicals is one of the focus areas in biomass feedstock development. In order to bridge lignin engineering and conversion technologies, this study aimed to fractionate and characterize lignin streams from wild-type and engineered switchgrass using three different pretreatment methods, i.e., dilute sulfuric acid (DA), ammonium hydroxide (AH), and aqueous ionic liquid (IL). Results demonstrate the low lignin content and high S/G ratio switchgrass mutant (4CL) was more susceptible to pretreatment and subsequently more digestible by enzymes as compared to wild-type switchgrass and AtLOV1 mutant. In addition, when compared to DA and AH pretreatment, aqueous IL (cholinium lysinate) was demostrated to be an efficient lignin solvent, as indicated by the high (> 80%) lignin solubility and reduced lignin molecular weight. FTIR and differential scanning calorimetry measurements suggest that pretreatment chemistry greatly influenced the structural and compositional changes and thermal properties of the pretreated switchgrass and recovered lignin-rich streams. The comparative data obtained from this work deepen our understanding of how lignin modification impacts the fractionation and properties of biomass feedstocks.

Similar content being viewed by others

References

Obama B (2017) The irreversible momentum of clean energy. Science 355(6321):126–129

Ragauskas AJ, Williams CK, Davison BH, Britovsek G, Cairney J, Eckert CA, Frederick WJ, Hallett JP, Leak DJ, Liotta CL (2006) The path forward for biofuels and biomaterials. Science 311(5760):484–489

Lynd LR, Laser MS, Bransby D, Dale BE, Davison B, Hamilton R, Himmel M, Keller M, McMillan JD, Sheehan J (2008) How biotech can transform biofuels. Nat Biotechnol 26(2):169

Kim H, Kim S, Dale BE (2009) Biofuels, land use change, and greenhouse gas emissions: some unexplored variables. Environ Sci Technol 43(3):961–967

Ragauskas AJ, Beckham GT, Biddy MJ, Chandra R, Chen F, Davis MF, Davison BH, Dixon RA, Gilna P, Keller M, Langan P, Naskar AK, Saddler JN, Tschaplinski TJ, Tuskan GA, Wyman CE (2014) Lignin valorization: improving lignin processing in the biorefinery. Science 344(6185):1246843

Shi J, Ebrik M, Yang B, Wyman CE (2009) The potential of cellulosic ethanol production from municipal solid waste: a technical and economic evaluation. University of California Energy Institute, Berkeley

Chundawat SP, Beckham GT, Himmel ME, Dale BE (2011) Deconstruction of lignocellulosic biomass to fuels and chemicals. Annu Rev Chem Biomol Eng 2:121–145

Swanson RM, Platon A, Satrio JA, Brown RC (2010) Techno-economic analysis of biomass-to-liquids production based on gasification. Fuel 89:S11–S19

Parrish DJ, Fike JH (2005) The biology and agronomy of switchgrass for biofuels. Crit Rev Plant Sci 24(5–6):423–459

McLaughlin SB, Kszos LA (2005) Development of switchgrass (Panicum virgatum) as a bioenergy feedstock in the United States. Biomass Bioenergy 28(6):515–535

Linger JG, Vardon DR, Guarnieri MT, Karp EM, Hunsinger GB, Franden MA, Johnson CW, Chupka G, Strathmann TJ, Pienkos PT (2014) Lignin valorization through integrated biological funneling and chemical catalysis. Proc Natl Acad Sci 111(33):12013–12018

Himmel ME, Ding S-Y, Johnson DK, Adney WS, Nimlos MR, Brady JW, Foust TD (2007) Biomass recalcitrance: engineering plants and enzymes for biofuels production. Science 315(5813):804–807

Hisano H, Nandakumar R, Wang Z-Y (2011) Genetic modification of lignin biosynthesis for improved biofuel production. In: Vitro Cell Dev Biol-Plant. Springer 45(3):306–313

Xu B, Sathitsuksanoh N, Tang Y, Udvardi MK, Zhang J-Y, Shen Z, Balota M, Harich K, Zhang PY-H, Zhao B (2012) Overexpression of AtLOV1 in switchgrass alters plant architecture, lignin content, and flowering time. PLoS One 7(12):e47399

Chen F, Dixon RA (2007) Lignin modification improves fermentable sugar yields for biofuel production. Nat Biotechnol 25(7):759–761

Lu F, Ralph J (1997) Derivation followed by reductive cleavage (DFRC method), a new method for lignin analysis: protocol for analysis of DFRC monomers. J Agric Food Chem 45(7):2590–2592

Barta Z, Oliva J, Ballesteros I, Dienes D, Ballesteros M, Réczey K (2010) Refining hemp hurds into fermentable sugars or ethanol. Chem Biochem Eng Q 24(3):331–339

Xu B, Escamilla-Treviño LL, Sathitsuksanoh N, Shen Z, Shen H, Percival Zhang YH, Dixon RA, Zhao B (2011) Silencing of 4-coumarate: coenzyme A ligase in switchgrass leads to reduced lignin content and improved fermentable sugar yields for biofuel production. New Phytol 192(3):611–625

Fu C, Mielenz JR, Xiao X, Ge Y, Hamilton CY, Rodriguez M, Chen F, Foston M, Ragauskas A, Bouton J (2011) Genetic manipulation of lignin reduces recalcitrance and improves ethanol production from switchgrass. Proc Natl Acad Sci 108(9):3803–3808

Wyman CE, Balan V, Dale BE, Elander RT, Falls M, Hames B, Holtzapple MT, Ladisch MR, Lee Y, Mosier N (2011) Comparative data on effects of leading pretreatments and enzyme loadings and formulations on sugar yields from different switchgrass sources. Bioresour Technol 102(24):11052–11062

Li C, Knierim B, Manisseri C, Arora R, Scheller HV, Auer M, Vogel KP, Simmons BA, Singh S (2010) Comparison of dilute acid and ionic liquid pretreatment of switchgrass: biomass recalcitrance, delignification and enzymatic saccharification. Bioresour Technol 101(13):4900–4906

Foston M, Ragauskas AJ (2010) Changes in lignocellulosic supramolecular and ultrastructure during dilute acid pretreatment of Populus and switchgrass. Biomass Bioenergy 34(12):1885–1895. https://doi.org/10.1016/j.biombioe.2010.07.023

Jensen JR, Morinelly JE, Gossen KR, Brodeur-Campbell MJ, Shonnard DR (2010) Effects of dilute acid pretreatment conditions on enzymatic hydrolysis monomer and oligomer sugar yields for aspen, balsam, and switchgrass. Bioresour Technol 101(7):2317–2325

Dien BS, O'Bryan PJ, Hector RE, Iten LB, Mitchell RB, Qureshi N, Sarath G, Vogel KP, Cotta MA (2013) Conversion of switchgrass to ethanol using dilute ammonium hydroxide pretreatment: influence of ecotype and harvest maturity. Environ Technol 34(13–14):1837–1848

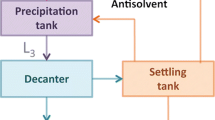

Sherman SR, Goodell JJ, Milliken CE, Morris JA, Gorensek MB (2012) A new process developed for separation of lignin from ammonium hydroxide pretreatment solutions. Environ Prog Sustain Energy 31(1):130–138

Gupta R, Lee Y (2010) Investigation of biomass degradation mechanism in pretreatment of switchgrass by aqueous ammonia and sodium hydroxide. Bioresour Technol 101(21):8185–8191

Rogers R, Seddon K (2003) CHEMISTRY: ionic liquids—solvents of the future? Science 302(5646):792

Singh S, Simmons BA, Vogel KP (2009) Visualization of biomass solubilization and cellulose regeneration during ionic liquid pretreatment of switchgrass. Biotechnol Bioeng 104(1):68–75

Perez-Pimienta JA, Lopez-Ortega MG, Varanasi P, Stavila V, Cheng G, Singh S, Simmons BA (2013) Comparison of the impact of ionic liquid pretreatment on recalcitrance of agave bagasse and switchgrass. Bioresour Technol 127:18–24

Shi J, Gladden JM, Sathitsuksanoh N, Kambam P, Sandoval L, Mitra D, Zhang S, George A, Singer SW, Simmons BA (2013) One-pot ionic liquid pretreatment and saccharification of switchgrass. Green Chem 15(9):2579–2589

Sun N, Parthasarathi R, Socha AM, Shi J, Zhang S, Stavila V, Sale KL, Simmons BA, Singh S (2014) Understanding pretreatment efficacy of four cholinium and imidazolium ionic liquids by chemistry and computation. Green Chem 16(5):2546–2557

Sun J, Konda NM, Shi J, Parthasarathi R, Dutta T, Xu F, Scown CD, Simmons BA, Singh S (2016) CO 2 enabled process integration for the production of cellulosic ethanol using bionic liquids. Energy Environ Sci 9(9):2822–2834

Xu F, Sun J, Konda NM, Shi J, Dutta T, Scown CD, Simmons BA, Singh S (2016) Transforming biomass conversion with ionic liquids: process intensification and the development of a high-gravity, one-pot process for the production of cellulosic ethanol. Energy Environ Sci 9(3):1042–1049

Shi J, Balamurugan K, Parthasarathi R, Sathitsuksanoh N, Zhang S, Stavila V, Subramanian V, Simmons BA, Singh S (2014) Understanding the role of water during ionic liquid pretreatment of lignocellulose: co-solvent or anti-solvent? Green Chem 16(8):3830–3840

Xia S, Baker GA, Li H, Ravula S, Zhao H (2014) Aqueous ionic liquids and deep eutectic solvents for cellulosic biomass pretreatment and saccharification. RSC Adv 4(21):10586–10596

Fu D, Mazza G (2011) Aqueous ionic liquid pretreatment of straw. Bioresour Technol 102(13):7008–7011

Beckham GT, Johnson CW, Karp EM, Salvachúa D, Vardon DR (2016) Opportunities and challenges in biological lignin valorization. Curr Opin Biotechnol 42:40–53

Joffres B, Lorentz C, Vidalie M, Laurenti D, Quoineaud A-A, Charon N, Daudin A, Quignard A, Geantet C (2014) Catalytic hydroconversion of a wheat straw soda lignin: characterization of the products and the lignin residue. Appl Catal B Environ 145:167–176

Samuel R, Pu Y, Raman B, Ragauskas AJ (2010) Structural characterization and comparison of switchgrass ball-milled lignin before and after dilute acid pretreatment. Appl Biochem Biotechnol 162(1):62–74

Liu E (2017) Fractionation and characterization of lignin streams from genetically engineered switchgrass. Theses and Dissertations—BioSyst Agric Eng 49. https://doi.org/10.13023/ETD.2017.171

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass. Laboratory Analytic Procedure (LAP) of the National Renewable Energy Laboratory (NREL), Colorado USA Google Scholar

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D (2006) Determination of sugars, byproducts, and degradation products in liquid fraction process samples. National Renewable Energy Laboratory, Golden

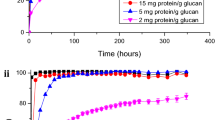

Selig M, Weiss N, Ji Y (2008) Enzymatic saccharification of lignocellulosic biomass: laboratory analytical procedure (LAP). National Renewable Energy Laboratory, Jefferson County issue date, 3/21/2008

Yoo CG, Pu Y, Li M, Ragauskas AJ (2016) Elucidating structural characteristics of biomass using solution-state 2 D NMR with a mixture of deuterated dimethylsulfoxide and hexamethylphosphoramide. ChemSusChem 9(10):1090–1095

Hu Z, Yeh T-F, Chang H-M, Matsumoto Y, Kadla JF (2006) Elucidation of the structure of cellulolytic enzyme lignin. Holzforschung 60(4):389–397

Segal L, Creely J, Martin A Jr, Conrad C (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29(10):786–794

Studer MH, DeMartini JD, Davis MF, Sykes RW, Davison B, Keller M, Tuskan GA, Wyman CE (2011) Lignin content in natural Populus variants affects sugar release. Proc Natl Acad Sci 108(15):6300–6305

Donohoe BS, Vinzant TB, Elander RT, Pallapolu VR, Lee Y, Garlock RJ, Balan V, Dale BE, Kim Y, Mosier NS (2011) Surface and ultrastructural characterization of raw and pretreated switchgrass. Bioresour Technol 102(24):11097–11104

Donohoe BS, Decker SR, Tucker MP, Himmel ME, Vinzant TB (2008) Visualizing lignin coalescence and migration through maize cell walls following thermochemical pretreatment. Biotechnol Bioeng 101(5):913–925

Pu Y, Hu F, Huang F, Davison BH, Ragauskas AJ (2013) Assessing the molecular structure basis for biomass recalcitrance during dilute acid and hydrothermal pretreatments. Biotechnol Biofuels 6(1):15

Kim TH, Taylor F, Hicks KB (2008) Bioethanol production from barley hull using SAA (soaking in aqueous ammonia) pretreatment. Bioresour Technol 99(13):5694–5702

Yoo CG, Kim H, Lu F, Azarpira A, Pan X, Oh KK, Kim JS, Ralph J, Kim TH (2016) Understanding the physicochemical characteristics and the improved enzymatic saccharification of corn stover pretreated with aqueous and gaseous ammonia. Bioenergy Res 9(1):67–76

Konda NM, Shi J, Singh S, Blanch HW, Simmons BA, Klein-Marcuschamer D (2014) Understanding cost drivers and economic potential of two variants of ionic liquid pretreatment for cellulosic biofuel production. Biotechnology for Biofuels 7(1):86

Klein-Marcuschamer D, Simmons BA, Blanch HW (2011) Techno-economic analysis of a lignocellulosic ethanol biorefinery with ionic liquid pre-treatment. Biofuels Bioprod Biorefin 5(5):562–569. https://doi.org/10.1002/bbb.303

Li H, Pu Y, Kumar R, Ragauskas AJ, Wyman CE (2014) Investigation of lignin deposition on cellulose during hydrothermal pretreatment, its effect on cellulose hydrolysis, and underlying mechanisms. Biotechnol Bioeng 111(3):485–492

Zhao C, Xie SX, Pu YQ, Zhang R, Huang F, Ragauskas AJ, Yuan JS (2016) Synergistic enzymatic and microbial lignin conversion. Green Chem 18(5):1306–1312. https://doi.org/10.1039/c5gc01955a

Kim TH, Kim JS, Sunwoo C, Lee Y (2003) Pretreatment of corn stover by aqueous ammonia. Bioresour Technol 90(1):39–47

Liu L, Sun J, Li M, Wang S, Pei H, Zhang J (2009) Enhanced enzymatic hydrolysis and structural features of corn stover by FeCl 3 pretreatment. Bioresour Technol 100(23):5853–5858

Xu F, Yu J, Tesso T, Dowell F, Wang D (2013) Qualitative and quantitative analysis of lignocellulosic biomass using infrared techniques: a mini-review. Appl Energy 104:801–809

Kumar R, Mago G, Balan V, Wyman CE (2009) Physical and chemical characterizations of corn stover and poplar solids resulting from leading pretreatment technologies. Bioresour Technol 100(17):3948–3962

Olsson A-M, Salmén L (2004) The association of water to cellulose and hemicellulose in paper examined by FTIR spectroscopy. Carbohydr Res 339(4):813–818

Lau MW, Dale BE, Balan V (2008) Ethanolic fermentation of hydrolysates from ammonia fiber expansion (AFEX) treated corn stover and distillers grain without detoxification and external nutrient supplementation. Biotechnol Bioeng 99(3):529–539

El Mansouri N-E, Salvadó J (2007) Analytical methods for determining functional groups in various technical lignins. Ind Crop Prod 26(2):116–124

Boeriu CG, Bravo D, Gosselink RJ, van Dam JE (2004) Characterisation of structure-dependent functional properties of lignin with infrared spectroscopy. Ind Crop Prod 20(2):205–218

Colthup N (2012) Introduction to infrared and Raman spectroscopy. Elsevier, Amsterdam

Kumar S, Gupta R, Lee Y, Gupta RB (2010) Cellulose pretreatment in subcritical water: effect of temperature on molecular structure and enzymatic reactivity. Bioresour Technol 101(4):1337–1347

Tsujiyama S-I, Miyamori A (2000) Assignment of DSC thermograms of wood and its components. Thermochim Acta 351(1):177–181

Reh U, Kraepelin G, Lamprecht I (1987) Differential scanning calorimetry as a complementary tool in wood biodegradation studies. Thermochim Acta 119(1):143–150

Acknowledgements

The information reported in this paper (17-05-079) is part of a project of the Kentucky Agricultural Experiment Station and is published with the approval of the Director. We thank Novozymes for providing enzyme samples and Taylor Frazier for preparing plant materials.

Funding Information

The authors acknowledge the National Science Foundation under Cooperative Agreement No. 1355438 and 1632854 and the National Institute of Food and Agriculture, US Department of Agriculture, Hatch-Multistate project under accession number 1003563 for supporting this research. The Virginia Tech work was partially supported by USDA-NIFA Grant Number 2011-67009-30133 and by a Virginia Tech CALS integrative grant and the Virginia Agricultural Experiment Station (VA135872).

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

ESM 1

(DOCX 786 kb)

Rights and permissions

About this article

Cite this article

Liu, E., Das, L., Zhao, B. et al. Impact of Dilute Sulfuric Acid, Ammonium Hydroxide, and Ionic Liquid Pretreatments on the Fractionation and Characterization of Engineered Switchgrass. Bioenerg. Res. 10, 1079–1093 (2017). https://doi.org/10.1007/s12155-017-9868-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-017-9868-x