Abstract

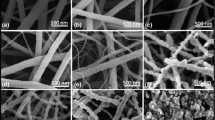

The synthesis of nanoparticles and nanofibres was carried out by preparing a homogeneous solution of poly(vinylpyrrolidone) (PVP) with titanium dioxide (TiO2), followed by electrospinning. The influence of the solution flow rate was 20, 10, 5 and 1 ml h–1 during the synthesis of the nanostructure polymer/semiconductor composite examine. Raman and photoluminescence analyses confirm the presence of TiO2 anatase phase; both intensity and broadening of peaks are sensitive to the flow rate. X-ray diffraction patterns show sharp and well-defined peaks, which correspond to the anatase phase, also the relative intensity of the peaks varies with the flow rate. Field-emission scanning electron microscope images reveal that nanoparticles were formed initially, which gradually transforms into nanofibres, thus forming a nanostructured composite. The study is the focus on the form of multiple nanostructures that can be easily controlled by changing the solution flow rate during electrospinning. We focused to synthesize both nanoparticles and nanofibres using electrospinning compared to what has been done in previous studies, where only nanofibres have been obtained. We studied the transformation of nanoparticles into nanofibres with respect to change in flow rate; it gives us many options for the fabrication of polymer solar cell layers.

Similar content being viewed by others

References

Fischer F and Bauer S 2009 Chem. Unserer Zeit 43 376

Al-Hazeem N Z, Ahmed N M, Matjafri M and Ramizy A 2021 Nanocomposites 7 70

Al-Hazeem N Z, Ahmed N M, MatJafri M and Bououdina M 2021 Microsyst. Technol. 27 293

Pravarthana D, Tyagi A, Jagadale T, Prellier W and Aswal D 2021 Appl. Surf. Sci. 549 149281

Fujishima A 1972 Nature 238 37

Chuangchote S, Sagawa T and Yoshikawa S 2008 Appl. Phys. Lett. 93 33310

Zhang Q, Gao L and Guo J 2000 J. Eur. Ceram. Soc. 20 2153

Lei L, Yuming C, Bo L, Xingfu Z and Weiping D 2010 Appl. Surf. Sci. 256 2596

Nyamukamba P, Okoh O, Mungondori H, Taziwa R and Zinya S 2018 Titanium dioxide—material for a sustainable environment (ed) D Yang 151 (https://doi.org/10.5772/intechopen.75425)

Kumar A, Jose R, Fujihara K, Wang J and Ramakrishna S 2007 Chem. Mater. 19 6536

Al-Hazeem N Z A 2018 Novel nanomaterials—synthesis and applications (ed) George Z Kyzas and Athanasios C Mitropoulos, In TechOpen 191

Zhang W, Zhu R, Liu X, Liu B and Ramakrishna S 2009 Appl. Phys. Lett. 95 43304

Wu H, Hu L, Rowell M W, Kong D, Cha J J, McDonough J R et al 2010 Nano Lett. 10 4242

Al-Hazeem N Z and Ahmed N M 2020 ACS Omega 5 22389

Tang Z S, Bolong N, Saad I, Ismail A F and Lim F T Y 2017 Adv. Sci. Lett. 23 11237

Rodoplu D and Mutlu M 2012 J. Eng. Fibers Fabr. 7 118

Liu F, Guo R, Shen M, Wang S and Shi X 2009 Macromol. Mater. Eng. 294 666

Zargham S, Bazgir S, Tavakoli A, Rashidi A S and Damerchely R 2012 J Eng Fibers Fabr. 7 42

Supaphol P, Mit‐Uppatham C and Nithitanakul M 2005 J. Polym. Sci. Part B Polym. Phys. 43 3699

Zhou F-L, Gong R-H and Porat I 2009 J. Mater. Sci. 44 5501

Yuan X, Zhang Y, Dong C and Sheng J 2004 Polym. Int. 53 1704

Wu G, Yang F, Tan Z, Ge H and Zhang H 2012 Iran Polym. J. 21 793

Nakhowong R 2020 SNRU J. Sci. Tech. 12 137

Strongone V, Bartoli M, Jagdale P, Arrigo R, Tagliaferro A and Malucelli G 2020 Polymers 12 796

Selvanathan V, Yahya R, Ruslan M H, Sopian K, Amin N, Nour M et al 2020 Polymers 12 516

Lee J E, Kim Y, Na Y H, Baek N S, Jung J W, Choi Y et al 2021 Polymers 13 393

Bai J, Li Y, Zhang C, Liang X and Yang Q 2008 Colloids Surf. A Physicochem. Eng. Asp. 329 165

Arbiol J, Cerda J, Dezanneau G, Cirera A, Peiro F, Cornet A et al 2002 J. Appl. Phys. 92 853

Ruiz A M, Dezanneau G, Arbiol J, Cornet A and Morante J R 2004 Chem. Mater. 16 862

Nuansing W, Ninmuang S, Jarernboon W, Maensiri S and Seraphin S 2006 Mater. Sci. Eng. B 131 147

Avram D, Patrascu A A, Istrate M C, Cojocaru B and Tiseanu C 2021 J. Alloys Compd. 851 156849

Hanaor D A and Sorrell C C 2011 J. Mater. Sci. 46 855

Someswararao M, Dubey R and Subbarao P 2021 J. Photochem. Photobiol. 6 100016

Pal M, Pal U, Jiménez J M G Y and Pérez-Rodríguez F 2012 Nanoscale Res. Lett. 7 1

Santara B, Pal B and Giri P 2011 J. Appl. Phys. 110 114322

Ding K, Miao Z, Liu Z, Zhang Z, Han B, An G et al 2007 J. Am. Chem. Soc. 129 6362

Ren X, Yang L, Li Y and Li X 2021 Appl. Surf. Sci. 544 148879

Melendres C, Narayanasamy A, Maroni V and Siegel R 1989 MRS Proceedings (Cambridge University Press) p 21

Dhage S R, Choube V D, Samuel V and Ravi V 2004 Mater. Lett. 58 2310

Rianjanu A, Kusumaatmaja A, Suyono E A and Triyana K 2018 Heliyon 4 e00592

Arinstein A and Zussman E 2011 J. Polym. Sci. Part B Polym. Phys. 49 691

Mahdavi H, Mazinani N and Heidari A A 2020 Polym. Int. 69 1187

Zargham S, Bazgir S, Tavakoli A, Rashidi A S and Damerchely R 2012 J. Eng. Fibers Fabr. 7 155892501200700400

Homayoni H, Ravandi S A H and Valizadeh M 2009 Carbohydr. Polym. 77 656

Ahmadi T, Monshi A, Mortazavi V, Fathi M H, Sharifi S, Kharaziha M et al 2020 Mater. Sci. Eng. C 106 110172

Vijayalakshmi R and Rajendran V 2012 Arch. Appl. Sci. Res. 4 1183

Song S, Sheng Z, Liu Y, Wang H and Wu Z 2012 J. Environ. Sci. 24 1519

Dhanalakshmi J, Iyyapushpam S, Nishanthi S, Malligavathy M and Padiyan D P 2017 Adv. Nat. Sci.: Nanosci. Nanotechnol. 8 015015

Lee H U, Lee S C, Choi S H, Son B, Lee S J, Kim H J et al 2013 Appl. Catal. B 129 106

Yu J C, Ho W, Yu J, Yip H, Wong P K and Zhao J 2005 Environ. Sci. Technol. 39 1175

Rockafellow E M, Stewart L K and Jenks W S 2009 Appl. Catal. B 91 554

Gilbert B, Huang F, Zhang H, Waychunas G A and Banfield J F 2004 Science 305 651

Mo S-D and Ching W 1995 Phys. Rev. B 51 13023

Valencia S, Marín J M and Restrepo G 2009 Open. Mater. Sci. 4 9

Acknowledgements

We would like to thank the Institute of Nano Optoelectronics Research and Technology (INOR) and the School of Physics at Universiti Sains Malaysia (USM) for supporting this research and providing the appropriate research environment. Our gratitude also goes to the Research Creativity and Management Office (RCMO) USM, for supporting us with the Short-Term grant (304. CINOR.6315364).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Al-Hazeem, N.Z., Hassan, Z., Mohammad, S.M. et al. Formation of titanium dioxide/poly(vinylpyrrolidone) nanostructure composite by changing the flow rate of polymer solution during electrospinning. Bull Mater Sci 45, 67 (2022). https://doi.org/10.1007/s12034-022-02656-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-022-02656-x