Abstract

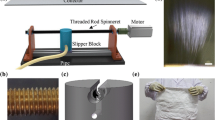

Electrospinning is a simple but highly versatile technology to produce nanofibers from solutions or melts mostly of polymers using electrostatic forces. A primary challenge facing electrospinning is its low productivity mainly limited by flow rate. In this work, a custom-made three-hole spinneret instead of conventional needles was adopted to enhance the flow rate of electrospinning. Three-jet formation, nanofiber deposition, nanofiber morphology and size were characterized by digital camera and scanning electron microscopy (SEM) as the effects of several governing parameters in electrospinning, including applied voltage from 19.8 to 21.0 kV, working distance from 15.2 to 16.8 cm and flow rate from 6.0 to 9.0 mL/h. It was found that three simultaneous stable jets were ejected from the three-hole spinneret under suitable operating conditions. Moreover, it was found that the fibers collected from the jets from each hole deposited separately in circular spots on a stationary collector. The resultant fibers mostly have an average diameter of less than 300 nm. It has been proved that simple holes on a flat surface can be used to electrospin nanofibers. The three-hole spinneret produces nanofibers at flow rates greater than that in single needle electrospinning. Flow rate has the potential to be easily scaled up by increasing the spinneret diameter and the number of holes.

Similar content being viewed by others

References

Srivastava Y, Marquez M, Thorsen T (2007) J Appl Polym Sci 106:3171

Brown PJ, Stevens K (eds) (2007) Nanofibers and nanotechnology in textiles. Woodhead Publishing Limited, UK

Zhou FL, Gong RH, Porat I (2009) Polym Int 58:331

Yarin AL, Zussman E (2004) Polymer 45:2977

Lozano P, Martínez-Sánchez M, Lopez-Urdiales JM (2004) J Colloid Interface Sci 276:392

Bocanegra R et al (2005) J Aerosol Sci 36:1387

Byun D et al (2008) Appl Phys Lett 92:093507

Zhou FL, Gong RH, Porat I (2009) Polym Eng Sci (in production)

Tang K et al (2001) Anal Chem 73:1658

Ding B et al (2006) Nanotechnology 17:3685

Vaseashtaa A (2007) Appl Phys Lett 90:093115

Zong X et al (2002) Polymer 43:4403

Deitzel JM et al (2001) Polymer 42:261

Bowman J et al (2003) Mater Res Soc Symp 752:AA1.5.1

Hubacz AN, Marijnissen JCM (2003) J Aerosol Sci 34(Suppl 1):S1269

Quang TSB, Byun D, Lee S (2007) J Aerosol Sci 38:924

Theron SA et al (2005) Polymer 46:2889

Tomaszewski W, Szadkowski M (2005) Fibers Text East Eur 52:22

Varabhas JS, Chase GG, Reneker DH (2008) Polymer 49:4226

Subbiah T et al (2005) J Appl Polym Sci 96:557

Geng X, Kwon OH, Jang J (2005) Biomaterials 26:5427

Buchko CJ et al (1999) Polymer 40:7397

Megelski S et al (2002) Macromolecules 35:8456

Wang C, Hsu CH, Lin JH (2006) Macromolecules 39:7662

Demir MM et al (2002) Polymer 43:3303

Hsu CM, Shivkumar S (2004) Macromol Mater Eng 289:334

Heikkil P, Harlin A (2008) Eur Polym J 44:3067

Thompson CJ et al (2007) Polymer 48:6913

Fridrikh SV et al (2003) Phys Rev Lett 90:144502/1

Sen AK, Darabi JD, Knapp DR (2007) Microfluid Nanofluid 3:283

Duby MH et al (2006) J Aerosol Sci 37:306

Zeng J et al (2003) J Appl Polym Sci 89:1085

Li L, Hsieh YL (2005) Polymer 46:5133

Acknowledgements

Financial supports from the ORS award and School of Materials, The University of Manchester, are gratefully acknowledged. We would also like to thank Mr. S. Butt for the constructions of the electrospinning setup and flat spinnerets.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, FL., Gong, RH. & Porat, I. Three-jet electrospinning using a flat spinneret. J Mater Sci 44, 5501–5508 (2009). https://doi.org/10.1007/s10853-009-3768-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3768-1