Abstract

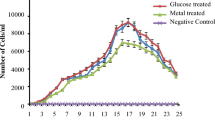

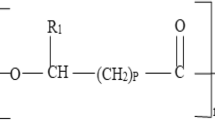

Commercialization of biosurfactant remained a challenge due to lack of structural variation and economical process using low-cost materials and low productivity. Improvement in production of biosurfactant using fried oil with hydrophilic co-substrate by an indigenous strain was studied. Microbe isolated from exhaust chimney condensate was screened for utilization of mixed carbon source and then identified as Pseudomonas aeruginosa NJ2 by 16S rDNA gene sequence. FTIR, HPLC, and NMR analyses confirmed that biosurfactant was rhamnolipids. Batch fermentation using mixed substrates improved the cell growth yield to 1.48 g/L (2.34 times) and product yield to 4.28 g/L (3.4 times) with maximum specific growth rate 0.1 h−1 (two times) and specific production rate 0.5 h−1 (13 times) due to higher cell density and direct synthesis of lipid and rhamnose moieties through central metabolic pathways of the two substrates. Increase in carrying capacity and coefficient value (two times) of logistic equation confirmed the significance of mixed substrates. The biosurfactant showed excellent surface active and thermo-chemical stability properties. Economical production of biosurfactant with high yield and productivity could be possible by isolation of mixed carbon source utilizing strain and optimization of waste substrates from oil/soapstock and sugar/corn syrup industries in media.

Similar content being viewed by others

References

Fssai. Repurpose used cooking oil. Retrieved August 30, 2019, from https://fssai.gov.in/ruco/background-note.php

Murthy, A. V. N., & Sudhir, M. N. (2016). Marketing scenario of edible oil in India (marketing strength of edible oil in Andhra Pradesh). International Journal of Business and General Management (IJBGM), 5(2), 27–36 Retrieved from http://www.iaset.us/view_archives.php?year=2016&jtype=2&id=32&details=archives.

Haba, E., Espuny, M. J., Busquets, M., & Manresa, A. (2000). Screening and production of rhamnolipids by Pseudomonas aeruginosa 47T2 NCIB 40044 from waste frying oils. Journal of Applied Microbiology, 88(3), 379–387. https://doi.org/10.1046/j.1365-2672.2000.00961.x.

De Lima, C. J. B., Ribeiro, E. J., Sérvulo, E. F. C., Resende, M. M., & Cardoso, V. L. (2009). Biosurfactant production by Pseudomonas aeruginosa grown in residual soybean oil. Applied Biochemistry and Biotechnology, 152(1), 156–168. https://doi.org/10.1007/s12010-008-8188-1.

Maddikeri, G. L., Gogate, P. R., & Pandit, A. B. (2015). Improved synthesis of sophorolipids from waste cooking oil using fed batch approach in the presence of ultrasound. Chemical Engineering Journal, 263, 479–487. https://doi.org/10.1016/j.cej.2014.11.010.

Kourmentza, C., Plácido, J., Venetsaneas, N., Burniol-Figols, A., Varrone, C., Gavala, H. N., & Reis, M. A. M. (2017). Recent advances and challenges towards sustainable polyhydroxyalkanoate (PHA) production. Bioengineering, 4(2), 55. https://doi.org/10.3390/bioengineering4020055.

Abed, K. A., El Morsi, A. K., Sayed, M. M., Shaib, A. A. E., & Gad, M. S. (2018). Effect of waste cooking-oil biodiesel on performance and exhaust emissions of a diesel engine. Egyptian Journal of Petroleum, 27(4), 985–989. https://doi.org/10.1016/j.ejpe.2018.02.008.

Dubey, K. V., Charde, P. N., Meshram, S. U., Shendre, L. P., Dubey, V. S., & Juwarkar, A. A. (2012). Surface-active potential of biosurfactants produced in curd whey by Pseudomonas aeruginosa strain-PP2 and Kocuria turfanesis strain-J at extreme environmental conditions. Bioresource Technology, 126, 368–374. https://doi.org/10.1016/j.biortech.2012.05.024.

Joy, S., Rahman, P. K. S. M., Khare, S. K., & Sharma, S. (2019). Production and characterization of glycolipid biosurfactant from Achromobacter sp. (PS1) isolate using one-factor-at-a-time (OFAT) approach with feasible utilization of ammonia-soaked lignocellulosic pretreated residues. Bioprocess and Biosystems Engineering, 42(8), 1301–1315. https://doi.org/10.1007/s00449-019-02128-3.

Santos, D. K. F., Rufino, R. D., Luna, J. M., Santos, V. A., & Sarubbo, L. A. (2016). Biosurfactants: multifunctional biomolecules of the 21st century. International Journal of Molecular Sciences, 1–31. https://doi.org/10.3390/ijms17030401.

Juwarkar, A. A., Dubey, K. V., Nair, A., & Kumar, S. (2008). Bioremediation of multi-metal contaminated soil using biosurfactant—a novel approach. Indian Journal of Microbiology, 48(1), 142–146.

Abdel-Mawgoud, A. M., Hausmann, R., Lépine, F., Müller, M. M., & Déziel, E. (2011). Rhamnolipids: detection, analysis, biosynthesis, genetic regulation, and bioengineering of production. Microbiology Monographs, 20, 13–55. https://doi.org/10.1007/978-3-642-14490-5_2.

Hultberg, M., Bengtsson, T., & Liljeroth, E. (2010). Late blight on potato is suppressed by the biosurfactant-producing strain Pseudomonas koreensis 2.74 and its biosurfactant. BioControl, 55(4), 543–550. https://doi.org/10.1007/s10526-010-9289-7.

Suthar, H., & Nerurkar, A. (2016). Characterization of biosurfactant produced by Bacillus licheniformis TT42 having potential for enhanced oil recovery. Applied Biochemistry and Biotechnology, 180(2), 248–260. https://doi.org/10.1007/s12010-016-2096-6.

Sharma, R., Singh, J., & Verma, N. (2018). Optimization of rhamnolipid production from Pseudomonas aeruginosa PBS towards application for microbial enhanced oil recovery. 3 Biotech, 8(1). https://doi.org/10.1007/s13205-017-1022-0.

Dehghan-Noudeh, G., Housaindokht, M., & Bazzaz, B. S. F. (2005). Isolation, characterization, and investigation of surface and hemolytic activities of a lipopeptide biosurfactant produced by Bacillus subtilis ATCC 6633. Journal of Microbiology, 43(3), 272–276.

Janek, T., Łukaszewicz, M., Rezanka, T., & Krasowska, A. (2010). Isolation and characterization of two new lipopeptide biosurfactants produced by Pseudomonas fluorescens BD5 isolated from water from the Arctic archipelago of Svalbard. Bioresource Technology, 101(15), 6118–6123. https://doi.org/10.1016/j.biortech.2010.02.109.

Varjani, S. J., & Upasani, V. N. (2016). Carbon spectrum utilization by an indigenous strain of Pseudomonas aeruginosa NCIM 5514: production, characterization and surface active properties of biosurfactant. Bioresource Technology, 221, 510–516. https://doi.org/10.1016/j.biortech.2016.09.080.

Lan, G., Fan, Q., Liu, Y., Liu, Y., Liu, Y., Yin, X., & Luo, M. (2015). Effects of the addition of waste cooking oil on heavy crude oil biodegradation and microbial enhanced oil recovery using Pseudomonas sp. SWP-4. Biochemical Engineering Journal, 103, 219–226. https://doi.org/10.1016/j.bej.2015.08.004.

Shah, V., Jurjevic, M., & Badia, D. (2007). Utilization of restaurant waste oil as a precursor for sophorolipid production. Biotechnology Progress, 23(2), 512–515. https://doi.org/10.1021/bp0602909.

Kim, H. S., Jeon, J. W., Kim, B. H., Ahn, C. Y., Oh, H. M., & Yoon, B. D. (2006). Extracellular production of a glycolipid biosurfactant, mannosylerythritol lipid, by Candida sp. SY16 using fed-batch fermentation. Applied Microbiology and Biotechnology, 70(4), 391–396. https://doi.org/10.1007/s00253-005-0092-9.

Khopade, A., Biao, R., Liu, X., Mahadik, K., Zhang, L., & Kokare, C. (2012). Production and stability studies of the biosurfactant isolated from marine Nocardiopsis sp. B4. Desalination, 285, 198–204. https://doi.org/10.1016/j.desal.2011.10.002.

Abouseoud, M., Maachi, R., Amrane, A., Boudergua, S., & Nabi, A. (2008). Evaluation of different carbon and nitrogen sources in production of biosurfactant by Pseudomonas fluorescens. Desalination, 223(1–3), 143–151. https://doi.org/10.1016/j.desal.2007.01.198.

Patowary, R., Patowary, K., Kalita, M. C., & Deka, S. (2016). Utilization of paneer whey waste for cost-effective production of rhamnolipid biosurfactant. Applied Biochemistry and Biotechnology, 180(3), 383–399. https://doi.org/10.1007/s12010-016-2105-9.

Wei, Y. H., Chou, C. L., & Chang, J. S. (2005). Rhamnolipid production by indigenous Pseudomonas aeruginosa J4 originating from petrochemical wastewater. Biochemical Engineering Journal, 27(2), 146–154. https://doi.org/10.1016/j.bej.2005.08.028.

Wu, J. Y., Yeh, K. L., Lu, W. B., Lin, C. L., & Chang, J. S. (2008). Rhamnolipid production with indigenous Pseudomonas aeruginosa EM1 isolated from oil-contaminated site. Bioresource Technology, 99(5), 1157–1164. https://doi.org/10.1016/j.biortech.2007.02.026.

Zhang, L., Veres-Schalnat, T. A., Somogyi, A., Pemberton, J. E., & Maiera, R. M. (2012). Fatty acid cosubstrates provide β-oxidation precursors for rhamnolipid biosynthesis in Pseudomonas aeruginosa, as evidenced by isotope tracing and gene expression assays. Applied and Environmental Microbiology, 78(24), 8611–8622. https://doi.org/10.1128/AEM.02111-12.

Tan, Y. N., & Li, Q. (2018). Microbial production of rhamnolipids using sugars as carbon sources. Microbial Cell Factories, 17(1). https://doi.org/10.1186/s12934-018-0938-3.

Garrity, G. M. & Searles, D. B. (2001). Taxonomic Outline of the Procaryotic Genera: Bergey’s Manual of Systematic Bacteriology, Second Edition, Springer, New York. https://doi.org/10.1007/978-0-387-21609-6

Muyzer, G., Teske, A., Wirsen, C. O., & Jannasch, H. W. (1995). Phylogenetic relationships of Thiomicrospira species and their identification in deep-sea hydrothermal vent samples by denaturing gradient gel electrophoresis of 16S rDNA fragments. Archives of Microbiology, 164(3), 165–172. https://doi.org/10.1007/BF02529967.

Inka, S., & Fritz, W. (1991). New method for detecting rhamnolipids excreted by Pseudomonas species during growth on mineral agar. Biotechnology Techniques, 5(4), 265–268.

Thomas, P. (1977). Methods in carbohydrate chemistry. Carbohydrate research (vol. III., Vol. 56). NY: Academic Press. https://doi.org/10.1016/s0008-6215(00)84261-5.

Benincasa, M., Contiero, J., Manresa, M. A., & Moraes, I. O. (2002). Rhamnolipid production by Pseudomonas aeruginosa LBI growing on soapstock as the sole carbon source. Journal of Food Engineering, 54, 283–288.

Miller, G. L. (1959). Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry, 31(3), 426–428. https://doi.org/10.1021/ac60147a030.

Lotfabad, T. B., Abassi, H., Ahmad Khaniha, R., Roostaazad, R., Masoomi, F., Zahiri, H. S., & Noghabi, K. A. (2010). Structural characterization of a rhamnolipid-type biosurfactant produced by Pseudomonas aeruginosa MR01: enhancement of di-rhamnolipid proportion using gamma irradiation. Colloids and Surfaces B: Biointerfaces, 81(2), 397–405. https://doi.org/10.1016/j.colsurfb.2010.06.026.

Zhu, X., Wang, K., Zhu, J., & Koga, M. (2001). Analysis of cooking oil fumes by ultraviolet spectrometry and gas chromatography-mass spectrometry. Journal of Agricultural and Food Chemistry, 49(10), 4790–4794. https://doi.org/10.1021/jf001084y.

Jiang, X., Zhu, S., Wu, Y., & Huai, H. (2009). The effects of cooking oil fume condensates (COFCs) on the vegetative growth of Salvinia natans (L.) All. Journal of Hazardous Materials, 172(1), 240–246. https://doi.org/10.1016/j.jhazmat.2009.07.001.

Da Silva, G. P., Mack, M., & Contiero, J. (2009). Glycerol: a promising and abundant carbon source for industrial microbiology. Biotechnology Advances, 27(1), 30–39. https://doi.org/10.1016/j.biotechadv.2008.07.006.

Docoslis, A., Giese, R. F., & Van Oss, C. J. (2000). Influence of the water-air interface on the apparent surface tension of aqueous solutions of hydrophilic solutes. Colloids and Surfaces B: Biointerfaces, 19(2), 147–162. https://doi.org/10.1016/S0927-7765(00)00137-5.

Shogren, R., & Biresaw, G. (2007). Surface properties of water soluble maltodextrin, starch acetates and starch acetates/alkenylsuccinates. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 298(3), 170–176. https://doi.org/10.1016/j.colsurfa.2006.10.070.

Takamura, K., Fischer, H., & Morrow, N. R. (2012). Physical properties of aqueous glycerol solutions. Journal of Petroleum Science and Engineering, 98–99, 50–60. https://doi.org/10.1016/j.petrol.2012.09.003.

Hasegawa, M., Kishino, H., Yano, & Aki, T. (1985). Dating of the human-ape splitting by a molecular clock of mitochondrial DNA. Journal of Molecular Evolution, 22(2), 160–174. https://doi.org/10.1007/BF02101694.

Schmidberger, A., Henkel, M., Hausmann, R., & Schwartz, T. (2013). Expression of genes involved in rhamnolipid synthesis in Pseudomonas aeruginosa PAO1 in a bioreactor cultivation. Applied Microbiology and Biotechnology, 97(13), 5779–5791. https://doi.org/10.1007/s00253-013-4891-0.

Reis, R. S., Pereira, A. G., Neves, B. C., & Freire, D. M. G. (2011). Gene regulation of rhamnolipid production in Pseudomonas aeruginosa—a review. Bioresource Technology, 102(11), 6377–6384. https://doi.org/10.1016/j.biortech.2011.03.074.

Churchill, M. E., & Chen, L. (2011). Structural basis of acyl-homoserine lactone-dependent signaling. Chemical Reviews, 111(1), 68–85. https://doi.org/10.1021/cr1000817.

Maier, R. M., & Sobero, G. (2000). Pseudomonas aeruginosa rhamnolipids: biosynthesis and potential applications. Applied Microbiology and Biotechnology, 54(5), 625–633.

Lotfabad, T. B., Shourian, M., Roostaazad, R., Najafabadi, A. R., Adelzadeh, M. R., & Noghabi, K. A. (2009). An efficient biosurfactant-producing bacterium Pseudomonas aeruginosa MR01, isolated from oil excavation areas in south of Iran. Colloids and Surfaces B: Biointerfaces, 69(2), 183–193. https://doi.org/10.1016/j.colsurfb.2008.11.018.

Dusane, D. H., Zinjarde, S. S., Venugopalan, V. P., McLean, R. J. C., Weber, M. M., & Rahman, P. K. S. M. (2010). Quorum sensing: implications on rhamnolipid biosurfactant production. Biotechnology and Genetic Engineering Reviews, 27(1), 159–184. https://doi.org/10.1080/02648725.2010.10648149.

Schuster, M., Lostroh, C. P., Ogi, T., & Greenberg, E. P. (2003). Identification, timing, and signal specificity of Pseudomonas aeruginosa quorum-controlled genes: a transcriptome analysis. Journal of Bacteriology, 185(7), 2066–2079. https://doi.org/10.1128/JB.185.7.2066-2079.2003.

Shuler, M. L., & Kargi, F. (1992). Bioprocess engineering: basic concepts. Journal of Controlled Release (Vol. 22). Englewood Cliffs: Prentice Hall International. https://doi.org/10.1016/0168-3659(92)90106-2.

Ashby, R. D., Solaiman, D. K. Y., Foglia, T. A., & Liu, C. K. (2001). Glucose/lipid mixed substrates as a means of controlling the properties of medium chain length poly(hydroxyalkanoates). Biomacromolecules, 2(1), 211–216. https://doi.org/10.1021/bm000098+.

Sharma, P. K., Munir, R. I., de Kievit, T., & Levin, D. B. (2017). Synthesis of polyhydroxyalkanoates (PHAs) from vegetable oils and free fatty acids by wild-type and mutant strains of Pseudomonas chlororaphis. Canadian Journal of Microbiology, 63(12), 1009–1024. https://doi.org/10.1139/cjm-2017-0412.

Nitschke, M., Costa, S. G. V. A. O., & Contiero, J. (2005). Rhamnolipid surfactants: an update on the general aspects of these remarkable biomolecules. Biotechnology Progress, 21(6), 1593–1600. https://doi.org/10.1021/bp050239p.

Campos, J. M., Montenegro Stamford, T. L., Sarubbo, L. A., de Luna, J. M., Rufino, R. D., & Banat, I. M. (2013). Microbial biosurfactants as additives for food industries. Biotechnology Progress, 29(5), 1097–1108. https://doi.org/10.1002/btpr.1796.

Abdel-Mawgoud, A. M., Aboulwafa, M. M., & Hassouna, N. A. H. (2009). Characterization of rhamnolipid produced by Pseudomonas aeruginosa isolate Bs20. Applied Biochemistry and Biotechnology, 157(2), 329–345. https://doi.org/10.1007/s12010-008-8285-1.

Kim, H. S., Yoon, B. D., Lee, C. H., Suh, H. H., Oh, H. M., Katsuragi, T., & Tani, Y. (1997). Production and properties of a lipopeptide biosurfactant from Bacillus subtilis C9. Journal of Fermentation and Bioengineering, 84(1), 41–46. https://doi.org/10.1016/S0922-338X(97)82784-5.

Acknowledgments

Mr. Arun Singh Pathania gratefully acknowledges the Ministry of Human Resource Development (MHRD), Govt. of India, for providing the fellowship during the study. All authors are highly thankful to Dr. B R A, National Institute of Technology (NIT), Jalandhar, for the administrative supports of this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

ESM 1

(DOCX 192 kb)

Rights and permissions

About this article

Cite this article

Pathania, A.S., Jana, A.K. Improvement in Production of Rhamnolipids Using Fried Oil with Hydrophilic Co-substrate by Indigenous Pseudomonas aeruginosa NJ2 and Characterizations. Appl Biochem Biotechnol 191, 1223–1246 (2020). https://doi.org/10.1007/s12010-019-03221-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-019-03221-9