Abstract

Recent advances in machine learning have revolutionized numerous research domains by extracting the hidden features and properties of complex systems, which are not otherwise possible using conventional ways. One such development can be seen in designing smart materials, which intersects the ability of microfluidics and metamaterials with machine learning to achieve unprecedented abilities. Microfluidics involves generating and manipulating fluids in the form of liquid streams or droplets from microliter to femtoliter regimes. However, analysis of such fluid flows is always tiresome and challenging due to the complexity involved in the integration and detection of various chemical or biological processes. On the other hand, acoustic metamaterials manipulate acoustic waves to achieve unparalleled properties, which is not possible using natural materials. Nonetheless, the design of such metamaterials relies on the expertise of specialists or on analytical models that require an enormous number of expensive function evaluations, making this method extremely complex and time-consuming. These complexities and exorbitant function evaluations of both fluidic and metamaterial systems embark on the need for the support of computational tools that can identify, process, and quantify the large amounts of intricacy, thus machine learning techniques. This review discusses the shortcomings of microfluidics and acoustic metamaterials, which are overcome by neoteric machine learning approaches for building smart materials. The following review ends by providing the importance and future perspective of integrating machine learning and optimization approaches with microfluidic-based acoustic metamaterials to build smart and efficient intelligent next-generation materials.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

1 Introduction

Artificial intelligence and machine learning methods have metamorphosed the existing research domains and set up new pathways for researchers, academics, and industrialists to establish far-fetched research goals. These interdisciplinary tools have benefitted emerging research areas by exploring the complex phenomenon of existing systems and extracting the useful features based on the historic data values [1,2,3]. Moreover, forecasting or predicting the future events/states is another paradigm achieved by integrating machine learning techniques in various systems [4, 5]. Leveraging the capability of machine learning algorithms to efficiently process the large data sets and surrogating the computationally expensive analysis with relatively cheap black-box models have led to the development of intelligent or smart systems to achieve superlative performance in contrast to conventional ways [6,7,8]. In this review, we present the development of smart systems focusing on two domains of microfluidics and acoustic metamaterials, which are recently been merged to develop next-generation fluid-based metamaterials. It has been observed that integrating the merits of fluidic systems and acoustic metamaterials with machine learning techniques resulted in the intelligent systems enabling their applicability in real-time for varied application spaces. This work demonstrates an efficient paradigm for engineering multifunctional microfluidic devices and smart acoustic materials by utilizing the machine learning (ML) algorithms such as deep neural, convolutional and recurrent networks, autoencoders, reinforcement learning, etc. We have first described the important works on microfluidic integrated machine learning intelligent devices where ML algorithms have been utilized to efficiently optimize the design of challenging and cumbersome existing microfluidic systems. In addition, we highlighted the unique approach of developing acoustofluidic systems, which combines the strengths of microfluidics and acoustics to achieve the remarkable capabilities of acoustic metamaterials. Although extensive work has been done in designing acoustic metamaterials with machine learning techniques, allowing for real-time design by addressing expensive function calls, no studies have reported combining microfluidic acoustic metamaterials with machine learning. Through this review, we are proposing the possibility of merging these emerging fields with the neoteric machine learning approaches to create innovative acoustofluidic machine learning smart materials with exceptional capabilities.

Over the past two decades, microfluidics has emerged as a potential tool that deals with the manipulation and control of the fluids from microliter (10−6 L) to femtoliter (10−15 L) regimes [9, 10]. The fluid surface properties such as viscosity and surface tension become dominant at the micro/nano scale [11], and microfluidics defines the physics of fluids at this scale [12]. Microfluidics has become a solution for various industries and applications, such as, cosmetics [13], biomedical [14], electronics [15], lab on chip [16,17,18], sensing [19], generation of micron-sized droplets [20, 21] etc. However, the design and analysis of such microfluidic systems is a skillful and time-consuming task [22]. Depending upon the nature of the application and analysis, the competence of machine learning models in learning and generalizing the large data sets have proven to be successful in such scenarios [23, 24].

Acoustic metamaterials (AMMs), on the other hand, are the artificially created materials, designed with extraordinary properties to manipulate, and control sound waves [25, 26]. The most common examples of acoustic metamaterials [27] are Helmholtz resonators [28], space-coiling metamaterial [29, 30], slit-type metamaterials [31] and many more. Conventionally, the design of these metamaterials relies on the time-consuming and complex modelling methods, thus hindering its applicability and limiting its application spaces. The emphasis nowadays is to develop smart metamaterial structures to attain chimeric tunability and reconfigurability by integrating them with machine learning methods. Recently, studies have been carried out to integrate the microfluidic systems with metamaterials to achieve wide-scale tunability and applicability of next-gen metamaterials in real-time.

Machine learning (ML) approaches have emerged as powerful tools for designing novel smart materials with engineered properties. Various types of machine learning techniques include- supervised learning (where the algorithm is trained on labelled data), unsupervised learning (where the algorithm is trained on unlabelled data), reinforcement learning (in which the algorithm learns by interacting with an environment), and Deep Learning (which utilizes artificial neural networks to model complex patterns in large datasets). Machine learning (ML) algorithms have been utilized in the design of both microfluidic devices and acoustic metamaterials. As per a recent review article [32], the database construction process for building metamaterials can be assessed using quantum–mechanical, atomistic, and macroscale simulation methods. Another article [33] discusses the integration of machine learning with microfluidics and its potential applications. In the case of microfluidics, ML algorithms have also been utilized to efficiently optimize the design of acoustofluidic devices. A unique approach for design automation of acoustofluidic devices was introduced in a study by integrating machine learning and multi-objective heuristic optimization approaches [34]. In the case of acoustic metamaterials, ML algorithms have been used to develop efficient design methodologies for one-dimensional periodic and non-periodic metamaterial systems [35]. The study proposes two ML-based approaches for the design of these systems: a reinforcement learning-based approach for periodic metamaterials and a neural network-based approach for non-periodic metamaterials. The proposed approaches are capable of modeling different metamaterial assemblies satisfying user-defined properties while requiring only a one-time network training procedure [35].

In summary, the integration of machine learning with microfluidics and metamaterials can enable the design of novel smart materials with engineered properties. ML-based approaches and simulation methods can be used to create a database for building smart materials, making it possible to achieve effective results. Specifically, smart materials are a special type of material that can have one or more properties significantly altered in a controlled manner through external stimuli. Some examples of smart materials include photoelectric, piezoelectric, thermochromic, and various other materials. In this work, we demonstrate an efficient paradigm for engineering multifunctional microfluidic devices and acoustic metamaterials by utilizing machine learning (ML) algorithms such as deep neural, convolutional and recurrent networks, autoencoders, reinforcement learning, etc. We have first described the important works on microfluidic integrated machine learning smart devices where ML algorithms have been utilized to efficiently optimize the design of challenging and cumbersome existing microfluidic systems. In addition, we highlighted the unique approach of developing acoustofluidic systems, which combines the strengths of microfluidics and acoustics to achieve the remarkable capabilities of acoustic metamaterials. Although extensive work has been done in designing acoustic metamaterials with machine learning techniques, allowing for real-time design by addressing expensive function calls, no studies have been reported combining microfluidic-acoustic metamaterials design with machine learning. Through this review, we are proposing the possibility of merging these emerging fields with the neoteric machine learning approaches to create innovative acoustofluidic machine learning smart systems with exceptional capabilities.

Overall, this review brings together the convergence of machine learning methods in the integrated systems of fluidics-based acoustic metamaterials. The paper is organized as follows: Sect. 2 describes the microfluidics-integrated machine learning smart systems, which is followed by reviewing the development of machine learning based intelligent acoustic metamaterials in Sect. 3. Section 4 concludes the study with future directions and perspectives.

2 Microfluidics integrated with machine learning

2.1 Introduction to microfluidics

Despite the immense potential of microfluidics in multiple domains, analysis of fluidics at such a small regime is always a complex and time-consuming process and generates large amounts of data which limits its reproducibility and generalizability [36]. In addition, microfluidics design and operation can take months and years of iterations to optimize their performance [33]. To remove these hindrances and offer a wide scale applicability, in recent days, the amalgamation of microfluidics with machine learning has led to the formation of intelligent microfluidic devices enabling the microfluidic systems to achieve unparalleled properties, which was not possible earlier. Exploiting the merits of both microfluidics (high-throughput nature, miniaturization fluid flow, and controllability) and machine learning (accessing large complex data, surrogate modelling), has led the researchers to explore the applicability of microfluidics in real time and in high-dimensional space with reduced computational efforts [11, 37]. Various kinds of machine learning methods categorized such as supervised, unsupervised, reinforcement and deep learning methods have been applied to analyse, process, and develop intelligent microfluidic devices (Fig. 1).

2.2 Significance of machine learning in microfluidics

Integration of machine learning (ML) in the microfluidic device design has demonstrated the effectiveness of the statistical methods, thus providing a trade-off between the analytical and numerical methods. Machine learning has mostly been used for automated data analysis and has proven to be effective for device performance prediction and design automation [38]. The design of multicomponent microfluidic devices is achieved through several iterations and is quite expensive to fabricate [39]. The use of machine learning techniques has proven to be helpful in the design of such devices. The capability of the machine learning models to process a large amount of data has accelerated the development of single devices that can generate large experimental data. Nitta et al. [40] combined the cell sorting microfluidic technique with neural network architecture to build the first smart cell sorter for accurate focusing of sample cells at the center of a two-step 3D hydrodynamic microfluidic cell focuser. Fidalgo and Maerkl [41] have devised a general-purpose programmable software-based microfluidic device for large-scale microfluidic integration. This work demonstrated the merits of using automated computing devices for numerous applications like microfluidic display, surface immunoassays, cell culture, and fluid metering, and active mixing. Yu et al. [42] utilized supervised machine- learning models for classifying the microscopic images of yeast cells in a microfluidic channel environment. A distance-based classification technique as a combination of k-nearest neighbour and support vector machine (SVM) is developed to extract the useful features from a large data of microscopic yeast images. ML has also been used to predict various complex microfluidic instabilities such as Hele-Shaw flow [43]. Lendhe et al. [43] used an accurate and robust ML model to predict the fractal pattern generated due to Saffman–Taylor instability in Hele-Shaw flow.

Automation of the complete microfluidic systems, ranging from flow control to droplet classification, is conceivable with proper training and the use of optimal machine learning models leading to efficient droplet classification, sorting, droplet flow recognition, and droplet size prediction [44]. Laskaripour et al. [38] categorized the fluid droplets in different size, shapes, and frequencies by devising an automation tool using an adaptive neuro-fuzzy interference method trained on 888 data points with six different geometric parameters. In another work, Mahdi et al. [45] employed Reynolds and capillary number data to train ML algorithm to predict the water droplet size in glycerine oil to achieve momentum in the performance of droplet generation. Banaei et al. [46] utilized the merits of intelligent microfluidics in creating a smart multiplex protein biomarker detection platform for efficiently predicting and differentiating diseases like pancreatic cancer, ovarian cancer, etc. Khor et al. [47], predicted the droplet stability in tightly packed emulsion using a 8-dimensional convolutional auto-encoder feature extraction model trained on 5,00,000 droplets with an improvement of 31.7% in droplet breakup as compared to conventional methods. The attempts towards automated flow control include robotics automation of droplet microfluidics to allow simultaneous processing of thousands of reactions, which has also been made possible using machine learning methods [48].

Reinforcement learning algorithms represent another paradigm of the machine learning approaches where an agent maximizes reward based on the performance within the environment [49, 50]. The amalgamation of microfluidics and reinforcement learning has progressed significantly in the last couple of years. Integrated microfluidic network design requires a large combinatorial space and worthwhile exploration of such a design space is possible through the learned decisions [33]. The network-based microfluidic design identification using Reinforcement learning algorithms is expected to create a unified framework that can support a large number of droplets with varying capabilities and functionalities [51]. Techniques like temporal difference-based Q-Learning and model-free episodic controllers (MFECs) have been successfully implemented in microfluidic systems for applications like target sequencing, droplet sorting and droplet control [52,53,54].

The collection of large amounts of microfluidic data as images or pictures has recently opened the pathways for deep learning methods to extract useful features. Chen et al. [55] explored the predictive capability of the Deep Learning methods for cell identification. They integrated feature extraction and deep learning with the high throughput quantitative imaging to retrieve label-free classification of cells with higher operational accuracy. Wang et al. [56] utilized the convolution networks to predict the fluid velocity and solute concentration in randomly designed grid micro-mixers with 86.7% accuracy. Riordon et al. [57] categorized the deep neural network, from an application viewpoint, into different classifications: (a) Unstructured to unstructured neural networks, (b) Sequence to unstructured neural networks, (c) Sequence to sequence neural networks, (d) Image to unstructured neural networks, and (e) Image to image neural networks and showed their applicability in different microfluidic biological and chemical domains. Image analysis is one of the key traits in various microfluidic experiments like rapid throughput and multiplexing. In such cases, deep learning can accelerate the classification process with the minimum human intervention [58]. Zaimi et al. [59] demonstrated the usage of image-to-image neural network architecture and extracted a useful feature from successive frames of a video/images, image segmentation, and depth image analysis for nerve cell segmentation applications.

2.3 Machine learning in designing acoustofluidic systems

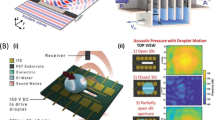

Interestingly, a limited number of studies have also been conducted in designing smart acoustofluidic systems using the fusion of machine learning with acoustic waves and microfluidics. Raymond et al. [60] addressed the problem of limited patterning activities (up to one or two-dimensional grids) in microfluidic channels to generate a desired acoustic field by using deep neural networks (DNN). Here, at first, a spatial variable acoustic pressure field image library consisting of 1000 s of distinct shapes is first generated by mapping acoustic waves with different channel geometries to train the DNN model. This trained DNN model is then utilized to create novel microchannel architectures for designing microparticle patterning. Figure 2 shows the stepwise procedure for generating deep learning-based channel geometries that produce designed acoustic fields. In another work, Yiannacou et al. [61] worked on the design of the programmable acoustic-microfluidic setup using bulk acoustic waves and closed-loop machine learning control algorithms inside a microfluidic chip for the 2D manipulation of droplets. Through this work, a machine-learning-assisted particle sorting, transportation, and merging processes of water droplets in oil, and oil droplets in water are demonstrated, enabling the development of a robust programmable droplet microfluidic device. Figure 3 depicts the machine-learning-assisted manipulation of droplets and the transport and merging of droplets inside a programmable microfluidic chip environment.

Schematic procedure for generating deep neural network (DNN)-based channel geometries that produce designed acoustic fields [60]

Illustration of the controlled acoustic-microfluidic manipulation setup using bulk acoustic waves and closed-loop machine learning techniques inside a microfluidic chip [61]

3 Acoustic metamaterials integrated with machine learning

By periodically arranging structures, metamaterials have opened an exciting path for acoustic and elastic wave manipulation, which was not achievable before using natural materials [35, 62]. In recent days, the acoustics and mechanics communities have gained significant interest in applying ML methods in designing and optimizing metamaterial structures [37]. Various ML techniques such as Convolution neural network (CNN) [63], Generative Adversarial Networks (GAN) [64], Genetic algorithms (GA) [65], Multilayer Perceptron (MP) [66], Auto-Encoders (AE) [67], Reinforcement Learning (RL) [35] etc. have been adopted in the literature in designing machine learning-based metamaterials.

Conventionally, the design of acoustic metamaterials (AMM) relies on the expertise of specialists based on localized solutions or on analytical models that require an enormous number of expensive function evaluations, highly intensive search in the design space, and many physical and geometrical parameters, thus making this method extremely complex and time-consuming. Therefore, developing an efficient design methodology for AMM design remains a challenging problem in front of the acoustics community. Very few works have been carried out in the literature to extend the current knowledge of the design of AMM using ML and Deep learning (DL) methods. Gurbuz et al. [64] developed the ML-based design method using the conditional GAN method and achieved novel AMM design directives that can be tailored to attain desired acoustic transmission characteristics to be implemented in varied application spaces like designing absorption layers in vehicle cabins, design of acoustic scatterers, etc. Liu et al. [2] tackled the limited working bandwidth of the resonators and the problem complexity of coupling resonators by using deep learning methods. Here, the coupling effect among resonators is investigated in a broad frequency regime from 800 to 8000 Hz by harnessing the power of CNNs for designing the broadband AMM to realize near-perfect (~ 97%) absorption characteristics. Tran et al. [68] have worked with sets of cylindrical objects in a confined space and used machine learning methods to streamline the 2D configurations of the acoustic cloak designs. In this work, an inverse design algorithm is developed by combining the variational AE trained with total scattering cross-section data to predict the optimal arrangements of cylindrical scatterers at different wavenumbers by eliminating the use of time-consuming gradient-based optimization methods. Other works conducted in designing smart acoustic metamaterials are listed in Table 1.

4 Conclusion and futuristic directions

Over the last few years, recent advancements in machine learning methods have gained significant attention in microfluidics and acoustic metamaterial domains for building intelligent systems. Surpassing the drawbacks of conventional systems, such as enormous expensive functional calls, tiresome experimental processes, complex phenomena, and many more, intelligent microfluidics and smart metamaterials have paved the way in establishing fanciful research goals with reduced computational efforts in real-time. This review has summarized the prominent works of machine learning techniques integrated with microfluidics and acoustic metamaterial domains.

The high throughput nature and capability of dealing with fluidics at a small-scale regime have enabled microfluidics to be amalgamated with numerous interdisciplinary fields like lab-on-chip and acoustics. One such advancement has been made where microfluidics is combined with acoustics and machine learning to develop a robust programmable microfluidic device [61]. Similarly, deploying the merits of microfluidics for active fluid control through various actuation mechanisms has led to its integration with acoustic metamaterial designs to achieve wide-scale active tunability and dynamic controllability [31, 73]. However, the proposition of applying machine learning to the combined field of microfluidic-integrated acoustic metamaterials is still missing in the literature. Despite research in its infancy, there lies a vast scope ahead to intersect the ability of acoustic-microfluidics and machine learning methods with the novel emerging acoustic metamaterials to design efficient INtelligent Acoustic-Microfluidic Metamaterial (INAMM) structures.

References

Chen, J., Chen, Y., Xu, X., Zhou, W., Huang, G.: A physics-guided machine learning for multifunctional wave control in active metabeams. Extreme Mech. Lett. 55, 101827 (2022). https://doi.org/10.1016/j.eml.2022.101827

Liu, L., Xie, L.X., Huang, W., Zhang, X.J., Lu, M.H., Chen, Y.F.: Broadband acoustic absorbing metamaterial via deep learning approach. Appl. Phys. Lett. (2022). https://doi.org/10.1063/5.0097696

Pan, G., Wang, F., Shang, C., Wu, H., Wu, G., Gao, J., Wang, S., Gao, Z., Zhou, X., Mao, X.: Advances in machine learning- and artificial intelligence-assisted material design of steels. Int. J. Miner. Metall. Mater. 30, 1003–1024 (2023). https://doi.org/10.1007/s12613-022-2595-0

Mohanty, S.P., Hughes, D.P., Salathé, M.: Using deep learning for image-based plant disease detection. Front. Plant Sci. 7, 1–10 (2016). https://doi.org/10.3389/fpls.2016.01419

Pujari, K.N., Miriyala, S.S., Mittal, P., Mitra, K.: Better wind forecasting using evolutionary neural architecture search driven green deep learning. Expert Syst. Appl. 214, 119063 (2023). https://doi.org/10.1016/J.ESWA.2022.119063

Raj, A., Chadha, U., Chadha, A., Mahadevan, R.R., Sai, B.R., Chaudhary, D., Selvaraj, S.K., Lokeshkumar, R., Das, S., Karthikeyan, B., Nagalakshmi, R., Chandramohan, V., Hadidi, H.: Weld quality monitoring via machine learning-enabled approaches. Int. J. Interact. Design Manuf. (IJIDeM). (2023). https://doi.org/10.1007/s12008-022-01165-9

Bhanuteja, S., Srinivas, V., Moorthy, C.V.K.N.S.N., Jai Kumar, S., Lakshmipathi Raju, B.: Prediction of thermophysical properties of hybrid nanofluids using machine learning algorithms. Int. J. Interact. Design Manuf. (2023). https://doi.org/10.1007/s12008-023-01293-w

Jiang, J., Xu, C., An, H.: Research on the effect of wind turbine bearing fault diagnosis method based on multi-feature calculation and Bayesian optimized machine learning method. Int. J. Interact. Des. Manuf. (2022). https://doi.org/10.1007/s12008-022-01085-8

Xu, X., Cai, L., Liang, S., Zhang, Q., Lin, S., Li, M., Yang, Q., Li, C., Han, Z., Yang, C.: Digital microfluidics for biological analysis and applications. Lab Chip 23(5), 1169–1191 (2023). https://doi.org/10.1039/D2LC00756H

Moragues, T., Arguijo, D., Beneyton, T., Modavi, C., Simutis, K., Abate, A.R., Baret, J.-C., deMello, A.J., Densmore, D., Griffiths, A.D.: Droplet-based microfluidics. Nat. Rev. Methods Primers. 3, 32 (2023). https://doi.org/10.1038/s43586-023-00212-3

Battat, S., Weitz, D.A., Whitesides, G.M.: An outlook on microfluidics: the promise and the challenge. Lab Chip 22, 530–536 (2022). https://doi.org/10.1039/d1lc00731a

Lathia, R., Nampoothiri, K.N., Sagar, N., Bansal, S., Modak, C.D., Sen, P.: Advances in microscale droplet generation and manipulation. Langmuir 39, 2461–2482 (2023). https://doi.org/10.1021/acs.langmuir.2c02905

Park, D., Kim, H., Kim, J.W.: Microfluidic production of monodisperse emulsions for cosmetics. Biomicrofluidics 15, 1–6 (2021). https://doi.org/10.1063/5.0057733

Wu, K., He, X., Wang, J., Pan, T., He, R., Kong, F., Cao, Z., Ju, F., Huang, Z., Nie, L.: Recent progress of microfluidic chips in immunoassay. Front. Bioeng. Biotechnol. 10, 1–16 (2022). https://doi.org/10.3389/fbioe.2022.1112327

Khater, A., Abdelrehim, O., Mohammadi, M., Mohamad, A., Sanati-Nezhad, A.: Thermal droplet microfluidics: from biology to cooling technology. TrAC Trends Anal. Chem. 138, 116234 (2021). https://doi.org/10.1016/j.trac.2021.116234

Bansal, S., Sen, P.: Mixing enhancement by degenerate modes in electrically actuated sessile droplets. Sens. Actuators B Chem. 232, 318–326 (2016). https://doi.org/10.1016/j.snb.2016.03.109

Nampoothiri, K.N., Srinivasan, V., Bobji, M.S., Sen, P.: A novel sub-picoliter monodispersed droplet generation device based on liquid dielectrophoresis. In: Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems (MEMS). pp. 87–90. IEEE (2017)

Nampoothiri, K.N., Bobji, M.S., Sen, P.: De-icing device with self-adjusting power consumption and ice sensing capabilities. J. Microelectromech. Syst. 29, 562–570 (2020). https://doi.org/10.1109/JMEMS.2020.3004502

Bansal, S., Sen, P.: Electrowetting based local sensing of liquid properties using relaxation dynamics of stretched liquid interface. J. Colloid Interface Sci. 568, 8–15 (2020). https://doi.org/10.1016/j.jcis.2020.02.035

Nampoothiri, K.N., Satpathi, N.S., Sen, A.K.: Surface acoustic wave-based generation and transfer of droplets onto wettable substrates. RSC Adv. 12, 23400–23410 (2022). https://doi.org/10.1039/d2ra04089a

Nampoothiri, K.N., Sen, P.: Motion of generated dumbbell-shaped satellite droplets during liquid dielectrophoresis. J. Micromech. Microeng. 31, 095006 (2021). https://doi.org/10.1088/1361-6439/ac1845

Sackmann, E.K., Fulton, A.L., Beebe, D.J.: The present and future role of microfluidics in biomedical research. Nature 507, 181–189 (2014). https://doi.org/10.1038/nature13118

Dedeloudi, A., Weaver, E., Lamprou, D.A.: Machine learning in additive manufacturing & microfluidics for smarter and safer drug delivery systems. Int. J. Pharm. (2023). https://doi.org/10.1016/j.ijpharm.2023.122818

Ahmadi, F., Simchi, M., Perry, J.M., Frenette, S., Benali, H., Soucy, J.P., Massarweh, G., Shih, S.C.C.: Integrating machine learning and digital microfluidics for screening experimental conditions. Lab Chip 23, 81–91 (2022). https://doi.org/10.1039/d2lc00764a

Liao, G., Luan, C., Wang, Z., Liu, J., Yao, X., Fu, J.: Acoustic metamaterials: a review of theories, structures, fabrication approaches, and applications. Adv. Mater. Technol. 6, 1–29 (2021). https://doi.org/10.1002/admt.202000787

Cummer, S.A., Christensen, J., Alù, A.: Controlling sound with acoustic metamaterials. Nat. Rev. Mater. 1, 1–13 (2016). https://doi.org/10.1038/natrevmats.2016.1

Choi, C., Bansal, S., Münzenrieder, N., Subramanian, S.: Fabricating and assembling acoustic metamaterials and phononic crystals. Adv. Eng. Mater. 23, 2000988 (2021). https://doi.org/10.1002/adem.202000988

Gao, N., Wang, M., Cheng, B.: Deep auto-encoder network in predictive design of Helmholtz resonator: on-demand prediction of sound absorption peak. Appl. Acoust. 191, 108680 (2022). https://doi.org/10.1016/j.apacoust.2022.108680

Ghaffarivardavagh, R., Nikolajczyk, J., Glynn Holt, R., Anderson, S., Zhang, X.: Horn-like space-coiling metamaterials toward simultaneous phase and amplitude modulation. Nat. Commun. 9, 1349 (2018). https://doi.org/10.1038/s41467-018-03839-z

Memoli, G., Caleap, M., Asakawa, M., Sahoo, D.R., Drinkwater, B.W., Subramanian, S.: Metamaterial bricks and quantization of meta-surfaces. Nat. Commun. 8, 14608 (2017). https://doi.org/10.1038/ncomms14608

Bansal, S., Subramanian, S.: A microfluidic acoustic metamaterial using electrowetting: enabling active broadband tunability. Adv. Mater. Technol. 6, 2100491 (2021). https://doi.org/10.1002/admt.202100491

Song, J.H., Lee, J.H., Kim, N., Min, K.: Artificial intelligence in the design of innovative metamaterials: a comprehensive review. Int. J. Precis. Eng. Manuf. (2023). https://doi.org/10.1007/s12541-023-00857-w

McIntyre, D., Lashkaripour, A., Fordyce, P., Densmore, D.: Machine learning for microfluidic design and control. Lab Chip 22, 2925–2937 (2022). https://doi.org/10.1039/d2lc00254j

Talebjedi, B., Heydari, M., Taatizadeh, E., Tasnim, N., Li, I.T.S., Hoorfar, M.: Neural network-based optimization of an acousto microfluidic system for submicron bioparticle separation. Front. Bioeng. Biotechnol. 10, 878398 (2022). https://doi.org/10.3389/fbioe.2022.878398

Wu, R.T., Liu, T.W., Jahanshahi, M.R., Semperlotti, F.: Design of one-dimensional acoustic metamaterials using machine learning and cell concatenation. Struct. Multidiscip. Optim. 63, 2399–2423 (2021). https://doi.org/10.1007/s00158-020-02819-6

Battat, S., Weitz, D.A., Whitesides, G.M.: Nonlinear phenomena in microfluidics. Chem. Rev. 122, 6921–6937 (2022). https://doi.org/10.1021/acs.chemrev.1c00985

Zheng, J., Cole, T., Zhang, Y., Kim, J., Tang, S.Y.: Exploiting machine learning for bestowing intelligence to microfluidics. Biosens. Bioelectron. 194, 113666 (2021). https://doi.org/10.1016/j.bios.2021.113666

Lashkaripour, A., Rodriguez, C., Mehdipour, N., Mardian, R., McIntyre, D., Ortiz, L., Campbell, J., Densmore, D.: Machine learning enables design automation of microfluidic flow-focusing droplet generation. Nat. Commun. 12, 25 (2021). https://doi.org/10.1038/s41467-020-20284-z

Chu, A., Nguyen, D., Talathi, S.S., Wilson, A.C., Ye, C., Smith, W.L., Kaplan, A.D., Duoss, E.B., Stolaroff, J.K., Giera, B.: Automated detection and sorting of microencapsulation: via machine learning. Lab Chip 19, 1808–1817 (2019). https://doi.org/10.1039/c8lc01394b

Nitta, N., Sugimura, T., Isozaki, A., Mikami, H., Hiraki, K., Sakuma, S., Iino, T., Arai, F., Endo, T., Fujiwaki, Y., Fukuzawa, H., Hase, M., Hayakawa, T., Hiramatsu, K., Hoshino, Y., Inaba, M., Ito, T., Karakawa, H., Kasai, Y., Koizumi, K., Lee, S.W., Lei, C., Li, M., Maeno, T., Matsusaka, S., Murakami, D., Nakagawa, A., Oguchi, Y., Oikawa, M., Ota, T., Shiba, K., Shintaku, H., Shirasaki, Y., Suga, K., Suzuki, Y., Suzuki, N., Tanaka, Y., Tezuka, H., Toyokawa, C., Yalikun, Y., Yamada, M., Yamagishi, M., Yamano, T., Yasumoto, A., Yatomi, Y., Yazawa, M., Di Carlo, D., Hosokawa, Y., Uemura, S., Ozeki, Y., Goda, K.: Intelligent image-activated cell sorting. Cell 175, 266-276.e13 (2018). https://doi.org/10.1016/j.cell.2018.08.028

Fidalgo, L.M., Maerkl, S.J.: A software-programmable microfluidic device for automated biology. Lab Chip 11, 1612–1619 (2011). https://doi.org/10.1039/c0lc00537a

Yang Yu, B., Elbuken, C., Ren, C.L., Huissoon, J.P.: Image processing and classification algorithm for yeast cell morphology in a microfluidic chip. J. Biomed. Opt. 16, 066008 (2011). https://doi.org/10.1117/1.3589100

Lendhe, A.A., Raykar, N., Kale, B.S., Bhole, K.S.: Machine learning approach to predict viscous fingering in Hele-Shaw cells. Int. J. Interact. Des. Manuf. (2023). https://doi.org/10.1007/s12008-023-01404-7

Srikanth, S., Dubey, S.K., Javed, A., Goel, S.: Droplet based microfluidics integrated with machine learning. Sens. Actuators A Phys. 332, 113096 (2021). https://doi.org/10.1016/j.sna.2021.113096

Mahdi, Y., Daoud, K.: Microdroplet size prediction in microfluidic systems via artificial neural network modeling for water-in-oil emulsion formulation. J. Dispers. Sci. Technol. 38, 1501–1508 (2017). https://doi.org/10.1080/01932691.2016.1257391

Banaei, N., Moshfegh, J., Mohseni-Kabir, A., Houghton, J.M., Sun, Y., Kim, B.: Machine learning algorithms enhance the specificity of cancer biomarker detection using SERS-based immunoassays in microfluidic chips. RSC Adv. 9, 1859–1868 (2019). https://doi.org/10.1039/C8RA08930B

Khor, J.W., Jean, N., Luxenberg, E.S., Ermon, S., Tang, S.K.Y.: Using machine learning to discover shape descriptors for predicting emulsion stability in a microfluidic channel. Soft Matter 15, 1361–1372 (2019). https://doi.org/10.1039/c8sm02054j

Tran, T.M., Kim, S.C., Modavi, C., Abate, A.R.: Robotic automation of droplet microfluidics. Biomicrofluidics (2022). https://doi.org/10.1063/5.0064265

Gao, W., Li, X., Wang, Y., Cai, Y.: Medical image segmentation algorithm for three-dimensional multimodal using deep reinforcement learning and big data analytics. Front. Public Health 10, 1–9 (2022). https://doi.org/10.3389/fpubh.2022.879639

Li, D., Yang, Q., Ma, L., Peng, Z., Liao, X.: Offense and defence against adversarial sample: a reinforcement learning method in energy trading market. Front. Energy Res. 10, 2001 (2023). https://doi.org/10.3389/fenrg.2022.1071973

Shahab, M., Rengaswamy, R.: Reinforcement-learning designs droplet microfluidic networks. Comput. Chem. Eng. 161, 107787 (2022). https://doi.org/10.1016/j.compchemeng.2022.107787

Dressler, O.J., Howes, P.D., Choo, J., Demello, A.J.: Reinforcement learning for dynamic microfluidic control. ACS Omega 3, 10084–10091 (2018). https://doi.org/10.1021/acsomega.8b01485

Fu, X., Zhang, Y., Xu, Q., Sun, X., Meng, F.: Recent advances on sorting methods of high-throughput droplet-based microfluidics in enzyme directed evolution. Front. Chem. 9, 1–9 (2021). https://doi.org/10.3389/fchem.2021.666867

Eastburn, D.J., Huang, Y., Pellegrino, M., Sciambi, A., Ptáček, L.J., Abate, A.R.: Microfluidic droplet enrichment for targeted sequencing. Nucleic Acids Res. 43, e86 (2015). https://doi.org/10.1093/nar/gkv297

Chen, C.L., Mahjoubfar, A., Tai, L.C., Blaby, I.K., Huang, A., Niazi, K.R., Jalali, B.: Deep learning in label-free cell classification. Sci. Rep. 6, 1–16 (2016). https://doi.org/10.1038/srep21471

Wang, J., Zhang, N., Chen, J., Su, G., Yao, H., Ho, T.Y., Sun, L.: Predicting the fluid behavior of random microfluidic mixers using convolutional neural networks. Lab Chip 21, 296–309 (2021). https://doi.org/10.1039/D0LC01158D

Riordon, J., Sovilj, D., Sanner, S., Sinton, D., Young, E.W.K.: Deep learning with microfluidics for biotechnology. Trends Biotechnol. 37, 310–324 (2019). https://doi.org/10.1016/j.tibtech.2018.08.005

Bock, C., Farlik, M., Sheffield, N.C.: Multi-omics of single cells: strategies and applications. Trends Biotechnol. 34, 605–608 (2016). https://doi.org/10.1016/j.tibtech.2016.04.004

Zaimi, A., Wabartha, M., Herman, V., Antonsanti, P.L., Perone, C.S., Cohen-Adad, J.: AxonDeepSeg: automatic axon and myelin segmentation from microscopy data using convolutional neural networks. Sci. Rep. 8, 1–11 (2018). https://doi.org/10.1038/s41598-018-22181-4

Raymond, S.J., Collins, D.J., O’Rorke, R., Tayebi, M., Ai, Y., Williams, J.: A deep learning approach for designed diffraction-based acoustic patterning in microchannels. Sci. Rep. 10, 1–12 (2020). https://doi.org/10.1038/s41598-020-65453-8

Yiannacou, K., Sariola, V.: Controlled manipulation and active sorting of particles inside microfluidic chips using bulk acoustic waves and machine learning. Langmuir 37, 4192–4199 (2021). https://doi.org/10.1021/acs.langmuir.1c00063

Muhammad, Kennedy, J., Lim, C.W.: Machine learning and deep learning in phononic crystals and metamaterials–a review. Mater. Today Commun. 33, 104606 (2022). https://doi.org/10.1016/j.mtcomm.2022.104606

Li, X., Ning, S., Liu, Z., Yan, Z., Luo, C., Zhuang, Z.: Designing phononic crystal with anticipated band gap through a deep learning based data-driven method. Comput. Methods Appl. Mech. Eng. 361, 112737 (2020). https://doi.org/10.1016/j.cma.2019.112737

Gurbuz, C., Kronowetter, F., Dietz, C., Eser, M., Schmid, J., Marburg, S.: Generative adversarial networks for the design of acoustic metamaterials. J. Acoust. Soc. Am. 149, 1162–1174 (2021). https://doi.org/10.1121/10.0003501

Mittal, P., Mitra, K.: Decomposition based multi-objective optimization to simultaneously determine the number and the optimum locations of wind turbines in a wind farm. IFAC-PapersOnLine. 50, 159–164 (2017). https://doi.org/10.1016/j.ifacol.2017.08.027

He, L., Wen, Z., Jin, Y., Torrent, D., Zhuang, X., Rabczuk, T.: Inverse design of topological metaplates for flexural waves with machine learning. Mater. Des. 199, 109390 (2021). https://doi.org/10.1016/j.matdes.2020.109390

Wang, L., Chan, Y.C., Ahmed, F., Liu, Z., Zhu, P., Chen, W.: Deep generative modeling for mechanistic-based learning and design of metamaterial systems. Comput. Methods Appl. Mech. Eng. 372, 113377 (2020). https://doi.org/10.1016/j.cma.2020.113377

Tran, T., Amirkulova, F., Khatami, E.: Broadband acoustic metamaterial design via machine learning. J. Theor. Comput. Acoust. 30, 2240005 (2022)

Bacigalupo, A., Gnecco, G., Lepidi, M., Gambarotta, L.: Machine-learning techniques for the optimal design of acoustic metamaterials. J. Optim. Theory Appl. 187, 630–653 (2020). https://doi.org/10.1007/s10957-019-01614-8

Ciaburro, G., Iannace, G.: Modeling acoustic metamaterials based on reused buttons using data fitting with neural network. J. Acoust. Soc. Am. 150, 51–63 (2021). https://doi.org/10.1121/10.0005479

Zheng, B., Yang, J., Liang, B., Cheng, J.C.: Inverse design of acoustic metamaterials based on machine learning using a Gauss-Bayesian model. J. Appl. Phys. (2020). https://doi.org/10.1063/5.0012392

Donda, K., Zhu, Y., Merkel, A., Fan, S.W., Cao, L., Wan, S., Assouar, B.: Ultrathin acoustic absorbing metasurface based on deep learning approach. Smart Mater. Struct. 30, 085003 (2021). https://doi.org/10.1088/1361-665X/ac0675

Tian, Z., Shen, C., Li, J., Reit, E., Gu, Y., Fu, H., Cummer, S.A., Huang, T.J.: Programmable acoustic metasurfaces. Adv. Funct. Mater. 29, 1808489 (2019). https://doi.org/10.1002/adfm.201808489

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mittal, P., Nampoothiri, K.N., Jha, A. et al. Convergence of machine learning with microfluidics and metamaterials to build smart materials. Int J Interact Des Manuf (2024). https://doi.org/10.1007/s12008-023-01707-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-023-01707-9