Abstract

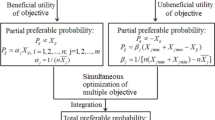

Appropriate welding and machining of material is very significant to guarantee the comprehensive improving quality of product and reducing cost. The recently proposed probability-based approach for multi-objective optimization is with the intrinsic characteristic of simultaneous optimization of multiple objectives in respect of probability theory. In this paper, the probability-based approach for multi-objective optimization is utilized to deal with the material welding and machining problems so as to guaranty the comprehensive improving quality of product and reducing cost, the welding of turbine rear structure hub sectors and thin-wall machining are taken as examples. By performing the assessment of preferable probability of each scheme, the quantitatively optimum design of materials processing is thus completed. The results indicate that the proposed method is very significant to guarantee the comprehensive improving quality of product and reducing cost in material processing.

Similar content being viewed by others

References

Madrid, J., Andersson, P., Söderberg, R., Wärmefjord, K., Kveselys, D., Lindkvist, L., Lööf, J.: Automated and interactive evaluation of welding producibility in an multidisciplinary design optimization environment for aircraft components. Int. J. Interact. Des. Manuf. (IJIDeM) 15, 463–479 (2021)

Bolar, G., Joshi, S.N., Das, S.: Sustainable thin-wall machining: holistic analysis considering the energy efficiency, productivity, and product quality. Int. J. Interact. Des. Manuf. (IJIDeM) (2023). https://doi.org/10.1007/s12008-022-01130-6

Park, J.H., Cho, H.J., Kwun, Y.C.: Extension of the VIKOR method for group decision making with interval-valued intuitionistic fuzzy information. Fuzzy Optim. Decis. Mak. 10(3), 233–253 (2011)

Rostamzadeh, R., Govindan, K., Esmaeili, A., Sabaghi, M.: Application of fuzzy VIKOR for evaluation of green supply chain management practices. Ecol. Indic. 49, 188–203 (2015)

Opricovic, S., Tzeng, G.H.: Compromise solution by MCDM methods: a comparative analysis of VIKOR and TOPSIS. Eur. J. Oper. Res. 156(2), 445–455 (2004)

San Cristóbal Mateo, J.R.: Multi Criteria Analysis in the Renewable Energy Industry. Springer, London (2012)

Maleque, M.A., Salit, M.S.: Materials Selection and Design. Springer, Heidelberg (2013)

Zheng, M., Teng, H., Yu, J., Cui, Y., Wang, Y.: Probability-Based Multi-objective Optimization for Material Selection. Springer, Singapore (2022)

Marler, R.T., Arora, J.S.: Survey of multi-objective optimization methods for engineering. Struct. Multidiscip. Optim. 26, 369–395 (2004)

Opricovic, S., Tzeng, G.H.: Compromise solution by MCDM methods: a comparative analysis of VIKOR and TOPSIS. Eur. J. Oper. Res. 156, 445–455 (2004)

Trung, D.D.: Multi-criteria decision making under the MARCOS method and the weighting methods: applied to milling, grinding and turning processes. Manuf. Rev. 9(3), 1–13 (2022)

Rouniyar, A.K., Shandilya, P.: Multi-objective optimization using Taguchi and grey relational analysis on machining of Ti–6Al–4V Alloy by powder mixed EDM process. Mater Today Proc. 5(11), 23779–23788 (2018)

Singh, A., Ghadai, R.K., Kalita, K., Chatterjee, P., Pamučar, D.: EDM process parameter optimization for efficient machining of Inconel-718. Facta Univ. Ser. Mech. Eng. 18(3), 473–490 (2020)

Kechagias, J., Billis, M., Maropoulos, S.: A parameter design of CNC plasma-arc cutting of carbon steel plates using robust design. Int. J. Exp. Des. Process Optim. 1(4), 315–326 (2010)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zheng, M., Yu, J. Utilization of probability-based multi-objective optimization in material welding and machining. Int J Interact Des Manuf 18, 297–303 (2024). https://doi.org/10.1007/s12008-023-01478-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-023-01478-3