Abstract

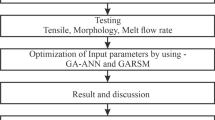

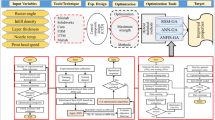

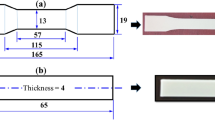

The proposed work presents a novel composite polymer filament made by blending High-Density Polyethylene (HDPE) and Polycarbonate (PC) with Acrylonitrile Butadiene Styrene (ABS), resulting in improved properties such as strength-to-weight ratio and impact resistance, expanding the applicability of ABS in healthcare, automotive, and engineering industries. The composite polymer filament was fabricated using a single screw extruder at different parameters like barrel temperature, rotational speed of the screw and different thermoplastic polymer compositions. The tensile strength was measured using a Universal Testing Machine (UTM). The input/output data were optimized using hybrid tools, including genetic algorithm artificial neural networks (GA-ANN) and response surface methodology (GA-RSM). The results obtained from GA-ANN were validated experimentally, demonstrating a maximum tensile strength of 39.8 MPa at 280 °C, 10.001 RPM, 16.783%wt of HDPE, and 8.839%wt of PC. It is observed that the proposed work with GA-ANN model effectively improved the tensile strength by 7.2% in comparison with GA-RSM. This research highlights the potential of the proposed composite material in various applications, emphasizing its cost-effectiveness and improved mechanical properties.

Similar content being viewed by others

References

Ibrahim, Y., Elkholy, A., Schofield, J.S., Melenka, G.W., Kempers, R.: Effective thermal conductivity of 3D-printed continuous fiber polymer composites. Adv. Manuf. Polym. Compos. Sci. 6(1), 17–28 (2020)

Harris, M., Potgieter, J., Ray, S., Archer, R., Arif, K.M.: Preparation and characterization of thermally stable ABS/HDPE blend for fused filament fabrication. Mater. Manuf. Process. 35(2), 230–240 (2020)

Kannan, S., Ramamoorthy, M.: Mechanical characterization and experimental modal analysis of 3D printed ABS, PC and PC-ABS materials. Mater. Res. Express. 7(1), 015341 (2020)

Al Rashid, A., Khan, S.A., Al-Ghamdi, S.G., Koç, M.: Additive manufacturing of polymer nanocomposites: needs and challenges in materials, processes, and applications. J. Mater. Res. Technol. 14, 910–941 (2021)

Bala, N., Kamaruddin, I., Napiah, M., Sutanto, M.H.: Polymer nanocomposite-modified asphalt: characterisation and optimisation using response surface methodology. Arab. J. Sci. Eng. 44(5), 4233–4243 (2019)

Sur, A., Darvekar, S., Shah, M.: Recent advancements of micro-lattice structures: application, manufacturing methods, mechanical properties, topologies and challenges. Arab. J. Sci. Eng. 46(12), 11587–11600 (2021)

Phogat, A., Chhabra, D., Sindhu, V., Ahlawat, A.: Analysis of wear assessment of FDM printed specimens with PLA, multi-material and ABS via hybrid algorithms. Mater. Today Proc. (2022)

El Moumen, A., Tarfaoui, M., Lafdi, K.: Additive manufacturing of polymer composites: processing and modeling approaches. Compos. Part B Eng. 171, 166–182 (2019)

Pignatelli, F., Percoco, G.: An application-and market-oriented review on large format additive manufacturing, focusing on polymer pellet-based 3D printing. Progr. Addit. Manuf. 7, 1363–1377 (2022)

Kechagias, J., Petropoulos, G., Iakovakis, V., Maropoulos, S.: An investigation of surface texture parameters during turning of a reinforced polymer composite using design of experiments and analysis. Int. J. Exp. Des. Process Optim. 1(2–3), 164–177 (2009)

Shanmugam, V., Das, O., Babu, K., Marimuthu, U., Veerasimman, A., Johnson, D.J., …, Berto, F.: Fatigue behaviour of FDM-3D printed polymers, polymeric composites and architected cellular materials. Int. J. Fatigue. 143, 106007 (2021)

Shu, H.: Filling method of thin shell 3D printing material based on implicit surface. Int. J. Mater. Prod. Technol. 64(3–4), 199–210 (2022)

Nasirov, A., Fidan, I.: Prediction of mechanical properties of fused filament fabricated structures via asymptotic homogenization. Mech. Mater. 145, 103372 (2020)

El-Sayed, M.A., El-Nakeeb, N., Shyha, I., Ghazy, M.: Response surface method for optimisation of SLA processing parameters. Int. J. Mater. Prod. Technol. 64(3–4), 222–241 (2022)

Saravanan, A., Jerald, J., Rani, A.D.C.: An explicit methodology for manufacturing cost–tolerance modeling and optimization using the neural network integrated with the genetic algorithm. AI EDAM. 34(3), 430–443 (2020)

Butt, J., Oxford, P., Sadeghi-Esfahlani, S., Ghorabian, M., Shirvani, H.: Hybrid manufacturing and mechanical characterization of Cu/PLA composites. Arab. J. Sci. Eng. 45(11), 9339–9356 (2020)

Vidakis, N., Petousis, M., Kechagias, J.D.: A comprehensive investigation of the 3D printing parameters’ effects on the mechanical response of polycarbonate in fused filament fabrication. Progr. Addit. Manuf. 7, 713–722 (2022)

Chadha, U., Abrol, A., Vora, N.P., Tiwari, A., Shanker, S.K., Selvaraj, S.K.: Performance evaluation of 3D printing technologies: a review, recent advances, current challenges, and future directions. Progr. Addit. Manuf. 7, 853–886 (2022)

Ahlawat, A., Sahdev, R.K., Gupta, R.K., Chhabra, D.: 3D FDM Printable polymer composites and polymer nanocomposites: state of the art. J. Nano Electron. Phys. 13(2). (2021)

Uşun, A., Gümrük, R.: The mechanical performance of the 3D printed composites produced with continuous carbon fiber reinforced filaments obtained via melt impregnation. Addit. Manuf. 46, 102112 (2021)

Alam, M.A., Patel, A., Purohit, R., Taufik, M.: Thermal analysis for improvement of mechanical properties in fused filament fabricated parts. Int. J. Interact. Des. Manuf. (IJIDeM). 17, 603–635 (2023)

Shanmugam, V., Rajendran, D.J.J., Babu, K., Rajendran, S., Veerasimman, A., Marimuthu, U., Ramakrishna, S.: The mechanical testing and performance analysis of polymer-fibre composites prepared through the additive manufacturing. Polym. Test. 93, 106925 (2021)

Kumar, R., Singh, R.P., Kataria, R.: Study on mechanical properties of fabricated hybrid natural fibre polymeric composites. Int. J. Mater. Prod. Technol. 60, 73–91 (2020)

Kojima, T., Sato, D., Notomi, M.: Damping properties of pre-stressed shape-memory polymer sandwich beam. Int. J. Mater. Prod. Technol. 64(1), 78–92 (2022)

Koualiarella, A., Arvanitidis, A., Argyros, A., Kousiatza, C., Karakalas, A., Lagoudas, D., Michailidis, N.: Tuning of shape memory polymer properties by controlling 3D printing strategy. CIRP Ann. 69(1), 213–216 (2020)

Thakur, V., Singh, R., Kumar, R., Gehlot, A.: 4D printing of thermoresponsive materials: a state-of-the-art review and prospective applications. Int. J. Interact. Des. Manuf. (IJIDeM) (2022). https://doi.org/10.1007/s12008-022-01018-5

Yadav, A., Rohru, P., Babbar, A., Kumar, R., Ranjan, N., Chohan, J.S., Gupta, M.: Fused filament fabrication: a state-of-the-art review of the technology, materials, properties and defects. Int. J. Interact. Des. Manuf. (IJIDeM) (2022). https://doi.org/10.1007/s12008-022-01026-5

Phan, N.H., Pi, V.N., Tuan, N.Q., Shirguppikar, S., Patil, M.S., Ilani, M.A., Hung, T.Q.: Tool wear rate analysis of uncoated and AlCrNi coated aluminum electrode in EDM for Ti-6Al-4 V titanium alloy. In Advances in Engineering Research and Application: Proceedings of the International Conference on Engineering Research and Applications, ICERA 2020, pp. 832–838. Springer International Publishing (2021)

Phan, N.H., Pi, V.N., Shirguppikar, S., Patil, M.S., Ilani, M.A., Hung, L.X., Hung, T.Q.: Material removal rate in electric discharge machining with aluminum tool electrode for Ti-6Al-4V titanium alloy. In: Advances in Engineering Research and Application: Proceedings of the International Conference on Engineering Research and Applications, ICERA 2020, pp. 527–533. Springer International Publishing (2021)

Ilani, M.A., Khoshnevisan, M.: Powder mixed-electrical discharge machining (EDM) with the electrode is made by fused deposition modeling (FDM) at Ti-6Al-4V machining procedure. Multiscale Multidis. Model. Exp. Des. 3, 173–186 (2020)

Ilani, M.A., Khoshnevisan, M.: Mathematical and physical modeling of FE-SEM surface quality surrounded by the plasma channel within Al powder-mixed electrical discharge machining of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 112, 3263–3277 (2021)

Ilani, M.A., Khoshnevisan, M.: An evaluation of the surface integrity and corrosion behavior of Ti-6Al-4 V processed thermodynamically by PM-EDM criteria. Int. J. Adv. Manuf. Technol. 120(7–8), 5117–5129 (2022)

Hosseini Rad, R., Baniasadi, S., Yousefi, P., Morabbi Heravi, H., Al-Ani, S., Ilani, A.: M. Presented a framework of computational modeling to identify the patient admission scheduling problem in the healthcare system. J. Healthcare Eng. 2022 (2022)

Mahdavinejad, R.A., Ilani, M.A.: Superior advance research in the electro-discharge machining of Ti alloys. Int. J. Sci. Res. Mech. Mater. Eng. 3, 19–38 (2019)

Ilani, M.A., Khoshnevisan, M.: Study of surfactant effects on intermolecular forces (IMF) in powder-mixed electrical discharge machining (EDM) of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 116(5–6), 1763–1782 (2021)

µ-Al2O3 Powder-Mixed-EDM process on machining of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 116(5–6), 1783–1799

Baca, D., Ahmad, R.: The impact on the mechanical properties of multi-material polymers fabricated with a single mixing nozzle and multi-nozzle systems via fused deposition modeling. Int. J. Adv. Manuf. Technol. 106(9), 4509–4520 (2020)

Deswal, S., Narang, R., Chhabra, D.: Modeling and parametric optimization of FDM 3D printing process using hybrid techniques for enhancing dimensional preciseness. Int. J. Interact. Des. Manuf. (IJIDeM). 13, 1197–1214 (2019)

Spreafico, C.: Can TRIZ (theory of inventive problem solving) strategies improve material substitution in eco-design? Sustain. Prod. Consum. 30, 889–915 (2022)

Atakok, G., Kam, M., Koc, H.B.: A review of mechanical and thermal properties of products printed with recycled filaments for use in 3D printers. Surf. Rev. Lett. 29(02), 2230002 (2022)

Spreafico, C., Landi, D.: Investigating students’ eco-misperceptions in applying eco-design methods. J. Clean. Prod. 342, 130866 (2022)

Çevik, Ã., Kam, M.: A review study on mechanical properties of obtained products by FDM method and metal/polymer composite filament production. J. Nanomater. 2020, 1–9 (2020)

Gao, J., Li, C., Shilpakar, U., Shen, Y.: Improvements of mechanical properties in dissimilar joints of HDPE and ABS via carbon nanotubes during friction stir welding process. Mater. Des. 86, 289–296 (2015)

Dabees, S., Tirth, V., Mohamed, A., Kamel, B.M.: Wear performance and mechanical properties of MWCNT/HDPE nanocomposites for gearing applications. J. Mater. Res. Technol. 12, 2476–2488 (2021)

Montalvo Navarrete, J.I., Hidalgo-Salazar, M.A., Nunez, E., E., Rojas Arciniegas, A.J.: Thermal and mechanical behavior of biocomposites using additive manufacturing. Int. J. Interact. Des. Manuf. (IJIDeM). 12, 449–458 (2018)

Fountas, N.A., Papantoniou, I., Kechagias, J.D., Manolakos, D.E., Vaxevanidis, N.M.: Modeling and optimization of flexural properties of FDM-processed PET-G specimens using RSM and GWO algorithm. Eng. Fail. Anal. 138, 106340 (2022)

Kumar, P., Gupta, P., Singh, I.: Parametric Optimization of FDM Using the ANN-based Whale Optimization Algorithm, p. 36. AI EDAM (2022)

Chen, J.: Research on structure optimisation method of 3D printer based on decoupling parallel connection. Int. J. Mater. Prod. Technol. 63(1–2), 96–108 (2021)

Deshwal, S., Kumar, A., Chhabra, D.: Exercising hybrid statistical tools GA-RSM, GA-ANN and GA-ANFIS to optimize FDM process parameters for tensile strength improvement. CIRP J. Manufact. Sci. Technol. 31, 189–199 (2020)

Jahangir, M.N., Billah, K.M.M., Lin, Y., Roberson, D.A., Wicker, R.B., Espalin, D.: Reinforcement of material extrusion 3D printed polycarbonate using continuous carbon fiber. Addit. Manuf. 28, 354–364 (2019)

Malleswari, V.N., Manaswy, G.K., Pragvamsa, P.G.: Prediction of surface roughness for fused deposition in fabricated work pieces by RSM and ANN technique. Mater. Today Proc. (2023)

Yadav, M., Yadav, D., Garg, R.K., Gupta, R.K., Kumar, S., Chhabra, D.: Modeling and optimization of piezoelectric energy harvesting system under dynamic loading. In Advances in Fluid and Thermal Engineering: Select Proceedings of FLAME 2020, pp. 339–353. Springer, Singapore. (2021)

Yadav, M., Kumar, S., Kaushik, A., Garg, R.K., Ahlawat, A., Chhabra, D.: Modeling and simulation of Piezo-beam structure mounted in a circular pipe using laminar flow as energy harvester

Yadav, M., Kaushik, A., Garg, R.K., Yadav, M., Chhabra, D., Rohilla, S., Sharma, H.: Enhancing dimensional accuracy of small parts through modelling and parametric optimization of the FDM 3D printing process using GA-ANN. In: International Conference on Computational Modelling, Simulation and Optimization (ICCMSO), vol. 2022, Pathum Thani, Thailand, pp. 89–94. (2022). https://doi.org/10.1109/ICCMSO58359.2022.00030

Kechagias, J.D., Tsiolikas, A., Petousis, M., Ninikas, K., Vidakis, N., Tzounis, L.: A robust methodology for optimizing the topology and the learning parameters of an ANN for accurate predictions of laser-cut edges surface roughness. Simul. Model. Pract. Theory. 114, 102414 (2022)

Kechagias, J., Iakovakis, V.: A neural network solution for LOM process performance. Int. J. Adv. Manuf. Technol. 43, 1214–1222 (2009)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interest or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ahlawat, A., Phogat, A., Yadav, M. et al. Fabrication and analysis of ABS-HDPE-PC composite polymer filament used for FDM printing using hybrid algorithm. Int J Interact Des Manuf 17, 3199–3209 (2023). https://doi.org/10.1007/s12008-023-01389-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-023-01389-3