Abstract

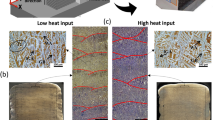

Additive manufacturing (AM) creates three-dimensional objects by depositing materials layer by layer. Selective laser melting (SLM) is one of the important AM processes used for metal. In SLM the fully melt metal transforms into a solid three-dimensional part. This process allows for faster, more complex, and less time-consuming manufacturing. The material INCONEL718 (IN718) is a nickel superalloy used due to its good weldability and can be processed using a variety of manufacturing technologies. More than 50 process parameters control the quality of SLM-manufactured components. The process parameters control the performance parameters. The anisotropic behavior is observed in the IN718. In this research, the superalloy IN718 was created by additive manufacturing (AM) using a selective laser melting approach, and the post-AM thermal treatments were evaluated. The effect of heat treatment on mechanical properties is observed using UTS and Hardness as performance and heat treatment’s impacts on microstructure, process-induced flaws, and microstructural behavior were investigated using Scanning Electron Microscopy (SEM). The samples are simulated using the SIMUFACT ADDITIVE to calculate the yield stress. The microstructure and tensile characteristics of Inconel 718 superalloy were seen to be improved by ageing treatment.

Similar content being viewed by others

References

Fayed, E.M.: Mahmoud Mohamed “Influence of Thermal Post-Processing on the Microstructure and Mechanical Behavior of the Additively Manufactured Inconel 718 Superalloy using the Laser Powder Bed Fusion Process” PhD thesis, Concordia University. (2020)

Kohale, V., Jawade, S., Kakandikar, G.: “A Review- Modelling Approach and Numerical Analysis of Additive Manufacturing”. J. Eng. Res. Sci. 1(3), 116–125 (2022). https://doi.org/10.55708/js0103012

Zhang, D., Sun, S., Qiu, D., Gibson, M.A., Dargusch, M.S., Brandt, M., Qian, M., Easton, M.: “Metal Alloys for Fusion-Based Additive Manufacturing”, Volume20, Issue5 01 February 2018 https://doi.org/10.1002/adem.201700952

Wen, H.: “Laser Surface Treatment and Laser Powder Bed Fusion Additive Manufacturing Study Using Custom Designed 3D Printer and the Application of Machine Learning in Materials Science” (2021). LSU Doctoral Dissertations, 5640, https://digitalcommons.lsu.edu/gradschool_dissertations/5640

Popovich, V.A., Borisov, E.V., Popovich, A.A., Sufiiarov, V.S., Masaylo, D.V., Alzina, L.: Impact of heat treatment on mechanical behaviour of Inconel 718 processed with tailored microstructure by selective laser melting. Mater. Design. 131, 12–22 (2017). https://doi.org/10.1016/j.matdes.2017.05.065

Small, K.: “Characterization And Measurement Of Microstructural Features In Laser Processed Alloys” (Doctoral dissertation, Johns Hopkins University). (2021)

Jawade, S.A., Joshi, R.S., Desai, S.B.: “Comparative study of mechanical properties of additively manufactured aluminum alloy”, Materials Today: Proceedings, Volume 46, Part 19, 2021, Pages 9270–9274, https://doi.org/10.1016/j.matpr.2020.02.096

Akca, E., Gursel, A.: “A Review on Superalloys and IN718 Nickel-Based INCONEL Superalloy”. PERIODICALS OF ENGINEERING AND NATURAL SCIENCES. 1. (2015). https://doi.org/10.21533/penv3i1.43

Özer, S.: “Effect of post-processing heat treatment on the mechanical properties of inconel 718 fabricated by selective laser melting,” Thesis (M.S.) -- Graduate School of Natural and Applied Sciences. Metallurgical and Materials Engineering., Middle East Technical University, (2020)

Chlebus, E., Gruber, K., Kuźnicka, B., Kurzac, J., Kurzynowski, T.: Effect of heat treatment on the microstructure and mechanical properties of Inconel 718 processed by selective laser melting. Mater. Sci. Engineering: Volume. 639, 647–655 (2015). https://doi.org/10.1016/j.msea.2015.05.035

Ravichander, B.B., Mamidi, K., Rajendran, V., Farhang, B., Ganesh-Ram, A., Hanumantha, M., Moghaddam, N.S., Amerinatanzi, A.: Experimental investigation of laser scan strategy on the microstructure and properties of Inconel 718 parts fabricated by laser powder bed fusion. Mater. Charact. 186 (2022). https://doi.org/10.1016/j.matchar.2022.111765

Popovich, A.A., Sh, V., Sufiiarov, I.A., Polozov, Borisov, E.V.: “Microstructure and Mechanical Properties of Inconel 718 Produced by SLM and Subsequent Heat Treatment.”,Key Engineering Materials651–653 (July 2015):665–70. https://doi.org/10.4028/www.scientific.net/kem.651-653.665

Yesim Yalcin, M., Bora Derin, C., Aydogan, E.: Development and Additive Manufacturing of Oxide Dispersion strengthened Inconel 718: Thermochemical and Experimental Studies. J. Alloys Compd. (2022). https://doi.org/10.1016/j.jallcom.2022.165193

Ott, E., Liu, X., Andersson, J., Bi, Z., Bockenstedt, K., Dempster, I., Sudbrack, C. (eds.): Proceedings of the 9th International Symposium on Superalloy 718 & Derivatives: Energy, Aerospace, and Industrial Applications. Springer. (2018)

Jayahari, L., Nagachary, K., Sharath, C., Ch, Hussaini, S.M.: “Anisotropy Study of Inconel 718 alloy at Sub-Zero temperatures”, E3S Web of Conferences 184, 01004 (2020). https://doi.org/10.1051/e3sconf/202018401004

Balamurugan, K., Rajendran, D.: “A Review on Status of Research in Metal Additive Manufacturing”.95–100. (2017). https://doi.org/10.1007/978-981-10-0812-2_8

Riipinen, T.: Heat treatment of AM alloys. VTT Technical Research Centre of Finland. VTT Research Report No. VTT-R-00899-20. (2020)

Agarwal Venkesh, J., Samidha, A., Sagar, K., Omkar: The role of mechanical testing in additive manufacturing: a review. Mater. Sci. Eng. Appl. 1(2), 21–31 (2021). https://doi.org/10.21595/msea.2021.22258

Davies, P.A., Dunstan, G.R., Howells, R.I.L., Hayward, A.C.: Aerospace adds lustre to appeal of master alloy MIM feedstocks. Met. Powder Rep. 59(10), 14–19 (2004). https://doi.org/10.1016/S0026-0657(04)00277-2

Giulio Marchese, M., Lorusso, S., Parizia, E., Bassini, J.-W., Lee, F., Calignano, D., Manfredi, M., Terner, H.-U., Hong, D., Ugues, M., Lombardi, S., Biamino: Influence of heat treatments on microstructure evolution and mechanical properties of Inconel 625 processed by laser powder bed fusion. Mater. Sci. Engineering: A. 729, 64–75 (2018). https://doi.org/10.1016/j.msea.2018.05.044

Huang, W., Wang, Z., Yang, J., Yang, H., Zeng, X.: “Effects of Process Parameters and Heat Treatment on the Microstructure and Mechanical Properties of Selective Laser Melted Inconel 718”. In 2018 International Solid Freeform Fabrication Symposium. University of Texas at Austin. (2018)

Tucho, W., Cuvillier, P., Sjolyst-Kverneland, A., Hansen, V.: Microstructure and hardness studies of Inconel 718 manufactured by selective laser melting before and after Solution Heat Treatment. Mater. Sci. Engineering: A. 689 (2017). https://doi.org/10.1016/j.msea.2017.02.062

Xuenan Liu, et al.: IOP Conf. Ser. : Mater. Sci. Eng. 772, 012075 (2020)

Popovich, V.A., Borisov, E.V., Heurtebise, V., Riemslag, T., Popovich, A.A., Sufiiarov, V.S.: “Creep and Thermomechanical Fatigue of Functionally Graded Inconel 718 Produced by Additive Manufacturing”. In: & Materials Society, T. (eds) TMS 2018 147th Annual Meeting & Exhibition Supplemental Proceedings. TMS 2018. The Minerals, Metals & Materials Series. Springer, Cham. (2018). https://doi.org/10.1007/978-3-319-72526-0_9

Caliari, F., Candioto, K., Reis, D., Couto, A., Neto, Carlos, Nunes, C.: Study of the mechanical behavior of an Inconel 718 aged Superalloy submitted to hot Tensile tests. SAE Tech. Papers. (2011). https://doi.org/10.4271/2011-36-0328

Guher, P., Toker, M., Nematollahi, S.E., Saghaian, Keyvan, S., Baghbaderani, O., Benafan, M., Elahinia, H.E., Karaca: “Shape memory behavior of NiTiHf alloys fabricated by selective laser melting”, Scripta Materialia, Volume 178, Pages361–365, (2020). https://doi.org/10.1016/j.scriptamat.2019.11.056

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kohale, V., Jawade, S. & Kakandikar, G. Investigation on mechanical behaviour of inconel 718 manufactured through additive manufacturing. Int J Interact Des Manuf 17, 1645–1651 (2023). https://doi.org/10.1007/s12008-022-01183-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-022-01183-7