Abstract

Enzymatically synthesized hexyl (C6) and palmitoyl (C16) esters of sinapic acid were incorporated into microencapsulated flaxseed oil as antioxidants. The antioxidant activity and lipid oxidation retarding effect of the sinapic acid esters were tested during storage using different methods. Sinapate-enriched microencapsulated flaxseed oils were found to be more stable against oxidation during storage compared to microencapsulated and free oil. In addition, the results of antioxidant analyses and lipid oxidation measurements revealed the superiority of palmitoyl sinapate (longer alkyl side chain) over hexyl sinapate. The polarity of the analysis medium provides information on the antioxidant properties and stability of the added sinapic acid esters since sinapic acid alkyl esters gave different results when tested directly in the analysis medium. The results showed that lipophilic esters of sinapic acid, especially palmitoyl sinapate, can be successfully used as antioxidants to stabilize microencapsulated flaxseed oil.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Flaxseed (Linum usitatissimum) is an oilseed well known for its rich content of polyunsaturated fatty acids, soluble and insoluble fibers, phytoestrogenic lignans, antioxidants, and protein (Yakdhane et al., 2021). Flaxseed contains a high percentage of total oil, over 40% on a wet-weight basis. Omega 3 and 6 fatty acids are abundant in flaxseed oil and have various functional properties, such as reducing the risk of diabetes and some types of cancer, contributing to the development of cell membranes and acting as precursor molecules in the control of inflammatory reactions, blood pressure, and heart disease. Most diets today contain high ω-6/ω-3 ratio when it should be 4/1 or less (Singh et al., 2011b), which further increases the importance of ω-3 sources. On the other hand, due to its high unsaturated fatty acid content, flaxseed oil is very susceptible to oxidation, which reduces the shelf-life of the product and leads to the formation of unhealthy free radicals, reactive aldehydes, and off-flavors (Tontul & Topuz, 2013). A number of commercial synthetic antioxidants with free radical scavenging activity and metal chelating properties are available to retard lipid oxidation. However, toxic and carcinogenic effects of synthetic antioxidants for human health limit their use in food products. In recent years, consumers prefer food and cosmetic products containing only natural additives. Therefore, interest in natural antioxidants of plant origin has increased (Taghavei & Jafari, 2015).

Natural antioxidants extracted from plants, herbs, and spices tested in oils to increase stability against oxidation (Maleki et al., 2016). Phenolics, which are widely found in nature, are one of the most important radical scavengers. One of the most important natural plant antioxidants is phenolic acids, which are derivatives of benzoic and cinnamic acids (caffeic acid). In many studies, a relationship has been established between the structures of phenolic acids and their antioxidant activities in lipids. Cinnamic acid derivatives were found to be more active antioxidants than benzoic acid derivatives. The presence of the CH = CH-COOH group in cinnamic acid derivatives provides more antioxidant activity than the COOH group in benzoic acids. Sinapic acid (3,5-dimethoxy-4-hydroxycinnamic acid), a derivative of hydroxycinnamic acid, is widely found in fruits, vegetables, and cereals (Niciforovic & Abramovic, 2014; Chen, 2016). It is known to possess strong antioxidant activity (Gaspar et al., 2010) and many pharmacological effects. Sinapic acid is demonstrated to show hepatoprotective (Shin et al., 2013 a, b), neuroprotective and nephroprotective (Ansari et al., 2017), and cardioprotective activity (Bin-Jardan et al., 2020). It has also protective role against diabetes (Cherng et al., 2013), inflammation (Lee, 2018), and cancer (Huang et al., 2022; Mustafa, 2019).

Due to their low solubility and stability in non-polar media, it has become important to improve the solubility of phenolic acids to increase their usefulness as antioxidant components in fats, oils, and emulsions. In recent years, phenolics have been lipophilized to obtain amphiphilic molecules to increase their antioxidant potential. The addition of an alkyl ester side chain improves the utilization of phenolics as antioxidants in lipophilic media by providing a positive effect on the partition coefficient (Sørensen et al., 2014). Phenolic derivatives with high lipophilicity, also known as phenolipids or lipophenols, are obtained chemically by coupling a fatty acid or fatty alcohol to a phenolic moiety and can be prepared through different reactions such as esterification, amidation, etherification, or transesterification, which can be performed chemically or enzymatically depending on the structure and reactivity of the starting molecules (Giraldo et al., 2007; Laguerre et al., 2013). It is well known that phenolipids can improve the antioxidant activity and oxidative stability of vegetable oils, and extend their shelf-life (Catel et al., 2012; Szydłowska-Czerniak et al., 2018). In addition to acting as antioxidant, phenolic esters may provide some additional health benefits. Akanbi and Barrow (2018) obtained hydroxytyrosyl eicosapentaenoate by esterifying hydroxytyrosol and eicosapentaenoic acid. The authors suggested that due to the synergistic effects of hydroxytyrosyl eicosapentaenoate, it may provide effects beyond the known benefits of hydroxytyrosol, especially in neurodegenerative diseases.

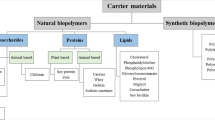

To balance the high intake of ω-6 fatty acids in a regular diet, enrichment of food products with ω-3-rich oils, such as flaxseed oil, has become prominent. However, the rancidity and off-flavor due to lipid oxidation limit the use of these oils (Singh et al., 2011a). To overcome these drawbacks, microencapsulation of flaxseed oil is a prerequisite that ensures its stability in the food matrix. Microencapsulation is an emerging technology that enables the protection of bioactive compounds and control of their release. The process begins by emulsifying bulk oil through the combination of different wall materials and various encapsulation methods, such as spray-drying, spray-coating, and freeze-drying. If necessary, supercritical encapsulation processes, complex coacervation, ionotropic gelation, and molecular inclusion (Comunian & Favaro-Trindade, 2016) can be applied as the second stage of encapsulation to protect the highly polyunsaturated oil from the high temperatures and atmospheric oxygen (Goyal et al., 2015; Gouin, 2004; Liu & Yang, 2011). Spray-drying is a commonly used method for encapsulating oils due to its relative simplicity and cost-effictiveness (Carneiro et al., 2013; Gharsallaoui et al., 2007). The conversion of emulsions containing polyunsaturated fatty acids (PUFA) into powdered products using the spray-drying technique is a promising solution to improve their oxidative stability. Although microencapsulated oils have high stability compared to bulk oil, the heat treatment applied during spray drying and the large surface area of the powder form have an effect on the oxidative stability of microcapsules (Tontul & Topuz, 2013). Therefore, various antioxidants are utilized to further improve the stability (Comunian & Favaro-Trindade, 2016; Le Priol et al., 2021; Chasquibol et al., 2023). In a recent study, Cáceres et al., (2022) utilized hydroxytyrosol alkyl esters as an antioxidant in spray-dried walnut oil microcapsules and observed a significant extension in shelf-life in terms of oxidation. To the best of the authors’ knowledge, there are no studies investigating the effects of sinapic acid esters on the stability of microencapsulated oils.

The aim of the study was to improve the oxidation resistance and the bioactivity of flaxseed oil stabilized with phenolipids by encapsulation using spray drying. To achieve this, hexyl (C6) and palmitoyl (C16) esters of sinapic acid were enzymatically synthesized. The antioxidative efficiency of the alkyl esters was tested in microencapsulated flaxseed oil using various antioxidant activity analyses to investigate the impact of chain length in the microencapsulation medium.

Material and Methods

Chemicals and Materials

The flaxseed oil was cold pressed with a screw press (Arsel, Turkey) and the oil was stored in the dark at 8 °C until use. The sinapic acid, β-carotene, and linoleic acid used in the study were purchased from Tokyo Chemical Industry (Japan). Novozymes A/S (Denmark) kindly donated Candida antarctica lipase B (Novozyme 435). Folin-Ciocalteu’s phenol reagent, DPPH, 1-hexanol, molecular sieves 4 Å, 2-methyl 2-butanol, ABTS, phosphoric acid, and Amberlite IRC 120 H were purchased from Sigma-Aldrich Chemicals (St. Louis, MO, USA). Palmitoyl chloride was procured from Nu Chek Prep. Inc. (USA). Hydrogen peroxide, formic acid, hydrochloric acid, sulfuric acid, diethyl ether, dichloromethane, isooctane, methanol, potassium iodide, potassium dichromate, sodium thiosulfate, sodium carbonate, and p-anisidine crystals were purchased from Isolab (Germany). Acetonitrile, butylated hydroxytoluene (BHT), sulfuric acid, n-hexane, and 2-propanol were bought from Honeywell (USA). Acetic acid, acetone, tetrahydrofuran, ethyl acetate, and chloroform were obtained from Carlo Erba (France). Sodium hydroxide and phenolphthalein were purchased from Scharlau Chemie (Barcelona, Spain). Maltodextrine (Tito, Türkiye) and whey protein isolate (Hardline Bipro, Turkey) were used as wall materials in spray drying.

Enzymatic Synthesis of Sinapic Acid Esters

Sinapic acid esters were synthesized via lipase-catalyzed esterification using hexanol and palmitoyl chloride as acyl donors in methanol (Salem et al., 2010 and Viskupicova et al., 2010). Molecular sieves and amberlite were dried under vacuum at 110 °C for 24 h prior to the reaction. Each reaction involved mixing 13.16 mmol of sinapic acid with the appropriate amount of acyl donor (phenolic acid:acyl donor molar ratio 1:5) in 200 mL of methanol, previously had been dried on a 4 Å molecular sieve. The esterification process was initiated by adding 5 wt% of immobilized lipase to the reaction mixture, which consisted of a solvent with molecular sieve (100 g/L). The reaction medium was stirred under vacuum (600 mbar) at 150 rpm and kept in an orbital shaker at 55 °C for 5 days. The ambient water content was maintained below 2% using molecular sieves. The progress of the reaction was monitored using an HPLC system. After 5 days, the enzyme and molecular sieves were filtered, and the reaction was stopped. Detailed procedure is described in Arslan et al. (2024).

Qualitative analyses of the resulting mixture were conducted through thin-layer chromatography on silica gel plates (Si 60 F254) using a solvent mixture of hexane, ethyl acetate, and formic acid (3:3:0.12, v/v/v). The esters were detected by spraying 3.5% phosphomolybdic acid in methanol, followed by the application of 20% sulfuric acid at 150 °C for 2 min. The spots were visualized under a UV light (254 nm).

Purification of Acylated Products

The reaction medium was filtered in order to remove the enzyme and molecular sieves. Then, approximately half of the solvent was evaporated and the volume was halved. The mixture was passed through silicagel (60 Å pore size, 230–400 mesh, Macherey Nagel, Germany) in a 400 mm × 20 mm column and fractions were obtained by eluting with dichloromethane:ethyl acetate (90:10). The fractions containing the target product were then pooled and the solvent was evaporated under vacuum. The purity of the products was confirmed by HPLC analysis as described before Arslan et al. (2024).

The purified esters were obtained as amorphous powders with colors ranging from cream, pale yellow to bright yellow. The percentage yield was determined by taking into account the calibration curves created for the standards (Laguerre et al., 2010) and comparing the initial moles of the esterified compound with the moles of the reacting phenolic compound (Mellou et al., 2005, Zhang et al., 2020). The production of sinapic acid esters was carried out in three replicates. To obtain a sufficient amount of sinapic acid esters (sinapates) for subsequent analyses, the esterification process was scaled up by increasing the materials sixfold. The dry matter of the acylated samples, hexyl sinapate and palmitoyl sinapate, was 88.12 and 88.38%, respectively.

Identification of Sinapic Acid Esters

The identification of the acylated compounds was carried out by using reversed phase ultra high-performance liquid chromatography-mass spectrometry on an ACQUITY UPLC H-Class PLUS System unit (Waters, USA) with a UV–VIS PDA detector as described before (Arslan et al., 2024). Brifly, separation was performed on a C18 column (ACQUITY UPLC BEH (100 mm × 2.1 mm × 1.7 μm particle size, 130 Å pore size). The chromatographic conditions were as follows: (A) an aqueous solution of formic acid (0.1% v/v) and (B) methanol containing 0.1% v/v of formic acid. Elution gradient was 40% B in 0–10 min, 98% (B) from 10.1 to 12 min, and 40% (B) from 12.1 to 15 min with a flow rate of 0.4 mL/min. The scanning range was set to 240–500 nm. The column and sample temperatures were set to 35 °C and 10 °C, respectively, and injection volume was 2 μL.

The LC was coupled with an electrospray ionization ion source (ESI, ± polarity switching) (Xevo TQ-S micro). The ion source parameters used were cone voltage of 30 V, cone gas flow of 50 L/h, gas temperature of 150 °C, and desolvation gas temperature of 600 °C at a flow rate of 1000 L/h. The acquisition mode was set to scan 100–900 m/z, with a capillary voltage of + 1.00/ − 1.5 kV. MassLynx v4.2 software was used for data acquisition and TargetLynx XS was used for data processing. The compounds presented had a purity of over 80% and were identified based on their expected molecular mass values after lipophilization.

Production of Sinapate Incorporated Microencapsulated Flaxseed Oil by the Spray-Drying Process

The microencapsulation of flaxseed oil with phenolipid was performed using the method described by Tontul and Topuz (2013). To prepare the inner phase of the microcapsules, 500 mg of sinapic acid esters or 200 mg of BHT were added to the 1 L of flaxseed oil. Simultaneously, a carrier solution (240 g) containing a 20% concentration of wall materials (maltodextrin:whey protein isolate, 4:1 (w/w)) was prepared and stirred for at least 1 h. Ten grams of flaxseed oil fortified with phenolipid or with BHT (as a control) was added to 240 mL of carrier solution and stirred for an additional 30 min. The solution was homogenized at 15,000 rpm for 5 min using a rotor–stator homogenizer (Ika T25, Germany) and then dried using a lab-scale spray dryer (Unopex, İzmir). The inlet and outlet temperatures during spray drying were adjusted to 180 °C and 80 °C, respectively. The feed flow rate was fixed at 12 mL/min. The microcapsules were removed from the collection vessel and used in storage stability trials. Bulk oil was used as the negative control, while encapsulated oils with BHT were used as the positive control. All samples were stored in sealed dark glass containers for 45 days at 24 °C. Samples were taken on days 0, 15, 30, and 45 days and analyzed after oil extraction.

Determination of Microencapsulation Efficiency (ME)

The microencapsulation efficiency was calculated by determining the ratio between the difference of the total oil content and the surface oil content of the microcapsules to the total oil content using the equation below:

To extract the surface oil, 2 g of microcapsules was treated with hexane and the hexane phase was dried (Tontul & Topuz, 2013). Total oil content was determined by Soxhlet extraction.

Extraction of Oil from the Microcapsules

The oil was extracted from microcapsules (2–3 g) with 20 mL of aqueous ethanol (85% v/v) and 50 mL of n-hexane. After stirring the mixture for 30 min, the organic layer was separated. The solvent was removed at 40 °C using a vacuum evaporator (Heidolph, Hei-Vap Core, Germany). The resulting oil was stored in the dark and used for analysis (Lee et al., 2020).

Oxidation-Related Determinations on Microcapsules Supplemented by the Sinapic Acid Esters

Peroxide value (PV), conjugated dienes, and trienes (K232 and K270) were determined following the analytical methods described in EEC/2568/91 regulations of the European Commission (EEC, 2003). The oxidative stability of oil in microcapsules was determined by the Rancimat technique (model 892 Metrohm Co., Herisau, Switzerland). For this purpose, 3-g oil sample was oxidized under a 20 L/h air flow at 120 °C (Pawar et al., 2014).

Antioxidative Activity Analyses on Microcapsules Supplemented by the Sinapic Acid Esters

The phenolic extracts of microencapsulated samples of flaxseed oil were obtained from using the method performed by Velázquez Martinez et al. (2021). 0.5 g of powder was mixed with 10 mL by adding ethyl acetate:ethanol 80:20 (v/v) solution and stirred for 30 min at room temperature (25 °C) in the dark. The extract was then filtered through analytical filter paper and adjusted to a final volume of 10 mL. The total phenolic content of the microencapsules was determined spectrophotometrically using the method reported by Yoo et al. (2004). The results were expressed as mg gallic acid equivalents per kg oil (mg GAE/kg fat). The DPPH radical scavenging activity (percent inhibition, %) (DPPH-RSA), Trolox equivalent antioxidant activity (TEAC), and β-carotene bleaching activity (β-CBA) were determined by using the methods reported by Brand-Williams et al. (1995), Re et al. (1999), and Amin et al. (2004), respectively.

Statistical Analysis

The parameters were put to statistical analysis with SPSS 13 software. (SPSS Inc., USA). Multivariate analysis under the general linear model was used to evaluate sample type and storage time-dependent differences regarding the parameters analyzed. Duncan and t tests were performed to determine the significant differences between the mean values (P < 0.05). Experiments were performed in triplicate.

Results and Discussion

The sinapic acid esters; sinapic acid + hexanol (hexyl sinapate); and sinapic acid + palmitoyl chloride (palmitoyl sinapate) were produced with 85.3 and 80.7% yield, respectively. The formation of hexyl sinapate and palmitoyl sinapate was detected by LC–ESI–MS chromatography as fragments [M + H]+ m/z ratios 309.18 and 449.22, respectively (Supplementary Fig. 1).

The microencapsulation efficiencies (67.2–71.0%) for the negative control, positive control, and sample microcapsules were similar. This result is in line with the expectations asantioxidant substances were added to the oil in very low amounts. Previous studies have shown that the efficiency of microencapsulation is related to the characteristics of the feed solution properties (wall material concentration, oil loading, emulsification conditions, etc.) and spray-drying parameters rather than active material composition (Gharsallaoui et al., 2007). This finding is consistent with the literature on encapsulation of oils incorporation with phenolics (Cáceres et al., 2022; Velasco et al., 2009) (Fig. 1).

Antioxidant Activity of Sinapic Acid Esters Directly in Analyses Media

The phenolic content and antioxidant activity of the synthesized ester compounds were also analyzed directly (Fig. 2). Palmitoyl sinapate, which had a higher level of phenolic content than hexyl sinapate, was found to be more effective than hexyl sinapate in β-CBA analysis. However, there was no significant difference in DPPH-RSA and TEAC analyses, in contrast to the microencapsulated lipid medium. The effectiveness of sinapic acid derivatives varied across the different systems studied, free radical species, and mechanisms of antioxidant action. Due to the poor solubility of lipophilic antioxidants, assays based on aqueous systems (e.g., DPPH-RSA) may not adequately reflect the activity. The relatively longer alkyl side chain increases the hydrophobicity of palmitoyl sinapate compared to hexyl sinapate. This may have caused it to disperse as micelles in the aqueous system and to be less present in the environment as free esters (Lue et al., 2010). Rubilar et al. (2012) concluded that the antioxidant activity of compounds, as determined by the DPPH method, was not consistent with their effects on peroxide and conjugated diene formation in the microencapsulated oil medium. However, the phenolipid, which was synthesized using palmitoyl chloride, showed a lower DPPH-RSA. This result was thought to be due to increased hydrophobicity and decreased solubility with the increase in chain length in a polar environment. A previous study found that the fatty acid esters of erythorbic acid had an antioxidant effect in DPPH and TEAC analyses, regardless of of the length of the alkyl chain. The report suggested that the radical scavenging activity (RSA) of these esters was due to enediols (hydroxyl groups at C-2 and C-3) conjugated with a carbonyl group in the lactone ring of erythorbic acid (Barba et al., 2014; Kim et al., 2023). Silveira et al. (2020) concluded that the antioxidant activity measured by lipophilic ORAC and DPPH analyses was less affected by the chain length of sinapic acid esters compared to hydrophilic ORAC and FRAP assays. This was associated with greater dissolution of alkyl esters in more apolar solvent media, such as ethanol in DPPH and β-cyclodextrin in ORAClipo. In the present study, besides the DPPH results, there was no significant difference between hexyl and palmitoyl esters in the TEAC assay medium as well. It is worth noting that extraction from free and microencapsulated oil may also be a factor that affects the results.

Effects of Sinapic Acid Esters on the Oxidative Stability of Flaxseed Oil (FSO) Microcapsules

In this study, cold-pressed flaxseed oil was microencapsulated by spray-drying with the addition of hexyl sinapate and palmitoyl sinapate and their stability against oxidation was tested. The stability was tested using peroxide value, conjugated diene and triene (K232 and K270) values, and oxidative stability index (OSI). Figure 3 illustrates the increase in the peroxide values of the individual stored microcapsules. The hydroperoxide content in the microencapsulated BHT-enriched flaxseed oils (0.34–3.12 meqO2/kg) was much lower than that of the bulk oil sample (1.09–31.53 meqO2/kg) at 30 days of storage. The amount of hydroperoxide in the oils containing palmitoyl sinapate and hexyl sinapate (7.32 and 7.42 meqO2/kg, respectively) was lower at the end of the storage than the oil without antioxidants (9.51 meqO2/kg). During storage, bulk flaxseed oil showed a greater increase in peroxide values compared to microencapsulated samples. The encapsulated oil stabilized with palmitoyl sinapate has an almost 50% lower peroxide value compared to the encapsulated FSO. The same trend was observed for the K232 and K270 values. The addittion of palmitoyl and hexyl sinapates had a competitive effect on K232 compared to BHT. Palmitoyl sinapate showed a strong inhibitory effect on the increase of K270, which was comparable to that of BHT.

The OSI value of unencapsulated flaxseed oil (0.40–0.88 h) increased significantly by microencapsulation (0.57–1.40 h) even without the addition of an antioxidant. In the presence of alkyl esters, much higher OSI values (hexyl sinapate 0.62–2.12 h and palmitoyl sinapate 0.75–2.07 h) were achieved compared to microencapsulated FSO. Although the induction time of microencapsulated oils stabilized with both sinapic acid alkyl esters was similar during the first 15 days of storage, the palmitoyl ester was able to provide higher induction time. On the contrary, hexyl sinapate did not cause any difference compared to unstabilized microcapsules during storage for 30 days and above. At day 15 of storage, BHT, which initially had the highest induction time, provided similar time values to alkyl ester-fortified encapsulated FSO. However, at 30 and 45 days of storage, palmitoyl sinapate and BHT provided similar stability.

The longer alkyl side chain length in the structure of palmitoyl sinapate may have contributed to its higher efficiency in lipid oxidation tests compared to hexyl sinapate. Velasco et al. (2009) reported that dodecyl gallate, which has a longer alkyl chain length and higher lipophilicity, exhibited stronger antioxidant behavior than propyl gallate in microencapsulated sunflower oil. For this reason, Rubilar et al. (2012) recommended to use lipophilic and low polarity antioxidants for microencapsulated oils. The polar paradox theory suggests that non-polar antioxidants in oil-in-water emulsions exhibit greater antioxidative activity than polar ones due to their superior affinity at the oil–water interface. Polar antioxidants, on the other hand, are located in the water phase of the emulsion and their effectiveness in the microencapsulated oil decreases. Several factors, such as molecular size and antioxidant structure, contribute to this phenomenon (Cuvelier et al., 2000). Drozłowska et al. (2021) reported that antioxidant phenolic compounds transfer more easily transfer into the oil phase during the emulsification and spray drying procedures. They found that the polyphenol-rich extract in high-fat microcapsules was more effective than the low-fat microcapsules.

On the other hand, non-polar antioxidant compounds can act as a protective barrier by surrounding oil droplets (Shahidi & Zhong, 2011). It is important to consider that the increase in solubility, along with the increase in lipophilicity, also played a role when interpreting the results. Sun-Waterhouse et al. (2012) found that the effectiveness of BHT and phloridzin in encapsulating avocado oil varies based on their solubility in oil. Because of better solubility, they concluded that BHT is more effective in terms of oxidative stability.

Effects of Sinapic Acid Esters on the Total Phenolics and Antioxidative Activity in FSO Microcapsules

The phenolic content of microencapsulated flaxseed oil was found to be similar to that of bulk oil, suggesting that spray drying does not result in phenolic degradation (Table 1). The total phenolic content in the FSO was increased by the addition of sinapic acid conjugates (369–441 mg/kg) or BHT (430 mg/kg), as expected. During storage, the phenolic content of the bulk oil was determined ranged between 92 and 211 mg/kg, while in the microencapsulated flaxseed oil, it was ranged between 172 and 190 mg/kg.

A significant decrease in the phenolic content was observed in bulk flaxseed oil during the 45 days of storage. The most notable loss of phenolics occurred in the first and last 15 days of storage. The reduction in phenolic content observed in encapsulated samples was less pronounced, with a 56% decrease in the bulk oil and a 5–15% decrease in the stabilized oils. This suggests that encapsulation has a protective effect on phenolics, both those naturally present in the oil and those added externally (Sun-Waterhouse et al., 2012).

Drozłowska et al. (2021) reported that the total phenolic content in microencapsulated flaxseed oil enriched with the extract obtained from flaxseed press cake decreased with increasing storage time. The additional phenolics bound to the microcapsule shell protected the phenolics in the seed and also the oil from oxidation.

The analysis of antioxidant activity showed similar trends, which were consistent with the total phenolic values. The study confirmed that encapsulation has a positive effect on protecting phenolics from degradation and stabilizing antioxidant activity. Palmitoyl sinapate and hexyl sinapate showed competitive activity with BHT. The synthesized alkyl esters, which had one hydroxyl and two methoxyl groups, possibly served as antioxidants by donating H-atoms to free radicals.

The microencapsulated samples containing phenolipids showed high DPPH inhibition values ranging from 60 to 73%, which were slightly lower than those of BHT (70–80%) (Table 1). Among the samples, those containing palmitoyl sinapate in microencapsulated oil exhibited better antioxidant activity than the others.

In the TEAC and β-CBA assays, phenolipids showed compatible effects. Samples with incorporated phenolipids showed higher activity compared to the encapsulated oil sample without antioxidants. The esters provided antioxidant activity similar to that of BHT. In the antioxidant analysis of microencapsulated oil samples, palmitoyl sinapate showed higher activity than hexyl sinapate. On the other hand, in the DPPH-RSA and TEAC analyses, palmitoyl sinapate was initially found to exhibit high inhibitory activityduring the first 30 days of storage. However, on the last day of storage, hexyl sinapate showed better activity. It is worth noting that this effect was not observed for β-CBA results, highlighting the influence of polarity and hydrophilicity of the analysis medium. Therefore, based on the findings of Chen et al. (2023), who studied the effect of alkyl ferulates which were synthesized by using different chain length fatty acids, it was expected that palmitoyl ester would be more stable. The study demonstrated that compared to TBHQ, the long-chain alkyl ferulates (C12:0–C16:0) were less volatile and more stable. Additionally, the β-CBA analysis showed that alkyl esters were effective, although not equally as effective as BHT.

When interpreting the results, it is important to note that palmitoyl ester exhibits stronger antioxidant activity than hexyl ester in both lipophilic and hydrophilic antioxidant activity analyses, specifically in preventing lipid oxidation. This may be attributed to the longer alkyl side chain of the molecule. The chain length and degree of unsaturation of the acyl donors used in the synthesis can also affect on the antioxidant activity of phenolic esters. Palmitoyl sinapate was found to be more effective than hexyl sinapate in terms of antioxidant activity and oxidative stability. This is likely due to the longer alkyl side chain of the phenolipid. Abd El-Maksoud et al. (2019) reported that the hydroxyl scavenging activity of caffeic acid esters generally increases with the length of the alkyl chain. Choe and Min (2009) suggested that the stabilization of the phenoxy radical increases with longer alkyl chain length. The long alkyl side chains in the structure of the phenolipid stabilize phenoxy radicals, allowing it to chelate metal ions (Abd El-Maksoud et al., 2019) and other oxidation promoters. This effect could help explain why palmitoyl sinapate has higher radical scavenging and bleaching activity.

Kim et al. (2023) reported that antioxidant activity against oil oxidation increases with chain length in oil-in-water emulsion systems. They also found that the esters with high activity can concentrate at the oil–water interface, while esters with low activity can be found in lower concentrations in this region. The authors reported that the ester with a 16-carbon chain was better partitioned at the interface compared to other derivatives. Therefore, it showed the maximum antioxidant effect at the oil–water interface (Kim et al., 2023), which was also observed in the present study.

Table 2 shows the relationship between the parameters of antioxidant activity of microencapsulated flaxseed oils. The results show a significant correlation between the peroxide value and the conjugated diene – triene (K232 – K270), as well as the induction time. In contrast, total phenolic content showed a significant correlation mainly with β-CBA (r = 0.904), followed by DPPH and TEAC results. Induction time showed the highest correlation with the K270 value, followed by PV.

Conclusions

This study aimed to limit oxidation by using microencapsulation and lipophilic sinapic acid esters. The results showed that microencapsulation successfully limited oxidation, and the incorporation of sinapic acid derivatives not only prevented lipid oxidation but also increased antioxidant activity.

According to the DPPH-RSA, β-CBA, and TEAC analyses, as well as lipid oxidation tests, palmitoyl sinapate showed the strongest activity. This was attributed to the longer alkyl side chain of the molecule.

During the 45-day storage period, sinapic acid esters provided the microencapsulated oil significant protection against oxidation. In comparison, phenolics content and antioxidant activity of the bulk flaxseed oil decrease more. The total phenolic content showed a significant correlation especially with β-CBA results (r = 0.904), followed by the DPPH and TEAC results. The phenolic content showed a weaker correlation with lipid oxidation results.

In the direct analysis, palmitoyl sinapate was found to have higher levels of phenolic content than hexyl sinapate. In addition, it was more effective than hexyl sinapate in β-CBA analysis, but did not show a significant difference in DPPH-RSA and TEAC analyses, unlike the microencapsulated oils. This difference was likely due to the hydrophilicity of the DPPH-RSA and TEAC analysis media. The lack of an extraction step when working directly with the extract could also be a distinguishing feature.

Data Availability

Data generated or analyzed during this study are available from the corresponding author upon reasonable request.

References

Abd El-Maksoud, A. A., Anankanbil, S., Zhou, Ye., Abd El-Ghany, I. H., El-Beltagi, H. S., Banerjee, C., Petersen, S. V., & Guo, Z. (2019). Grafting phenolics onto milk protein via conjugated polymerization for delivery of multiple functionalities: Synthesis and characterization. Food Chemistry,301, 125298. https://doi.org/10.1016/j.foodchem.2019.125298

Akanbi, T. O., & Barrow, C. J. (2018). Lipase-produced hydroxytyrosyl eicosapentaenoate is an excellent antioxidant for the stabilization of omega-3 bulk oils, emulsions and microcapsules. Molecules,23(2), 275. https://doi.org/10.3390/molecules23020275

Amin, I., Zamaliah, M. M., & Chin, W. F. (2004). Total antioxidant activity and phenolic content in selected vegetables. Food Chemistry,87(4), 581–586. https://doi.org/10.1016/j.foodchem.2004.01.010

Ansari, M. A., Raish, M., Ahmad, A., Alkharfy, K. M., Ahmad, S. F., Attia, S. M., Alsaad, A. M. S., & Bakheet, S. A. (2017). Sinapic acid ameliorate cadmium-induced nephrotoxicity: possible involvement of oxidative stress, apoptosis, and inflammation via NF-kappaB downregulation. Environmental Toxicology Pharmacology,51, 100–107.

Arslan, D., Polak, T., & Poklar Ulrih, N. (2024). Antioxidative effects of alkyl esters of sinapic acid on flaxseed oil and its fatty acid methyl esters. Journal of the American Oil Chemists’ Society. https://doi.org/10.1002/aocs.12819

Barba, F. J., Esteve, M. J., & Frígola, A. (2014). Bioactive components from leaf vegetable products. Studies in Natural Products Chemistry,41, 321–346.

Bin-Jardan, Y. A., et al. (2020). Sinapic acid ameliorates oxidative stress, inflammation, and apoptosis in acute doxorubicin-induced cardiotoxicity via the NF-κB-mediated pathway. BioMed Research International,10, 921796.

Brand-Williams, W., Cuvelier, M., & Berset, C. (1995). Use of a free radical method to evaluate antioxidant activity. LWT-Food Science and Technology,28, 25–30. https://doi.org/10.1016/S0023-6438(95)80008-5

Cáceres, D., Giménez, B., Márquez-Ruiz, G., Holgado, F., Vergara, C., Romero-Hasler, P., ... Robert, P. (2022). Incorporation of hydroxytyrosol alkyl esters of different chain length as antioxidant strategy in walnut oil spray-dried microparticles with a sodium alginate outer layer. Food Chemistry, 395, 133595.

Carneiro, H. C., Tonon, R. V., Grosso, C., & Hubinger, M. D. (2013). Encapsulation efficiency and oxidative stability of flaxseed oil microencapsulated by spray drying using different combinations of wall materials. Journal of Food Engineering,115, 443–451.

Catel, Y., Aladedunye, F., & Przybylski, R. (2012). Radical scavenging activity and performance of novel phenolic antioxidants in oils during storage and frying. Journal of the American Oil Chemists’ Society,89, 55–66. https://doi.org/10.1007/s11746-011-1889-6goyal

Chasquibol, N., Gonzales, B. F., Alarcón, R., Sotelo, A., Gallardo, G., García, B., & Pérez-Camino, M. D. C. (2023). Co-microencapsulation of sacha inchi (Plukenetia huayllabambana) oil with natural antioxidants extracts. Foods,12(11), 2126.

Chen, C. (2016) Sinapic acid and its derivatives as medicine in oxidative stress-induced diseases and aging. Journal of Oxidative Medicine and Cellular Longevity, 1, 3571614.

Chen, J., Zhang, L., Zhao, P., Ma, G., Li, Q., & Yu, X. (2023). Synthesized alkyl ferulates with different chain lengths inhibited the formation of lipid oxidation products in soybean oil during deep frying. Food Chemistry, 410, 135458.

Cherng, Y. G., Tsai, C. C., Chung, H. H., Lai, Y. W., Kuo, S. C., & Cheng, J. T. (2013). Antihyperglycemic action of sinapic acid in diabetic rats. Journal of Agricultural and Food Chemistry,61, 12053–12059.

Choe, E., & Min, D. B. (2009). Mechanisms of antioxidants in the oxidation of foods. Comprehensive Reviews in Food Science and Food Safety,8(4), 345–358.

Comunian, T. A., & Favaro-Trindade, C. S. (2016). Microencapsulation using biopolymers as an alternative to produce food enhanced with phytosterols and omega-3 fatty acids: A review. Food Hydrocolloids,61, 442–457.

Cuvelier, M., Bondet, V., & Berset, C. (2000). Behavior of phenolic antioxidants in a partitioned medium: Structure, activity relationship. Journal of the American Oil Chemists’ Society,77, 819–824.

Drozłowska, E., Bartkowiak, A., Trocer, P., Kostek, M., Tarnowiecka-Kuca, A., Bienkiewicz, G., & Łopusiewicz, Ł. (2021). The influence of flaxseed oil cake extract on oxidative stability of microencapsulated flaxseed oil in spray-dried powders. Antioxidants,10(2), 211.

EEC. (2003). Characteristics of olive and olive pomace oils and their analytical methods. EEC Regulation 1989/2003. Official Journal of the European Commission,295, 57–77.

Gaspar, A., Martins, M., Silva, P., Garrido, E. M., Garrido, J., Firuzi, O., ... & Borges, F. (2010). Dietary phenolic acids and derivatives. Evaluation of the antioxidant activity of sinapic acid and its alkyl esters. Journal of agricultural and food chemistry, 58(21), 11273–11280.

Gharsallaoui, A., Roudaut, G., Chambin, O., Voilley, A., & Saurel, R. (2007). Applications of spray-drying in microencapsulation of food ingredients: An overview. Food Research International,40, 1107–1121.

Giraldo, L. J. L., Laguerre, M., Lecomte, J., Figueroa-Espinoza, M. C., Barouh, N., Baréa, B., & Villeneuve, P. (2007). Lipase-catalyzed synthesis of chlorogenate fatty esters in solvent-free medium. Enzyme and Microbial Technology,41(6–7), 721–726.

Gouin, S. (2004). Microencapsulation: Industrial appraisal of existing technologies and trends. Trends in Food Science and Technology,15, 330–347.

Goyal, A., Sharma, V., Upadhyay, N., Singh, A. K., Arora, S., Lal, D., & Sabikhi, L. (2015). Development of stable flaxseed oil emulsions as a potential delivery system of ω-3 fatty acids. Journal of Food Science and Technology,52, 4256–4265.

Huang, Z., Chen, H., Tan, P., Huang, M., Shi, H., Sun, B., ... & Fu, W. (2022). Sinapic acid inhibits pancreatic cancer proliferation, migration, and invasion via downregulation of the AKT/Gsk-3β signal pathway. Drug Development Research, 83(3), 721–734.

Kim, J., Yu, H., Yang, E., Choi, Y., & Chang, P. S. (2023). Effects of alkyl chain length on the interfacial, antibacterial, and antioxidative properties of erythorbyl fatty acid esters. LWT-Food Science and Technology,174, 114421.

Laguerre, M., Lopez Giraldo, L. J., Lecomte, J., Figueroa-Espinoza, M. C., Baréa, B., Weiss, J., & Villeneuve, P. (2010). Relationship between hydrophobicity and antioxidant ability of “phenolipids” in emulsion: A parabolic effect of the chain length of rosmarinate esters. Journal of Agricultural and Food Chemistry,58(5), 2869–2876. https://doi.org/10.1021/jf904119v

Laguerre, M., Bayrasy, C., Lecomte, J., Chabi, B., Decker, E. A., Wrutniak-Cabello, C., et al. (2013). How to boost antioxidants by lipophilization? Biochimie,95(1), 20–26. https://doi.org/10.1016/j.biochi.2012.07.018

Le Priol, L., Gmur, J., Dagmey, A., Morandat, S., El Kirat, K., Saleh, K., & Nesterenko, A. (2021). Co-encapsulation of vegetable oils with phenolic antioxidants and evaluation of their oxidative stability under long-term storage conditions. LWT-Food Science and Technology,142, 111033.

Lee, J. Y. (2018). Anti-inflammatory effects of sinapic acid on 2,4,6-trinitrobenzenesulfonic acid-induced colitis in mice. Archives of Pharmacal Research,41, 243–250.

Lee, W. J., Tan, C. P., Sulaiman, R., Hee, Y. Y., & Chong, G. H. (2020). Storage stability and degradation kinetics of bioactive compounds in red palm oil microcapsules produced with solution-enhanced dispersion by supercritical carbon dioxide: A comparison with the spray-drying method. Food Chemistry,304, 125427.

Liu, T. T., & Yang, T. S. (2011). Optimization of emulsification and microencapsulation of evening primrose oil and its oxidative stabil-ity during storage by response surface methodology. Journal of Food Quality,34, 64–73.

Lue, B. M., Nielsen, N. S., Jacobsen, C., Hellgren, L., Guo, Z., & Xu, X. (2010). Antioxidant properties of modified rutin esters by DPPH, reducing power, iron chelation and human low density lipoprotein assays. Food Chemistry,123(2), 221–230.

Maleki, M., Ariaii, P., & Fallah, H. (2016). Effects of celery extracts on the oxidative stability of canola oil under thermal condition. Journal of Food Process Preservation,40(3), 531–540.

Mellou, F., Lazari, D., Skaltsa, H., Tselepis, A. D., Kolisis, F. N., & Stamatis, H. (2005). Biocatalytic preparation of acylated derivatives of flavonoid glycosides enhances their antioxidant and antimicrobial activity. Journal of Biotechnology,116(3), 295–304. https://doi.org/10.1016/j.jbiotec.2004.12.002

Mustafa, Y. F. (2019). Synthesis, characterization and preliminary cytotoxic study of sinapic acid and its analogues. Journal of Global Pharma Technology,11(9), 1–10.

Nićiforović, N., & Abramovič, H. (2014). Sinapic acid and its derivatives: Natural sources and bioactivity. Comprehensive Reviews in Food Science and Food Safety,13(1), 34–51.

Pawar, N., Purohit, A., Gandhi, K., Arora, S., & Singh, R. R. B. (2014). Effect of operational parameters on determination of oxidative stability measured by Rancimat method. International Journal of Food Properties,17(9), 2082–2088. https://doi.org/10.1080/10942912.2012.680220

Re, R., Pellegrini, N., Proteggente, A., Pannala, A., Yang, M., & Rice-Evans, C. (1999). Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radical Biology Medicine,26, 1231–1237. https://doi.org/10.1016/S0891-5849(98)00315-3

Rubilar, M., Morales, E., Sáez, R., Acevedo, F., Palma, B., Villarroel, M., & Shene, C. (2012). Polyphenolic fractions improve the oxidative stability of microencapsulated linseed oil. European Journal of Lipid Science and Technology,114(7), 760–771.

Salem, J. H., Humeau, C., Chevalot, I., Harscoat-Schiavo, C., Vanderesse, R., Blanchard, F., & Fick, M. (2010). Effect of acyl donor chain length on isoquercitrin acylation and biological activities of corresponding esters. Process Biochemistry,45(3), 382–389. https://doi.org/10.1016/j.procbio.2009.10.012

Shahidi, F., & Zhong, Y. (2011). Revisiting the polar paradox theory: A critical overview. Journal of Agricultural and Food Chemistry,59(8), 3499–3504. https://doi.org/10.1021/jf104750m

Shin, D. S., Kim, K. W., Chung, H. Y., Yoon, S., & Moon, J. O. (2013). Effect of sinapic acid against dimethylnitrosamine-induced hepatic fibrosis in rats. Archives of Pharmacal Research,36, 608–618.

Silveira, T. F. F., Cajaíba, L. M., Valentin, L., Baréa, B., Villeneuve, P., & Castro, I. A. (2020). Effect of sinapic acid ester derivatives on the oxidative stability of omega-3 fatty acids rich oil-in-water emulsions. Food Chemistry,309, 125586. https://doi.org/10.1016/j.foodchem.2019.125586

Singh, K. K., Mridula, D., Rehal, J., & Barnwal, P. (2011a). Flaxseed: A potential source of food, feed and fiber. Critical Reviews in Food Science and Nutrition,51, 210–222.

Singh, R. B., Moshiri, M., De Meester, F., Juneja, L., Muthusamy, V., & Manoharan, S. (2011b). The evolution of low ω-6/ ω-3 ratio dietary pattern and risk of cardiovascular diseases and diabetes. Journal of Alternative Medicine Research,3, 45–70.

Sørensen, A. D. M., Durand, E., Laguerre, M., Bayrasy, C., Lecomte, J., Villeneuve, P., & Jacobsen, C. (2014). Antioxidant properties and efficacies of synthesized alkyl caffeates, ferulates, and coumarates. Journal of Agricultural and Food Chemistry,62(52), 12553–12562. https://doi.org/10.1021/jf500588s

Sun-Waterhouse, D., Penin-Peyta, L., Wadhwa, S. S., & Waterhouse, G. I. (2012). Storage stability of phenolic-fortified avocado oil encapsulated using different polymer formulations and co-extrusion technology. Food and Bioprocess Technology,5, 3090–3102.

Szydłowska-Czerniak, A., Rabiej, D., & Krzemiński, M. (2018). Synthesis of novel octyl sinapate to enhance antioxidant capacity of rapeseed–linseed oil mixture. Journal of the Science of Food and Agriculture,98(4), 1625–1631. https://doi.org/10.1002/jsfa.8637

Taghvaei, M., & Jafari, S. M. (2015). Application and stability of natural antioxidants in edible oils in order to substitute synthetic additives. Journal of Food Science and Technology,52, 1272–1282.

Tontul, I., & Topuz, A. (2013). Mixture design approach in wall material selection and evaluation of ultrasonic emulsification in flaxseed oil microencapsulation. Drying Technology,31(12), 1362–1373.

Velasco, J., Holgado, F., Dobarganes, C., & Márquez-Ruiz, G. (2009). Antioxidant activity of added phenolic compounds in freeze-dried microencapsulated sunflower oil. Journal of the American Oil Chemists’ Society,86, 445–452.

Velazquez-Martinez, V., Valles-Rosales, D., Rodriguez-Uribe, L., Holguin, O., Quintero-Quiroz, J., Reyes-Jaquez, D., & Delgado, E. (2021). Antimicrobial, shelf-life stability, and effect of maltodextrin and gum arabic on the encapsulation efficiency of sugarcane bagasse bioactive compounds. Foods,10(1), 116.

Viskupicova, J., Martina, D., Miroslav, O., Tibor, L., & Ernest, S. (2010). Lipophilic rutin derivatives for antioxidant protection of oil-based foods. Food Chemistry,123, 45–50. https://doi.org/10.1016/j.foodchem.2010.03.125

Yakdhane, A., Labidi, S., Chaabane, D., Tolnay, A., Nath, A., Koris, A., & Vatai, G. (2021). Microencapsulation of flaxseed oil—state of art. Processes,9(2), 295.

Yoo, K. M., Lee, K. W., Park, J. B., Lee, H. J., & Hwang, I. K. (2004). Variation in major antioxidants and total antioxidant activity of Yuzu (Citrus junos SiebexTanaka) during maturation and between cultivars. Journal of Agricultural and Food Chemistry, 52, 5907–5913.

Zhang, W., Peng, H., Sun, H., Hua, X., Zhao, W., & Yang, R. (2020). Effect of acidic moisture-conditioning as pretreatment for aqueous extraction of flaxseed oil with lower water consumption. Food and Bioproducts Processing, 121, 20–28.

Acknowledgements

We gratefully acknowledge Novozymes (Bagsværde, Denmark) for delivering lipase B form Candida antarctica (Lipozyme CalB).

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK). This study was funded by “The Scientific and Technological Research Council of Türkiye” and “Slovenian Research Agency” (TÜBİTAK-ARRS international joint research project, No:119O056).

Author information

Authors and Affiliations

Contributions

DA: conceptualization, formal analysis, investigation, methodology, supervision, visualization, and writing—original draft; İT: methodology, investigation, visualization writing—review and editing; TP: methodology, investigation, visualization; NPU: methodology, visualization, writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Arslan, D., Tontul, İ., Polak, T. et al. Use of Sinapic Acid Alkyl Esters as Antioxidants in Microencapsulated Flaxseed Oil. Food Bioprocess Technol (2024). https://doi.org/10.1007/s11947-024-03469-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11947-024-03469-y