Abstract

We proposed here a non-destructive technology for pre-sorting eggs into subclasses characterized by a specifical acceptable shelf life and quality requirements. Egg characteristics were identified suiting a predictive model for controlling storage periods. Accordingly, the relationships of egg parameters were assessed, with weight loss (ΔW) during storage being the best indicator of changes in egg contents variables. Using changes in ΔW, we established three indicators with the maximum effect on fast egg drying and shrinkage. These included egg weight (W), egg volume-to-surface area ratio, and air cell diameter. The relationship formulae were derived to estimate the ΔW value accurately. This approach enables to judge regarding the potential of each particular egg subclass for its acceptable weight shrinkage and assign an optimal storage period for it. The proposed non-invasive analytical method can be implemented in industrial conditions for both table and hatching eggs with the available set of automated technological equipment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Modern industrial technologies for egg production are associated with the need to take into account aspects of handling large batches of eggs, their packaging, transporting, and other production processes, including the problem of temporary storage of eggs. The latter is also crucial for the incubation of hatching eggs on an industrial scale (Ayeni et al., 2020) and processing of poultry eggs for the production of other food products (Wang et al., 2012). Herewith, storage conditions should guarantee the maintenance of certain quality indicators by the end of the storage period for both table and hatching eggs. To prevent deterioration of egg quality, a number of technological solutions have been developed, which can be conditionally divided into the following categories:

-

1.

The most common technology known for over 100 years (Jenkins & Pennington, 1919) is provision of special storage conditions, such as low temperatures and/or controlled humidity, as well as artificial gas environment (Brake et al., 1997; Giampietro-Ganeco et al., 2015; Park et al., 2003; Salamon, 2020; Samli et al., 2005).

-

2.

Use of special packaging in which eggs are placed during storage (Imai, 1981; Okonkwo et al., 2021; Renukadevi et al., 2018).

-

3.

Application of protective coatings to egg shells (Al-Hajo et al., 2010; Almeida e Silva et al., 2020; Dudusola, 2009; Nongtaodum et al., 2013; Oleforuh-Okoleh & Eze, 2016; Park et al., 2003).

However, use of these technical solutions entails additional costs for equipment, energy, and auxiliary materials. Moreover, no developed technology guarantees that absolutely all eggs stored in such conditions will reach the end of their shelf life with guaranteed quality indicators required for further use.

As a possible solution, the pre-sorting of eggs into subclasses can be suggested so that each subclass will have its own acceptable shelf life, after which the eggs will still meet the required quality characteristics. Despite the obviousness of such a technological approach, its development potential was claimed relatively recently, although, judging from the lack of such studies, this has not received a worthy response in the egg research community. As a result of investigating quality of chicken eggs in relation to extended period of storage, Hagan et al. (2013) argued that “the significant interaction effects observed in some of the egg quality characteristics are indications of the need to consider the strain of layer and how long the eggs can be stored so as not to compromise the quality.” Their study revealed that eggs from different strains can differ in characteristics like egg weight (W), albumen weight (Wa), and Haugh unit (HU). Thus, if we approach the proposed technique of inter-strain egg sorting more broadly, it would be advisable to perform a pre-storing arrangement depending on those quality characteristics that are most vulnerable to the duration of the storage process.

Perhaps, when choosing variables that are most subject to change during storage, all researchers agree that these are the parameters of the egg contents (or interior). For example, according to Jin et al. (2011), eggs have their highest possible albumen height (H) value (and hence HU derived from it) when they are freshly laid and reduces with increasing storage time. Stojčić and Perić (2018) made a similar statement that H and HU were “affected by the storage period and are of immense importance.” Accordingly, their findings suggested that H and HU are the most important parameters of egg quality. Earlier, Alleoni and Antunes (2001) came to a comparable conclusion that HU and H “decreased significantly during storage.” Similar trends in changes in egg white indicators have been confirmed, probably, by all researchers who have studied this issue (Karoui et al., 2006; Khan et al., 2014; Lall et al., 2018; Samli et al., 2005; Tabidi, 2011).

Since most of the changes in egg quality in terms of HU and H are related to moisture loss by evaporation through the shell pores and CO2 release from albumen (Hinton, 1968; Robinson, 1987; Shenstone, 1968), W steadily reduces during storage. This phenomenon was confirmed by Scott and Silversides (2000), Park et al. (2003), Samli et al. (2005), Oleforuh-Okoleh and Eze (2016), and many others.

Change in egg weight, i.e., its loss (ΔW), is quite easy to track during storage without violating egg integrity, whereas the albumen parameters cannot ensure this because the egg must be broken to measure them. Therefore, the variable ΔW can be the most convenient alternative for assessing the egg freshness (quality) and, accordingly, its suitability for further use at the end of the storage process. Thus, ΔW can be safely used in analytical studies aimed at developing technological solutions related to egg sorting before storage.

On the other hand, it is not convenient in industrial conditions to use ΔW as an indicator by which eggs can be sorted. Indeed, the eggs in this case have to be weighed daily during a certain period of their storage, after which a decision should be made on the degree of suitability of each egg for this storage period to sort the eggs properly. It is much more attractive to estimate in advance the potential of each egg for a specific shelf life. Hence, it is extremely relevant to explore what methodological, technological and engineering solutions can be developed to predict the optimal duration of egg storage. An analysis of the studies conducted on this topic made it possible to structure them into few main categories as outlined below.

Engineering Solutions

Previously, most of the research focused on identifying the rates of fresh eggs and stale eggs using visible-near-infrared (Vis–NIR) Spectroscopy. For example, Berardinelli et al. (2005) found this equal to 80% of fresh eggs, while Zhao et al. (2010) achieved even higher identification accuracy (93.3%). Lin et al. (2015) and Coronel-Reyes et al. (2018) tried to improve further the egg freshness identification rate through multivariate calibration modeling procedures. However, recent studies using Vis–NIR spectroscopy have proved their greater potential as engineering solutions. A number of relevant works were aimed at predicting possible changes in the quality indicators of egg contents. For instance, Abdel-Nour et al. (2011) demonstrated that Vis–NIR transmission spectroscopy, as a useful instrument for determining albumen pH and egg freshness, can also be used to predict HU, albumen pH, and number of storage days non-destructively. By estimating the ultrasonic phase velocity within the egg material, Aboonajmi et al. (2010, 2014) looked into the feasibility of non-destructive prediction of the primary quality indices of commercial eggs. It was discovered that the phase velocity dropped over three weeks as the eggs' storage time increased. In a later work, Aboonajmi et al. (2015) used Vis–NIR spectroscopy for the same purpose, with which they achieved a satisfactory prediction accuracy of HU for intact eggs (R2 = 0.745 and 0.760) and air cell height (h) (R2 = 0.835 and 0.844) under room and refrigerated settings, respectively. Conversely, Kim et al. (2022) argued that the NIR spectroscopy method did not demonstrate sufficient prediction efficiency for HU.

Suitable predictive models for egg shelf life have also been devised using the state-of-the-art e-nose technology. Yimenu et al. (2017) determined egg volatile during storage and, based on the data obtained, developed a fairly accurate model for predicting storage time. However, in their later work, the authors still lean towards controlling egg freshness by predicting HU in a real-time cold chain environment when applying non-destructive ΔW-related parameters (Kim et al., 2022).

High predictive accuracy (with R2 values up to 0.985) was demonstrated for egg shelf life by Ragni et al. (2007) and Ragni et al. (2010), who explored the non-invasive prediction of fundamental quality characteristics of shell eggs employing an open-ended coaxial probe dielectric measurement technique. The variables under investigation involved yolk index, H, HU, and air cell size as a function of time spent for storage at ambient temperature.

The use of fluorescence to assess the quality of eggs during storage can also be a viable alternative to other engineering systems. For example, Karoui et al. (2008) summarized the results of their research on eggs storage time and conditions, suggesting that the fluorescence spectrum of vitamin A may be a useful tool for determining the freshness of eggs.

The rapid development of instrumentation and the possibility of its use for the needs of various industries promise a great potential for further research in this direction. Exploration based on impedance measurement (Ching et al., 2023), a technique using terahertz waves (Khaliduzzaman et al., 2020), even more advanced near-infrared hyperspectral imaging systems (e.g., Liu & Ngadi, 2013) and, possibly, a number of others may be propitious.

Undoubtedly, the use of sophisticated devices that can quickly and accurately measure the condition of the egg contents without destroying it is extremely attractive. However, the issue of predicting the term of possible egg storage at the earliest stage (ideally, immediately after the egg is laid) remains open. Given the lack of highly efficient industrial appliances and/or their high cost, it is impossible to disagree with Kim et al. (2022) that the monitoring of the egg storage process can be performed by conventional weighing, i.e., recording the ΔW values. In this regard, we argue that it is precisely by W that a certain margin of safety can be predicted for the possible albumen shrinkage during storage. Otherwise, the greater the initial W value, the longer the egg will probably be stored.

Initial Egg Weight

There are no directly predictive models of egg storage time in the specialized scientific literature, based on the W value before storage. Nevertheless, a number of studies indicate the possible prospect of using the W parameter for this purpose. For example, according to Washburn (1990), there is a correlation between W and H, meaning that as egg size increases, so does the percent of albumen. Scott and Silversides (2000) discovered that correlation coefficients between W and three egg components, i.e., albumen, yolk, and shell, indicated that W overall and at each storage period was closely correlated with albumen weight (Wa). According to Feddern et al. (2017), better egg quality (measured at week 1 of storage) was associated with higher values of W, yolk height, H, HU, and egg density (D). As a result of a comparative analysis using eggs of different W subclasses, Gogo et al. (2021) showed that the average ΔW values for large (60–64 g), extra-large (65–69 g), and jumbo (> 70 g) were 1.67, 1.78, and 1.99 g, respectively. That is, if you recalculate these results as relative ΔW values, the values will be placed in reverse order. In other words, the greater the W value, the less weight shrinkage during egg storage.

Thus, it is indeed possible that eggs of higher W values may have a much greater long-term storage potential than lighter eggs due to losing relatively less moisture.

Air cell size is the parameter that is associated with moisture loss due to evaporation via the shell pores and CO2 release from albumen in the course of storage (Hinton, 1968; Robinson, 1987; Shenstone, 1968). In this regard, this parameter can also be used to predict the predisposition of eggs to different periods of their storage.

Air Cell Dimensions

As soon as the egg is laid, the two shell membranes separate, creating an air space. Then, as CO2 and moisture gradually escape via the shell pores, the air cell grows in height (Romanoff & Romanoff, 1949). Samli et al. (2005) demonstrated in their research that, in addition to such parameters as H, HU, pH of albumen, and yolk, which can only be accurately determined by destructive methods, the air cell size was found to be one of the most important parameters and was greatly influenced by storage time and temperature. A similar assumption about the importance of the air cell size, along with quality indicators of the contents, was made by Aboonajmi et al. (2010, 2015). According to them, HU and air cell height (h) are the two basic indicators of egg freshness. In that study, h was more than tripled when stored at 25 °C for 35 days. A similar increase in h was noted in the studies of Ragni et al. (2007) and Ragni et al. (2010) after 16 days of storage, as well as Drabik et al. (2021) who examined this relationship during 35 days of storage of chicken eggs.

Following are some conclusions that may be drawn from the above literature review:

-

1.

The technology of egg sorting prior to storage, depending on their potential to withstand a certain period of time with the required quality indicators of the contents, is extremely promising, is relatively easy to implement, and can be quite effective in terms of the desired egg storage results.

-

2.

Clearly, there are not enough available studies aimed at developing predictive models for the suitable storage time of eggs depending on the values of their parameters, which can be measured quite simply, in relation to industrial conditions and, moreover, in a non-invasive way.

In view of this, we set ourselves the objective to evaluate the potential of using the parameters of chicken eggs, which can be determined without violating their integrity, and to build a predictive model of their possible shelf life. To achieve this goal, we carried out the relevant studies that included the following tasks:

-

1.

Determined the relationship between the indicators of egg contents and ΔW during storage.

-

2.

Measured the following parameters, obtained without violating the egg integrity: W, its linear dimensions, i.e., length (L) and maximum breadth (B), volume (V), density (D), surface area (S), and air cell dimensions.

-

3.

Carried out a correlation analysis of dependences of ΔW during storage and the measured parameters of eggs.

-

4.

Built a predictive model for calculating ΔW during storage depending on the complex of the most significant non-destructive parameters.

Material and Methods

The planned studies were designed to be more exploratory in nature, as a result of which they required a thorough and careful approach in determining a large number of analytical measurements. As a result, we were forced to limit the size of the experimental sample. A total of forty five table eggs were examined here that were produced by Yasensvit LLC (Kyiv Region, Ukraine) from a flock of 23- to 35-week-old Hy-Line W36 laying hens. From the moment of egg laying to purchase, the eggs were stored at a temperature of 4 °C for three days. Each egg was weighed (W) using an electronic scale to the nearest 0.01 g, and their L and B were measured to the nearest 0.1 mm using a vernier caliper. All eggs were photographed (Narushin, Lu et al., 2020) and the distance (w) of the B axis shift from the center of the egg was measured from their images with an accuracy of 0.1 mm (Narushin, Romanov et al., 2020). The values of V and S were determined using the following calculation formulae from Narushin, Romanov et al. (2021):

where V is egg volume (cm3); S is its surface area (cm2); L is its length (cm); B is its maximum breadth (cm); and w is the distance between two vertical axes, one of which conforms to B and the other of which crosses the egg at L/2 (cm).

The air cell diameter (d) was measured by candling the egg and using a vernier caliper with an accuracy of 0.1 mm in two measurements, after which the results were averaged. The process of measuring d is depicted in Fig. 1.

The values of air cell height (h) and volume (Vac) were calculated using the following formulae from Narushin, Romanov, Griffin et al. (2021):

where h is air cell height (cm), d is its diameter (cm), and Vac is its volume (cm3).

After performing the non-invasive evaluation, the eggs were divided into three groups. Group 1 (20 eggs) was used for destructive measurements. The eggs were broken, their contents were poured onto a flat surface, and H and the diameter of yolk (Dy) were measured with an accuracy of 0.1 mm. Based on the measured parameters H and Dy, the egg quality indices, i.e., HU (Haugh, 1937) and EQI (Narushin, Romanov, Griffin et al., 2021), were computed as follows:

where H is the height of thick albumen (mm in Eq. 5 and cm in Eq. 6), W is egg weight (g), G is the gravitational constant equal to 32.2, and Dy is yolk diameter (cm).

The egg shell was thoroughly washed from the remains of the contents without separating the shell membrane, dried in air for a day, and weighed (Ws) with an accuracy of 0.01 g. The thickness of the shell along with the shell membrane (T) was measured with a micrometer with an accuracy of 0.01 mm at six points, after which the measurement results were averaged. Shell volume (Vs) was calculated using the following formula from Narushin et al. (2022):

where Vs is shell volume (cm3), L and B are egg length and maximum breadth (cm), respectively, and T is mean shell thickness (cm).

Characteristics of egg interior were evaluated as the following differences between the corresponding values of the whole egg and the shell: volume, Vi = V − Vs; and weight, Wi = W − Ws. Density of interior, Di, was calculated as the ratio of Wi to Vi.

Eggs of Group 2 (15 pieces) and Group 3 (10 pieces) were stored for 8 and 15 days, respectively, at ambient temperature of 18 °C with daily weighing. At the end the storage period, the eggs were broken and subjected to a destructive assessment of internal parameters similar to Group 1 as described above. The ΔW parameter was defined as the difference between W values before and after storage.

The significance of the results between groups was assessed using Student’s t-test and the tightness of the relationship using the Pearson correlation coefficient. Given the limited nature of the planned samples, special attention was paid to the issue of their representativeness. To do this, we used the Cochran (1977) calculation formula for minimum sample and an assumption on the margin of error (E). Following Cochran (1977), the level of 5% (0.05) conformed to the acceptable value of Emax. Accordingly, we converted the Cochran (1977) calculation formula to the following equation:

where n is the number of eggs in the particular sample, N is the total number of eggs in the batch being investigated, and σy is the standard deviation of the studied parameter, in this instance the sex ratio of ducklings in each sample.

The STATISTICA 5.5 program (StatSoft, Inc./TIBCO, Palo Alto, CA, USA) and computational Excel tools were used to process the data obtained.

Results and Discussion

The results of examination of the three egg groups are presented in Table 1. These data indicated that the differences in major external and internal egg parameters between the three groups were insignificant, except for H, Dy, HU, and EQI. Notably, the difference in the Dy values was significant for Groups 2 and 3 only in comparison with Group 1, but not between themselves. Obviously, the yolk grew in diameter and, accordingly, lost its height at the first stages of storage, after which these parameters remained unchanged. The process of so-called spreading out of the yolk was explained by Fromm and Matrone (1962). According to them, the yolk’s flattening occurs due to the vitelline membrane’s thinning. Since, judging by the data we obtained, the weakening of the vitelline membrane occurred unevenly, the Dy parameter can carry an equally important informational component in a comprehensive pattern of changes in the quality of egg contents. In this regard, we believe that EQI that takes into account both H and Dy (Narushin, Romanov, Griffin et al., 2021) is much preferable for such studies than HU.

The representativeness assessment showed that the size of each sample was clearly significant. The criterion of E ≤ 0.05 was entirely satisfied because the value of E equaled 0.0008. As a result, it was feasible to guarantee the accuracy of the statistical processing of the outcomes of the conducted observations.

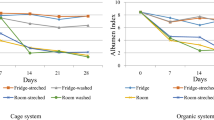

Consequently, having the necessary set of initial parameters (Table 1), we were able to accomplish the first task we set with regard to the adequacy of the relationship between ΔW during storage and quality indicators of the egg contents, i.e., H, HU, and EQI. These relationships are represented as graphical dependencies in Fig. 2.

All these dependencies characterized a steady linear drop in each of the quality indicators of the egg contents in proportion to the amount of weight shrinkage during storage. Although the used three time points were not enough to carry out a full-fledged approximation of the obtained data, we decided to describe these dependencies with the following mathematical formulae:

with \(R^2=0.9969\;(p<0.01);\)

with \(R^2=0.9981\;(p<0.01);\)

with \(R^2=0.9995\;(p<0.01)\).

Thus, having data on ΔW during egg storage and according to formulae (9) to (11), we were able to carry out an appropriate recalculation for the main egg quality characteristics and, based on these, decide on the termination or further extension of the storage period. In our case, these dependences were necessary in order to verify the adequacy of choosing ΔW as an indirect characteristic of egg quality in the further analysis of the experimental results. The obtained relationships are in full agreement with the results of other authors (e.g., Oleforuh-Okoleh & Eze, 2016; Park et al., 2003; Samli et al., 2005; Scott & Silversides, 2000).

The next stage of this analysis is aimed at assessing the correlations between ΔW during storage and other egg parameters that can be determined using non-invasive analytical methods. The purpose of this analysis was to select a set of parameters whose values can be used to predict the ability of an egg to withstand a certain period of storage without a dramatic deterioration in its properties. As a result of the literature review, it was found that W (e.g., Feddern et al., 2017; Scott & Silversides, 2000; Washburn, 1990) and air cell dimensions (e.g., Aboonajmi et al., 2010, 2015; Drabik et al., 2021; Ragni et al., 2007, 2010) have the greatest potential for this analysis. However, in addition to these non-destructive parameters, we considered it interesting to include for analysis a number of other indicators obtained as a result of destructive experiments. In particular, these included shell characteristics and Di. The development of computational methods (Nordstrom & Ousterhou, 1982; Narushin, 1997, 1998) and instrumentation (Kibala et al., 2015; Narushin et al., 2004; Narushin, Chausov et al., 2021; Schoorl & Boersma, 1962) to determine the shell characteristics without its destruction, as well as our recent study (Narushin et al., 2023) on the calculation of Di based on the external egg parameters and elastic shell deformation, suggest that the use of these parameters to predict the egg shelf life can be very promising.

The results of the correlation analysis are presented in Table 2. Considering the complex prediction of egg storage during the two studied periods (8 and 15 days), the V/S parameter showed the highest correlation (0.666 and 0.840, respectively). Judging by the obtained correlation coefficients (0.712 and 0.835, respectively), B can also be a very promising parameter. However, B is included in the calculation formulae for determining V and S (Eqs. 1 and 2, respectively); therefore, we suggested that the integral indicator V/S that combined few values was much more suitable for the prediction purpose. Moreover, the significant correlation for B could be due to the experimental sample, which also testified in favor of the integral estimate V/S. From a physical point of view, the influence of the V/S ratio on ΔW during storage is also quite reasonable. The V parameter characterizes the reservoir of potential moisture that will evaporate during storage, thereby reducing W. At the same time, the S parameter, as the area of potential evaporation, has a direct impact on the moisture loss.

Considering the significant relationship between ΔW and V/S, we assumed that the W/S ratio could also have no less effect on the weight shrinkage process. Taking into account the fact that, in the physical sense, W (in addition to V) also includes D, the W/S ratio is an even more complex parameter than V/S. However, the correlation analysis (Table 2) showed rather low and insignificant coefficient values for W/S in both studied storage periods (0.264 and 0.493, respectively). Additionally, the insignificant relationship between ΔW and Di was rather unexpected for us, although it would be quite logical to assume that the shrinkage of the inner liquid part of the egg directly affects the change in Di. We suggest that the methodology for determining Di requires a further and more careful study in order to improve the accuracy. Of practical interest could be the fact that, among the parameters characterizing the air cell, the highest correlation was noted for d (0.432 and 0.410, respectively), although these coefficients were insignificant. Realizing that just numbers of correlation coefficients do not always contribute to the best understanding of relationships between parameters, we decided to visualize them using graphical dependencies (Fig. 3) for the first storage period (8 days).

At the next stage, we tried to increase the potential for predicting ΔW during storage through a multivariate analysis of this process. As influencing parameters, we chose various combinations of W, V/S, and d, the relationship of which can be presented using the following formulae:

with \(R^2=0.571\;(p<0.01);\)

with \(R^2=0.529\;(p<0.01).\)

We also decided to test how much the prediction accuracy will change if V and S are used separately, instead of V/S ratio:

with R2 = 0.573 (p < 0.01).

In formulae (12) to (14), W was taken in g, V in cm3, S in cm2, and d in cm.

Since the obtained determination coefficient for Eq. 13 (R2 = 0.573) was not too much different from that for Eq. 11 (R2 = 0.571) and the exponents for V and S were practically identical and differed only in opposite signs, we decided to recommend dependence (11) for practical use.

We also made a similar calculation using the same data for the 15-day storage period. The result was expressed by the following dependence:

with \(R^2=0.847\;(p<0.01).\)

Thus, having a set of initial egg data, including W, V/S, and d, we can, with a sufficient degree of accuracy (R = 0.756 for Eq. 11 and R = 0.921 for Eq. 14, both significant at p < 0.01), estimate ΔW during storage for 8 (Eq. 12) or 15 (Eq. 15) days and, as a result, decide on the potential of each particular egg to its acceptable weight shrinkage.

Comparing the obtained results of egg parameters that affect the process of changing its qualitative characteristics and based on the literature data, it can be argued that, in addition to W and air cell size, an important factor is the V/S ratio.

At the same time, according to our assumption, further research in this field should focus more on the parameters of the eggs themselves, without reference to the breeds and characteristics of laying hens. Without a doubt, the age and other characteristics of the birds impact the morphological and physical parameters of the eggs. In particular, egg parameters such as W, V/S, and d have the most direct effect on the permissible periods of egg storage.

The fundamental importance in applying scientific developments to their industrial implementation is the availability of instrumental and technological base. Engineering support for egg sorting techniques before storage is a completely solvable task at a modern stage of technology development. Currently, there are many proven methods applicable to this need, e.g., machine vision-based systems with more or less complex components for egg grading using such properties as defects and size of eggs (Dehrouyeh et al., 2010; Garcia-Alegre et al., 1997, 2000; Omid et al., 2013; Patel et al., 1994). Similar systems have been developed to determine V and S (Narushin, Lu et al., 2020; Nyalala et al., 2021). Also, ovoscopy systems equipped with various additional devices, like ovoscope and ultrasonographic imaging techniques (Önler et al., 2017), can be used to determine the air cell parameters. Furthermore, such engineering systems are available not only as research samples, but are also actively used in industry, e.g., egg sorting machines produced by Titus & Jack GmbH (Neckargemünd, Germany; Titus & Jack, 2023) and automatic egg candling machines that can be used to determine the air cell size (e.g., Nabel, 2022).

Conclusions

Based on the results of the research carried out and presented here, the following conclusions can be drawn:

-

(i)

Pre-storage egg sorting technology based on the non-invasive analytical principles we described here is innovative and promising to minimize waste and ensure the best quality of the final produce.

-

(ii)

The ΔW parameter during storage is an effective indicator that can be used for a robust estimate of the quality of the egg contents.

-

(iii)

The EQI parameter is preferable than HU for assessing and controlling the quality of egg contents during storage, as it takes into account not only the change in H but also the condition of the yolk. Given the varying degrees of degradation of these parameters during storage, the use of only one of them can lead to erroneous conclusions about the actual egg quality.

-

(iv)

The combination of W, V/S, and d allows to estimate, with a reasonable degree of accuracy, the possible ΔW value during storage. This value can be calculated using formulae (12) or (15) derived on the basis of the present study. The expediency of performing similar experiments on other samples of chicken or other poultry eggs cannot be ruled out.

Data Availability

Data will be made available upon request.

References

Abdel-Nour, N., Ngadi, M., Prasher, S., & Karimi, Y. (2011). Prediction of egg freshness and albumen quality using visible/near infrared spectroscopy. Food and Bioprocess Technology, 4, 731–736. https://doi.org/10.1007/s11947-009-0265-0

Aboonajmi, M., Akram, A., Nishizu, T., Kondo, N., Setarehdan, S. K., & Rajabipour, A. (2010). An ultrasound based technique for the determination of poultry egg quality. Research in Agricultural Engineering, 56(1), 26–32. https://doi.org/10.17221/18/2009-rae

Aboonajmi, M., Setarehdan, S. K., Akram, A., Nishizu, T., & Kondo, N. (2014). Prediction of poultry egg freshness using ultrasound. International Journal of Food Properties, 17(9), 1889–1899. https://doi.org/10.1080/10942912.2013.770015

Aboonajmi, M., Saberi, A., Abbasian Najafabadi, T., & Kondo, N. (2015). Quality assessment of poultry egg based on Vis-NIR spectroscopy and RBF networks. International Journal of Food Properties, 19(December), 1163–1172. https://doi.org/10.1080/10942912.2015.1075215

Al-Hajo, N. N. A., Oleiwi, W. S., Hadel, S. N., Ahmed, A.-R. S., & Safaa, H. F. (2010). The effect of coating and storage time on internal quality of quail eggs in room temperature 2- shellac. Anbar Journal of Agricultural Sciences, 8(4), 1-e–6-e.

Alleoni, A. C. C., & Antunes, A. J. (2001). Haugh unit as a measure of the quality of hen eggs stored under refrigeration. Scientia Agricola, 58(4), 681–685. https://doi.org/10.1590/S0103-90162001000400005

Almeida e Silva, T., Gorup, L. F., de Araújo, R. P., Fonseca, G. G., Martelli, S. M., de Oliveira, K. M. P., Faraoni, L. H., de Arruda, E. G. R., Gomes, R. A. B., da Silva, C. H. M., & de Arruda, E. J. (2020). Synergy of biodegradable polymer coatings with quaternary ammonium salts mediating barrier function against bacterial contamination and dehydration of eggs. Food and Bioprocess Technology, 13, 2065–2081. https://doi.org/10.1007/s11947-020-02545-3

Ayeni, A. O., Agbede, J. O., Igbasan, F. A., Onibi, G. E., & Adegbenro, M. (2020). Effects of storage periods and positioning during storage on hatchability and weight of the hatched chicks from different egg sizes. Bulletin of the National Research Centre, 44, 101. https://doi.org/10.1186/s42269-020-00362-4

Berardinelli, A., Giunchi, A., Guarnieri, A., Pezzi, F., & Ragni, L. (2005). Shell egg albumen height assessment by FT-NIR spectroscopy. Transactions of the ASAE, 48(4), 1423–1428. https://doi.org/10.13031/2013.19167

Brake, J., Walsh, T. J., Benton, C. E., Jr., Petitte, J. N., Meijerhof, R., & Peñalva, G. (1997). Egg handling and storage. Poultry Science, 76(1), 144–151. https://doi.org/10.1093/ps/76.1.144

Ching, C. T. S., Wang, C.-K., Tang, P.-C., Ha, M.-K., Li, C., Chiu, H.-N., Yao, F.Y.-D., Nhan, N. C., Hieu, N. V., & Phan, T.-L. (2023). Bioimpedance-measurement-based non-invasive method for in ovo chicken egg sexing. Biosensors, 13(4), 440. https://doi.org/10.3390/bios13040440

Cochran, W. G. (1977). Sampling techniques (3rd ed.). John Wiley & Sons.

Coronel-Reyes, J., Ramirez-Morales, I., Fernandez-Blanco, E., Rivero, D., & Pazos, A. (2018). Determination of egg storage time at room temperature using a low-cost NIR spectrometer and machine learning techniques. Computers and Electronics in Agriculture, 145, 1–10. https://doi.org/10.1016/j.compag.2017.12.030

Dehrouyeh, M. H., Omid, M., Ahmadi, H., Mohtasebi, S. S., & Jamzad, M. (2010). Grading and quality inspection of defected eggs using machine vision. International Journal of Advanced Science and Technology, 16, 43–50.

Drabik, K., Próchniak, T., Kasperek, K., & Batkowska, J. (2021). The use of the dynamics of changes in table eggs during storage to predict the age of eggs based on selected quality traits. Animals, 11, 3192. https://doi.org/10.3390/ani11113192

Dudusola, I. O. (2009). Effects of storage methods and length of storage on some quality parameters of Japanese quail eggs. Tropicultura, 27(1), 45–48.

Feddern, V., Prá, M. C. D., Mores, R., da Nicoloso, R., & S., Coldebella, A., & Abreu, P. G. de. (2017). Egg quality assessment at different storage conditions, seasons and laying hen strains. Ciência e Agrotecnologia, 41(3), 322–333. https://doi.org/10.1590/1413-70542017413002317

Fromm, D., & Matrone, G. (1962). A rapid method for evaluating the strength of the vitelline membrane of the hen’s egg yolk. Poultry Science, 41(5), 1516–1521. https://doi.org/10.3382/ps.0411516

Garcia-Alegre, M. C., Enciso, J., Ribeiro, A., & Guinea, D. (1997, September). To an automatic visual inspection of egg-shell defects. In F. Yuste et al. (Eds), International workshop on robotics & automated machinery for bio-robotics (pp. 255–260). Gandia, Spain.

Garcia-Alegre, M. C., Ribeiro, A., Guinea, D., & Cristobal, G. (2000, January). Eggshell defects detection based on color processing. In K. W. Tobin Jr., J. C. Stover (Eds.), Proceedings of SPIE, machine vision applications in industrial inspection VIII (Volume 3966, pp. 280–287). The International Society for Optical Engineering: San Jose, CA, USA. https://doi.org/10.1117/12.380082

Giampietro-Ganeco, A., Borba, H., Scatolini-Silva, A. M., Boiago, M. M., de Souza, P. A., & de Mello, J. L. M. (2015). Quality assessment of eggs packed under modified atmosphere. Ciência e Agrotecnologia, 39(1), 82–88. https://doi.org/10.1590/S1413-70542015000100010

Gogo, J. A., Atitwa, B. E., Gitonga, C. N., & Mugo, D. M. (2021). Modelling conditions of storing quality commercial eggs. Heliyon, 7(8), e07868. https://doi.org/10.1016/j.heliyon.2021.e07868

Hagan, J. K., Adjei, I. A., & Baah, A. (2013). Effects of extended period of storage and strain of layer on quality of chicken eggs. Journal of Science and Technology, 33(2), 1–11. https://doi.org/10.4314/just.v33i2.1

Haugh, R. R. (1937). The Haugh unit for measuring egg quality. U.S. Egg & Poultry Magazine, 43, 552–573.

Hinton, H. R. (1968). Storage of eggs. In T. C. Carter (Ed.), Egg quality: a study of the hen’s egg (pp. 251–261). Oliver and Boyd: Edinburgh, UK.

Imai, C. (1981). Effect of coating eggs on storage stability. Poultry Science, 60(1), 2053–2061. https://doi.org/10.3382/ps.0602053

Jenkins, M. K., & Pennington, M. E. (1919). Commercial preservation of eggs by cold storage. United States Department of Agriculture Bulletin, 755, 1–35.

Jin, Y. H., Lee, K. T., Lee, W. I., & Han, Y. K. (2011). Effects of storage temperature and time on the quality of eggs from laying hens at peak production. Asian-Australasian Journal of Animal Sciences, 24(2), 279–284. https://doi.org/10.5713/ajas.2011.10210

Karoui, R., Kemps, B., Bamelis, F., De Ketelaere, B., Decuypere, E., & De Baerdemaeker, J. (2006). Methods to evaluate egg freshness in research and industry: A review. European Food Research and Technology, 222, 727–732. https://doi.org/10.1007/s00217-005-0145-4

Karoui, R., Nicolaï, B., & De Baerdemaeker, J. (2008). Monitoring the egg freshness during storage under modified atmosphere by fluorescence spectroscopy. Food and Bioprocess Technology, 1, 346–356. https://doi.org/10.1007/s11947-007-0011-4

Khaliduzzaman, A., Konagaya, K., Suzuki, T., Kashimori, A., Kondo, N., & Ogawa, Y. (2020). A nondestructive eggshell thickness measurement technique using terahertz waves. Scientific Reports, 10, 1052. https://doi.org/10.1038/s41598-020-57774-5

Khan, M. J., Khan, S. H., Bukhsh, A., & Amin, M. (2014). The effect of storage time on egg quality and hatchability characteristics of Rhode Island Red (RIR) hens. Veterinarski Arhiv, 84(3), 291–303.

Kibala, L., Rozempolska-Rucinska, I., Kasperek, K., Zieba, G., & Lukaszewicz, M. (2015). Ultrasonic eggshell thickness measurement for selection of layers. Poultry Science, 94(10), 2360–2363. https://doi.org/10.3382/ps/pev254

Kim, T. H., Kim, J. H., Kim, J. Y., & Oh, S. E. (2022). Egg freshness prediction model using real-time cold chain storage condition based on transfer learning. Foods, 11(19), 3082. https://doi.org/10.3390/foods11193082

Lall, J. G., Santra, A. K., & Sahu, S. S. (2018). Effect of storage period on internal and external parameters of Deshi Chicken fowl. Journal of Applied and Natural Science, 10(1), 41–44. https://doi.org/10.31018/jans.v10i1.1575

Lin, H., Zhao, J., Sun, L., Bi, X. K., & Cai, J. (2015, July). Effective variables selection in eggs freshness graphically oriented local multivariate analysis using NIR spectroscopy. In Proceedings of the international conference on chemical, material and food engineering, advances in engineering research series (Volume 22, pp. 13–18). Atlantis Press: Dordrecht, The Netherlands. https://doi.org/10.2991/cmfe-15.2015.4

Liu, L., & Ngadi, M. O. (2013). Detecting fertility and early embryo development of chicken eggs using near-infrared hyperspectral imaging. Food and Bioprocess Technology, 6, 2503–2513. https://doi.org/10.1007/s11947-012-0933-3

Nabel. (2022). Egg candling machine. Retrieved from https://nabel.com/products/evs/. Accessed June 3, 2023

Narushin, V. G. (1997). Non-destructive measurements of egg parameters and quality characteristics. World’s Poultry Science Journal, 53(2), 141–153. https://doi.org/10.1079/WPS19970014

Narushin, V. G. (1998). Mathematical algorithm for quality control in egg production. Acta Horticulturae, 476, 345–348. https://doi.org/10.17660/ActaHortic.1998.476.40

Narushin, V. G., Van Kempen, T. A., Wineland, M. J., & Christensen, V. L. (2004). Comparing infrared spectroscopy and egg size measurements for predicting eggshell quality. Biosystems Engineering, 87(3), 101–107. https://doi.org/10.1016/j.biosystemseng.2003.12.006

Narushin, V. G., Lu, G., Cugley, J., Romanov, M. N., & Griffin, D. K. (2020). A 2-D imaging-assisted geometrical transformation method for non-destructive evaluation of the volume and surface area of avian eggs. Food Control, 112, 107112. https://doi.org/10.1016/j.foodcont.2020.107112

Narushin, V. G., Romanov, M. N., Lu, G., Cugley, J., & Griffin, D. K. (2020). Digital imaging assisted geometry of chicken eggs using Hügelschäffer’s model. Biosystems Engineering, 197, 45–55. https://doi.org/10.1016/j.biosystemseng.2020.06.008

Narushin, V. G., Romanov, M. N., & Griffin, D. K. (2021). A novel Egg Quality Index as an alternative to Haugh unit score. Journal of Food Engineering, 289, 110176. https://doi.org/10.1016/j.jfoodeng.2020.110176

Narushin, V. G., Romanov, M. N., Lu, G., Cugley, J., & Griffin, D. K. (2021). How oviform is the chicken egg? New mathematical insight into the old oomorphological problem. Food Control, 119, 107484. https://doi.org/10.1016/j.foodcont.2020.107484

Narushin, V. G., Romanov, M. N., & Griffin, D. K. (2021). Non-destructive evaluation of the volumes of egg shell and interior: Theoretical approach. Journal of Food Engineering, 300, 110536. https://doi.org/10.1016/j.jfoodeng.2021.110536

Narushin, V. G., Chausov, M. G., Shevchenko, L. V., Pylypenko, A. P., Davydovych, V. A., Romanov, M. N., & Griffin, D. K. (2021). Shell, a naturally engineered egg packaging: Estimated for strength by non-destructive testing for elastic deformation. Biosystems Engineering, 210, 235–246. https://doi.org/10.1016/j.biosystemseng.2021.08.023

Narushin, V. G., Griffin, A. W., Romanov, M. N., & Griffin, D. K. (2022). Measurement of the neutral axis in avian eggshells reveals which species conform to the golden ratio. Annals of the New York Academy of Sciences, 1517(1), 143–153. https://doi.org/10.1111/nyas.14895

Narushin, V. G., Kent, J. P., Salamon, A., Romanov, M. N., & Griffin, D. K. (2023). Density of egg interior: Looking inside an egg while keeping it intact. Innovative Food Science & Emerging Technologies, 87, 103387. https://doi.org/10.1016/j.ifset.2023.103387

Nongtaodum, S., Jangchud, A., Jangchud, K., Dhamvithee, P., No, H. K., & Prinyawiwatkul, W. (2013). Oil coating affects internal quality and sensory acceptance of selected attributes of raw eggs during storage. Journal of Food Science, 78(2), S329–S335. https://doi.org/10.1111/1750-3841.12035

Nordstrom, J. D., & Ousterhout, L. E. (1982). Estimation of shell weight and shell thickness from egg specific gravity and egg weight. Poultry Science, 61(10), 1991–1995. https://doi.org/10.3382/ps.0611991

Nyalala, I., Okinda, C., Kunjie, C., Korohou, T., Nyalala, L., & Chao, Q. (2021). Weight and volume estimation of poultry and products based on computer vision systems: A review. Poultry Science, 100(5), 101072. https://doi.org/10.1016/j.psj.2021.101072

Okonkwo, J. C., Chiamaka, O., Okonkwo, I. F., & Marire, B. N. (2021). Effect of storage method and storage duration on chicken egg quality. International Journal of Environmental & Agriculture Research, 7(8), 13–16. https://doi.org/10.5281/zenodo.5335999

Oleforuh-Okoleh, V. U., & Eze, J. (2016). Effect of storage period and method on internal egg quality traits of the Nigerian native chicken. Livestock Research for Rural Development, 28(6), 115. Retrieved from http://www.lrrd.org/lrrd28/6/olef28115.html. Accessed June 3, 2023

Omid, M., Soltani, M., Dehrouyeh, M. H., Mohtasebi, S. S., & Ahmadi, H. (2013). An expert egg grading system based on machine vision and artificial intelligence techniques. Journal of Food Engineering, 118(1), 70–77. https://doi.org/10.1016/j.jfoodeng.2013.03.019

Önler, E., Çelen, I. H., Gulhan, T., & Boynukara, B. (2017). A study regarding the fertility discrimination of eggs by using ultrasound. Indian Journal of Animal Research, 51(2), 322–326. https://doi.org/10.18805/ijar.v0iOF.4561

Park, Y. S., Yoo, I. J., Jeon, K. H., Kim, H. K., Chang, E. J., & Oh, H. I. (2003). Effects of various eggshell treatments on the egg quality during storage. Asian-Australasian Journal of Animal Sciences, 16(8), 1224–1229. https://doi.org/10.5713/ajas.2003.1224

Patel, V. C., McClendon, R. W., & Goodrum, J. W. (1994). Crack detection in eggs using computer vision and neural networks. AI Applications, 8(2), 21–31.

Ragni, L., Al-Shami, A., Berardinelli, A., Mikhaylenko, G., & Tang, J. (2007). Quality evaluation of shell eggs during storage using a dielectric technique. Transactions of the ASABE, 50(4), 1331–1340. https://doi.org/10.13031/2013.23610

Ragni, L., Cevoli, C., & Berardinelli, A. (2010). A waveguide technique for non-destructive determination of egg quality parameters. Journal of Food Engineering, 100(2), 343–348. https://doi.org/10.1016/j.jfoodeng.2010.04.020

Renukadevi, B., Himali, H. M. C., & Silva, G. L. L. P. (2018). Quality and shell integrity of Japanese quail eggs: An assessment during storage and at market. Sri Lanka Journal of Food and Agriculture, 4(1), 27–34. https://doi.org/10.4038/sljfa.v4i1.55

Robinson, D. S. (1987). The chemical basis of albumen quality. In R. G. Wells & C. G. Belyavin (Eds.), Egg quality: Current problems and recent advances, Poultry Science Symposium Series (pp. 179–191). Butterworths.

Romanoff, A. L., & Romanoff, A. J. (1949). The avian egg. John Wiley & Sons Inc.

Salamon, A. (2020). Fertility and hatchability in goose eggs: A review. International Journal of Poultry Science, 19(2), 51–65. https://doi.org/10.3923/ijps.2020.51.65

Samli, H. E., Agma, A., & Senkoylu, N. (2005). Effects of storage time and temperature on egg quality in old laying hens. Journal of Applied Poultry Research, 14(3), 548–553. https://doi.org/10.1093/japr/14.3.548

Schoorl, P., & Boersma, H. Y. (1962). Research on the quality of the egg shell. In Proceedings of the 12th World’s Poultry Congress (pp. 432–435). Sydney, Australia: World's Poultry Science Association.

Scott, T. A., & Silversides, F. G. (2000). The effect of storage and strains of hen on egg quality. Poultry Science, 79(12), 1725–1729. https://doi.org/10.1093/ps/79.12.1725

Shenstone, F. S. (1968). The gross composition, chemistry and physicochemical basis of organization of the yolk and white. In T. C. Carter (Ed.), Egg quality: A study of the hen’s egg (pp. 26–58). Oliver and Boyd: Edinburgh, UK.

Stojčić, M. Đ, & Perić, L. (2018). Influence of the storage period on the quality characteristics of table eggs. Contemporary Agriculture, 67(3–4), 202–206. https://doi.org/10.1515/contagri-2018-0029

Tabidi, M. H. (2011). Impact of storage period and quality on composition of table egg. Advances in Environmental Biology, 5(5), 856–861.

Titus & Jack GmbH. (2023). Eiersortiermaschinen: optimierung und Automatisierung von Verarbeitung- und Verpackungsprozessen von Eiern. Retrieved from https://www.eiersortiermaschinen.de/en/. Accessed June 3, 2023

Wang, J., Omana, D. A., & Wu, J. (2012). Effect of shell eggs storage on ovomucin extraction. Food and Bioprocess Technology, 5, 2280–2284. https://doi.org/10.1007/s11947-011-0558-y

Washburn, K. W. (1990). Genetic variation in egg composition. In R. D. Crawford (Ed.), Poultry breeding and genetics (pp. 781–804). Elsevier Science Publisher, B. V.

Yimenu, S. M., Kim, J. Y., & Kim, B. S. (2017). Prediction of egg freshness during storage using electronic nose. Poultry Science, 96(10), 3733–3746. https://doi.org/10.3382/ps/pex193

Zhao, J., Lin, H., Chen, Q., Huang, X., Sun, Z., & Zhou, F. (2010). Identification of egg’s freshness using NIR and support vector data description. Journal of Food Engineering, 98(4), 408–414. https://doi.org/10.1016/j.jfoodeng.2010.01.018

Author information

Authors and Affiliations

Contributions

Valeriy G. Narushin: conceptualization, data curation, formal analysis, investigation, methodology, resources, software, visualization, writing—original draft, and writing—review and editing. Michael N. Romanov: project administration, validation, writing—original draft, and writing—review and editing. Attila Salamon: validation and writing—review and editing. John P. Kent: validation and writing—review and editing.

Corresponding authors

Ethics declarations

Ethics Approval

Only measuring eggs was done for this study; no experiments on animals were used.

Competing Interests

The authors declare no conflicts of interest.

Permission to Reproduce Material From Other Sources

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Narushin, V.G., Romanov, M.N., Salamon, A. et al. An Innovative Non-destructive Technology for Controlling the Storage Period of Chicken Eggs Using Egg Parameters. Food Bioprocess Technol (2023). https://doi.org/10.1007/s11947-023-03290-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11947-023-03290-z