Abstract

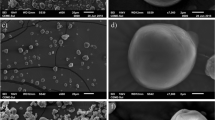

In this study, Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus as yoghurt bacteria were encapsulated by electrospraying using mixture solutions of whey protein isolate and inulin. The yoghurt capsules with the highest encapsulation efficiency and tolerance to low pH were used in stirred yoghurt manufacture. The viability of yoghurt bacteria in the stirred yoghurts with and without yoghurt bacteria capsules during 30-day storage and following passage through an in vitro digestive model, and physicochemical properties of the stirred yoghurts during the storage were assessed. Yoghurt bacteria were not found in the yoghurt without the capsules after its passage through the digestive model, while viable counts were above 6 log cfu/g for S. thermophilus and L. delbrueckii subsp. bulgaricus in the yoghurts with the capsules after their passage through the digestive model, regardless of the storage period of the yoghurts. No significant difference was found in syneresis among the yoghurts, but hardness and apparent viscosity of the yoghurts with the capsules were lower than that without the capsules.

Similar content being viewed by others

Data Availability

The data is available upon request to the corresponding author.

References

Ajlouni, S., Ranadheera, C. S., & Chua, E. L. (2021). Encapsulation increases the in vitro bioaccessibility of probiotics in yoghurt. International Journal of Dairy Technology, 74, 118–127. https://doi.org/10.1111/1471-0307.12746

Alehosseini, A., Sarabi-Jamab, M., Ghorani, B., & Kadkhodaee, R. (2019). Electro-encapsulation of Lactobacillus casei in high-resistant capsules of whey protein containing transglutaminase enzyme. LWT - Food Science and Technology, 102, 150–158. https://doi.org/10.1016/j.lwt.2018.12.022

Amatayakul, T., Halmos, A. L., Sherkat, F., & Shah, N. P. (2006). Physical characteristics of yoghurts made using exopolysaccharide-producing starter cultures and varying casein to whey protein ratios. International Dairy Journal, 16, 40–51. https://doi.org/10.1016/j.idairyj.2005.01.004

Amiri, S., Teymorlouei, M. J., Bari, M. R., & Khaledabad, M. A. (2021). Development of Lactobacillus acidophilus LA5-loaded whey protein isolate/lactose bionanocomposite powder by electrospraying: A strategy for entrapment. Food Bioscience, 43, 101222. https://doi.org/10.1016/j.fbio.2021.101222

AOAC. (2000a). Solids (total) in milk, method no. 925.23. In W. Horowitz (Ed.), Official methods of analysis of AOAC International, 17th edn. AOAC International, Maryland, USA.

AOAC. (2000b). Protein nitrogen content of milk, method no. 991.22. In W. Horowitz (Ed.), Official methods of analysis of AOAC International, 17th edn. AOAC International, Maryland, USA.

AOAC. (2000c). Fat content of raw and pasteurized whole milk, method no. 2000c.18. In W. Horowitz (Ed.), Official methods of analysis of AOAC International, 17th edn. AOAC International, Maryland, USA.

AOAC. (2000d). Ash of milk, method no. 945.46. In W. Horowitz (Ed.), Official methods of analysis of AOAC International, 17th edn. AOAC International, Maryland, USA.

Atia, A., Gomaa, A., Fernandez, B., Subirade, M., & Fliss, I. (2018). Study and understanding behavior of alginate-inulin synbiotics beads for protection and delivery of antimicrobial-producing probiotics in colonic simulated conditions. Probiotics and Antimicrobial Proteins, 10, 157–167. https://doi.org/10.1007/s12602-017-9355-x

Atia, A., Gomma, A. I., Fliss, I., Beyssac, E., Garrait, G., & Subirade, M. (2017). Molecular and biopharmaceutical investigation of alginate–inulin synbiotic coencapsulation of probiotic to target the colon. Journal of Microencapsulation, 34, 171–184. https://doi.org/10.1080/02652048.2017.1313330

Bagheri, L., Madadlou, A., Yarmand, M., & Mousavi, M. E. (2013). Nanoencapsulation of date palm pit extract in whey protein particles generated via desolvation method. Food Research International, 51, 866–871. https://doi.org/10.1016/j.foodres.2013.01.058

Balasubramani, P., Palaniswamy, P. T., Visvanathan, R., Thirupathi, V., Subbarayan, A., & Maran, J. P. (2015). Microencapsulation of garlic oleoresin using maltodextrin as wall material by spray drying technology. International Journal of Biological Macromolecules, 72, 210–217. https://doi.org/10.1016/j.ijbiomac.2014.08.011

Ballesta, S., Velasco, C., Borobio, M. V., Argüelles, F., & Perea, E. J. (2008). Yogures frescos frente a pasteurizados: Estudio comparativo de sus efectos sobre los parámetros microbiológicos, inmunológicos y el bienestar gastrointestinal. Enfermedades Infecciosasy Microbiologia Clinica, 26, 552–557. https://doi.org/10.1157/13128271

Bosnea, L. A., Moschakis, T., & Biliaderis, C. G. (2014). Complex coacervation as a novel microencapsulation technique to improve viability of probiotics under different stresses. Food and Bioprocess Technology, 7, 2767–2781. https://doi.org/10.1007/s11947-014-1317-7

Bradley, R. L., Arnold, E., Barbano, D. M., Semerad, R. G., Smith, D. E., & Vines, B. K. (1992). Standard methods for the examination of dairy products. In R. T. Marshall (Ed.), Chemical and Physical Methods (16th ed., pp. 433–531). American Public Health Assn.

Brigidi, P., Swennen, E., Vitali, B., Rossi, M., & Matteuzzi, D. (2003). PCR detection of Bifidobacterium strains and Streptococcus thermophilus in feces of human subjects after oral bacteriotherapy and yogurt consumption. International Journal of Food Microbiology, 81, 203–209. https://doi.org/10.1016/S0168-1605(02)00245-3

Cassani, L., Gomez-Zavaglia, A., & Simal-Gandara, J. (2020). Technological strategies ensuring the safe arrival of beneficial microorganisms to the gut: From food processing and storage to their passage through the gastrointestinal tract. Food Research International, 129, 108852. https://doi.org/10.1016/j.foodres.2019.108852

Chandan, R. C., Gandhi, A., & Shah, N. P. (2017). Yogurt: Historical background, health benefits, and global trade. Elsevier Inc.

Chandrapala, J., Oliver, C., Kentish, S., & Ashokkumar, M. (2012). Ultrasonics in food processing - Food quality assurance and food safety. Trends in Food Science & Technology, 26, 88–98. https://doi.org/10.1016/j.tifs.2012.01.010

Chen, H. Y., Li, X. Y., Liu, B. J., & Meng, X. H. (2017a). Microencapsulation of Lactobacillus bulgaricus and survival assays under simulated gastrointestinal conditions. Journal of Functional Foods, 29, 248–255. https://doi.org/10.1016/j.jff.2016.12.015

Chen, L., Yang, T., Song, Y., Shu, G., & Chen, H. (2017b). Effect of xanthan-chitosan-xanthan double layer encapsulation on survival of Bifidobacterium BB01 in simulated gastrointestinal conditions, bile salt solution and yogurt. LWT - Food Science and Technology, 81, 274–280. https://doi.org/10.1016/j.lwt.2017.04.005

Coghetto, C. C., Brinques, G. B., Siqueira, N. M., Pletsch, J., Soares, R. M. D., & Ayub, M. A. Z. (2016). Electrospraying microencapsulation of Lactobacillus plantarum enhances cell viability under refrigeration storage and simulated gastric and intestinal fluids. Journal of Functional Foods, 24, 316–326. https://doi.org/10.1016/j.jff.2016.03.036

Comak Gocer, E. M., Ergin, F., Kücükcetin, I. O., & Kücükcetin, A. (2021). In vitro gastrointestinal resistance of Lactobacillus acidophilus in some dairy products. Brazilian Journal of Microbiology, 52, 2319–2334. https://doi.org/10.1007/s42770-021-00590-4

Ćujić, N., Trifković, K., Bugarski, B., Ibrić, S., Pljevljakušić, D., & Šavikin, K. (2016). Chokeberry (Aronia melanocarpa L.) extract loaded in alginate and alginate/inulin system. Industrial Crops and Products, 86, 120–131. https://doi.org/10.1016/j.indcrop.2016.03.045

de Fernandes, R. V., & B., Borges, S. V., Botrel, D. A., & Oliveira, C. R. de. (2014). Physical and chemical properties of encapsulated rosemary essential oil by spray drying using whey protein-inulin blends as carriers. International Journal of Food Science and Technology, 49, 1522–1529. https://doi.org/10.1111/ijfs.12449

De Prisco, A., van Valenberg, H. J., Fogliano, V., & Mauriello, G. (2017). Microencapsulated starter culture during yoghurt manufacturing, effect on technological features. Food and Bioprocess Technology, 10, 1767–1777. https://doi.org/10.1007/s11947-017-1946-8

Del Campo, R., Bravo, D., Cantón, R., Ruiz-Garbajosa, P., García-Albiach, R., Montesi-Libois, A., Yuste, F. J., Abraira, V., & Baquero, F. (2005). Scarce evidence of yogurt lactic acid bacteria in human feces after daily yogurt consumption by healthy volunteers. Applied and Environmental Microbiology, 71, 547–549. https://doi.org/10.1128/AEM.71.1.547-549.2005

Dini, C., Islan, G. A., de Urraza, P. J., & Castro, G. R. (2012). Novel biopolymer matrices for microencapsulation of phages: Enhanced protection against acidity and protease activity. Macromolecular Bioscience, 12, 1200–1208. https://doi.org/10.1002/mabi.201200109

Drosou, C. G., Krokida, M. K., & Biliaderis, C. G. (2017). Encapsulation of bioactive compounds through electrospinning/electrospraying and spray drying: A comparative assessment of food-related applications. Drying Technology, 35, 139–162. https://doi.org/10.1080/07373937.2016.1162797

Duman, D., & Karadag, A. (2021). Inulin added electrospun composite nanofibres by electrospinning for the encapsulation of probiotics: Characterisation and assessment of viability during storage and simulated gastrointestinal digestion. International Journal of Food Science and Technology, 56, 927–935. https://doi.org/10.1111/ijfs.14744

El Kadri, H., Lalou, S., Mantzouridou, F., & Gkatzionis, K. (2018). Utilisation of water-in-oil-water (W1/O/W2) double emulsion in a set-type yogurt model for the delivery of probiotic Lactobacillus paracasei. Food Research International, 107, 325–336. https://doi.org/10.1016/j.foodres.2018.02.049

Elli, M., Callegari, M. L., Ferrari, S., Bessi, E., Cattivelli, D., Soldi, S., & Antoine, J. M. (2006). Survival of yogurt bacteria in the human gut. Applied and Environmental Microbiology, 72, 5113–5117. https://doi.org/10.1128/AEM.02950-05

Espírito Santo, A. P., Perego, P., Converti, A., & Oliveira, M. D. (2012). Influence of milk type and addition of passion fruit peel powder on fermentation kinetics, texture profile and bacterial viability in probiotic yoghurts. LWT - Food Science and Technology, 47, 393–399. https://doi.org/10.1016/j.lwt.2012.01.038

Gholami, A., Tavanai, H., & Moradi, A. R. (2011). Production of fibroin nanopowder through electrospraying. Journal of Nanoparticle Research, 13, 2089–2098. https://doi.org/10.1007/s11051-010-9965-7

Gilbet, A., & Turgeon, S.L. (2021). Studying stirred yogurt microstructure and its correlation to physical properties: A review. Food Hydrocolloids, 121, 106970. https://doi.org/10.1016/j.foodhyd.2021.106970

Gomez-Mascaraque, L. G., Morfin, R. C., Pérez-Masiá, R., Sanchez, G., & Lopez-Rubio, A. (2016). Optimization of electrospraying conditions for the microencapsulation of probiotics and evaluation of their resistance during storage and in-vitro digestion. LWT - Food Science and Technology, 69, 438–446. https://doi.org/10.1016/j.lwt.2016.01.071

Guénard-Lampron, V., St-Gelais, D., Villeneuve, S., & Turgeon, S. L. (2020). Effect of stirring operations on changes in physical and rheological properties of nonfat yogurts during storage. Journal of Dairy Science, 103, 2210–2214. https://doi.org/10.3168/jds.2019-16434

Guggisberg, D., Eberhard, P., & Albrecht, B. (2007). Rheological characterization of set yoghurt produced with additives of native whey proteins. International Dairy Journal, 17, 1353–1359. https://doi.org/10.1016/j.idairyj.2007.01.013

Hirsch, E., Pantea, E., Vass, P., Domján, J., Molnár, M., Suhajda, Á., Andersen, S. K., Vigh, T., Verreck, G., & Marosi, G. J. (2021). Probiotic bacteria stabilized in orally dissolving nanofibers prepared by high-speed electrospinning. Food and Bioproducts Processing, 128, 84–94. https://doi.org/10.1016/j.fbp.2021.04.016

Krasaekoopt, W., & Watcharapoka, S. (2014). Effect of addition of inulin and galactooligosaccharide on the survival of microencapsulated probiotics in alginate beads coated with chitosan in simulated digestive system, yogurt and fruit juice. LWT - Food Science and Technology, 57, 761–766. https://doi.org/10.1016/j.lwt.2014.01.037

Librán, C. M., Castro, S., & Lagaron, J. M. (2017). Encapsulation by electrospray coating atomization of probiotic strains. Innovative Food Science and Emerging Technologies, 39, 216–222. https://doi.org/10.1016/j.ifset.2016.12.013

López-Rubio, A., Sanchez, E., Wilkanowicz, S., Sanz, Y., & Lagaron, J. M. (2012). Electrospinning as a useful technique for the encapsulation of living bifidobacteria in food hydrocolloids. Food Hydrocolloids, 28, 159–167. https://doi.org/10.1016/j.foodhyd.2011.12.008

Maleki, O., Khaledabad, M. A., Amiri, S., Asl, A. K., & Makouie, S. (2020). Microencapsulation of Lactobacillus rhamnosus ATCC 7469 in whey protein isolate-crystalline nanocellulose-inulin composite enhanced gastrointestinal survivability. LWT- Food Science and Technology, 126, 109224. https://doi.org/10.1016/j.lwt.2020.109224

Meybodi, N. M., Mortazavian, A. M., Arab, M., & Nematollahi, A. (2020). Probiotic viability in yoghurt: A review of influential factors. International Dairy Journal, 109, 104793. https://doi.org/10.1016/j.idairyj.2020.104793

Moayyedi, M., Eskandari, M. H., Rad, A. H. E., Ziaee, E., Khodaparast, M. H. H., & Golmakani, M. T. (2018). Effect of drying methods (electrospraying, freeze drying and spray drying) on survival and viability of microencapsulated Lactobacillus rhamnosus ATCC 7469. Journal of Functional Foods, 40, 391–399. https://doi.org/10.1016/j.jff.2017.11.016

Mokoonlall, A., Nöbel, S., & Hinrichs, J. (2016). Post-processing of fermented milk to stirred products: Reviewing the effects on gel structure. Trends in Food Science & Technology, 54, 26–36. https://doi.org/10.1016/j.tifs.2016.05.012

Montgomery, D. C. (2017). Design and analysis of experiments. John Wiley & Sons Inc.

Niu, B., Shao, P., Luo, Y., & Sun, P. (2020). Recent advances of electrosprayed particles as encapsulation systems of bioactives for food application. Food Hydrocolloids, 99, 105376. https://doi.org/10.1016/j.foodhyd.2019.105376

Oikonomopoulou, V., Stramarkou, M., Plakida, A., & Krokida, M. (2022). Optimization of encapsulation of stevia glycosides through electrospraying and spray drying. Food Hydrocolloids, 131, 107854. https://doi.org/10.1016/j.foodhyd.2022.107854

Picot, A., & Lacroix, C. (2004). Encapsulation of bifidobacteria in whey protein-based microcapsules and survival in simulated gastrointestinal conditions and in yoghurt. International Dairy Journal, 14, 505–515. https://doi.org/10.1016/j.idairyj.2003.10.008

Pradeep Prasanna, H., & Charalampopoulos, D. (2019). Encapsulation in an alginate–goats’ milk–inulin matrix improves survival of probiotic Bifidobacterium in simulated gastrointestinal conditions and goats’ milk yoghurt. International Journal of Dairy Technology, 72, 132–141. https://doi.org/10.1111/1471-0307.12568

Premjit, Y., & Mitra, J. (2021). Optimization of electrospray-assisted microencapsulation of probiotics (Leuconostoc lactis) in soy protein isolate-oil particles using Box-Behnken experimental design. Food and Bioprocess Technology, 14, 1712–1729. https://doi.org/10.1007/s11947-021-02670-7

Quintana, G., Gerbino, E., & Gómez-Zavaglia, A. (2017). Okara: A nutritionally valuable by-product able to stabilize Lactobacillus plantarum during freeze-drying, spray-drying, and storage. Frontiers in Microbiology, 8, 641. https://doi.org/10.3389/fmicb.2017.00641

Rajam, R., & Anandharamakrishnan, C. (2015). Microencapsulation of Lactobacillus plantarum (MTCC 5422) with fructooligosaccharide as wall material by spray drying. LWT - Food Science and Technology, 60, 773–780. https://doi.org/10.1016/j.lwt.2014.09.062

Ramos-Hernández, J. A., Lagarón, J. M., Calderón-Santoyo, M., Prieto, C., & Ragazzo-Sánchez, J. A. (2021). Enhancing hygroscopic stability of agave fructans capsules obtained by electrospraying. Journal of Food Science and Technology, 58, 1593–1603. https://doi.org/10.1007/s13197-020-04672-3

Renan, M., & Guyomarc’h, F., Arnoult-Delest, V., Denis Paˆquet, D., rard Brule´, G., & Famelart, M. H. (2008). The rebodying of stirred yoghurt: Interactions between proteins. Journal of Dairy Research, 75, 450–456. https://doi.org/10.1017/S002202990800352X

Sabikhi, L., Babu, R., Thompkinson, D. K., & Kapila, S. (2010). Resistance of microencapsulated Lactobacillus acidophilus LA1 to processing treatments and simulated gut conditions. Food and Bioprocess Technology, 3, 586–593. https://doi.org/10.1007/s11947-008-0135-1

Sahin, Y. M., Su, S., Ozbek, B., Yücel, S., Pinar, O., Kazan, D., Oktar, F. N., Ekren, N., & Gunduz, O. (2018). Production and characterization of electrospun fish sarcoplasmic protein based nanofibers. Journal of Food Engineering, 222, 54–62. https://doi.org/10.1016/j.jfoodeng.2017.11.013

Shi, L. E., Li, Z. H., Li, D. T., Xu, M., Chen, H. Y., Zhang, Z. L., & Tang, Z. X. (2013). Encapsulation of probiotic Lactobacillus bulgaricus in alginate-milk microspheres and evaluation of the survival in simulated gastrointestinal conditions. Journal of Food Engineering, 117, 99–104. https://doi.org/10.1016/j.jfoodeng.2013.02.012

Shihata, A., & Shah, N. P. (2002). Influence of addition of proteolytic strains of Lactobacillus delbrueckii subsp. bulgaricus to commercial ABT starter cultures on texture of yoghurt, exopolysaccharide production and survival of bacteria. International Dairy Journal, 12, 765–772. https://doi.org/10.1016/S0958-6946(02)00071-7

Shinde, T., Sun-Waterhouse, D., & Brooks, J. (2014). Co-extrusion encapsulation of probiotic Lactobacillus acidophilus alone or together with apple skin polyphenols: An aqueous and value-added delivery system using alginate. Food and Bioprocess Technology, 7, 1581–1596. https://doi.org/10.1007/s11947-013-1129-1

Sohail, A., Turner, M. S., Coombes, A., & Bhandari, B. (2013). The viability of Lactobacillus rhamnosus GG and Lactobacillus acidophilus NCFM following double encapsulation in alginate and maltodextrin. Food and Bioprocess Technology, 6, 2763–2769. https://doi.org/10.1007/s11947-012-0938-y

Tabasco, R., Paarup, T., Janer, C., Peláez, C., & Requena, T. (2007). Selective enumeration and identification of mixed cultures of Streptococcus thermophilus, Lactobacillus delbrueckii subsp. bulgaricus, L. acidophilus, L. paracasei subsp. paracasei and Bifidobacterium lactis in fermented milk. International Dairy Journal, 17, 1107–1114. https://doi.org/10.1016/j.idairyj.2007.01.010

Tamime, A. Y., & Robinson, R. K. (2007). Tamime and Robinson’s Yoghurt: Science and Technology (3rd ed.) (Chapter 7). Cambridge, UK: CRC Press.

Veselá, K., Kumherová, M., Klojdová, I., Solichová, K., Horáčková, Š., & Plocková, M. (2019). Selective culture medium for the enumeration of Lactobacillus plantarum in the presence of Lactobacillus delbrueckii subsp. bulgaricus and Streptococcus thermophilus. LWT-Food Science and Technology, 114, 108365. https://doi.org/10.1016/j.lwt.2019.108365

Vodnar, D. C., Socaciu, C., Rotar, A. M., & Stãnilã, A. (2010). Morphology, FTIR fingerprint and survivability of encapsulated lactic bacteria (Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus) in simulated gastric juice and intestinal juice. International Journal of Food Science and Technology, 45, 2345–2351. https://doi.org/10.1111/j.1365-2621.2010.02406.x

Wang, L., Yu, X., Xu, H., Aguilar, Z. P., & Wei, H. (2016). Effect of skim milk coated inulin-alginate encapsulation beads on viability and gene expression of Lactobacillus plantarum during freeze-drying. LWT - Food Science and Technology, 68, 8–13. https://doi.org/10.1016/j.lwt.2015.12.001

Zabot, G. L., Silva, E. K., Azevedo, V. M., & Meireles, M. A. A. (2016). Replacing modified starch by inulin as prebiotic encapsulant matrix of lipophilic bioactive compounds. Food Research International, 85, 26–35. https://doi.org/10.1016/j.foodres.2016.04.005

Zaeim, D., Sarabi-Jamab, M., Ghorani, B., & Kadkhodaee, R. (2019). Double layer co-encapsulation of probiotics and prebiotics by electro-hydrodynamic atomization. LWT - Food Science and Technology, 110, 102–109. https://doi.org/10.1016/j.lwt.2019.04.040

Zaeim, D., Sarabi-Jamab, M., Ghorani, B., Kadkhodaee, R., & Tromp, R. H. (2018). Electrospray-assisted drying of live probiotics in acacia gum microparticles matrix. Carbohydrate Polymers, 183, 183–191. https://doi.org/10.1016/j.carbpol.2017.12.001

Funding

Akdeniz University Scientific Research Projects Coordination Unit provided funding for this study (Project number: FYL-2020–5551).

Author information

Authors and Affiliations

Contributions

Çiğdem Hökelekli: Investigation, Writing. Firuze Ergin: Conceptualization, Investigation, Writing—Original Draft. Ahmet Kucukcetin: Conceptualization, Writing—Review & Editing.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hökelekli, Ç., Ergin, F. & Kucukcetin, A. Incorporation of Encapsulated Yoghurt Bacteria into Stirred Yoghurt to Improve their Survival in an In Vitro Digestive Conditions. Food Bioprocess Technol 17, 747–766 (2024). https://doi.org/10.1007/s11947-023-03161-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-023-03161-7