Abstract

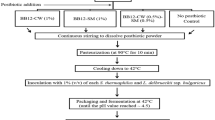

The potential of living cell microencapsulation in sustaining cells’ viability, functionality and targeted release in gastrointestinal tract is relatively well documented. Differently, the effects exerted by the capsules on cell metabolic activities during fermentation of a food matrix as well as on cell physiology are poorly addressed. This paper aimed at studying the effects of chitosan-alginate capsules (matrix and core-shell) on metabolic activities of Streptococcus thermophilus and probiotic Lactobacillus delbrueckii during milk fermentation for yoghurt production. This food system has been used to monitor growth, acidification kinetics and strain proteolytic activity. Bacterial viability has been monitored during yoghurt storage at 4 °C for 28 days and an in vitro digestion to evaluate the protective effect exerted by the capsules. Furthermore, production of volatile metabolites associated with starter culture activity was monitored by headspace solid-phase microextraction-GC/MS to explore possible influence of microenvironment on cell metabolism. Results indicate that both kinds of capsules influenced at different extent cell functionalities (growth, acidification and proteolysis), while they improve cell viability during yoghurt storage and simulated gastrointestinal passage. The volatile pattern revealed that capsules influenced their production in yoghurt: 12 out of 28 volatiles recovered in yoghurt fermented by free and encapsulated starters had significantly different concentration. However, concentration of the main aroma constituents (e.g. acetaldehyde, diacetyl, acetoin) was not significantly affected. Due to the leakage of bacteria from microcapsules during fermentation, the final product resulted in co-existing of free and still encapsulated cells, with the main advantage of an increased viability during yoghurt storage and simulated digestion of the encapsulated counterpart.

Similar content being viewed by others

References

Alonso, S., Rendueles, M., & Díaz, M. (2015). A novel approach to monitor stress-induced physiological responses in immobilized microorganism. Journal of Applied Microbiology and Biotechnology, 99(8), 3573–3583.

Arioli, S., Della Scala, G., Remagni, M. C., Stuknyte, M., Colombo, S., Guglielmetti, S., De Noni, I., & Mora, D. (2016). Streptococcus thermophilus urease activity boosts Lactobacillus delbrueckii subsp. bulgaricus homolactic fermentation. International Journal of Food Microbiology. doi:10.1016/j.ijfoodmicro.2016.01.006.

Barone, C., Pettinato, R., Avola, E., Alberti, A., Greco, D., Failla, P., & Romano, C. (2000). Comparison of three probiotics in the treatment of acute diarrhea in mentally retarded children. Minerva Pediatrica, 52(3), 161–165.

Bilenler, T., Karabulut, I., & Candogan, K. (2017). Effects of encapsulated starter cultures on microbial and physicochemical properties of traditionally produced and heat treated sausages (sucuks). LWT-Food Science and Technology, 75, 425–433.

Blaiotta, G., Ercolini, D., Mauriello, G., Salzano, G., & Villani, F. (2004). Rapid and reliable identification of Staphilococcus equorum by a species-specific PCR assay targeting the sodA gene. Systematic and Applied Microbiology, 27(6), 696–702.

Borch, E., Berg, H., & Holst, O. (1991). Heterolactic fermentation by a homofermentative Lactobacillus sp. during glucose limitation in anaerobic continuous culture with complete cell recycle. Journal of Applied Bacteriology, 71(3), 265–269.

Carcoba, R., Delgado, T., & Rodríguez, A. (2000). Comparative performance of a mixed strain starter in cow’s milk, ewe’s milk and mixtures of these milks. European Food Research and Technology, 211(2), 141–146.

Champagne, C. P., Lacroix, C., & Sodini-Gallo, I. (1994). Immobilized cell technologies for the dairy industry. Critical Reviews in Biotechnology, 14(2), 109–134.

Champagne, C. P., Ross, R. P., Saarela, M., Flemming Hansen, K., & Charalampopoulos, D. (2011). Recommendations for the viability assessment of probiotics as concentrated cultures and in food matrices. International Journal of Food Microbiology, 149, 185–193.

Cheng, H. (2010). Volatile flavor compounds in yoghurt: a review. Critical Reviews in Food Science and Nutrition, 50(10), 938–950.

Cook, M. T., Tzortzis, G., Charalampopoulos, D., & Khutoryanskiy, V. (2012). Microencapsulation of probiotics for gastrointestinal delivery. Journal of Controlled Release, 162(1), 56–67.

Corbo, M. R., Bevilacqua, A., Gallo, M., Speranza, B., & Sinigaglia, M. (2013). Immobilization and microencapsulation of Lactobacillus plantarum: performances and in vivo applications. Innovative Food Science and Emerging Technology, 18, 196–201.

Corbo, M. R., Bevilacqua, A., Speranza, B., Di Maggio, B., Gallo, M., & Sinigalia, M. (2016). Use of alginate beads as carriers for lactic acid bacteria in a structured system and preliminary validation in a meat product. Meat Science, 111, 198–203.

Corona-Hernandez, R. I., Alvarez-Parrilla, E., Lizardi-Mendoza, J., Islas-Rubio, A. R., De la Rosa, A., & Wall-Medrano, A. (2013). Structural stability and viability of microencapsulated probiotic bacteria: a review. Comprehensive Reviews in Food Science and Food Safety, 12(6), 614–628.

Dandoy, D., Fremaux, C., de Frahan, M. H., Horvath, P., Boyaval, P., Hols, P., & Fontaine, L. (2011). The fast milk acidifying phenotype of Streptococcus thermophilus can be acquired by natural transformation of the genomic island encoding the cell-envelope proteinase PrtS. Microbial Cell Factories, 10, S21.

De Angelis, M., Rizzitiello, C. G., Fasano, A., Clemente, M. G., De Simone, C., Silano, M., De Vincenzi, M., Losito, I., & Gobbetti, M. (2006). VSL#3 probiotic preparation has the capacity to hydrolyze gliadin polypeptides responsible for celiac sprue. Biochimica et Biophysica Acta, 1762(1), 80–93.

De Prisco, A., Maresca, D., Ongeng, D., & Mauriello, G. (2015). Microencapsulation by vibrating technology of the probiotic strain Lactobacillus reuteri DSM 17938 to enhance its survival in foods and in gastrointestinal environment. LWT-Food Science and Technology, 61(2), 452–462.

Doleyres, Y., Fliss, I., & Lacroix, C. (2004). Increased stress tolerance of Bifidobacterium longum and Lactococcus lactis produced during continuous mixed-strain immobilized-cell fermentation. Journal of Applied Microbiology, 97(3), 527–539.

Galia, W., Jameh, N., Perrin, C., Genay, M., & Dary-Mourot, A. (2016). Acquisition of PrtS in Streptococcus thermophilus is not enough in certain strains to achieve rapid milk acidification. Dairy Science and Technology, 96(2), 623–636.

Gallo, M., Bevilacqua, A., Speranza, B., Sinigaglia, M., & Corbo, M. R. (2014). Alginate beads and apple pieces as carriers for Saccharomyces cerevisiae var. boulardii, as representative of yeast functional starter cultures. International Journal of Food Science and Technology, 49(9), 2092–2100.

Gao, M., Song, H., Zheng, H., Ren, Y., Li, S., Liu, X., Yu, W., & Ma, X. (2016). Cultures of low density E. coli cells in alginate-chitosan microcapsules facilitates stress resistance by up-regulating luxS/AI-2 system. Carbohydrate Polymers, 141, 160–165.

Georgala, A. I. K., Tsakalidou, E., Kandaraki, I., & Kalantzopoulos, G. (1995). Flavour production in ewe’s milk and ewe’s milk yoghurt, by single strains and combinations of Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus, isolated from traditional Greek yoghurt. Le Lait, 75(3), 271–283.

Gombotz, W. R., Wee, S. F. (2012) Protein release from alginate matrices. Advanced Drug Delivery Reviews, 64, 194–205

Hettinga, K. A., van Valenberg, H. J. F., Lam, T. J. G. M., & van Hooijdonk, A. C. M. (2008). Detection of mastitis pathogens by analysis of volatile bacterial metabolites. Journal of Dairy Science, 91(10), 3834–3839.

Hettinga, K. A., van Valenberg, H. J. F., Lam, T. J. G. M., & van Hooijdonk, A. C. M. (2009). The influence of incubation on the formation of volatile bacterial metabolites in mastitis milk. Journal of Dairy Science, 92(10), 4901–4905.

Junter, G. A., Coquet, L., Vilain, S., & Jouenne, T. (2002). Immobilized-cell physiology: current data and the potentialities of proteomics. Enzyme and Microbial Technology, 31(3), 201–212.

Kearney, L., Upton, M., & McLoughlin, A. (1990). Meat fermentations with immobilized lactic acid bacteria. Applied Microbiology and Biotechnology, 33(6), 648–651.

Krisch, J., & Szajani, B. (1997). Ethanol and acetic acid tolerance in free and immobilized cells of Saccharomyces cerevisiae and Acetobacter aceti. Biotechnology Letters, 19(6), 525–528.

Krishnan, S., Gowda, L. R., Misra, M. C., & Karanth, N. G. (2001). Physiological and morphological changes in immobilized L. plantarum NCIM 2084 cells during repeated batch fermentation for production of lactic acid. Food Biotechnology, 15(3), 193–202.

Krunic, T. Z., Bulatovic, M. L. J., Obradovic, N. S., Vukašinovic-Sekulic, M. S., & Rakinb, M. B. (2015). Effect of immobilisation materials on viability and fermentation activity of dairy starter culture in whey-based substrate. Journal of the Science of Food and Agriculture, 96(5), 1723–1729.

Kwak, H. S. (1995). Effect of volatile flavor compounds on yogurt during refrigerated storage. Korean Journal of Food Science and Technology, 27(3), 939–943.

Lin, W. H., Hwang, C. F., Chen, L. W., & Tsen, H. Y. (2006). Viable counts, characteristic evaluation for commercial lactic acid bacteria products. Food Microbiology, 23(1), 74–81.

Martín, M. J., Lara-Villoslada, F., Ruiz, M. A., & Morales, M. E. (2015). Microencapsulation of bacteria: a review of different technologies and their impact on the probiotic effects. Innovative Food Science and Emerging Technologies, 27, 15–25.

Mauriello, G., Moschetti, G., Blaiotta, G., Villani, F., & Coppola, S. (1998). Proteolytic activity of lactococcal strains from water-buffalo mozzarella starter cultures. Journal of Dairy Research, 65(1), 109–118.

Mirzaei, H., Pourjafar, H., & Homayouni, A. (2012). Effect of calcium alginate and resistant starch microencapsulation on the survival rate of Lactobacillus acidophilus La5 and sensory properties in Iranian white brined cheese. Food Chemistry, 132(4), 1996–1970.

Nedović, V., Gibson, B., Mantzouridou, T. F., Bugarski, B., Djordjević, V., Kalušević, A., Paraskevopoulou, A., Sandell, M., Šmogrovičová, D., & Yilmazteki, M. (2015). Aroma formation by immobilized yeast cells in fermentation processes. Yeast, 32(1), 173–216.

Ott, A., Fay, B. L., & Chaintreau, A. (1997). Determination and origin of the aroma impact compounds of yogurt flavor. Journal of Agricultural and Food Chemistry, 45(3), 850–858.

Prevost, H., Divies, C., & Rousseau, E. (1985). Continuous yogurt production with Lactobacillus bulgaricus and Streptococcus thermophilus entrapped in Ca-alginate. Biotechnology Letters, 7(4), 247–252.

Rathore, S., Desai, PM., Liew C. V., Chan L. W., Heng P. W. S. (2013) Microencapsulation of microbial cells. Journal of Food Engineering, 116(2), 369–381

Rodrigues, D., Sousa, S., Rocha-Santos, T., Silva, J. P., Sousa Lobo, J. M., Costa, P., Amaral, M. H., Pintado, M. M., Gomes, A. M., & Freitas, A. C. (2011). Influence of L-cysteine, oxygen and relative humidity upon survival throughout storage of probiotic bacteria in whey protein-based microcapsules. International Dairy Journal, 21(11), 869–876.

Routray, W., & Mishra, H. N. (2011). Scientific and technical aspect of yogurt aroma and taste: a review. Comprehensive Reviews in Food Science and Food Safety, 10(4), 208–220.

Savijoki, K., Ingmer, H., & Varmanen, P. (2006). Proteolytic system of lactic acid bacteria. Applied Microbiology and Biotechnology, 71(4), 394–406.

Settachaimongkon, S., Nout, R. M. J., Antunes Fernandes, E. C., Hetting, K. A., Vervoort, J. M., van Hooijdonk, T. C. M., Zwieterin, M. H., Smid, E. J., & van Valenberg, H. J. F. (2014). Influence of different proteolytic strains of Streptococcus thermophilus in co-culture with Lactobacillus delbrueckii subsp. bulgaricus on the metabolite profile of set-yoghurt. International Journal of Food Microbiology, 177, 29–36.

Sousa, S., Gomes, A. M., Pintado, M. M., Malcada, F. X., Silva, J. P., Sousa Lobo, J. M., Costa, P., Amaral, M. H., Rodrigues, D., Rocha-Santos, T. A. P., & Freitas, A. C. (2012). Encapsulation of probiotic strains in plain or cysteine-supplemented alginate improves viability at storage below freezing temperatures. Engineering in Life Science, 12(4), 457–465.

Thomas, D., & Turner, K. W. (1981). Carbohydrate fermentation by Streptococcus cremoris and Streptococcus lactis growing in agar gels. Applied and Environmental Microbiology, 41, 1289–1294.

Torino, M. I., Taranto, M. P., Sesma, F., & de Valdez, F. (2001). Heterofermentative pattern and exopolysaccharide production by Lactobacillus helveticus ATCC 15807 in response to environmental pH. Journal of Applied Microbiology, 91(5), 846–852.

Trauth, E., Lemaitre, J. P., Rojas, C., Diviès, C., & Cachon, R. (2001). Resistance of immobilized lactic acid bacteria to the inhibitory effect of quaternary ammonium sanitizers. Lebensmittel Wissenschaft und Techologie, 34(4), 239–243.

Unver, Y., Yildiz, M., Taskin, M., Arslan, N. P., & Ortuku, S. (2015). Protease production by free and immobilized cells of the cold-adapted yeast Cryptococcus victoriae CA-8. Biocatalysis and Biotransformation, 33(2), 105–110.

Vizoso Pinto, M. G., Franz, C. M. A. P., Schillinger, U., & Holzapfel, W. H. (2006). Lactobacillus spp. with in vitro probiotic properties from human faeces and traditional fermented products. International Journal of Food Microbiology, 109(3), 205–214.

Westman, J. O., Ylitervo, P., Franzén, C. J., & Taherzadeh, J. (2012). Effects of encapsulation of microorganisms on product formation during microbial fermentations. Applied Microbiology and Biotechnology, 96(6), 1441–1454.

Zhou, Y., Martins, E., Groboillot, A., Champagne, C. P., & Neufeld, R. J. (1998). Spectrophotometric quantification of lactic bacteria in alginate and control of cell release with chitosan coating. Journal of Applied Microbiology, 84(3), 342–348.

Acknowledgements

This work was supported by a grant from the “Ministero dell’Istruzione, dell’Università e della Ricerca” within the program PON01_02863 Research and Competitiveness 2007–2013. Project title: “Encapsulation of active ingredients for improving the quality and food safety”.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

De Prisco, A., van Valenberg, H.J.F., Fogliano, V. et al. Microencapsulated Starter Culture During Yoghurt Manufacturing, Effect on Technological Features. Food Bioprocess Technol 10, 1767–1777 (2017). https://doi.org/10.1007/s11947-017-1946-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-017-1946-8