Abstract

The global economy growth requires a sustainable management of agro-industrials and by-products, as they represent a source of bioactive compounds (BCs) (such as antioxidants and carbohydrates) with relevant biotechnological and nutritional value. Their use is potentially applicable to different fields, as it can provide an added value to food products, such as shelf-life improvement. Moreover, according to the “Zero” principles, the residual matrices can be also employed to obtain innovative and eco-friendly bio-composite materials. The review gives an overview of the different uses of extracts derived from renewable sources and proposed as food ingredients for the development of new functional foods with improved oxidative stability. It also focuses on the exploitation of by-products in the field of packaging, showing applications regarding the formulations of active films, and their use as fillers for the development of innovative materials. Besides, a remarkable note about safety assessment is important to underline the need for analytical controls to ensure health matters.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Bioactive compounds (BCs) are natural or synthetic compounds that can exert biological activity in the living tissue components producing a wide range of effects (antioxidant, anti-microbial, anti-inflammatory, prebiotic). Commonly, they are classified according to their physical–chemical properties, distribution in nature, biosynthetic route, or based on their biological and pharmacological effects (Leichtweis et al., 2021). This classification results in a heterogeneous family of chemical compounds, such as phenolic compounds, carotenoids, alkaloids, vitamins, dietary fiber, fatty acids, volatile compounds, anthocyanins, and other pigments generally occurring in foods (Leichtweis et al., 2021; Vilas-Boas et al., 2021).

The main sources of food-derived BCs are fruits, vegetables, legumes, whole grains, nuts, seeds, mushrooms, herbs, and spices (Martillanes et al., 2018) and other animal-derived components such as protein, enzymes, polyunsaturated fatty acids (PUFAs), vitamins, and biopolymer (Zhang et al., 2015). BCs are generally found in foods but also in other under-valorized sources such as the agri-food by-products and considered a worldwide issue that negatively impact on environmental system due to the current unsuitable management. Indeed, the Food and Agriculture Organization (FAO) estimated the fruit and vegetable losses up to 60% of the total horticulture production, and the 25–30% of the total amount of agri-food by-products are generated by fruits processing (Sagar et al., 2018). In this context, many governments are moving towards a more sustainable approaches, implementing the ambitious circular economy plan with the main goal of reducing, and encouraging the adequate reuse of an unexploited sources of valuable BCs such as agri-food by-products (e.g., seeds, skins, pomaces, rinds), as concrete renewable candidates for a sustainable implementation of “zero policies” to recover organic matter for other technological application (“European Environmental Agency”, 2023).

Thus, the recovery of bioactive components from non-edible bio-residues and by-products can provide an additional economic value, if used as new raw materials in the production processes (Grimaldi et al., 2022). Different extraction methods were reported for an efficient recovery of BCs from these residues. Lately, green extraction methods such as ultrasound-assisted, microwave-assisted, enzyme-assisted, and supercritical fluid extraction have overcome the conventional methods (i.e., maceration, infusion, Soxhlet extraction), which are expensive in cost and time and require large amount of organic solvents (Panzella et al., 2020). Natural BCs such as sugars and antioxidants have a potential nutritional and therapeutic value together with their presumed safety and profitability. On the other hand, the application of BCs from by-products in the packaging field, as eco-additives (fillers, plasticizers, dyes antioxidants, and compatibilizers) to improve the functional and structural properties of a wide range of biomaterials, represents an alternative and very interesting method for the technological up-cycling of these secondary raw materials.

Recent reviews described sustainable methodologies to reuse natural BCs mainly concerning on the sustainable extraction approaches and their application as natural additives and preservatives in the food industry (Faustino et al., 2019; Socas-Rodríguez et al., 2021; Vilas-Boas et al., 2021), or in the pharmaceutical and cosmetics fields (Laura et al., 2021; Simitzis, 2018). Some studies also regarded the design of novel eco-friendly materials such as edible films, coating, and bio-composites recycling the recovered matter derived from agro-industrial by-products (Das et al., 2022; Díaz-Montes & Castro-Muñoz, 2021; Karimi Sani et al., 2023; Ortega et al., 2021).

The purpose of the current review is to provide an overview on the recent development in the exploitation of BCs deriving from agri-food by-products as potential natural additives in different fields, not limited to the effects on food quality and preservation (shelf-life, oxidative stability, technological parameters) but also under-lining packaging applications and bio-composites properties improvement.

The first section describes beneficial properties of the main classes of bioactive compounds occurring in by-products, some of the well-known health benefits provided, and reports an overview of possible green extraction techniques for their recovery. The second part is then dedicated to the exploitation of extracts to improve food products stability. Then, the final section is dedicated to the packaging applications and describes possible uses of by-products as active film components or as fillers for the development of innovative materials. A paragraph concerning safety assessment was inserted to underline the strict need for analytical controls to ensure health matters.

Bioactive Compounds Occurring in Agri-Food By-Products

The wide availability, the large volumes, and the low costs make agri-food and by-products a considerable source of BCs that can be extracted through sustainable methodologies. Most of by-products deriving from agro-industrial transformation such as grain, legumes, fruits, and vegetables bio-residues are rich sources of macronutrients (carbohydrates, protein, and fatty acids) and micronutrients (vitamins, iron, calcium, and potassium). Most of them are considered BCs (including non-nutrients) and basically consist of phytochemical compounds, generally produced from primary and secondary metabolism of plant cell that play a key role in plant growth and development. These natural components are generally produced from primary and secondary metabolism of plant cell. The variety of metabolites produced in the plants include components able to promote antioxidant and antimicrobial effects, and enhance anti-inflammatory capability, cardioprotective and neuroprotective properties, preventing obesity and regulating diabetes (Banwo et al., 2021).

Phenolic compounds, carotenoids, and dietary fibers are considered ones of the most widespread BCs occurring in food and agri-food by-products. Thus, BCs may find application in several industrial fields as functional components to promote biomasses reuse and recycle that generally were designed for animal feed, fertilizers, or landfilling (Socas-Rodríguez et al., 2021).

These natural antioxidants, in particular carotenoids and polyphenols, possess a wide variety of biological attributes, such as anti-aging, anti-inflammatory, anti-viral, anti-microbial, anti-cancer agents, and generally occur in citrus fruits and pomace. A recent study conducted by Quesada-Gómez et al. (2018) figured out β-cryptoxanthin (carotenoid) mechanism implied in the inhibition of angiogenesis via retinoic acid receptors. Thus, compounds with these properties may be used as food supplement as natural colorant agents to enhance texture and chroma of products and to improve the shelf-life of food and beverages by preventing pathogens and contaminants or off-flavors formation (Vilas-Boas et al., 2021). These properties have therefore prompted the use of natural phenolic compounds and carotenoid derivates also as additives for functionalization of materials to be used in biomedicine and cosmetic industry (Panzella et al., 2020). Firstly, Wattanathorn et al. described the anti-osteoporosis effect in menopausal woman of polyphenol-rich herbal congee by a possible mechanism that improve bone markers turnover (Wattanathorn et al., 2018).

Dietary fibers refer to the indigestible long-chains polysaccharides generally occurring in plant cell wall that may impact on human diet and health. They promote gastrointestinal peristalsis to alleviate constipation, inducing absorption processes. Besides, they have a direct impact on human microbiota and provide energy and nutrition for probiotic proliferation. For instance, potato peels may be considered a source of protein and dietary fibers for nutritional and technological parameters improvement. Besides the improvements of nutritional value, the inclusion of potato peel powder at 5% boosted the dough’s strength and elasticity-to-extensibility ratio (Ben Jeddou et al., 2017). The functional properties of fibers depend on the particle size, extraction condition, structure of the plant polysaccharide, vegetable source, and different water holding capacity. Vegetable processing bio-residues consist of exhausted skin and seeds rich of fibers that may also be included in novel processed food because inexpensive, non-caloric bulking and thickener agents, water, and oil retainer and able to improve the emulsion or oxidative stabilities. The incorporation of dietary fibers in foods changes the textural, rheological, nutritional, and sensory properties of the food products. Dietary fibers represent a green opportunity also for functional and technological properties useful in packaging field, such as water- and oil-retention, glucose retardation index, swelling, viscosity, gel-forming, texturizing, and chelating capacity (Pathania & Kaur, 2022).

Overview of Sustainable Extraction Procedures

The extraction techniques for bioactive compounds recovery should be efficient and sustainable for a better management of agri-food by-products. The solid–liquid extraction represents the most widespread process for valuable BCs recovery especially for the case of agri-food by-products. Maceration was used since ancient times and consists of mixing organic samples with an appropriate solvent for a long time and frequently assisted by heating and/or stirring and involving isolation and purification steps. It is easy to perform, and it has low costs, but requires long time and high quantities of solvent (Gullón et al., 2020). Soxhlet was originally developed for the extraction of lipids from a solid material, but it was also useful for BCs recovery from various natural sources. Conventional methods were reported to typically involve long extraction times and large amounts of solvent (which can be toxic) and may degrade heat-labile compounds due to the long exposure and the high temperature required (Leichtweis et al., 2021; Zhang et al., 2018). For instance, Chatzimitakos et al. reported that a low extraction temperature (20 °C) may be a suitable extraction condition of BCs from bio-residues of coffee transformation such as spent coffee grounds (Chatzimitakos et al., 2023).

Many alternative extraction methods can be considered more sustainable since they use green solvents and more ecological methods lowering energy costs (Table 1). In terms of green solvents, water is the preferred one thanks to its affordability, safety, bioavailability, and lack of toxicity to humans or the environment. Additionally, adjustment of the temperature can modify its chemo-physical properties.

The ultrasound-assisted extraction (UAE) consists of a dispersion of sound waves inside the solvent phase that houses the sample. Cavitation bubbles are created when the waves are strong enough to cause repeated compression and distension in the medium. It is a low-cost approach able to improve extraction yield and accelerate kinetics, while using less energy, solvent, and extraction time, although heat-labile chemicals might be affected by the generated heat (Barba et al., 2016; Kumar et al., 2021a). This technique was used for bioactive compounds extraction derived from cauliflower stems and leaves (Amofa-Diatuo et al., 2017).

Microwave-assisted extraction (MAE) techniques is a method that uses microwave radiation, as non-ionizing electromagnetic waves (300 MHz to 300 GHz). Through this mechanism, pressure is generated inside the sample cells and determines consequent rupture, exposing the cell and then facilitating solvent penetration. MAE is characterized by green and economic features since it combines low-cost equipment and a reduced extraction time and amount of required solvent, and leads to an improved extraction yield, thus limiting energy consumption. The use of MAE showed the possibility to retain higher contents of bioactive compounds, in terms of higher antioxidant activities, thanks to the short processing time (Bandici et al., 2022). It also allows processing without using any solvent. A limitation may be the heat generated which can affect heat-sensitive components and its efficiency loss in scaling up. Bandici et al. evaluated the TPC form plant matrix after microwave treatment significantly increased the yield (Bandici et al., 2022).

Supercritical fluid extraction (SFE) is based on the use of the solvent fluid in its super-critical state. To achieve this, parameters as temperature and pressure are managed to induce a state for the fluid that is halfway between a gas and a liquid, with comparable liquid density and gas viscosity. The supercritical solvent generally passes through the raw material, is put in an extractor vessel, carries the dissolved solute to the separator, and can then be recycled and added back to the process. However, it still requires expensive operations for its scaling up in industrial dimension (Zhang et al., 2018). This novel technique was also applied to the extraction of carotenoids from tomato by-products, and has shown higher lycopene recovery than the conventional procedures. SFE led to lycopene recovery of 728.98 mg/kg d.w. compared to conventional extraction (Kehili et al., 2017).

High-pressure assisted extraction (HPE) is based on the use of high-pressure conditions (ranging from 100 to 1000 MPa) to recover a wide range of bioactive compounds from plant and animal derived samples. This technique takes shorter time analysis by using also mild temperature conditions (avoiding thermal degradation of heat labile components), and results in higher extraction yields. The process is energetically efficient and by using different solvents can differentially extract compounds with different polarities. The application of high-pressure leads to disruption of plant tissues enhancing the mass transfer of solvents into materials and their soluble constituents into solvents (Khan et al., 2019). Recently, some studies have reported the use of HPE to obtain higher extraction yield of bioactive compounds over traditional methods. Indeed, the authors demonstrated the treatment for 15 min of HPE of discarded blueberries allowed the highest content in terms of anthocyanins, polyphenols, flavonoids, and antioxidant capacities. Likewise, HPE for 15 min resulted also in the highest bio-accessibility of polyphenols (62.2%) and flavonoids (62.2%) (Briones-Labarca et al., 2019).

Deep eutectic solvents (DESs) are a class of solvents that can be used for extraction of various bioactive compounds. DESs are composed of mainly two constituents: the first is hydrogen bond acceptor and the second player is a hydrogen bond donor, containing large, nonsymmetric ions that have low lattice energy and hence low melting points. DESs present several advantages over traditional solvent extraction methods, including its non-toxicity, high selectivity and efficiency, tuneable properties, low costs, and biodegradable and renewable behavior (Saini et al., 2022). Pal et al. performed e microwave-assisted deep eutectic solvent extraction of phenolics compounds from onion peels (Pal & Jadeja, 2019).

The enzyme-assisted extraction (EAE) uses specific enzymes to disrupt the cell wall of source material to improve the extraction yield of bioactive compounds of interest. This technique can be also performed in combination with other methods (UAE, MAE, HPE, etc.…) improving extraction efficiency. It was reported that the digestive enzyme pancreatin is recommended before the solvent extraction of lycopene. Its use increased the yield of lycopene 2.5-fold compared to that obtained using the traditional extraction method (Streimikyte et al., 2022).

The membrane extraction (ME) technologies are considered another concrete candidates as green emerging technologies. They involve the use of a membrane as an intermediate between the donor phase and the acceptor phase allowing the analytes migration by permeating the membrane. Lately, the combination with DESs was reported to improve the separation performances due to a facilitated molecules transport and/or an adsorption mechanism occurring through the chemical interactions between the functional groups (Bitas et al., 2021; Taghizadeh et al., 2021).

Novel Applications Exploiting Natural Bioactive Compounds

To face the recent environmental problems, the European Union (EU) is promoting the reduction of food waste, searching for new potential end-uses of food by-products according to the circular economy principles. Initially, food by-products were exploited as nutraceuticals or as processed additives able to enhance the technological properties and/or shelf-life of food preparations. In some cases, the obtained food items can be considered functional foods if contain molecules conferring health benefits or acting for disease prevention, such in the case of antioxidant, anti-bacterial, anti-diabetic, and antifungal properties (Pattnaik et al., 2021). Table 2 reports a list of examples of novel application performed in the late years.

Process and storage are some of the parameters affecting quality of food and its oxidative stability. Lipid oxidation is a severe issue that affects organoleptic qualities and reduces shelf-life. In a recent study, Grimaldi et al. (2022) investigated this aspect through Oxitest reactor analysis. The authors successfully evaluate the induction period of the agro-food by-products extracts added to vegetable oil, which is time required to reach the starting point of oxidation and directly linked to the oxidative resistance of the samples. Vegetable oil was used as carrier oil when the sample investigated lacked fatty compounds susceptible to oxidation processes. It was demonstrated that a strong decrease on the oxidation processes is exerted by food by-products when added vegetable oil, suggesting a potential use of those materials for preventing oil degradation during storage.

An interesting practice may be the addition of powders or extracts from food by-products for processed food production enhancing their nutritional qualities (Demir & Ağaoğlu, 2021). The artichoke (Cynara scolymus) extracts were shown to induce antioxidant effect on the freeze-stored minced meat with reference to the metmyoglobin reducing activity, implying that the presence of bioactive components occurring in artichoke may be essential for oxidative stress preservation during meat storage. Pasqualone et al. (2017) extracted phenolic compounds from artichoke through ultrasonication-assisted extraction technology. The extracts were incorporated in the fresh pasta, and it was found that antioxidant activity, attributed to the phenolic compounds content, increased when compared to a control sample. A similar work by Canale and co-workers provided useful information about the reusing processed artichoke residues, to produce bread with higher content of polyphenols (Canale et al., 2022). It has also been noticed how by-products ethanolic extracts, enriched in polyphenol compounds, provide a positive modulation on the production of the interleukin-8, the cytokine produced by NF-kB pathway and linked to the inflammatory response (Abbasi-Parizad et al., 2021), confirming their antioxidant and anti-inflammatory abilities and a potential use as plant-based food supplement. During cookies making, grape pomace powder (0–20%) was used to partially replace wheat flour. In comparison to control cookies, the treated samples have shown an improved total phenolics content (TPC), flavonoids, and anthocyanin content by 2.3, 2, and 12.5 times, respectively (Maner et al., 2017).

The addition of olive leaf extract (Paciulli et al., 2023) or chestnut flour (Paciulli et al., 2018) was suggested to enhance physico-chemical properties of biscuits during storage. The chestnut flour provided higher oxidative stability values, probably in relation to the antioxidants present in chestnuts. On the other hand, the chestnut content increase determines the hardness increase in the final product. Also, biscuits produced with the addition of olive leaf extract showed higher value of TPC and antioxidant activity than the control samples and a better resistance to oxidation process assessed by Oxitest reactor.

Green coffee parchment was employed for structural, qualitative, and chemical properties enhancement in gluten-free bread production. The results showed that this natural additive does not affect hardness, cohesiveness, and staling process during storage. Interestingly, the addition of 2% of green coffee parchment significantly improved the total antioxidant capacity and oxidative stability of the bread, reducing the hydroxy-methyl-furfural (HMF) content (cooking process marker) thanks to its antioxidant compounds (Littardi et al., 2021). In general, the exploitation of natural-derived BCs for food quality improvement can be considered a powerful alternative to synthetic components. These practices were thought also for food beverage production as fruit juices. In this case, a sonication approach was used by Amofa–Diatuo et al. (2017) to extract isothiocyanates from cauliflower stems and leaves. The extracts were then added to apple juice, and a 10% extract addition promoted the improvement of the sensory characteristics and was considered acceptable because it does not modify the final product properties. Although BCs were extracted using MAE and UAE technologies, scientific research is currently ongoing on the extraction of interesting BCs and the creation of functional foods employing UAE and MAE continuous extraction technology. Therefore, more studies are required to generate novel food items employing green extraction techniques such as UAE, MAE, and SFE (Pattnaik et al., 2021).

Cosmetic and pharmaceutical sectors are considered potential target markets for the exploitation and the recycling of natural BCs deriving from agri-food by-products. Cosmetics can be classified as hygienic (deodorants, cleaning foams, soaps), decorative (hair dyes, eye and face cosmetics), corrective (lighteners, epilators, depigmented), or protective (skin care products, sunscreen, moisturizers, lubricants) items. By combining cosmetic products with natural components of fruits and grains including rice, oranges, and oat bran, the reuse of this organic matter can be increased (Laura et al., 2021). For example, colorless UV-adsorbing carotenoids such as phytoene and phytofluene were exploited for skin whitening products, offering obvious advantages, including their safety, which may be assumed from their constant consumption in the human diet worldwide (Meléndez-Martínez et al., 2019). Von Oppen-Bezalel et al. produced formulations enriched with phytoene and phytofluene, inducing skin lightening effects and other beneficial results like anti-aging and anti-wrinkling effects (Oppen-Bezalel & Shaish, 2019). They are all considered well-known scavengers of reacting oxygen species (ROS) generated under oxidative stress conditions and responsible for the oxidative stress protection in plant organism and for the onset of several inflammatory and degenerative diseases in human. They were proved to enhance positive effects on human health through the strong antioxidant activity able in preventing cancer, cardiovascular diseases, osteoporotic processes in bones, and neurodegenerative diseases (Leichtweis et al., 2021). Additionally, proteins have also been used for new technological strategies in the nutraceuticals field. Protein-based wall material from apple by-products was exploited for entrapping hydrophilic and hydrophobic bioactive chemicals due to flexibility, eco-friendly, and safety carrier properties. Gani et al. (2022) focused on the nutraceutical potential, the release behavior, and the encapsulation effectiveness of nano-encapsulating chlorogenic acid into apple protein as a wall material. In perspective, this application may be used in food and medicine sectors as protein supplement carrier to entrap hydrophilic and hydrophobic bioactive substances.

The synthetic chemicals used in cosmetic and biomedical areas might have drawbacks and side effects that may cause health alterations and bacterial resistance. To overcome these critical issues, several researches have suggested alternative uses of BCs in pharmaceutical field due to the anti-cancer activity, effects against diabetes, effects against neuro-degenerative disorders, benefits on cardiovascular health, and action as antimicrobial agents or anti-inflammatory effects (Laura et al., 2021). For instance, citrus peel extracts were employed by Ademosun et al. (2015) as alternative to in vitro treatment of primary human colonic cancer and the metastatic cell lines. BCs occurring in citrus peel extracts also showed a strong inhibition of proteasome, the complex responsible for the degradation of cell regulatory proteins and found in excess in cancer cells. The activity in extract-treated cells reduces the progression of cancer. To increase the therapeutic effectiveness of anticancer medicals and mitigate their toxicity, lipid nanocarriers supplemented with grape seed oil were designed as powerful eco-friendly tool in this area of application. The oxidative damage that grape seed oil components, including resveratrol, cause to the bacterial plasma membranes makes these by-products a suitable tool also in antimicrobial therapy. It has also been demonstrated how bioactive compounds from agri-food by-products may be potentially applied for SARS-CoV-2 infection treatment: in vivo clinical tests have shown a co-synergistic antiviral effect of vitamin C and quercitin, the bioactive compounds occurring in most of fruits and vegetables, in COVID-19 patients (Colunga Biancatelli et al., 2020). Furthermore, other study conducted by Meneguzzo et al. (2020) confirmed the one of the main functions performed by hesperedin, a glycosylated flavanone extracted from citrus by-products, binding with high affinity all significant viruses, including SARS-CoV-2, with the potential to prevent it from spreading to cells; additionally, the naringin can prevent the immune system’s pro-inflammatory response.

Application in the Field of Innovative Materials for Packaging

Considering the significant volume of discarded material produced by the food production sectors, the reuse of agri-food by-products represents a huge challenge for the future perspective of a green and sustainable economy. Numerous studies were conducted using agro-industrial by-products as a feedstock to produce new kind of materials, such as completely bio-based composites or natural extracts reinforced compounds that may potentially replace conventional plastics.

Some examples of valuable exploitation of agri-food by-products in the field of innovative packaging and for the improvement of bio-composite performances are reported in Table 3 and discussed in the following sections.

Active Edible Coatings and Films

Bioactive compounds (BCs) derived from agri-food by-products and processed residues offer valuable potential to produce active edible coatings and films. These coatings were suggested to preserve or enhance food quality, extend shelf life, and contribute to the development of eco-friendly packaging materials, as recently discussed in a review (Gomes et al., 2020). Gomes et al. evaluated coatings made from chitosan and extracts rich in phenolic compounds derived from by-products of acerola or jaboticaba processing. These coatings effectively controlled the development of papaya root rot caused by Lasiodiplodia species, which have a pathogenic effect.

BCs can also exhibit their activity when incorporated into commercial polymeric matrices, resulting in functional composite materials.

Previous examples of active packaging were reported: Lantano et al. (2014) proposed a polylactic acid (PLA) film that entrapped an active antifungal component, such as natamycin (Lantano et al., 2014). The analysis showed successful inhibition of mold growth on the surface of commercial semi-soft cheese during the application of the film. Similarly, natural ingredients with antimicrobial potential were utilized to confer active properties to conventional poly(ethylene-terephthalate) (PET) films. Corradini et al. (2013) developed a prototype of PET film enriched with lysozyme, an antimicrobial enzyme, for active packaging applications (Corradini et al., 2013). The antimicrobial activity was tested against Micrococcus lysodeikticus on agar plates, exhibiting a significant growth inhibition rate. High-performance liquid chromatography with UV detection (HPLC UV-DAD) confirmed that the incorporation of lysozyme into the sol–gel modified PET did not affect the enzyme’s activity, suggesting its suitability for active packaging in contact with food.

Proteins derived from agro-industrial by-products possess physical–chemical properties that make them suitable for novel packaging applications (Proaño et al., 2020). For example, proteins from brewer’s spent grains (BSG) were investigated for the development of active packaging films and coatings. The protein fractions found in BSG, which are commonly generated during beer processing, are predominantly composed of hordein proteins, glycoproteins widely distributed in various cereals. These proteins contain approximately 60% of hydrophobic and neutral side-chain amino acids. Films were formulated using polyethylene glycol (PEG) at different protein content levels and pH 2. Increasing the concentration of PEG (from 0 to 25%) led to increased opacity and water susceptibility of the films, as evidenced by higher solubility and water vapor permeability (WVP), likely due to stronger protein-water interactions. Lower concentrations of PEG (5–10% wt) resulted in higher tensile strength and Young’s modulus values but lower elongation at break. This behavior can be attributed to the stiffness of the protein system arising from protein–protein interactions, which restrict the mobility of polymeric chains. Notably, the protein fraction derived from BSG exhibited excellent antioxidant activity, thanks to its high content of oligopeptides and free amino acids (Proaño et al., 2020). Furthermore, BSG was utilized to produce films based on protein plasticized with glycerol at different alkaline pH levels (11–13) and protein concentrations (4–10% w/v). The protein content influenced the final color of the film, resulting in an opaque and light reddish-brown appearance. The proteins employed in the design of these active films demonstrated UV-barrier properties, attributed to the absorption of UV light by the aromatic groups of amino acids. The films also exhibited good mechanical performance and improved resistance to water vapor permeability with increasing protein content (Shroti & Saini, 2022).

The works mentioned highlighted the use of various edible coatings for food packaging applications, focusing on improving oxidative stability, shelf life, and sensory properties of different food products.

In the study by Hosseini et al. (2020), a coating made of whey protein concentrate, glycerol, carboxymethyl cellulose (CMC), and rosemary extract was developed for packaging applications (Hosseini et al., 2020). The addition of rosemary extract improved the oxidative stability of the coated sunflower seed kernels and provided better color characteristics in a sesame-based product. Sabaghi et al. (2015) investigated the use of chitosan and green tea extracts (GTE) as edible coatings for walnut kernels (Sabaghi et al., 2015). The coatings did not significantly affect lipid oxidation, inhibiting fungal growth during storage, suggesting the potential for prolonging the shelf life of dry foods. Other studies evaluated the influence of a chitosan-pullulan composite edible coating enriched with pomegranate peel extract on the quality and storage life of green bell peppers (Kumar et al., 2021a, b). The composite coating exhibited reduced weight loss, color browning, and maintained the overall quality attributes of the bell peppers during storage.

Alvarez et al. (2018) evaluated the effects of sodium alginate and chitosan edible coatings enriched with different dietary fibers (apple fiber, orange fiber, inulin, and oligofructose) on ready-to-eat fresh blueberries (Alvarez et al., 2018). The chitosan coatings, with or without fibers, inhibited the growth of bacteria and yeasts/molds, reduced decay rate, enhanced antioxidant properties, maintained fruit firmness, delayed off-flavor development, and improved the overall visual quality of blueberries. The addition of oligofructose and orange fiber further enhanced antioxidant properties and reduced yeast/mold counts. In the study by Yang et al. (2014), blueberry fruit and leaf extracts (BLE) were incorporated into chitosan coatings to extend the shelf life of blueberries. BLE exhibited antimicrobial activity and the chitosan coatings incorporating BLE showed decreased decay rates, maintained higher phenolic content, and radical scavenging activity compared to the control samples (Yang et al., 2014).

These studies demonstrate the potential of using edible coatings enriched with natural extracts, fibers, or bioactive compounds to enhance the quality, shelf life, and stability of different food products. The incorporation of such coatings can provide antioxidant and antimicrobial benefits, inhibit microbial growth, reduce decay, and maintain desirable sensory attributes.

Prebiotics, such as inulin, were utilized by Orozco-Parra et al. (2020) as active components in the production of symbiotic films. These films are based on cassava starch and the probiotic bacterium Lacticaseibacillus casei, resulting in an increase in elongation at break, water vapor permeability, and solubility in water due to the hygroscopic nature of inulin. Although the increased hydrophilicity of the films influences their properties and stability, limiting their application in food with high moisture content, they have potential use in the production of active flexible packaging for low-moisture foods such as nuts, dehydrated fruits, vegetables, and spices. Stoll and co-workers utilized extracts rich in carotenoids as active compounds to produce PLA films. These films, containing lycopene and β-carotene, act as oxygen barrier agents due to the gradual release of antioxidants (Stoll et al., 2019). Thivya et al. (2022) conducted a study on composite films made of gluten/alginate-cellulose/onion residues extracts, demonstrating that the addition of agri-food by-products in the film matrix improved water barrier properties and tensile strength compared to control films made of sodium alginate (SA) and carboxy-methylcellulose (CMC). The study also evaluated the total phenolic content, radical scavenging activity, and total microbial load, confirming that the addition of bioactive compounds derived from these sources in active packaging formulations can enhance the shelf-life of food products and occasionally exhibit antibacterial effects.

Szabo et al. (2020) suggested another example of valorizing food by-products by preparing active food packaging using a mixture of itaconic acid, chitosan, and tomato by-products enriched in carotenoids and phenolic compounds for poly(vinyl alcohol) (PVA)-based films. The results showed increased physical properties, and the antioxidant and bioactive compounds employed exhibited significant antimicrobial effects against different microorganisms, including Staphylococcus aureus and Pseudomonas aeruginosa. Additionally, cellulose and lignin derived from brewery process by-products were recovered and reused to produce transparent and free-standing bio-composite films at different concentrations of narigenin, a flavanone found in citrus by-products. The incorporation of bioactive compounds conferred a pale yellowish color, antioxidant and antimicrobial properties, UV-blocking capabilities, a plasticizing effect, and improved barrier properties against water vapor and oxygen (Guzman-Puyol et al., 2022).

Olive pomace and by-products were also emolyed to produce value-added active films for packaging applications. De Moraes Crizel et al. (2018) incorporated 10% olive microparticles into a chitosan-based film, resulting in a significant improvement in tensile strength (22.40 ± 0.22 MPa) without altering other properties. The addition of olive flour and microparticles enhanced the antioxidant capacity, which was proportional to the concentration of filler added. Films with 30% w/v of flour or microparticles effectively served as protective packaging against the oxidation of nuts for a duration of 31 days.

In a recent study by Grimaldi et al. (2022), agri-food by-products such as onions, artichokes, and thistles were utilized as bioactive supplements in alginate-based films for the development of edible food contact materials (Fig. 1). The investigations demonstrated that the meat samples treated with the active packaging showed higher durability and prolonged shelf-life in terms of oxidative stability. These positive results were attributed to the antioxidant properties of the BCs added to the films. Another research conducted by Luzi et al. (2021) described the use of extracts enriched in polyphenols, such as hydroxytyrosol and oleuropein from olive oil by-products, added to PVA-based films. These extracts acted as potential natural antioxidant agents, capable of extending the shelf-life by delaying lipid and protein oxidation in meat matrices.

Capello et al. (2020) reported the reuse of agri-food by-products derived from jabuticaba fruits and sweet potatoes for the manufacturing of novel colorimetric indicator films in the packaging field. The anthocyanins present in these by-products exhibited significant color variation (from red to blue) when applied in the monitoring of meat freshness at different storage temperatures. It was suggested that the addition of anthocyanins increases the molecular spacing in the polymer chains, thereby decreasing the thermal stability of the proposed film.

Also potato by-products, such as peels, were employed for the fabrication of edible films for packaging applications. The potato peels were hydrolyzed in a mild acid medium, gelatinized with different amounts of plasticizers (glycerol or polyglycerol-3), and films were obtained through casting followed by compression molding (Merino et al., 2021). The results showed that films plasticized with polyglycerol-3 exhibited higher thermal resistance and reduced water vapor permeability compared to those plasticized with glycerol. The mechanical properties of the polyglycerol-3-plasticized films were also improved. However, the oxygen permeability was not suitable for long-term protection of food susceptible to oxidation, making these materials more appropriate for packaging dry food where oxygen barrier properties are not crucial.

Quince kernel mucilage was identified as another source of bioactive compounds for active packaging applications due to its ability to form films and coatings. Films were developed using different concentrations of quince seed mucilage and xanthan and added to a whey protein solution emulsified in sunflower oil. The inclusion of 10% quince seed mucilage and 5% polyethylene glycol (PEG) in the films resulted in improved mechanical properties and thermal stability, with higher tensile strength and elongation compared to pure PEG. Additionally, incorporating different concentrations of nano-clay into the film solution improved the gas diffusion barrier and reduced water vapor permeability (Beikzadeh et al., 2020; Rather et al., 2023).

Agri-Food Derived Fillers for Bio-Composite Materials

In recent years, there was a focus on developing alternative materials to replace conventional oil-based plastics. Biopolymers, such as PHA, PLA, PCL, and starch-based polymers, have gained attention due to their biodegradability and renewable origin. However, the mechanical, thermal, and permeation stability of biopolymers are relatively low for some industrial applications (Ortega et al., 2021). To enhance their properties and commercial relevance, the addition of reinforcing agents was proposed. Thus BCs derived from natural sources can play a role as organic and/or inorganic fillers for novel bio-composite materials fabrication (Das et al., 2022).

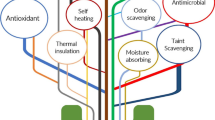

The incorporation of BCs from various agri-food by-products led to the development of novel materials with bioactive and structural potentials. This approach aligns with the principles of the circular economy, aiming to reduce production costs and valorise agro-industrial residues and by-products for packaging applications (Giubilini et al., 2021). These resulting materials, known as biopolymer composites or bio-composites, have found applications in medicine, electronics, construction, automotive, and packaging industries. Bio-composites typically consist of two or more constituents with distinct phases and compositions, forming micro- or nano-structures (Ortega et al., 2021). The properties of the composites are greatly influenced by the interfacial adhesions between the matrix (continuous phase) and the filler (discontinuous phase), as well as the composition, size, shape, and content of the reinforcement (see Fig. 2). Smaller filler particle sizes lead to a higher number of interactions between the matrix and the filler, resulting in improved composite performance (Palza et al., 2022).

Agri-food by-products offer a wide range of natural compounds, such as fibers rich in insoluble long-chain polysaccharides (e.g., cellulose, hemicellulose, lignin), which can serve as fillers for reinforcing bio-composites (Giubilini et al., 2020). The effect of fiber loading on polymer composites was evaluated by different researchers, and it was found to increase tensile strength. Engel and colleagues (2022) utilized fiber-rich bio-residues from cassava and grape processing by-products for food packaging applications, specifically for storing carrot cake and cherry tomatoes. These valuable agro-industrial residues were incorporated into polymeric matrices in the form of foams with significant water absorption capacity. The technological properties of the food matrices stored in the biodegradable packaging were not significantly different from those stored in traditional packaging. Cinelli and co-workers (2020) repurposed wood, legumes, potatoes, and bran fiber residues to produce bio-composites based on polyhydroxyalkanoates (PHA). PHAs are biopolymers derived from bacterial biosynthesis that are completely biodegradable. Their use in combination with agri-food by-products for bio-composites fabrication is of particular interest in establishing sustainable circularity in the production life cycle of plastic-based products. The researchers investigated the effect of adding potatoes pulp powder and natural waxes to poly(hydroxybutyrate-co-valerate) (PHBV)-based polymers (Righetti et al., 2019). The incorporation of these fillers resulted in a significant enhancement of mechanical properties, including elastic modulus, tensile strength, and elongation at break.

Giubilini et al. (2021) produced and characterized a bio-composite based on poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBH) and oat hull fibers. The results indicated that oat hull fibers slightly improved the mechanical properties of neat poly(hydroxybutyrate-co-hexanoate) (PHBH), increasing the Young’s modulus by approximately 12% without a loss in elongation at break (Giubilini et al., 2021). Quiles-Carrillo et al. (2018) characterized almond shell flour/poly(lactic acid) (PLA) composites. The addition of three different compatibilizers resulted in an improvement of approximately 6.5–7.5% in the hardness of the composites compared to neat PLA. Essabir et al. (2013) proposed a hybrid form of coir fiber and coconut shell particles as bio-fillers for reinforcing polypropylene (PP) without the use of coupling agents. They analyzed the mechanical properties and thermal stability of the resulting composites. The hybrid reinforcement significantly enhanced the Young’s modulus and tensile strength of the coir fiber/coconut shell/PP composites compared to neat PP.

Hemp-derived fibers were utilized as eco-fillers for the synthesis of thermal-resistant composites based on epoxy resin (Gargol et al., 2021). This eco-friendly filler positively influences the thermal resistance of composites and can help dampen vibrations. Dynamic-mechanical analysis (DMA) and hardness measurements have shown increased elasticity with higher amounts of the eco-filler used. Gigante et al. (2020) focused on wheat bran by-products as fillers in biodegradable composites based on poly(hydroxybutyrate-co-valerate) (PHBV) (Gigante et al., 2020). The addition of wheat bran as a filler improved the mechanical performance in terms of impact resistance. However, in this case, surface treatments of the organic filler with natural waxes such as carnauba wax and beeswax were necessary to enhance the matrix/filler adhesion and, consequently, the mechanical performance of the composites. This was confirmed by DMA analysis. Fibers derived from banana by-products and can also be suitable fillers for reinforcement in bio-composites. Agave plants, which are considered in the tequila industry, can provide alternative fibers. Torres-Tello et al. (2017) fabricated bio-composites based on poly(hydroxybutyrate) (PHB) and poly(hydroxybutyrate-co-valerate) (PHBV) with the addition of agave powder as a reinforcement agent (Torres-Tello et al., 2017). The results showed that the addition of agave fibers (up to 30 wt%) to both matrices significantly enhanced the tensile and flexural modulus compared to neat PHB and PHBV. There was no negative effect on tensile and flexural strength, but a significant increase in impact strength was obtained. Komal et al. (2020) developed a composite based on polylactic acid (PLA) reinforced with banana fiber powder (Komal et al., 2020). The composite exhibited significant improvements in mechanical properties, dynamic mechanical properties, and crystallinity compared to neat PLA. However, scanning electron microscopy (SEM) analysis revealed fiber damage in terms of breaking, bending, twisting, and the formation of clusters. Fiber pull-out and fracture were found to dominate the failure of the bio-composite under loading.

Saccani et al. (2022) explored the use of coffee processing by-products as fillers for mechanical improvement in post-industrial recycled polylactic acid (PLA) for composite material production (Saccani et al., 2022). The filler decreased the impact and tensile strength of the composites (by 35%), but it increased the elastic modulus (up to 20%). The authors suggested that the negative effects on strength can be mitigated by modifying the composite microstructure and adding a toughening component during the formulation process. Ferri et al. (2020) utilized red grape bio-residues from winery processing as an organic filler in PHBV-based polymers without the need for solvents or additives (Ferri et al., 2020). The researchers characterized the polyphenol fraction present in grape by-products using high-performance liquid chromatography with diode-array detection (HPLC–DAD) and Folin–Ciocalteu assay. The addition of grape residues (up to 20% w/w) did not worsen the properties of the PHBV matrix. In another study, grape pomace powder was used as a filler in PBS-based bio-composites, with in situ compatibilization using maleic anhydride (Gowman et al., 2018). The addition of 40 wt% grape pomace content led to improvements of 28.4% and 59% in flexural and impact strengths, respectively, compared to neat PBS. The heat distortion temperature also increased by 14.3% with the addition of grape pomace. Scanning electron microscopy revealed improved interfacial adhesion between the filler and polymeric matrix, and thermogravimetric analysis demonstrated the thermal stability of the grape pomace under processing conditions. Diken et al. (2022) evaluated bio-composites alternative for active packaging fabrication of a biodegradable polymeric matrix filled with phenolic compounds, specifically ferulic acid (FA) and gallic acid (GA) (Diken et al., 2022). The melt blending technique was used to create poly(ε-caprolactone) (PCL)/FA and PCL/GA bio-composites. The addition of organic fillers resulted in a higher storage modulus compared to pure PCL. The glass transition temperature of the PCL/FA sample with 5% ferulic acid content increased by 17 °C compared to the control PCL. The phenolic compounds exhibited high scavenging activity against DPPH and ABTS radicals and demonstrated antibacterial activity against both Escherichia coli and Staphylococcus aureus strains.

Another type of composite was developed using natural components to produce effective bio-foam formulations for various applications. Starch-based foams enriched with sugarcane bagasse powder or asparagus peels powder were fabricated. The trays made from this material had higher density and thickness than polystyrene trays. The addition of sugarcane bagasse fibers in concentrations above 20% led to a decrease in the water absorption capacity of the baked foams. However, the mechanical properties of the trays were not improved, suggesting poor distribution of the fibers in the polymer matrix. The thermal stability of the foams was also not enhanced by the addition of fibers. These trays may be suitable for packaging dry foods with a short shelf-life (Cruz-Tirado et al., 2017).

Peanut skins were investigated as fillers in cassava starch-based foams produced using a thermo-pressing process. The foam was created using cassava starch and the addition of 24% (w/w) peanut skin. The inclusion of peanut skin resulted in reduced stiffness due to increased mobility of the starch chains. The storage modulus and glass transition temperatures were also decreased as observed through dynamic mechanical analysis (DMA). The addition of peanut skin did not affect tensile stress and Young’s modulus but reduced the tensile strain of the foams compared to the control. The bio-composite foam exhibited a higher water contact angle than the cassava starch-based foam, indicating reduced hydrophilicity. The reduction in hydrophilicity was attributed to the composition of the additive, mainly lipids and proteins, as well as the interactions between cassava starch and peanut skin, which reduced the availability of hydroxyl (OH) groups to bond with water (Machado et al., 2020).

Scaffaro et al. (2022) investigated the mechanical properties of hybrid bio-composites based on polylactic acid (PLA) with the addition of two lignocellulosic-based fillers derived from dried Chamaerops humilis and Posidonia oceanica, which are aquatic plants commonly found in the Mediterranean Sea (Scaffaro et al., 2022). The researchers evaluated the effect of these fillers on the mechanical performance of the PLA matrix. The addition of the fillers led to improvements in the tensile strength and elastic modulus of the bio-composites. The use of these materials as fillers provides a sustainable approach to enhance the mechanical properties of the PLA matrix.

Particle-reinforced composites have gained significant interest due to their ability to improve various properties compared to the original system. However, researchers often suggest the need for some form of pre-treatment or compatibilizer to achieve enhanced composite properties. For example, the zein protein found in maize, when combined with titanium dioxide (TiO2), forms a complex in which the TiO2 particles are coated with a protein capping. This complex filler, when incorporated into a poly(butylene-adipate-terephthalate) (PBAT) matrix, acts as a compatibilizer, resulting in improved yield stress and Young’s modulus (Togliatti et al., 2022) (Fig. 3). Sciancalepore et al. (2022) utilized composite granules obtained by solvent casting of PBAT and zein complex solution for injection molding and 3D printing. By adjusting the filler content, they were able to customize the stiffness of the printed objects according to specific experimental requirements. These studies highlight the potential of utilizing various fillers and techniques to enhance the mechanical properties and tailor the performance of bio-composites for different applications.

The results of the study conducted by Scaffaro et al. (2022) demonstrated that the hybrid bio-composites based on PLA with the addition of Chamaerops humilis and Posidonia oceanica fillers exhibited improved dynamic-mechanical properties compared to neat PLA. The enhanced properties were attributed to the formation of a strong and extensive interphase region between the fillers and the PLA matrix. This interphase region is characterized by good adhesion and interactions between the fillers and the polymer matrix.

The presence of the two fillers in the bio-composites resulted in strengthening and stiffening effects. The synergistic effect of the fillers, combined with the bulk material, contributed to the improvement in mechanical properties. The formation of a strong interphase region is crucial in transferring stress between the fillers and the matrix, thereby enhancing the overall mechanical performance of the bio-composites. The strengthened interphase region and the resulting improvements in mechanical properties, such as increased stiffness and strength, highlight the potential of using lignocellulosic fillers from Chamaerops humilis and Posidonia oceanica as sustainable and effective reinforcements in PLA-based bio-composites.

Experimental approach for composite fabrication by means of injection molding and filament extrusion, as adopted in Togliatti et al. (2022)

The use of chicken eggshells, which are abundant by-products of aviculture, was explored as a reinforcement agent in bio-composites due to their rich inorganic composition. The main inorganic component in eggshells is calcium carbonate (CaCO3) or limestone, comprising approximately 95% of the shell’s composition (Das et al., 2022).

Boronat et al. (2015) introduced a fully biodegradable bio-composite by incorporating eggshell powder as a reinforcement filler in bio-polyethylene (bio-PE) derived from sugar cane. The study demonstrated that the addition of modified CaCO3 from eggshells effectively enhanced the mechanical properties of bio-PE. The incorporation of eggshell powder resulted in increased stiffness, hardness, flexural modulus, and tensile modulus of the bio-composite (Boronat et al., 2015). To improve the adhesion between the filler and the polymer matrix, the researchers investigated the use of a titanate particle treatment as a coupling agent. The titanate particle treatment acted as a compatibilizer, promoting better adhesion between the eggshell powder and the bio-PE matrix. This improved adhesion between the filler and the polymer matrix contributed to better overall performance of the bio-composite. The combination of eggshell powder and bio-PE offers the potential to create sustainable and biodegradable bio-composites with enhanced mechanical properties. By utilizing materials from the agro-industrial chain, such as chicken eggshells, it is possible to develop environmentally friendly composites that effectively utilize available resources. The use of inorganic particles, such as calcium carbonate (CaCO3), as fillers for mechanical improvement was explored not only in bio-composites but also in conventional plastics like low-density polyethylene (LDPE). In a study by Zapata et al. (2019), organically modified CaCO3 nanoparticles, treated with oleic acid for improved compatibility with the polymer matrix, were incorporated into LDPE (Zapata et al., 2019). The resulting nano-composites were subjected to UV irradiation for photoaging. The photoaged CaCO3/LDPE nano-composites exhibited enhanced percent crystallinity, Young’s modulus and mechanical properties under tensile stress compared to pure LDPE. Additionally, the viscosity values of the photoaged nano-composites were lower than that of photoaged pure LDPE. Scanning electron microscopy (SEM) analysis revealed the formation of cavities around the nanoparticles, which may have accelerated the photo-degradation of the nano-composites. In another study by Sciancalepore et al. (2022), micro-particles of inorganic calcium-phosphate glass were used as reinforcement in bio-composites based on poly(butylene adipate-co-terephthalate) (PBAT) (Sciancalepore et al., 2022). The bio-composites, produced at different filler content, demonstrated an effective increase in Young’s modulus while reducing yield stress, stress at break, strain at break, and toughness. Moreover, the oxygen and water permeability of the samples were lower than that of LDPE as the organic filler content increased. These PBAT-based bio-composites show promise as biodegradable and eco-friendly alternatives to traditional thermoplastic polymers for food packaging applications. By incorporating inorganic fillers into conventional plastics or bio-composites, it is possible to enhance their mechanical properties and tailor their performance for specific applications. These developments contribute to the future development of novel eco-friendly polymers that can find application in various sectors, including agriculture and food packaging. Table 4 reports a schematic list of some of the described examples.

Safety Assessment of Agri-Food By-Products for Packaging Application

The exploitation of bioactive compounds from agri-food by-products in several industrial fields, especially for food and packaging companies, requires firstly the study of the efficacy and safety aspects before any scaling up. In fact, the natural origin of the employed materials does not guarantee safety, and recent studies evidenced the presence of potentially toxic compounds migrating from biobased objects in contact with food (Zimmermann et al., 2020). During the reuse of vegetable material, naturally occurring microorganisms and fungi can decompose and metabolize organic matter present, and can contain or originate potential pathogens, dangerous organic residues, and other physical and chemical contaminants which may negatively impact human health (Socas-Rodríguez et al., 2021). Besides, even potential allergens might occur (Cavazza et al., 2022).

Current EU regulations on food safety for human consumption state that newly processed foodstuffs enhanced with agri-food by-products must also follow legislation rules. Maximum levels for certain contaminants in food (nitrate, mycotoxins, metals, 3-monochloropropane-1,2-diol or 3-chloropropane-1,2-diol, dioxins, dioxin-like polychlorinated biphenyls, non-dioxin-like polychlorinated biphenyls, polycyclic aromatic hydrocarbons, melamine or erucic acid) are set in EC Regulation No, 1881/2006. In the case of food by-products used as food additives, they are regulated by EC Regulation No, 1333/2008.

Examples of the evaluation of hazardous substances agri-food by products were carried out by Moncalvo et al. (2016) that studied the influence of the ethanolic extraction process of grape skin from different varieties on the contamination levels in ochratoxin A, biogenic amines, pesticides, and metals in the final extract. Ochratoxin A, toxin produced by different Aspergillus and Penicillium species presented a migration in the range 36–88% during the extraction procedure by the high-performance liquid chromatography with tandem mass spectrometry (HPLC–MS/MS) results but were under the regulated limit for grapes and cereals. Several biogenic amines were found in both by-products including ethanolamine, ethylamine, and polyamines. Socas-Rodriguez and coworkers (2022) assessed the level pesticide residues in olive and citrus agro-food by-products samples demonstrating the presence of terbuthylazine (57.33 ± 29.50 µg/kg in olive by-products), malathion (85.53 ± 44.02 µg/kg and 45.43 ± 23.38 µg/kg in olive and citrus by-products respectively), endosulfan β (120.6 ± 62.1 µg/kg in olive by-products) that violate the maximum residue limits established by the UE Commission for the most of compounds evaluated. In the same way, some animal by-products also present the same problem, as it is the case of the accumulation of heavy metals in some specific organs, which can compromise any valuable valorization (Chen et al., 2019).

Thus, it is necessary to develop new and reliable analytical methods to evaluate the migration occurrence of contaminants in food from novel prototype of packaging enriched with BCs derived from agro-industrial by-products to safeguard safety of foodstuff and consumer health. The analytical approach to be addressed should be finalized not only at the determination of known analytes but also by an untargeted modality, directed to the search and the identification of possible unknown contaminants.

Conclusions, Challenges, and Future Works

In the described context, a great potential was underlined for food processing companies producing large amounts of food, through the exploitation of different by-products types. Many agro-industrial by-products have in fact been studied and employed as a low-cost material for the generation of value-added products.

In conclusion, the integration of circular economy principles in the industrial sector aims at turning the agri-food into high-value products with relevant potential applications in food, packaging, pharmaceutical and cosmetic sectors. This review reports several sustainable methodologies for the recovery of bioactive compounds from various sources that have great scale-up potentials. Several chemical components derived from agri-food by-products are reported to influence human health in a positive manner, and can be used as nutraceuticals, or to improve food technological parameters.

An interesting challenge that should be encouraged is the development of edible active films and coatings for packaging application, since it aims at improving food shelf-life working as antioxidant and antimicrobial agents, UV-light adsorbers, or as structural components. This strategy can be proposed to compensate the limited performance of biodegradable materials that at present constitute the main drawback of innovative packaging, and it causes a reduction of products shelf-life.

Besides, the recent advances in biobased and biodegradable polymers allow to develop bio-composite materials employing organic and inorganic bioactive compounds as reinforcement fillers that generally may enhance thermal and mechanical performances or provides bioactive effects reducing oxidative stress and the growth of specific pathogens.

As for possible prospects, the overview provided in this report highlights that there are many possibilities to improve the gain that can derive from by-products. Firstly, a deeper study on the effects of the parameters affecting the yields of the new extraction technologies should be encouraged. A chemometric approach could be useful to investigate the interaction between different variables involved. The results of a related data elaboration would permit to optimize the extraction conditions maximizing the final yields of selected targeted compounds. Besides, a more punctual analytical approach could also lead to discover different pattern of compounds deriving from more exhaustive extractions, thus achieving a more complete characterization of the occurring active substances. Furthermore, more experiments aimed at on the use of green and alternative technologies, avoiding high temperature, may allow to retain higher amounts of volatile and thermolabile compounds that could provide interesting features to the extracts.

New investigations on possible applications for the use of the extracts in different fields could be performed, including the herbal and nutraceutical sectors that are lately being more explored than in the past, due to an increasing interest of the consumers for natural-based formulations promoting health. Similarly, dietary supplements based on such extracts could be proposed, considering that synergistic effects may occur between different typologies of nutrients contained in the same vegetable. As example, an increase in the bioavailability and adsorption of polyphenols was described to be exerted by the joined presence of prebiotics in artichoke. Therefore, an antioxidant dietary supplement based on artichoke’s by-products could provide a higher effect than a purified mixture of the same compounds thanks to the simultaneous occurrence of oligosaccharides (Grimaldi et al., 2022).

Another interesting sector that could find great benefits is that of industrial food companies that could substitute chemical derived food additives such as coloring agents, antioxidants, stabilizers, emulsifiers, and thickening agents with natural derived compounds that the company itself produces as by-products. This would represent a real achievement of a circular economy towards the accomplishment of zero- and would also provide an economic added value to the farm.

As for packaging, a great challenge is ahead, and a multitude of developments can be found for innovative applications involving several aspects. Even design and marketing could find myriads of interesting ideas for original strategies of communication, based on nature inspired packaging: a peel that in origin represented the natural protective tool of a vegetable can become a raw material to realize a new packaging for a product based on the same vegetable.

Finally, a strict point that needs to be addressed urgently is connected to the lack of studies related to safety assessment of materials derived from by-products. Suitable analytical approaches should be developed to identify possible contaminants and to detect them at trace levels to assess safety. Adequate legislation should also appear for giving a regulation on the suitability and safety of new products enriched with BCs deriving from agri-food by-products. This review, as well, highlights the need for significant advancements in appropriate methodologies and effective procedures that allow a more adequate industrial processing, considering the safety of the finished products.

Data Availability

Not applicable.

References

Abbasi-Parizad, P., De Nisi, P., Scaglia, B., Scarafoni, A., Pilu, S., & Adani, F. (2021). Recovery of phenolic compounds from agro-industrial by-products: Evaluating antiradical activities and immunomodulatory properties. Food and Bioproducts Processing, 127, 338–348. https://doi.org/10.1016/J.FBP.2021.03.015

Ademosun, A. O., Oboh, G., Passamonti, S., Tramer, F., Ziberna, L., Boligon, A. A., & Athayde, M. L. (2015). Inhibition of metalloproteinase and proteasome activities in colon cancer cells by citrus peel extracts. Journal of Basic and Clinical Physiology and Pharmacology, 26(5), 471–477. https://doi.org/10.1515/JBCPP-2013-0127

Alexandre, E. M. C., Araújo, P., Duarte, M. F., de Freitas, V., Pintado, M., & Saraiva, J. A. (2017). High-pressure assisted extraction of bioactive compounds from industrial fermented fig by-product. Journal of Food Science and Technology, 54(8), 2519. https://doi.org/10.1007/S13197-017-2697-2

Alvarez, M. V., Ponce, A. G., & Moreira, M. R. (2018). Influence of polysaccharide-based edible coatings as carriers of prebiotic fibers on quality attributes of ready-to-eat fresh blueberries. Journal of the Science of Food and Agriculture, 98(7), 2587–2597. https://doi.org/10.1002/JSFA.8751

Amofa-Diatuo, T., Anang, D. M., Barba, F. J., & Tiwari, B. K. (2017). Development of new apple beverages rich in isothiocyanates by using extracts obtained from ultrasound-treated cauliflower by-products: Evaluation of physical properties and consumer acceptance. Journal of Food Composition and Analysis, 61, 73–81. https://doi.org/10.1016/J.JFCA.2016.10.001

Bandici, L., Teusdea, A. C., & Soproni, V. D. (2022). Influence of microwave heating on food bioactives, 369–395. https://doi.org/10.1007/978-3-030-96885-4_12

Banwo, K., Olojede, A. O., Adesulu-Dahunsi, A. T., Verma, D. K., Thakur, M., & Tripathy, S., et al. (2021). Functional importance of bioactive compounds of foods with potential health benefits: A review on recent trends. Food Bioscience, 43, 101320. https://doi.org/10.1016/J.FBIO.2021.101320

Barba, F. J., Zhu, Z., Koubaa, M., & Sant’Ana, A. S., & Orlien, V. (2016). Green alternative methods for the extraction of antioxidant bioactive compounds from winery wastes and by-products: A review. Trends in Food Science & Technology, 49, 96–109. https://doi.org/10.1016/J.TIFS.2016.01.006

Beikzadeh, S., Ghorbani, M., Shahbazi, N., Izadi, F., Pilevar, Z., & Mortazavian, A. M. (2020). The effects of novel thermal and nonthermal technologies on the properties of edible food packaging. Food Engineering Reviews, 12(3), 333–345. https://doi.org/10.1007/S12393-020-09227-Y/TABLES/5

Ben Jeddou, K., Bouaziz, F., Zouari-Ellouzi, S., Chaari, F., Ellouz-Chaabouni, S., Ellouz-Ghorbel, R., & Nouri-Ellouz, O. (2017). Improvement of texture and sensory properties of cakes by addition of potato peel powder with high level of dietary fiber and protein. Food Chemistry, 217, 668–677. https://doi.org/10.1016/J.FOODCHEM.2016.08.081

Bitas, D., Samanidou, V., Kabir, A., Lucena, R., & Cárdenas, S. (2021). Membrane sorptive phases. Analytical Sample Preparation With Nano- and Other High-Performance Materials, 199–228. https://doi.org/10.1016/B978-0-12-822139-6.00015-8

Boronat, T., Fombuena, V., Garcia-Sanoguera, D., Sanchez-Nacher, L., & Balart, R. (2015). Development of a biocomposite based on green polyethylene biopolymer and eggshell. Materials & Design, 68, 177–185. https://doi.org/10.1016/J.MATDES.2014.12.027

Briones-Labarca, V., Giovagnoli-Vicuña, C., & Chacana-Ojeda, M. (2019). High pressure extraction increases the antioxidant potential and in vitro bio-accessibility of bioactive compounds from discarded blueberries. http://mc.manuscriptcentral.com/tcyt, 17(1), 622–631. https://doi.org/10.1080/19476337.2019.1624622

Canale, M., Spina, A., Summo, C., Strano, M. C., Bizzini, M., & Allegra, M., et al. (2022). Waste from artichoke processing industry: Reuse in bread-making and evaluation of the physico-chemical characteristics of the final product. Plants, 11(24), 3409. https://doi.org/10.3390/PLANTS11243409

Capello, C., Trevisol, T. C., Pelicioli, J., Terrazas, M. B., Monteiro, A. R., & Valencia, G. A. (2020). Preparation and characterization of colorimetric indicator films based on chitosan/polyvinyl alcohol and anthocyanins from agri-food wastes. Journal of Polymers and the Environment, 29(5), 1616–1629. https://doi.org/10.1007/S10924-020-01978-3

Cavazza, A., Mattarozzi, M., Franzoni, A., & Careri, M. (2022). A spotlight on analytical prospects in food allergens: From emerging allergens and novel foods to bioplastics and plant-based sustainable food contact materials. Food Chemistry, 388, 132951. https://doi.org/10.1016/J.FOODCHEM.2022.132951

Chatzimitakos, T., Athanasiadis, V., Kotsou, K., Palaiogiannis, D., Bozinou, E., & Lalas, S. I. (2023). Optimized isolation procedure for the extraction of bioactive compounds from spent coffee grounds. Applied Sciences, 13(5), 2819. https://doi.org/10.3390/APP13052819

Chen, J., Li, M., Yi, R., Bai, K., Wang, G., & Tan, R., et al. (2019). Electrodialysis extraction of pufferfish skin (Takifugu flavidus): A promising source of collagen. Marine drugs, 17(1). https://doi.org/10.3390/MD17010025

Cinelli, P., Seggiani, M., Coltelli, M. B., Danti, S., Righetti, M. C., & Gigante, V., et al. (2020). Overview of agro-food waste and by-products valorization for polymer synthesis and modification for bio-composite production. Proceedings, 69(1), 22. https://doi.org/10.3390/CGPM2020-07211

Colunga Biancatelli, R. M. L., Berrill, M., Catravas, J. D., & Marik, P. E. (2020). Quercetin and vitamin C: An experimental, synergistic therapy for the prevention and treatment of SARS-CoV-2 related disease (COVID-19). Frontiers in Immunology, 11, 1451. https://doi.org/10.3389/FIMMU.2020.01451/BIBTEX

Corradini, C., Alfieri, I., Cavazza, A., Lantano, C., Lorenzi, A., Zucchetto, N., & Montenero, A. (2013). Antimicrobial films containing lysozyme for active packaging obtained by sol-gel technique. Journal of Food Engineering, 119(3), 580–587. https://doi.org/10.1016/J.JFOODENG.2013.05.046

Cruz-Tirado, J. P., Siche, R., Cabanillas, A., Díaz-Sánchez, L., Vejarano, R., & Tapia-Blácido, D. R. (2017). Properties of baked foams from oca (Oxalis tuberosa) starch reinforced with sugarcane bagasse and asparagus peel fiber. Procedia Engineering, 200, 178–185. https://doi.org/10.1016/J.PROENG.2017.07.026

Das, O., Babu, K., Shanmugam, V., Sykam, K., Tebyetekerwa, M., & Neisiany, R. E., et al. (2022). Natural and industrial wastes for sustainable and renewable polymer composites. Renewable and Sustainable Energy Reviews, 158, 112054. https://doi.org/10.1016/J.RSER.2021.112054

de Moraes Crizel, T., de Oliveira Rios, A., Alves, D., & V., Bandarra, N., Moldão-Martins, M., & Hickmann Flôres, S. (2018). Active food packaging prepared with chitosan and olive pomace. Food Hydrocolloids, 74, 139–150. https://doi.org/10.1016/J.FOODHYD.2017.08.007

Demir, T., & Ağaoğlu, S. (2021). Antioxidant, antimicrobial and metmyoglobin reducing activity of artichoke (Cynara scolymus) powder extract-added minced meat during frozen storage. Molecules, 26(18), 5494. https://doi.org/10.3390/MOLECULES26185494

Díaz-Montes, E., & Castro-Muñoz, R. (2021). Edible films and coatings as food-quality preservers: An overview. Foods, 10(2), 249. https://doi.org/10.3390/FOODS10020249

Diken, M. E., Koçer Kizilduman, B., Doğan, S., & Doğan, M. (2022). Antibacterial and antioxidant phenolic compounds loaded PCL biocomposites for active food packaging application. Journal of Applied Polymer Science, 139(25), e52423. https://doi.org/10.1002/APP.52423

Engel, J. B., Luchese, C. L., & Tessaro, I. C. (2022). Making the reuse of agro-industrial wastes a reality for starch-based packaging sector: A storage case study of carrot cake and cherry tomatoes. International Journal of Biological Macromolecules, 206, 740–749. https://doi.org/10.1016/J.IJBIOMAC.2022.03.074

Essabir, H., Nekhlaoui, S., Malha, M., Bensalah, M. O., Arrakhiz, F. Z., Qaiss, A., & Bouhfid, R. (2013). Bio-composites based on polypropylene reinforced with Almond Shells particles: Mechanical and thermal properties. Materials and Design, Complete (51), 225–230. https://doi.org/10.1016/J.MATDES.2013.04.031

Europe needs to step up circular economy efforts, including on waste prevention. (n.d.). https://www.eea.europa.eu/en/newsroom/news/circular-economy-target-monitoring-waste-prevention. Accessed 5 Jun 2023.

Faustino, M., Veiga, M., Sousa, P., Costa, E. M., Silva, S., & Pintado, M. (2019). Agro-food byproducts as a new source of natural food additives. Molecules, 24(6). https://doi.org/10.3390/MOLECULES24061056

Ferri, M., Vannini, M., Ehrnell, M., Eliasson, L., Xanthakis, E., Monari, S., et al. (2020). From winery waste to bioactive compounds and new polymeric biocomposites: A contribution to the circular economy concept. Journal of Advanced Research, 24, 1–11. https://doi.org/10.1016/J.JARE.2020.02.015

Gani, A., Ashraf, Z. U., Shah, A., Naik, A. S., Wani, I. A., & Gani, A. (2022). Upscaling of apple by-product by utilising apple seed protein as a novel wall material for encapsulation of chlorogenic acid as model bioactive compound. Foods, 11(22), 3702. https://doi.org/10.3390/FOODS11223702

Gargol, M., Klepka, T., Klapiszewski, Ł, & Podkościelna, B. (2021). Synthesis and thermo-mechanical study of epoxy resin-based composites with waste fibers of hemp as an eco-friendly filler. Polymers, 13(4), 1–17. https://doi.org/10.3390/POLYM13040503

Gigante, V., Cinelli, P., Righetti, M. C., Sandroni, M., Polacco, G., Seggiani, M., & Lazzeri, A. (2020). On the use of biobased waxes to tune thermal and mechanical properties of polyhydroxyalkanoates–bran biocomposites. Polymers, 12(11), 2615. https://doi.org/10.3390/POLYM12112615

Giubilini, A., Sciancalepore, C., Messori, M., & Bondioli, F. (2020). New biocomposite obtained using poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBH) and microfibrillated cellulose. Journal of Applied Polymer Science, 137(32), 48953. https://doi.org/10.1002/APP.48953

Giubilini, A., Sciancalepore, C., Messori, M., & Bondioli, F. (2021). Valorization of oat hull fiber from agri-food industrial waste as filler for poly(3-hydroxybutyrate-co-3-hydroxyhexanoate). Journal of Material Cycles and Waste Management, 23(1), 402–408. https://doi.org/10.1007/S10163-020-01104-4/TABLES/1

Gomes, A. C. A., da Costa Lima, M., de Oliveira, K. Á. R., dos Santos Lima, M., Magnani, M., Câmara, M. P. S., & de Souza, E. L. (2020). Coatings with chitosan and phenolic-rich extract from acerola (Malpighia emarginata D.C.) or jabuticaba (Plinia jaboticaba (Vell.) Berg) processing by-product to control rot caused by Lasiodiplodia spp. in papaya (Carica papaya L.) fruit. International journal of food microbiology, 331. https://doi.org/10.1016/J.IJFOODMICRO.2020.108694

Gowman, A., Wang, T., Rodriguez-Uribe, A., Mohanty, A. K., & Misra, M. (2018). Bio-poly(butylene succinate) and its composites with grape pomace: Mechanical performance and thermal properties. ACS Omega, 3(11), 15205–15216. https://doi.org/10.1021/ACSOMEGA.8B01675/ASSET/IMAGES/MEDIUM/AO-2018-016752_M003.GIF

Grimaldi, M., Pitirollo, O., Ornaghi, P., Corradini, C., & Cavazza, A. (2022). Valorization of agro-industrial byproducts: Extraction and analytical characterization of valuable compounds for potential edible active packaging formulation. Food Packaging and Shelf Life, 33, 100900. https://doi.org/10.1016/J.FPSL.2022.100900