Abstract

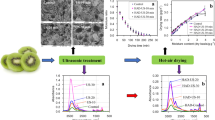

Drying is one of the most used options for the stabilization of the surpluses resulting from kiwifruit industrialization for their upcycling. However, drying conditions, such as drying temperature or ultrasound application during drying to intensify the process, can highly affect its final quality. Thus, with the aim to assess the combined influence of temperature and ultrasound application in the drying process of kiwifruit, ultrasonically assisted drying experiments were performed at 40, 50, 60 and 70 ºC. The process kinetics was greatly dependent on the temperature, as shown by the activation energy value obtained, 30.95 kJ/mol. Ultrasound application increased the drying kinetics, with its influence being more marked at the lowest temperatures tested. The increase in effective diffusivity and the mass transfer coefficient induced by ultrasound application was similar to the increase induced by an increase of drying temperature of 10 ºC. Drying caused a significant change in the color although the use of ultrasound helped to preserve it at the higher temperatures. Antioxidant capacity and vitamin C content decreased after drying, but the total phenolic content increased. The greatest retention of the antioxidant properties was observed in ultrasonically assisted samples dried at the highest temperatures. In the case of fiber properties, the best results were obtained at intermediate ones. Drying kiwifruit at 60 ºC with ultrasound application could serve as a means of balancing a fast drying process and good final quality.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Kiwifruit is one of the most widely cultivated and consumed fruits worldwide due to the fact that it has both great nutritional and sensory value. This fruit is known for its great antioxidant capacity, being a source of vitamins, especially ascorbic acid, and containing phenolic compounds of interest (Chamorro et al., 2022). The dietary fiber in kiwifruit is of high quality due to its good water and oil retention capacity, which contributes to the stabilization of the food structure (Wang et al., 2021). As a result of kiwifruit production, which is both extensive and industrialized, a large number of by-products and surpluses are generated, both considered as waste (Tylewicz et al., 2022). In the context of a circular economy, however, the upcycling is a must, and the stabilization of these by-products, for example via a drying process, is a necessary previous step for the purposes of reducing the degradation of compounds of interest. Thus, drying allows obtaining a kiwifruit-powdered product that can be used as ingredient to develop new products such as low-fat pork meatballs (Zhao et al., 2021) or healthy snacks (Tylewicz et al., 2020). In addition, the use of the whole by-product as ingredient has no need of intermediate operations (extraction, purification…), which can involve the use of solvents. This fact makes simpler and cheaper the processing, reduces the environmental impact and helps to achieve the clean label grade for the new products developed.

Hot air drying, despite being the most widely implemented industrial method for the dehydration of fruits and vegetables, involves high energy costs and is of limited efficiency (Kaur et al., 2020). In this sense, there has recently been a growing interest in studying new methods for drying kiwifruit, such as radio frequency-vacuum drying (Zhou et al., 2018), a combination of freeze drying and microwave vacuum drying (Huang et al., 2021), infrared heating-assisted hot air-drying (Wang et al., 2022) or a hybrid of convection and microwave drying (Bhat et al., 2022). Power ultrasound (US) has been shown to be efficient at enhancing the removal of moisture due to mechanical effects (Mousakhani-Ganjeh et al., 2021; Namjoo et al., 2022; Vallespir et al. 2019). However, one of the main challenges to make feasible this option is the generation and transmission of high intensity ultrasonic fields that induce significant changes in the process. Thus, the most common way to apply US is through solid–liquid pretreatments due to the availability of efficient commercial equipment (ultrasonic baths and probe systems) to generate US in liquid media. These pretreatment induces structural changes that can clearly enhance the kinetics of the later drying process (Kaveh et al., 2022; Prithani & Dash, 2020; Taghinezhad et al., 2021). However, this pretreatment can induce important losses of soluble compounds of interest (Wang et al., 2019), compromising the quality of the final product. Another alternative is the application of US by direct contact between ultrasonic transducers and samples. Thus, Liu et al. (2019, 2020b) have studied this alternative during drying of kiwifruit, finding shortenings of the drying process of great interest. However, the great friction generated between transducer and sample causes a significant thermal effect that could compromise thermosensitive compounds (Astráin-Redín et al., 2021). The third alternative is the application of airborne ultrasound during drying. This option overcomes some of the drawbacks of the former two ones, that is, the losses of soluble compounds and the samples temperature increase by friction, and significantly shorten drying process (García-Pérez et al., 2012). In this case, the generation and the transmission of US is a challenging issue due to the low impedance and the high attenuation properties of air. Product structure and drying temperature can highly influence the ultrasonic effects, not only from a kinetic point of view but also from the product quality one. Thus, the US influence in drying kinetics is greater in mushrooms (Vallespir et al., 2019) than in beetroot (Vallespir et al., 2018), being this probably linked with the different porosity of these products. Regarding quality, Fernandes et al. (2015) reported that the combined application of US and drying temperatures (45 and 60 ºC) affected the retention of B group vitamins differently. Do Nascimento et al. (2016) also reported a significant interaction effect in the antioxidant properties preservation of ultrasound and drying temperature (40 to 70 ºC) during passion fruit peel drying.

To our knowledge, the application of airborne ultrasound during kiwifruit drying has only been studied at low temperatures, 5, 10 and 15ºC (Vallespir et al., 2019). In these conditions, the US application at the highest temperature tested, 15 ºC, contributed to reduce the antioxidant capacity losses in dried samples. Then, the use of greater drying temperatures during the ultrasonically assisted drying of kiwifruit could contribute to a better preservation of antioxidant properties. No studies about the application of airborne US in kiwifruit drying in a moderate range of different temperatures have be found, those most commonly used at industrial level. In addition, also regarding the final quality of the product, the functional properties of the dried kiwifruit fiber has hardly been studied (Wang et al., 2021) and no studies about the effect of the temperature and US assisted drying interaction on color and functional properties of kiwifruit fiber have been found.

The aim of this study was to determine the influence of moderate drying temperatures and US application on the drying kinetics of kiwifruit and the quality of the final product, taking into account properties, such as color, antioxidant properties (antioxidant capacity, vitamin C, the total phenolic content) and functional properties (swelling capacity, water retention capacity and oil retention capacity).

Materials and Methods

Raw Material

Experiments were performed with kiwifruits (Actinidia deliciosa) obtained in a local market (Valencia, Spain) and stored at 4 ºC until drying experiments. Kiwifruits of similar size and degree of ripening (15.0 ± 1.0 ºBrix) were selected, since the kiwifruit ripeness influences the physicochemical properties and drying kinetics (Wang et al., 2022). The initial moisture content of the samples was 82.78 ± 0.89% and was determined in a vacuum oven at 60 ºC until constant weight. The kiwifruits were cut into slices of 6.0 ± 0.1 mm thickness and 55 ± 1 mm diameter with a sharp blade perpendicular to the vertical axis. Only samples from the central part of fruits were considered.

Drying Experiments

For each drying experiment, 9 slices from 3 different kiwifruits were randomly placed in a sample holder, which ensures a homogeneous air flow and ultrasound application during drying (Rojas et al., 2020). The experiments were carried out at 1 m/s at four different temperatures (40, 50, 60 and 70 ºC) in the range of those applied in drying fruit operations, without and with (US) power ultrasound application named 40, 50, 60, 70, 40-US, 50-US, 60-US and 70-US, respectively. For this purpose, an ultrasound-assisted convective dryer was used. The drying chamber consisted of a duraluminium cylinder (height: 0.31 m, diameter: 0.1 m, thickness 0.01 m) which is excited by several piezoelectric transducers in a sandwich arrangement. The system is provided by an impedance matching unit, which continuously tunes the impedance output of the generator (do Nascimento et al., 2016). Thus, the signal applied has always the resonance frequency (21.8 ± 0.4 Hz) which permits the system to achieve the best electrical yield and the power applied constant. In this sense, the ultrasonic assisted drying experiments were carried out at 50 W (20.5 kW/m3). The sample weight was automatically recorded every 5 min throughout the drying process until reaching a moisture content of 0.161 ± 0.003 kg water/ kg dm. This moisture content involves a water activity lower than 0.6 (Moraga et al., 2006), which ensures the stability of the product and was appropriate to get a kiwifruit powder for later use. Every drying condition was tested at least three times. After drying, the samples were stored in an environment of low relative humidity with silica gel until quality analysis.

Mathematical Modeling

The experimental data was modeled in order to quantify the influence of both temperature and ultrasound application on the drying kinetics with a diffusion model based on Fick’s second law. The samples were considered as an infinite slab of half-thickness, the effective diffusivity (\({D}_{eff}\)), constant, and the solid, isotropic (Eq. (1)):

where \(W\) is the moisture content (kg water (w)/kg dry matter (dm)), \({D}_{eff}\) is the effective diffusivity (m2/s), \(t\) is the drying time (s), and \(x\) is the direction of the water transport (m).

In order to solve Eq. (1), it was also assumed that the initial moisture content was uniform, the samples were symmetric and the volume during drying was constant.

In this way, \({D}_{eff}\) constitutes a measurement of the reverse of internal resistance to mass transport offered by the product. In addition, due to the low air velocity used, the external resistance was also considered (Corrêa et al., 2017). Thus, the mass transport coefficient (\(k\); kg water/m2s) was included in the model by the boundary condition shown in Eq. (2):

where \({\rho }_{ss}\) is the dry solid density (kg dm/m3), \({a}_{w}\) is the water activity,\(L\) is the half thickness of the kiwifruit samples, and \({\varphi }_{air}\) is the relative humidity of the air drying. This equation expresses the continuity of the moisture transport, by diffusion due to moisture content gradients inside the sample until to the solid surface and by convection from the solid surface to the drying air. The equilibrium moisture content was calculated according to the sorption isotherm reported by Moraga et al. (2006).

The model was numerically solved and the SIMPLEX optimization method of Matlab (Matlab 2015™, Inc, Natick, USA) was used to identify \({D}_{eff}\) and \(k\) by minimizing the squared sum of differences between the experimental and calculated moisture content. Explained variance (\(\% Var\)) was used to assess the model’s fit to the experimental data (Eq. (3)):

where \({S}_{xy}^{2}\) is the standard deviation of the estimation, and \({S}_{y}^{2}\) is the standard deviation of the experimental data.

The influence of the temperature on \({D}_{eff}\) was described by an Arrhenius type equation (Eq. (4)):

where \({D}_{0}\) is a pre-exponential factor of the Arrhenius equation (m2/s), \({E}_{a}\) is the activation energy for water diffusion (kJ/mol), \(R\) is the gas constant (kJ/mol K) and \(T\) is the temperature of each experiment (K).

Quality Analysis

Some quality parameters of dried samples were evaluated to determine the influence of temperature and ultrasound application. Every measurement was taken at least three times.

Color

The color of fresh and dried kiwifruit was directly determined in the green zone of the samples, avoiding the seeds and the whitish core areas with the aim of reducing the influence of the natural variance of fruits in the measurements. In this way, the \({L}^{*}\), \({a}^{*}\) and \({b}^{*}\) color coordinates were measured with a CM-2500d colorimeter (Konica Minolta, Japan). The system was provided with a measurement area of 8 mm in diameter, a reference system of illuminant D65 and an observation angle of 10º. The specular component was excluded. The total color difference (\(\Delta E\)) between the fresh (f) and the dried (d) samples was calculated by Eq. (5):

Antioxidant Properties

The antioxidant properties were evaluated before and after drying to determine their retention. Every measurement was replicated 9 times. For this purpose, an ethanol extract was prepared by placing 1.000 ± 0.002 g of ground sample, sieved through a pore size mesh of 200 µm, in 20 mL of 96% ethanol (analysis quality) and homogenized with an ultra-Turrax (T25 Digital, IKA, Germany) at 13,500 rpm. The mixture was kept at 4 ºC for 24 h, then centrifuged at 4,000 rpm for 10 min (Medifriger BL-S, P. Selecta, Spain) and filtered through glass microfiber with a 1.2 µm pore. The antioxidant properties determined in the filtrate were as follows:

-

Antioxidant Capacity (AC): AC was evaluated following the Ferric Reducing Ability Power (FRAP) method (Benzie & Strain, 1996). For this purpose, the FRAP reagent was prepared from an equivalent mix of 0.3 M acetate buffer (Panreac, Barcelona, Spain), 20 mM of FeCl3 6·H2O (Labkem, Barcelona, Spain) and 10 mM TPTZ (Sigma-Aldrich, Madrid, Spain) diluted in 40 mM HCl (Panreac, Barcelona, Spain), and it was incubated for 30 min at 37 ºC. 900 µL of the obtained reagent were mixed with 30 µL of distilled water and 30 µL of the ethanol extract. The mixture was incubated again at 37 ºC and, the absorbance at 595 nm was read after 30 min in a spectrophotometer (Helios, Gamma, Thermo Spectronic, Cambridge, UK). The results, expressed as Trolox equivalent, were determined through a calibration curve, previously made with Trolox solutions of known concentration (Sigma-Aldrich, Madrid, Spain).

-

Vitamin C (VC): For the VC determination (Jagota & Dani, 1982), 500 µL of the ethanol extract were mixed by shaking with 500 µL of 7.5% C2HCl3O2 (Panreac, Barcelona, Spain). After 5 min of incubation at 4 ºC, the mixed solution was filtered (0.45 µm pore). 200 µL of this filtered solution was mixed with 2 mL of distilled water and 200 µL L 1:10 Folin-Ciocalteu solution. It was incubated for 10 min before the absorbance was read at 760 nm in the spectrophotometer. The results were expressed as equivalent of ascorbic acid (AA) through a calibration curve prepared with ethanol solutions of known AA concentrations (Sigma-Aldrich, Madrid, Spain).

-

Total Phenolic Content (TPC): TPC was measured through the Folin-Ciocalteu method (Gao et al., 2000). For this purpose, 100 µL of the ethanol extract was mixed with 200 µL of the Folin-Ciocalteu reagent (Sigma–Aldrich, Madrid, Spain) and 2 mL of distilled water. After 3 min at room temperature, 1 mL of 20% Na2CO3 (Labkem, Barcelona, Spain) was added and it was incubated for 1 h at room temperature. Then, the absorbance of the samples was measured in a spectrophotometer at 765 nm. The equivalent concentration of gallic acid (GA) was obtained thanks to a calibration curve previously made with different ethanol solutions of known GA concentrations (Sigma-Aldrich, Madrid, Spain).

Functional Properties

The functional properties are closely related to the quality of a product and can define its use as functional ingredient. The drying process can modify physicochemical properties and thus these functional properties. In this sense, the kiwifruit powder obtained after drying process was sieved through a pore size mesh of 200 μm and the swelling capacity (SW), water retention capacity (WRC) and oil retention capacity (ORC) were analyzed following the procedure described by Garau et al. (2007) in order to evaluate the influence of the drying temperature and US application. In every case, the measurements were replicated 9 times.

-

Swelling Capacity (SW): SW was estimated by placing 0.20 ± 0.01 g of dried kiwifruit powder in a graduated cylinder and adding 10 mL of distilled water. The initial volume of the sample was compared with the volume after 24 h at room temperature. The results were expressed as mL/ g dm.

-

Water Retention Capacity (WRC): in order to measure WRC, 0.20 ± 0.01 g of dried kiwifruit was hydrated with 10 mL of distilled water. After 24 h at room temperature, the sample was centrifuged (15 min, 10,000 rpm, 4 ºC), removing the excess of water. The amount of water retained was determined by calculating the difference between the hydrated and the dried sample weight and the WRC expressed as kg water/kg dm.

-

Oil Retention Capacity (ORC): for the purposes of estimating ORC, 0.20 ± 0.01 g of the sample were immersed in 10 mL of sunflower oil. After 24 h at room temperature, it was centrifuged (15 min, 10,000 rpm, 4 ºC) and the excess of oil removed. The oil retained in the sample was calculated by differential weighing and the results indicated as kg oil/kg dm.

Statistical Analysis

Statistical analyses were performed to determine the significance of the impact of air temperature and ultrasound application on the drying kinetics and quality parameters. For this purpose, the experimental data was statistically analyzed by analysis of variance (ANOVA) using the Statgraphics Centurion XVIII software (Statpoint Technologies Inc., Warrenton, VA, USA). LSD (Least Significant Difference) intervals (p < 0.05) were also determined to identify the significance of the differences between the levels of factors tested.

Results and Discussion

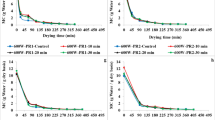

Drying

The air-drying temperature clearly affected the drying rate of the kiwifruit. At the higher temperatures, the total drying process was shorter than in the case of the experiments carried out at the lower temperatures. In this sense, to achieve a moisture content of 0.16 kg water/ kg dm, an increase from 40 to 70 ºC reduced the drying time by 62.42% (Fig. 1). Other authors also have reported drying time reductions with the increase of drying temperature (Darıcı & Şen, 2015; Mahjoorian et al., 2017). This can be linked to the greater energy provided by drying air at a high temperature, which increased the kinetic energy of the water molecules.

The application of power ultrasound (US) during the drying process also led to it being shorter at every temperature tested. Studying the convective drying of kiwifruit with a hybrid dryer, Kroehnke et al. (2021) also found significant reductions in the process time when applying ultrasound. However, the ultrasonic effect was not the same in all of them, the time reduction being 30.3, 29.2, 22.8 and 18.3% at 40, 50, 60 and 70 ºC, respectively (Fig. 1). This effect has previously been reported in the case of the US-assisted drying of passion fruit peel (Do Nascimento et al., 2016), cherry tomatoes (Fernandes et al., 2016) or red peppers (Carcel et al., 2019) over a similar temperature range. As the temperature increased, the drying air provided more energy to the system masking the effect of ultrasound application, which was more intense at low temperatures. In fact, studying the ultrasound-assisted drying (20.5 kW/m3) of kiwifruit at low temperature 5, 10 and 15 ºC, Vallespir et al. (2019) reported greater time reductions (between 55 and 65%). Therefore, the lower the drying air temperature, the more intense the ultrasound effects on drying kinetics.

Mathematical Modeling

Table 1 shows the mean values of effective diffusivity (\({D}_{eff}\)) and the mass transfer coefficient (\(k\)) identified in the modeling of drying kinetics obtained under the different experimental conditions tested. Regardless of the conditions considered, the percentage of explained variance (\(\% Var\)) was greater than 99%, which indicates the good fit of the model. The identified values were in the range as other reported for kiwifruit drying (Guine et al., 2017; Liu et al., 2020b).

The \({D}_{eff}\) values identified (from 1.7 to 6.0 ·10–9 m2/s) increased in line with the rise in the drying air temperature. Thus, it was observed that an increase in the air drying temperature from 40 to 70 ºC meant a 64% rise in \({D}_{eff}\). The increase in drying temperature provided more energy for the movement of the water molecules, thereby enhancing the diffusivity of the water within the sample (Martín-Gómez et al., 2020). The mass transfer coefficient, \(k\), was also affected by temperature, inducing an increase of about 49% when the temperature rose to 70 ºC from 40 ºC.

The application of ultrasound (US) increased both \({D}_{eff}\) and \(k\) compared with conventional drying (without ultrasound application) carried out at the same temperature. Inside the kiwifruit samples, US could weaken the internal resistance to mass transfer by the formation of internal microchannels facilitating the diffusion of water from the interior to the surface (Goztepe et al., 2022; Vallespir et al., 2019). US also affected the external resistance, generating turbulence and microstreaming at the interfaces which reduced the boundary layer of diffusion and caused changes in the surface of the product (Garcia-Perez et al., 2023). Thus, the intensification of the \({D}_{eff}\) and \(k\) values induced by US treatment applied in this study was found to be approximately equivalent to an increase in the drying temperature of 10 ºC.

The influence of temperature on \({D}_{eff}\) was quantified by fitting an Arrhenius relationship (Fig. 2). The correlation coefficients achieved (0.9891 and 0.9613 for experiments carried out without and with US application, respectively) showed the good fit of this equation. The activation energy value (\({E}_{a}\)) estimated for samples dried without US application was 30.95 kJ/mol. This value is coherent with other \({E}_{a}\) values found in kiwifruit drying (Chin et al., 2015; Guine et al., 2017; Simal et al., 2005) and indicates how the significant is temperature influence on the drying kinetics of kiwifruit. In the case of drying with US application, the \({E}_{a}\) value obtained, 27.41 kJ/mol, was lower. The additional mechanical energy provided by ultrasound reduced the influence of temperature on the drying kinetics (Bennaceur et al., 2021). Moreover, the application of US significantly reduced the pre-exponential value \({D}_{0}\), from 2.41 × 10–4 to 9.19 × 10–5 m2/s.

Color

Color is one of the most important quality parameters of dried food products, and can determine consumer acceptance. The use of high temperatures during drying can cause the degradation of some compounds, as well as Maillard browning reactions (Vieira da Silva Júnior et al., 2018). In the case of kiwifruit, it was found that drying produced changes in the color parameters regardless of the conditions applied (Table 2). Thus, the value of \({L}^{*}\) increased significantly after drying: the higher the drying temperature, the greater the value. Although some authors have reported a lower degree of luminosity after the drying of different products (Bhat et al., 2022; Martins et al., 2019). Simal et al. (2005) also observed that luminosity increased alongside the rise in temperature when studying the drying of kiwifruit. Parameter \({a}^{*}\) moved from negative values in fresh kiwifruit to positive in the case of dried samples, indicating a transition from green to red, which was enhanced with the increase in temperature. Chlorophyll is a thermosensitive compound, responsible for the greenness of kiwifruit (Kroehnke et al., 2021) and its degradation resulting from the thermal treatment involved in the drying process, could be associated with the changes in parameter \({a}^{*}\).

Regarding the effect of US application during drying, it did not induce significant changes in the color parameters at low temperatures. However, significantly lower \(\Delta E\) was observed in samples dried at 60 and 70 ºC with ultrasound application (Table 2), similar to those found at lower drying temperatures. The decrease in drying times caused by US could weaken the undesired thermal effects and reduce oxidation during drying, as has been seen in the US drying of other products, such as mushrooms (Szadzińska et al., 2022), raspberries (Kowalski et al., 2016) or sunflower seeds (Dibagar et al., 2020).

Antioxidant Properties

The retention percentage of the antioxidant capacity (AC), vitamin C (VC) and total phenolic content (TPC) were determined to evaluate the influence of the drying temperature and US application on the antioxidant properties of dried kiwifruit samples.

The AC of the fresh kiwifruit was 120 ± 26 μmol Trolox/ 100 g dm. This value dropped after drying, with the retention values observed being in the range of 43 and 58% (Table 3). The rise in the drying temperature resulted in higher AC retention percentages. The long drying times required when drying at low temperatures could lead to the oxidation of the antioxidant compounds. At the same time, high temperatures could better preserve the antioxidant activity because of the inactivation of oxidative enzymes as well as the formation of new antioxidant compounds derived from Maillard reactions (Llavata et al., 2022). The enhancement of the AC as the temperature rises has also been observed in the case of the drying of maqui berries (Rodríguez et al., 2016) or plums (Hassan et al., 2022).

US application affected the AC of samples dried at 60 ºC, during which process a significant decrease (p < 0.05) was observed. However, no significant differences were found for samples dried at the other temperatures tested. When drying passion fruit peel, Do Nascimiento et al. (2016) reported that the application of US did not produce any significant effect in AC at temperatures of 40 and 50 ºC, but caused an intense decrease at 60 and 70 ºC. These authors attributed this fact to the combination of the high temperature and cellular damage caused by US.

The antioxidant activity of a product is dependent on the content of antioxidant compounds. In this study, a close correlation was found between the percentage of AC retention and those of VC (correlation coefficient of 0.9118) and TPC (correlation coefficient of 0.8341). The VC content of fresh samples (90 ± 3 mg AA/100 g dm), which was similar to that found in other studies (Bhat et al., 2022; Zhou et al., 2018), decreased after drying until a retention range from 60 to 77% (Table 3). The greatest loss in VC was observed in the samples dried at 40 ºC. No significant differences were found among the other temperatures tested. The longer drying time at 40 ºC could lead to its greater degradation. The application of US involves a slight but significant (p < 0.05) decrease of VC retention at 50 and 60 ºC but an increase at 70 ºC, being this last results likely linked to the shorter drying process. When applying US in kiwifruit drying by contact among transducer and sample (no airborne US), Liu et al. (2019) found better VC retentions at every temperature studied. They attributed this fact to the reductions in the drying time and oxidation reaction time. Conversely, Vallespir et al. (2019), studying the drying of kiwifruit at low temperature (from 5 to 15 ºC), found that the application of airborne US reduced the VC content. They related this fact to the structural damage caused by ultrasonic waves. The results observed in the current study when applying US during drying could be attributed to the fact that the possible negative effects of US on VC could be masked by the positive ones induced by the shortening of the drying process.

The initial TPC of the kiwifruit samples was 3.0 ± 0.9 mg GA/ 100 g dm. Unlike AC and VC, the retention percentage of TPC increased after drying. Some studies reported a reduction of TPC after drying and attributed this to a possible degradation of phenolic compounds (Goztepe et al., 2022; Kayacan et al., 2020). However, higher TPC values have been found after the drying process in products such as guava (Liu et al., 2020), wolfberry (Dandan Zhao et al., 2019) or grape (Martín-Gómez et al., 2019). In these cases, new polyphenols can be released, such as some phenolic acids bounded to cellular structures. In addition, polyphenols in an intermediate oxidation state may have greater radical scavenging efficiency. Kiwifruit has a good phenolic profile, rich in phenols such as pyrogallol, quercetin, caffeic acid or ferulic acid among others (Bursal & Gülçin, 2011) which content and activity could be affected by drying conditions. Thus, only samples dried at 40 ºC without US application, which corresponded to the longest drying process, did not show a significant increase in TPC. US application at this temperature enhanced the TPC, possibly due to the shorter exposure to oxygen. A significant improvement in TPC was found when applying US at 70 ºC. The application of ultrasound, in this sense, could have promoted a greater extraction of phenolic compounds. Thus, Wang et al. (2019) reported an increase in the content of polyphenols such as ferulic acid, catechin and gallic acid in dried kiwifruit samples pretreated with ultrasound. They attributed this fact not only due to cell membrane rupture, but also due to the addition of hydroxyl radicals to their aromatic rings. This result disagrees with those reported by Do Nascimento et al. (2016) for passion fruit peel drying where a significant decrease of TPC was found in drying experiments with ultrasound application carried out at the same temperature, 70 ºC. This fact indicates that the combined effects of temperature and ultrasound are highly dependent on the product considered. Additional studies could help to a better understanding of the evolution of phenolic content and phenolic profile during drying of kiwifruit.

It could be stated that the high drying temperatures contributed to a better preservation of the antioxidant properties of kiwifruit samples. In addition, ultrasound generally did not have a negative effect on antioxidant properties; on the contrary, in some cases it even induced a better retention of antioxidant compounds.

Functional Properties

Kiwifruit is a source of both soluble and insoluble fiber due to its content of hemicelluloses, cellulose, pectic substances or lignin (Wang et al., 2021). The temperature of the drying process, as well as the application of ultrasound, can modify these compounds and, thus, the functional properties of the kiwifruit.

Swelling capacity (SW) indicates how much the matrix swells when water is absorbed. It is related with the satiating capacity of fiber when introduced into a diet. The SW of dried samples varied between 3.9 and 7.7 mL/g dm (Fig. 3a), which was in the range of those found by Zhuang et al. (2019). The highest value of SW was found in the samples dried at 60 ºC, while they were significantly lower (p < 0.05) at 40 and 70 ºC. Longer drying processes associated with lower temperatures can cause tissue shrinkage that affects porosity (Nieto-Calvache et al., 2019). On the contrary, the use of high temperatures can damage polysaccharides, and thus hinder water absorption. As far as US application is concerned, a SW improvement was found when applying US during drying process at 50 ºC. The mechanical effect produced by US could cause some cell rupture resulting in an enhancement of this property. However, at the remaining temperatures, no statistical differences were found. When working on the convective drying of orange peel, Mello et al. (2020) did not find any significant differences in the SW when applying US.

The water retention capacity (WRC) is related to an increase in the speed of the passage of feces through the intestinal tract. Therefore, it is associated with the prevention of disorders, such as constipation, and some types of cancer, such as colon cancer. The kiwifruit samples presented WRC values of between 2.7 and 4.4 kg w/kg dm (Fig. 3b). Similarly to SW, the highest value was also found in samples dried at 60 ºC, while samples dried at 70 ºC presented the lowest. High-temperature drying can generate a more rigid structure and lead to the collapse of channels, worsening the WRC (Llavata et al., 2022; Santos et al., 2022). Although the application of US during drying improved the WRC at the two lowest temperatures tested, 40 and 50 ºC, it reduced it at 60 and 70 ºC; these differences, however, were significant only in samples dried at 60 ºC.

The oil retention capacity (ORC) is a measurement of the ability of the product for retaining fats, avoiding their absorption in the intestinal tract. The ingestion of products with this functional property is related with a reduction of the cholesterol level in blood. The dried kiwifruit samples presented an ORC in the range of 2.5 to 3.1 kg oil/kg dm (Fig. 3c). These values were lower than those found for dehydrated mushroom samples (Vallespir et al., 2019) but higher than the ORC of other products, such as lemon peel (Ghanem et al., 2020) or apple and orange pomace (O’Shea et al., 2015). This could be of great interest since high ORC values can prevent oil losses during food processing or reduce cholesterol absorption during digestion (Liu et al., 2021). Again, it was found that drying at the intermediate temperatures tested, 50 and 60 ºC, better preserved ORC, indicating that both the long processing time and the high temperatures impair the functional properties. This trend was also observed in the drying of artichoke bracts and stems (Borsini et al., 2021). The application of ultrasound only affected ORC at the lowest temperature tested, 40 ºC, at which a significant (p < 0.05) increase in ORC was found. Vallespir et al. (2019) studying the drying of kiwifruit at low temperature (5–15 ºC) also reported an improvement of ORC when ultrasound was applied.

Therefore, the functional properties of kiwifruit were better preserved by drying at intermediate temperatures, especially at 60 ºC, without there being a marked influence of the application of ultrasound during drying.

Conclusions

The drying of kiwifruit at different temperatures with the application of airborne ultrasound was assessed. An increase in the drying temperature led to a reduction in the process time. Power ultrasound shortened the drying times in every case, the influence being more evident at lower temperatures. The diffusive model, which presented a good fit, revealed that US application reduced both internal and external mass transfer resistance. The increase in the \({D}_{eff}\) and \(k\) values was equivalent to an increase in the drying temperature of over 10 ºC. The identified \({E}_{a}\) value demonstrated the great influence of the drying temperature on the drying kinetics of kiwifruit, an influence which weakened when applying US. As for the quality parameters, the drying affected the color of the kiwifruit samples. The \({L}^{*}\) value increased significantly after drying and \({a}^{*}\) increased in line with the rise in the drying temperature. The AC and VC decreased after drying, being better preserved when high drying temperatures were used. In contrast, the TPC increased, which can be related with the formation of new phenolic compounds or a better extraction due to structural changes caused by the US. US application reduced the antioxidant properties of the samples dried at 50 and 60 ºC, but strengthened them at 40 and 70 ºC. Finally, the functional properties of kiwifruit fiber, SW, WRC and ORC, were greater at the intermediate drying temperatures tested of 50 and 60 ºC, which increased slightly when US was applied.

Therefore, as a whole, it can be stated that the drying of kiwifruit at 60 ºC with US application could represent a good balance between a short processing time and quality preservation. In these conditions, the drying time was similar to that obtained when drying at 70 ºC, and the quality parameters were similar to those obtained at 50–60 ºC.

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Astráin-Redín, L., Alejandre, M., Raso, J., Cebrián, G., & Álvarez, I. (2021). Direct Contact Ultrasound in Food Processing: Impact on Food Quality. Frontiers in Nutrition, 8(January), 1–11. https://doi.org/10.3389/fnut.2021.633070

Bennaceur, S., Berreghioua, A., Bennamoun, L., Mulet, A., Draoui, B., Abid, M., & Carcel, J. A. (2021). Effect of ultrasound on henna leaves drying and extraction of lawsone: Experimental and modeling study. Energies, 14(5). https://doi.org/10.3390/en14051329

Benzie, I. F. F., & Strain, J. J. (1996). The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: The FRAP assay. Analytical Biochemistry, 239(1), 70–76. https://doi.org/10.1006/abio.1996.0292

Bhat, T. A., Hussain, S. Z., Wani, S. M., Rather, M. A., Reshi, M., Naseer, B., Qadri, T., & Khalil, A. (2022). The impact of different drying methods on antioxidant activity, polyphenols, vitamin C and rehydration characteristics of Kiwifruit. Food Bioscience, 48(April), 101821. https://doi.org/10.1016/j.fbio.2022.101821

Borsini, A. A., Llavata, B., Umaña, M., & Cárcel, J. A. (2021). Artichoke by products as a source of antioxidant and fiber: How it can be affected by drying temperature. Foods, 10(2), 1–13. https://doi.org/10.3390/foods10020459

Bursal, E., & Gülçin, I. (2011). Polyphenol contents and in vitro antioxidant activities of lyophilised aqueous extract of kiwifruit (Actinidia deliciosa). Food Research International, 44(5), 1482–1489. https://doi.org/10.1016/j.foodres.2011.03.031

Carcel, J. A., Castillo, D., Simal, S., & Mulet, A. (2019). Influence of temperature and ultrasound on drying kinetics and antioxidant properties of red pepper. Drying Technology, 37(4), 486–493. https://doi.org/10.1080/07373937.2018.1473417

Chamorro, F., Carpena, M., Fraga-Corral, M., Echave, J., Riaz Rajoka, M. S., Barba, F. J., Cao, H., Xiao, J., Prieto, M. A., & Simal-Gandara, J. (2022). Valorization of kiwi agricultural waste and industry by-products by recovering bioactive compounds and applications as food additives: A circular economy model. Food Chemistry, 370(July 2021), 131315. https://doi.org/10.1016/j.foodchem.2021.131315

Chin, S. K., Siew, E. S., & Soon, W. L. (2015). Drying characteristics and quality evaluation of kiwi slices under hot air natural convective drying method. International Food Research Journal, 22(6), 2188–2195.

Corrêa, J. L. G., Rasia, M. C., Mulet, A., & Cárcel, J. A. (2017). Influence of ultrasound application on both the osmotic pretreatment and subsequent convective drying of pineapple (Ananas comosus). Innovative Food Science and Emerging Technologies, 41(November 2016), 284–291. https://doi.org/10.1016/j.ifset.2017.04.002

da Silva, V., Júnior, E., Lins de Melo, L., Batista de Medeiros, R. A., Pimenta Barros, Z. M., & Azoubel, P. M. (2018). Influence of ultrasound and vacuum assisted drying on papaya quality parameters. Lwt, 97(July), 317–322. https://doi.org/10.1016/j.lwt.2018.07.017

Darıcı, S., & Şen, S. (2015). Experimental investigation of convective drying kinetics of kiwi under different conditions. Heat and Mass Transfer/waerme- Und Stoffuebertragung, 51(8), 1167–1176. https://doi.org/10.1007/s00231-014-1487-x

Dibagar, N., Kowalski, S. J., Chayjan, R. A., & Figiel, A. (2020). Accelerated convective drying of sunflower seeds by high-power ultrasound: Experimental assessment and optimization approach. Food and Bioproducts Processing, 123, 42–59. https://doi.org/10.1016/j.fbp.2020.05.014

Do Nascimento, E. M. G. C., Mulet, A., Ascheri, J. L. R., De Carvalho, C. W. P., & Cárcel, J. A. (2016). Effects of high-intensity ultrasound on drying kinetics and antioxidant properties of passion fruit peel. Journal of Food Engineering, 170, 108–118. https://doi.org/10.1016/j.jfoodeng.2015.09.015

Fernandes, F. A., Rodrigues, S., García-Pérez, J. V., & Cárcel, J. A. (2016). Effects of ultrasound-assisted airdrying on vitamins and carotenoids of cherry tomatoes. Drying Technology, 34(8), 986–996. https://doi.org/10.1080/07373937.2015.1090445

Fernandes, F. A. N., et al. (2015). Ultrasound-assisted air-drying of apple (Malus domestica L.) and its effects on the vitamin of the dried product. Food and Bioprocess Technology, 8, 1503–1511. https://doi.org/10.1007/s11947-015-1519-7

Gao, X., Bjork, L., Trajkovski, V., & Uggla, M. (2000). Evaluation of antioxidant activities of rosehip ethanol extracts in different test systems. Journal of the Science of Food and Agriculture, 80(14), 2021–2027. https://doi.org/10.1002/1097-0010(200011)80:14%3c2021::AID-JSFA745%3e3.0.CO;2-2

Garau, M. C., Simal, S., Rosselló, C., & Femenia, A. (2007). Effect of air-drying temperature on physico-chemical properties of dietary fibre and antioxidant capacity of orange (Citrus aurantium v. Canoneta) by-products. Food Chemistry, 104(3), 1014–1024. https://doi.org/10.1016/j.foodchem.2007.01.009

Garcia-Perez, J. V., Carcel, J. A., Mulet, A., Riera, E., Roque R, A., & Gallego-Juarez, J. A. (2023). Ultrasonic drying for food preservation (Juan Gallego-Juarez, K. Graff, & M. Lucas (eds.); 2nd ed.). Elsevier. https://doi.org/10.1016/j.optmat.2011.11.002

Garcia-Perez, J. V., Ortuño, C., Puig, A., Carcel, J. A., & Perez-Munuera, I. (2012). Enhancement of water transport and microstructural changes induced by high-intensity ultrasound application on orange peel drying. Food and Bioprocess Technology, 5, 2256–2265. https://doi.org/10.1007/s11947-011-0645-0

Ghanem, N., Mihoubi, D., Bonazzi, C., Kechaou, N., & Boudhrioua, N. (2020). Drying Characteristics of Lemon By-product (Citrus limon. v. lunari): Effects of Drying Modes on Quality Attributes Kinetics’. Waste and Biomass Valorization, 11(1), 303–322. https://doi.org/10.1007/s12649-018-0381-z

Goztepe, B., Kayacan, S., Bozkurt, F., Tomas, M., Sagdic, O., & Karasu, S. (2022). Drying kinetics, total bioactive compounds, antioxidant activity, phenolic profile, lycopene and β-carotene content and color quality of Rosehip dehydrated by different methods. In Lwt (Vol. 153). https://doi.org/10.1016/j.lwt.2021.112476

Guine, R. P. F., Brito, M. F. S., & Ribeiro, J. R. P. (2017). Evaluation of Mass Transfer Properties in Convective Drying of Kiwi and Eggplant. International Journal of Food Engineering, 13(7). https://doi.org/10.1515/ijfe-2016-0257

Hassan, A. M. A., Zannou, O., Pashazadeh, H., Ali Redha, A., & Koca, I. (2022). Drying date plum (Diospyros lotus L.) fruit: Assessing rehydration properties, antioxidant activity, and phenolic compounds. Journal of Food Science. https://doi.org/10.1111/1750-3841.16322

Huang, L. L., Lian, M. M., Duan, X., Li, B., & Yang, S. Z. (2021). Studies on the quality and moisture distribution of kiwifruit dried by freeze drying combined with microwave vacuum drying. Journal of Food Process Engineering, 44(1). https://doi.org/10.1111/jfpe.13581

Jagota, S. K., & Dani, H. M. (1982). A new colorimetric technique for the estimation of vitamin C using Folin phenol reagent. Analytical Biochemistry, 127(1), 178–182. https://doi.org/10.1016/0003-2697(82)90162-2

Kaur, R., Kaur, K., & Ahluwalia, P. (2020). Effect of drying temperatures and storage on chemical and bioactive attributes of dried tomato and sweet pepper. Lwt, 117(April 2019), 108604. https://doi.org/10.1016/j.lwt.2019.108604

Kaveh, M., Taghinezhad, E., Witrowa-Rajchert, D., Imanian, K., Khalife, E., & Nowacka, M. (2022). Use of ultrasound pre-treatment before microwave drying of kiwifruits – An optimization approach with response surface methodology. Journal of Food Processing and Preservation, 46(7), 1–11. https://doi.org/10.1111/jfpp.16714

Kayacan, S., Karasu, S., Akman, P. K., Goktas, H., Doymaz, I., & Sagdic, O. (2020). Effect of different drying methods on total bioactive compounds, phenolic profile, in vitro bioaccessibility of phenolic and HMF formation of persimmon. LWT, 118, 108830. https://doi.org/10.1016/j.lwt.2019.108830

Kowalski, S. J., Pawłowski, A., Szadzińska, J., Łechtańska, J., & Stasiak, M. (2016). High power airborne ultrasound assist in combined drying of raspberries. Innovative Food Science and Emerging Technologies, 34, 225–233. https://doi.org/10.1016/j.ifset.2016.02.006

Kroehnke, J., Szadzińska, J., Radziejewska-Kubzdela, E., Biegańska-Marecik, R., Musielak, G., & Mierzwa, D. (2021). Osmotic dehydration and convective drying of kiwifruit (Actinidia deliciosa) – The influence of ultrasound on process kinetics and product quality. Ultrasonics Sonochemistry, 71(October 2020). https://doi.org/10.1016/j.ultsonch.2020.105377

Liu, X., Yan, X., Bi, J., Wu, X., Liu, J., & Zhou, M. (2020a). Identification of phenolic compounds and antioxidant activity of guava dehydrated by different drying methods. Drying Technology, 38(8), 987–1000. https://doi.org/10.1080/07373937.2019.1607872

Liu, Y., Zeng, Y., Guo, L., & Sun, X. (2019). Drying process and quality characteristics of contact ultrasound reinforced heat pump drying on kiwifruit slices. Journal of Food Processing and Preservation, 43(10), 1–8. https://doi.org/10.1111/jfpp.14162

Liu, Y., Zeng, Y., Hu, X., & Sun, X. (2020b). Effect of Ultrasonic Power on Water Removal Kinetics and Moisture Migration of Kiwifruit Slices During Contact Ultrasound Intensified Heat Pump Drying. Food and Bioprocess Technology, 13(3), 430–441. https://doi.org/10.1007/s11947-019-02401-z

Liu, Y., Zhang, H., Yi, C., Quan, K., & Lin, B. (2021). Chemical composition, structure, physicochemical and functional properties of rice bran dietary fiber modified by cellulase treatment. Food Chemistry, 342(October 2020), 128352. https://doi.org/10.1016/j.foodchem.2020.128352

Llavata, B., Picinelli, A., Simal, S., & Cárcel, J. A. (2022). Cider apple pomace as a source of nutrients: Evaluation of the polyphenolic profile, antioxidant and fiber properties after drying process at different temperatures. Food Chemistry: X, 15(July). https://doi.org/10.1016/j.fochx.2022.100403

Mahjoorian, A., Mokhtarian, M., Fayyaz, N., Rahmati, F., Sayyadi, S., & Ariaii, P. (2017). Modeling of drying kiwi slices and its sensory evaluation. Food Science and Nutrition, 5(3), 466–473. https://doi.org/10.1002/fsn3.414

Martín-Gómez, J., Ángeles Varo, M., Mérida, J., & Serratosa, M. P. (2019). The influence of berry perforation on grape drying kinetics and total phenolic compounds. Journal of the Science of Food and Agriculture, 99(9), 4260–4266. https://doi.org/10.1002/jsfa.9657

Martín-Gómez, J., Varo, M. Á., Mérida, J., & Serratosa, M. P. (2020). Influence of drying processes on anthocyanin profiles, total phenolic compounds and antioxidant activities of blueberry (Vaccinium corymbosum). Lwt, 120(May 2019), 108931. https://doi.org/10.1016/j.lwt.2019.108931

Martins, M. P., Cortés, E. J., Eim, V., Mulet, A., & Cárcel, J. A. (2019). Stabilization of apple peel by drying. Influence of temperature and ultrasound application on drying kinetics and product quality. Drying Technology, 37(5), 559–568. https://doi.org/10.1080/07373937.2018.1474476

Mello, R. E., Fontana, A., Mulet, A., Correa, J. L. G., & Cárcel, J. A. (2020). Ultrasound-assisted drying of orange peel in atmospheric freeze-dryer and convective dryer operated at moderate temperature. Drying Technology, 38(1–2), 259–267. https://doi.org/10.1080/07373937.2019.1645685

Moraga, G., Martínez-Navarrete, N., & Chiralt, A. (2006). Water sorption isotherms and phase transitions in kiwifruit. Journal of Food Engineering, 72(2), 147–156. https://doi.org/10.1016/j.jfoodeng.2004.11.031

Mousakhani-Ganjeh, A., Amiri, A., Nasrollahzadeh, F., Wiktor, A., Nilghaz, A., Pratap-Singh, A., & Mousavi Khaneghah, A. (2021). Electro-based technologies in food drying - A comprehensive review. Lwt, 145(March), 111315. https://doi.org/10.1016/j.lwt.2021.111315

Namjoo, M., Moradi, M., & Niakousari, M. (2022). Evaluation of the effect of high-power ultrasound waves on conventional air drying of cumin seeds. Sustainable Energy Technologies and Assessments, 52, 102262. https://doi.org/10.1016/j.seta.2022.102262

Nieto-Calvache, J. E., de Escalada Pla, M., & Gerschenson, L. N. (2019). Dietary fibre concentrates produced from papaya by-products for agroindustrial waste valorisation. International Journal of Food Science and Technology, 54(4), 1074–1080. https://doi.org/10.1111/ijfs.13962

O’Shea, N., Ktenioudaki, A., Smyth, T. P., McLoughlin, P., Doran, L., Auty, M. A. E., Arendt, E., & Gallagher, E. (2015). Physicochemical assessment of two fruit by-products as functional ingredients: Apple and orange pomace. Journal of Food Engineering, 153, 89–95. https://doi.org/10.1016/j.jfoodeng.2014.12.014

Prithani, R., & Dash, K. K. (2020). Mass transfer modelling in ultrasound assisted osmotic dehydration of kiwi fruit. Innovative Food Science and Emerging Technologies, 64(February), 102407. https://doi.org/10.1016/j.ifset.2020.102407

Rodríguez, K., Ah-Hen, K. S., Vega-Gálvez, A., Vásquez, V., Quispe-Fuentes, I., Rojas, P., & Lemus-Mondaca, R. (2016). Changes in bioactive components and antioxidant capacity of maqui, Aristotelia chilensis [Mol] Stuntz, berries during drying. Lwt, 65, 537–542. https://doi.org/10.1016/j.lwt.2015.08.050

Rojas, M. L., Augusto, P. E. D., & Cárcel, J. A. (2020). Ethanol pre-treatment to ultrasound-assisted convective drying of apple. Innovative Food Science and Emerging Technologies, 61(November 2019), 102328. https://doi.org/10.1016/j.ifset.2020.102328

Santos, D., Lopes da Silva, J. A., & Pintado, M. (2022). Fruit and vegetable by-products’ flours as ingredients: A review on production process, health benefits and technological functionalities. Lwt, 154(June 2021). https://doi.org/10.1016/j.lwt.2021.112707

Simal, S., Femenia, A., Cárcel, J. A., & Rosselló, C. (2005). Mathematical modelling of the drying curves of kiwi fruits: Influence of the ripening stage. Journal of the Science of Food and Agriculture, 85(3), 425–432. https://doi.org/10.1002/jsfa.2003

Szadzińska, J., Mierzwa, D., & Musielak, G. (2022). Ultrasound-assisted convective drying of white mushrooms (Agaricus bisporus). Chemical Engineering and Processing - Process Intensification, 172(October 2021). https://doi.org/10.1016/j.cep.2022.108803

Taghinezhad, E., Kaveh, M., & Szumny, A. (2021). Thermodynamic and quality performance studies for drying kiwi in hybrid hot air-infrared drying with ultrasound pretreatment. Applied Sciences (switzerland), 11(3), 1–17. https://doi.org/10.3390/app11031297

Tylewicz, U., Mannozzi, C., Castagnini, J. M., Genovese, J., Romani, S., Rocculi, P., & Rosa, M. D. (2022). Application of PEF- and OD-assisted drying for kiwifruit waste valorisation. Innovative Food Science and Emerging Technologies, 77(February), 102952. https://doi.org/10.1016/j.ifset.2022.102952

Tylewicz, U., Nowacka, M., Rybak, K., Drozdzal, K., Dalla Rosa, M., & Mozzon, M. (2020). Design of healthy snack based on kiwifruit. Molecules, 25(14). https://doi.org/10.3390/molecules25143309

Vallespir, F., Cárcel, J. A., Marra, F., Eim, V. S., & Simal, S. (2018). Improvement of mass transfer by freezing pretreatment and ultrasound application on the convective drying of beetroot (Beta vulgaris L.). Food and Bioprocess Technology, 11(1), 72–83. https://doi.org/10.1007/s11947-017-1999-8

Vallespir, F., Rodríguez, Ó., Cárcel, J. A., Rosselló, C., & Simal, S. (2019). Ultrasound assisted low-temperature drying of kiwifruit: Effects on drying kinetics, bioactive compounds and antioxidant activity. Journal of the Science of Food and Agriculture, 99(6), 2901–2909. https://doi.org/10.1002/jsfa.9503

Wang, H., Li, X., Wang, J., Vidyarthi, S. K., Wang, H., Zhang, X. G., Gao, L., Yang, K. W., Zhang, J. S., & Xiao, H. W. (2022). Effects of postharvest ripening on water status and distribution, drying characteristics, volatile profiles, phytochemical contents, antioxidant capacity and microstructure of kiwifruit (Actinidia deliciosa). In Food Control (Vol. 139). https://doi.org/10.1016/j.foodcont.2022.109062

Wang, J., Xiao, H. W., Ye, J. H., Wang, J., & Raghavan, V. (2019). Ultrasound Pretreatment to Enhance Drying Kinetics of Kiwifruit (Actinidia deliciosa) Slices: Pros and Cons. Food and Bioprocess Technology, 12(5), 865–876. https://doi.org/10.1007/s11947-019-02256-4

Wang, K., Li, M., Wang, Y., Liu, Z., & Ni, Y. (2021). Effects of extraction methods on the structural characteristics and functional properties of dietary fiber extracted from kiwifruit (Actinidia deliciosa). Food Hydrocolloids, 110(17). https://doi.org/10.1016/j.foodhyd.2020.106162

Zhao, D., Guo, C., Liu, X., & Xiao, C. (2021). Effects of insoluble dietary fiber from kiwi fruit pomace on the physicochemical properties and sensory characteristics of low-fat pork meatballs. Journal of Food Science and Technology, 58(4), 1524–1537. https://doi.org/10.1007/s13197-020-04665-2

Zhao, D., Wei, J., Hao, J., Han, X., Ding, S., Yang, L., & Zhang, Z. (2019). Effect of sodium carbonate solution pretreatment on drying kinetics, antioxidant capacity changes, and final quality of wolfberry (Lycium barbarum) during drying. Lwt, 99(September 2018), 254–261. https://doi.org/10.1016/j.lwt.2018.09.066

Zhou, X., Xu, R., Zhang, B., Pei, S., Liu, Q., Ramaswamy, H. S., & Wang, S. (2018). Radio Frequency-Vacuum Drying of Kiwifruits: Kinetics, Uniformity, and Product Quality. Food and Bioprocess Technology, 11(11), 2094–2109. https://doi.org/10.1007/s11947-018-2169-3

Zhuang, Z., Chen, M., Niu, J., Qu, N., Ji, B., Duan, X., Liu, Z., Liu, X., Wang, Y., & Zhao, B. (2019). The manufacturing process of kiwifruit fruit powder with high dietary fiber and its laxative effect. Molecules, 24(21). https://doi.org/10.3390/molecules24213813

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. This work was supported by the grants PID2019‐106148RRC42 and PID2019‐106148RRC43 funded by MCIN/AEI/ 10.13039/501100011033 and the PhD grant of Beatriz Llavata and funding for open access charge from the Universitat Politècnica de València (PAID-01–19).

Author information

Authors and Affiliations

Contributions

Juan A. Cárcel designed the experimental plan. Beatriz Llavata carried out the laboratory experiments helped by Gabriela Clemente and Antoni Femenia. All authors participated in the analysis of results. Beatriz Llavata and Juan A Cárcel wrote the main manuscript, text and figures. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Llavata, B., Femenia, A., Clemente, G. et al. Combined Effect of Airborne Ultrasound and Temperature On the Drying Kinetics and Quality Properties of Kiwifruit (Actinidia Deliciosa). Food Bioprocess Technol 17, 440–451 (2024). https://doi.org/10.1007/s11947-023-03138-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-023-03138-6