Abstract

One of the most significant dried foods is raisin, used directly as ingredients in confectionary and in the form of raisin paste used in sauces, fillings, baked goods, microwaveable coatings, and other culinary products to color them naturally. The purpose of this study is to investigate the effects of ultrasound pretreatment (53 kHz, 300 W, 30 °C, 300 s, in a mixture of 5% K2CO3+ 1% OO solution) and drying air temperatures (40–60 °C) on the drying behavior, color values, physicochemical properties (moisture content, VCC, TPC, RSC, and antioxidant capacity (DDPH)) and rehydration capacity of Sultani Çekirdeksiz grapes. Both the drying kinetic (drying time, drying rate, and effective moisture diffusivity) and the quality characteristics of grapes were significantly improved by ultrasound pretreatment (p < 0.05). In addition, the vitamin C (0.75–3.86 mg/g) and total phenolic content (1.31–1.80 mg GA/kg) of raisins were highly protected with the high drying temperature and ultrasound pretreatment. The antioxidant capacity (1.15–5.50 mM Trolox) of samples increased with drying temperature whereas the antioxidant capacity decreased with ultrasound application. The rehydration time of all samples was found around 800 min. As a result of this study, it can be said that the ultrasound application may be used successfully for drying grapes and that a greater degree of the nutritional value of the grapes can be maintained.

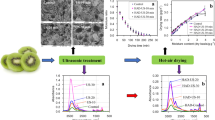

Graphical Abstract

Similar content being viewed by others

Data availability

All data are available upon request.

Abbreviations

- AC:

-

Antioxidant capacity

- a*:

-

Redness/ Greenness

- ANOVA:

-

Analysis of variance

- b*:

-

Blueness/ Yellowness

- DDPH:

-

1,1-diphenyl-2-picrylhydrazyl

- Deff :

-

Effective Moisture Diffusivity (m2/s)

- DM:

-

Dry matter

- D0 :

-

Pre-exponential factor (m2/s)

- DR:

-

Drying rate

- dt :

-

Drying time (min)

- Ea :

-

Activation energy (kJ/mol)

- FRAP:

-

Ferric reducing antioxidant power assay

- g:

-

Gram

- GA:

-

Gallic acid

- h:

-

Hours

- HA (°):

-

Hue angle

- HAD-40°C-US-P:

-

Hot air dried at 40 °C, ultrasound pretreated sample

- HAD-40°C-NON-P:

-

Hot air dried at 40 °C, untreated sample

- HAD-50°C-US-P:

-

Hot air dried at 50 °C, ultrasound pretreated sample

- HAD-50°C-NON-P:

-

Hot air dried at 50 °C,untreated sample

- HAD-60°C-US-P:

-

Hot air dried at 60 °C, ultrasound pretreated sample

- HAD-60°C-NON-P:

-

Hot air dried at 60 °C, untreated sample

- K2CO3 :

-

Potassium carbonate

- kHz:

-

Kilohertz

- L:

-

Liter

- L*:

-

Lightness

- L/s:

-

Liter/second

- ln:

-

Natural logarithm

- m/s:

-

Meter/second

- mg:

-

Milligram

- ml:

-

Milliliter

- MR:

-

Moisture ratio

- Mee :

-

Equilibrium moisture content

- Mt :

-

Moisture content at any time

- M0 :

-

Moisture content at the beginning

- NaOH:

-

Sodium hydroxide

- m:

-

Weight of the sample (g)

- min:

-

Minute

- Mt :

-

Moisture content at any time t (kg water/kg DM)

- Mt+dt :

-

Moisture content at time t + dt ( kg water/kg DM)

- nm:

-

Nanometer

- NON-P:

-

Untreated samples

- OO:

-

Olive oil

- PCA:

-

Principal component analysis

- R:

-

Gas constant (8.31451 J/mol K)

- R 2 :

-

Correlation coefficient

- RSC:

-

Reducing sugar content

- s:

-

Second

- t:

-

Time (s)

- T:

-

Absolute temperature (K)

- TPC:

-

Total phenolic content

- TS:

-

Turkish standart

- US-P:

-

Ultrasound pretreated

- UV:

-

Ultraviolet

- VCC:

-

Vitamin C content

- v:v:

-

Volume: volume

- W:

-

Watt

- wb:

-

Wet basis

- w:v:

-

Weight: volume

- w:w:

-

Weight: weight

- ΔE:

-

Total color change

References

Jeevarathinam G, Pandiselvam R, Pandiarajan T, Preetha P, Balakrishnan M, Thirupathi V, Kothakota A (2021) Infrared assisted hot air dryer for turmeric slices: effect on drying rate and quality parameters. LWT- Foo Sci Technol 144:111258. https://doi.org/10.1016/j.lwt.2021.111258

Winkler AJ, Cook JA, Kliewer M, Lider LA (1974) General Viticulture. University of California Press, Berkeley, CA

Doymaz I, Pala M (2002) The effects of dipping pretreatments on air-drying rates of the seedless grapes. J Food Eng 52(4):413–417. https://doi.org/10.1016/S0260-8774(01)00133-9

Vázquez G, Chenlo F, Moreira R, Cruz E (1997) Grape drying in a pilot plant with a heat pump. Drying Technol 15(3-4):899–920. https://doi.org/10.1080/07373939708917267

Grncarevic M (1963) Effect of various dipping treatments on the drying rate of grapes for raisins. Am J Enol Vitic 14(4):230–234

Esmaiili M, Sotudeh-Gharebagh R, Cronin K, Mousavi MAE, Rezazadeh G (2007) Grape drying: a review. Food Rev Int 23(3):257–280. https://doi.org/10.1080/87559120701418335

Deng LZ, Mujumdar AS, Zhang Q, Yang XH, Wang J, Zheng ZA, Gao ZJ, Xiao HW (2019) Chemical and physical pretreatments of fruits and vegetables: effects on drying characteristics and quality attributes–a comprehensive review. Crit Rev Food Sci Nutr 59(9):1408–1432. https://doi.org/10.1080/10408398.2017.1409192

Nowacka M, Tylewicz U, Laghi L, Dalla Rosa M, Witrowa-Rajchert D (2014) Effect of ultrasound treatment on the water state in kiwifruit during osmotic dehydration. Food Chem 144:18–25. https://doi.org/10.1016/j.foodchem.2013.05.129

Schössler K, Jäger H, Knorr D (2012) Effect of continuous and intermittent ultrasound on drying time and effective diffusivity during convective drying of apple and red bell pepper. J Food Eng 1:103–110. https://doi.org/10.1016/j.jfoodeng.2011.07.018

Çalışkan Koç G, Yüksel AN, Baş E, Erdoğan SL (2020) Foam mat drying of taro (Colocasia esculenta): the effect of ultrasonic pretreatment and drying techniques on the drying behavior, flow, and reconstitution properties of taro flour. J Food Process Eng 43(11):e13516. https://doi.org/10.1111/jfpe.13516

Garcia-Perez JV, Carcel JA, Simal S, García-Alvarado MA, Mulet A (2013) Ultrasonic intensification of grape stalk convective drying: kinetic and energy efficiency. Drying Technol 31(8):942–950. https://doi.org/10.1080/07373937.2012.716128

Clemente G, Sanjuán N, Cárcel JA, Mulet A (2014) Influence of temperature, air velocity, and ultrasound application on drying kinetics of grape seeds. Drying Technol 32(1):68–76. https://doi.org/10.1080/07373937.2013.811592

Onwude DI, Hashim N, Janius RB, Nawi NM, Abdan K (2016) Modeling the thin-layer drying of fruits and vegetables: a review. Compr Rev Food Sci Food Saf 15:599–618. https://doi.org/10.1111/1541-4337.12196

Turkish Standards Institute (2014) Turkish seedless raisins grape standards (TS 3411). Ankara, Turkey

Pathare PB, Opara LU, Al-Said FA (2013) Colour measurement and analysis in fresh and processed foods: a review. Food Bioprocess Tech 6(1):36–60. https://doi.org/10.1007/s11947-012-0867-9

Baloch AK, Buckle KA, Edwards RA (1973) Measurement of non-enzymic browning of dehydrated carrot. J Sci Food Agric 24(4):389–398. https://doi.org/10.1002/jsfa.2740240406

Özkan M (2001) Desuletitng methods of dried apricots, Ankara University Graduate School of Natural and Applied Sciences Department of Food Engineering, Ankara, Turkey (in Turkish)

Cemeroğlu B (2010) General methods in food analysis. Food analysis, Ankara, Turkey (in Turkish)

Ali S, Khan AS, Malik AU (2016) Postharvest L-cysteine application delayed pericarp browning, suppressed lipid peroxidation and maintained antioxidative activities of litchi fruit. Postharvest Biol Technol 121:135–142. https://doi.org/10.1016/j.postharvbio.2016.07.015

AOAC (2005) Official methods of analysis of AOAC international, (18th ed) edn. AOAC International, Gaithersburg, MD, USA

Figueiredo-González M, Cancho-Grande B, Simal-Gándara J (2013) Evolution of colour and phenolic compounds during Garnacha Tintorera grape raisining. Food Chem 141(3):3230–3240. https://doi.org/10.1016/j.foodchem.2013.05.142

Brand-Williams W, Cuvelier ME, Berset CLWT (1995) Use of a free radical method to evaluate antioxidant activity. LWT-Food Sci Technol 28(1):25–30. https://doi.org/10.1016/S0023-6438(95)80008-5

Li FH, Ya YUAN, Yang XL, Tao SY, Jian MING (2013) Phenolic profiles and antioxidant activity of buckwheat (Fagopyrum esculentum Möench and Fagopyrum tartaricum L Gaerth) hulls, brans and flours. J Integr Agric 12(9):1684–1693. https://doi.org/10.1016/S2095-3119(13)60371-8

Buzrul S (2022) Reassessment of thin-layer drying models for foods: a critical short communication. Processes 10(1):118. https://doi.org/10.3390/pr10010118

Ozkan K, Karadag A, Sagdic O (2022) The effects of different drying methods on the in vitro bioaccessibility of phenolics, antioxidant capacity, minerals and morphology of black “Isabel”grape. LWT- Food Sci Technol 158:113185. https://doi.org/10.1016/j.lwt.2022.113185

Cruz L, Clemente G, Mulet A, Ahmad-Qasem MH, Barrajón-Catalán E, García-Pérez JV (2016) Air-borne ultrasonic application in the drying of grape skin: kinetic and quality considerations. J Food Eng 168:251–258. https://doi.org/10.1016/j.jfoodeng.2015.08.001

Nascimento EM, Mulet A, Ascheri JLR, de Carvalho CWP, Cárcel JA (2016) Effects of high-intensity ultrasound on drying kinetics and antioxidant properties of passion fruit peel. J Food Eng 170:108–118. https://doi.org/10.1016/j.jfoodeng.2015.09.015

Çağlar A, Toğrul İT, Toğrul H (2009) Moisture and thermal diffusivity of seedless grape under infrared drying. Food Bioprod Process 87(4):292–300. https://doi.org/10.1016/j.fbp.2009.01.003

Azoubel PM, Baima MAM, Amorim MR, Oliveira SSB (2010) Effect of ultrasound on banana cv Pacovan drying kinetics. J Food Eng 97(2):194–198. https://doi.org/10.1016/J.JFOODENG.2009.10.009

Xiao HW, Pang CL, Wang LH, Bai JW, Yang WX, Gao ZJ (2010) Drying kinetics and quality of Monukka seedless grapes dried in an air-impingement jet dryer. Biosys Eng 105(2):233–240. https://doi.org/10.1016/j.biosystemseng.2009.11.001

Tiwari BK, Muthukumarappan K, O'Donnell CP, Cullen PJ (2008) Effects of sonication on the kinetics of orange juice quality parameters. J Agric Food Chem 56:2432–2428. https://doi.org/10.1021/jf073503y

Frias J, Penas E, Ullate M, Vidal-Valverde C (2010) Influence of drying by convective air dryer or power ultrasound on the vitamin C and β-carotene content of carrots. J Agric Food Chem 58(19):10539–10544. https://doi.org/10.1021/jf102797y

Langová R, Jůzl M, Cwiková O, Kos I (2020) Effect of different method of drying of five varieties grapes (Vitis vinifera L.) on the bunch stem on physicochemical, microbiological, and sensory quality. Foods 9(9):1183. https://doi.org/10.3390/foods9091183

Gamboa-Santos J, Montilla A, Soria AC, Cárcel JA, García-Pérez JV, Villamiel M (2014) Impact of power ultrasound on chemical and physicochemical quality indicators of strawberries dried by convection. Food Chem 161:40–46. https://doi.org/10.1016/j.foodchem.2014.03.106

Jacob A, Sudagar IP, Pandiselvam R, Rajkumar P, Rajavel M (2022) Optimization of ultrasound processing parameters for preservation of matured coconut water using a central composite design. Qual Assur Saf Crop Foods 14(SP1):33–41. https://doi.org/10.15586/qas.v14iSP1.1145

Aydar AY, Aydın T, Yılmaz T, Kothakota A, Terezia SC, Leontin CF, Pandiselvam R (2022) Investigation on the influence of ultrasonic pretreatment on color, quality and antioxidant attributes of microwave dried Inula viscosa (L.). Ultrason Sonochem 90:106184. https://doi.org/10.1016/j.ultsonch.2022.106184

Ren F, Perussello CA, Zhang Z, Kerry JP, Tiwari BK (2018) Impact of ultrasound and blanching on functional properties of hot-air dried and freeze dried onions. Lwt 87:102–111. https://doi.org/10.1016/j.lwt.2017.08.053

Valadez-Carmona L, Plazola-Jacinto CP, Hernández-Ortega M, Hernández-Navarro MD, Villarreal F, Necoechea-Mondragón H, Ortiz-Moreno A, Ceballos-Reyes G (2017) Effects of microwaves, hot air and freeze-drying on the phenolic compounds, antioxidant capacity, enzyme activity and microstructure of cacao pod husks (Theobroma cacao L.). Innov Food Sci Emerg Technol 41:378–386. https://doi.org/10.1016/j.ifset.2017.04.012

Vashisth T, Singh RK, Pegg RB (2011) Effects of drying on the phenolics content and antioxidant activity of muscadine pomace. LWT- Food Sci Technol 44(7):1649–1657. https://doi.org/10.1016/j.lwt.2011.02.011

Yilmaz Y, Toledo R (2005) Antioxidant activity of water-soluble Maillard reaction products. Food Chem 93(2):273–278. https://doi.org/10.1016/j.foodchem.2004.09.043

Nicoli MC, Anese M, Parpinel MT, Franceschi S, Lerici CR (1997) Loss and/or formation of antioxidants during food processing and storage. Cancer Lett 114(1-2):71–74. https://doi.org/10.1016/S0304-3835(97)04628-4

Demirkol M, Tarakci Z (2018) Effect of grape (Vitis labrusca L.) pomace dried by different methods on physicochemical, microbiological and bioactive properties of yoghurt. LWT- Food Sci Technol 97:770–777. https://doi.org/10.1016/j.lwt.2018.07.058

Nowak D, Gośliński M, Wojtowicz E, Przygoński K (2018) Antioxidant properties and phenolic compounds of vitamin C-rich juices. J Food Sci 83(8):2237–2246. https://doi.org/10.1111/1750-3841.14284

Davey MW, Montagu MV, Inze D, Sanmartin M, Kanellis A, Smirnoff N, Benzie JJ, StrainJJ FD, Fletcher J (2000) Plant L-ascorbic acid: chemistry, function, metabolism, bioavailability and effects of processing. J Sci Food Agric 80(7):825–860. https://doi.org/10.1002/(SICI)1097-0010(20000515)80:7<825::AID-JSFA598>3.0.CO;2-6

Kutlu N, Pandiselvam R, Kamiloglu A, Saka I, Sruthi NU, Kothakota A, Maerescu CM (2022) Impact of ultrasonication applications on color profile of foods. Ultrason Sonochem 89:106109. https://doi.org/10.1016/j.ultsonch.2022.106109

Soria AC, Corzo-Martínez M, Montilla A, Riera E, Gamboa-Santos J, Villamiel M (2010) Chemical and physicochemical quality parameters in carrots dehydrated by power ultrasound. J Agric Food Chem 58(13):7715–7722. https://doi.org/10.1021/jf100762e

Noshad M, Mohebbi M, Shahidi F, Mortazavi SA (2012) Kinetic modeling of rehydration in air-dried quinces pretreated with osmotic dehydration and ultrasonic. J Food Process Preserv 36:383–392. https://doi.org/10.1111/j.1745-4549.2011.00593.x

Ricce C, Rojas ML, Miano AC, Siche R, Augusto PED (2016) Ultrasound pretreatment enhances the carrot drying and rehydration. Food Rese Int 89:701–708. https://doi.org/10.1016/j.foodres.2016.09.030

Jambrak AR, Mason TJ, Paniwnyk L, Lelas V (2007) Accelerated drying of button mushrooms, brussels sprouts and cauliflower by applying power ultrasound and its rehydration properties. J Food Eng 81(1):88–97. https://doi.org/10.1016/j.jfoodeng.2006.10.009

Author information

Authors and Affiliations

Contributions

Ahmet Candemir: conceptualization, investigation, formal analysis, validation, data curation, writing—original draft.

Gülşah Çalışkan Koç: investigation, formal analysis, methodology, data curation,writing—original draft.

Safiye Nur Dirim: conceptualization, methodology, data curation, writing, review and editing.

Ravi Pandiselvam: conceptualization, resources, data curation, methodology, writing—review and editing.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable

Consent for publication

All authors agreed on the publication of this research work.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Candemir, A., Çalışkan Koç, G., Dirim, S.N. et al. Effect of ultrasound pretreatment and drying air temperature on the drying characteristics, physicochemical properties, and rehydration capacity of raisins. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04269-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04269-8