Abstract

Aqueous extracts from rice straw (RS), using ultrasound-assisted reflux heating extraction (USHT) and subcritical water extraction (SWE), under two process conditions (160 °C, 7 bars; and 180 °C, 11 bars), were obtained and characterised as to their phenolic content and antioxidant and antimicrobial capacities. These extracts were incorporated (6% wt.) into poly (lactic acid) (PLA) films by melt blending and compression moulding that were characterised as to their structural and functional properties and their capacity to preserve fresh pork meat, as vacuum thermo-sealed bags, throughout 16 days of cold storage. The extracts slightly reduced the extensibility, resistance to break, and water barrier capacity of the PLA films but enhanced their oxygen barrier capacity and the UV light-blocking effect. The films with RS extracts were effective at preserving meat quality parameters, inhibiting microbial growth, meat oxidation, discolouration, and weight loss. The SWE extract obtained at 180 °C was the most effective at obtaining active films for meat preservation, exhibiting the greatest antioxidant and antibacterial activity. Therefore, the green SWE technique is useful for obtaining active extracts from RS, allowing for its valorisation in the development of biodegradable active materials useful to preserve food quality.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Active food packaging improves food preservation by maintaining its quality and safety for longer, thus extending the food shelf-life (Baghi et al., 2022; Sung et al., 2013). To this end, it is necessary to release active compounds into the food or headspace in order to inhibit, minimise, or delay undesirable reactions, such as oxidation, discolouration, or microbial growth, that cause food spoilage (Han et al., 2018; Nerín et al., 2008). Of the different strategies to obtain active packaging materials, the direct incorporation of active compounds into the polymer matrix for their subsequent release into the food system is the most common practice (Almasi et al., 2021; Sabaghi et al., 2022). Specifically, antioxidant and antimicrobial compounds are frequently used in the development of active materials for food packaging since oxidation and microbial attack are the most common spoilage processes in food products (Campos et al., 2011; Sofi et al., 2018). In this sense, naturally occurring antioxidant/antimicrobial compounds are highly appreciated by consumers since these are seen as safer. Many plant extracts contain compounds with antioxidant or antimicrobial capacity (Zazharskyi et al., 2019; Saeed et al., 2012; Lee et al., 2003) that can be used as active ingredients for the formulation of active films. In this sense, the plant tissue from different agri-food waste could be valorised as sources of active extracts for different uses in the area of food preservation (Makris et al., 2007; Panzella et al., 2020; Torres-Valenzuela et al., 2020). Specifically, different active extracts obtained from agri-food wastes, such as pink pepper (Merlo et al., 2019), hops (Almeida et al., 2022), grape seed (Bof et al., 2016; Zhao et al., 2022), coffee and rice husks (Collazo-Bigliardi et al., 2019), or rice straw (RS) (Menzel et al., 2020), have been incorporated into polymer matrices to obtain active materials for food packaging or coating.

The use of biodegradable polymer matrices to obtain active food packaging materials is a highly recommended means of reducing the environmental impact of plastics, while the active properties add value to the more expensive biodegradable polymers. Thus, the valorisation of agro-industrial wastes and by-products into value-added products, useful for developing biodegradable, active packaging materials, represents an interesting practice in the reduction of ecological and environmental problems while boosting the circular economy (Bhat, 2021).

One of the most produced agro-industrial residues worldwide, rice straw (RS) is one of the leftovers generated after the rice harvest that has no direct economic value, and is usually burned in the rice paddies (Peanparkdee & Iwamoto, 2019; Saini et al., 2015). Given its renewability, availability, cheapness, and richness in lignocellulosic fractions (~70% dry matter), several environmentally-friendly approaches have been proposed to valorise and exploit its potential (Goodman, 2020). Obtaining bioactive extracts from RS, using green and sustainable extraction processes, is of great interest given the notable antioxidant and antimicrobial properties (Menzel et al., 2020; Freitas et al., 2021) of some of its components, such as ferulic, gallic, protocatechuic, or p-coumaric acids (Karimi et al., 2014; Menzel et al., 2020). The process extraction efficiency and the profile of active extract compounds depend on factors, such as temperature and time, kind of solvent, pressure, or sample pre-treatments (Alara et al., 2021; Herrero et al., 2012). Likewise, the extraction process must be green, fast, scalable, toxic solvent-free, and economically profitable. To this end, different technologies have been applied, such as supercritical extraction, microwave-assisted extraction, ultrasound-assisted extraction, or subcritical water extraction, using green solvents (Torres-Valenzuela et al., 2020).

Freitas et al. (2020) applied ultrasound pre-treatment and reflux heating water extraction to obtain RS antioxidant extracts that contain a notable content in polyphenols and antioxidant capacity. Application of high shear rates caused by acoustic cavitation promoted the extraction of the target compounds from the plant matrix due to the intense disruption of the plant structure and the exposure of the innermost cell tissues (Cheung & Wu, 2013; Luque-Garcı́a & Luque de Castro, 2003; Ojha et al., 2020), thus facilitating solvent accessibility in the subsequent heating step that promotes the debonding of phenolic compounds from the plant matrix.

Subcritical water extraction (SWE), also known as pressurised hot water extraction, is a green, innovative extraction technique that uses water under subcritical conditions, i.e., temperatures above the boiling point of water and pressures high enough to keep the liquid water below its critical point (~374 °C and 218 atm) (Castro-Puyana et al., 2013). SWE has been applied in the green extraction of a wide range of components from different plant sources (Collazo-Bigliardi et al., 2019; Moirangthemet al., 2021; Requena et al., 2019a), improving the mass transfer of non-polar compounds due to changes in the water solvent properties, such as the decrease in surface tension or dielectric constant, as a function of the pressure/temperature (Ong et al., 2006; Plaza et al., 2010a). Therefore, SWE at a different processing temperature/pressure will give rise to extracts with different composition profiles and bioactivity.

Poly (lactic acid) (PLA) is a compostable polymer that are used to obtain active packaging materials for food preservation purposes (Burgos et al., 2017). It is recognised as safe and has already been used as a food packaging material (Södergard & Stolt, 2002), fulfilling functions of mechanical protection, barrier to moisture, fats, and gases. The development of biodegradable PLA-based films incorporating active extracts obtained from agro-industrial waste has great potential to extend the shelf-life of packaged foods. These materials would contribute to a reduction in food residues and plastic contamination, and to the valorisation of agro-industrial waste, boosting the circular economy.

In this study, aqueous extracts from rice straw, using US assisted reflux heating extraction (USHT) and SWE under two extraction conditions (160 °C, 7 bars; and 180 °C, 11 bars), were obtained and characterised as to their phenolic content and antioxidant and antimicrobial capacity. These extracts were incorporated into PLA films obtained by melt blending and compression moulding that were analysed as to their structural and functional properties (mechanical, optical, thermal, and barrier properties). Likewise, the capacity of the films to preserve fresh pork meat, as vacuum thermo-sealed bags, was analysed through the control of the meat quality parameters (pH, colour, weight loss, microbial counts, and oxidation) throughout 16 days of cold storage.

Material and Methods

Materials

RS (Oryza sativa L. var. J. Sendra) was obtained as waste from the rice industry and collected in a L’Albufera paddy field (Valencia, Spain). The RS was dried, milled, and sieved as previously described by Freitas et al. (2020) and stored at 20 ± 2 °C until further use.

Amorphous PLA 4060D (average molecular weight of 106,226 D and density 1.24 g/cm3) was purchased from Natureworks (USA). Trichloroacetic acid (> 99% purity), magnesium nitrate (Mg(NO3)2), and di-phosphorous pentoxide (P2O5) were supplied by PanReac Química S.L.U (Castellar del Vallés, Barcelona, Spain). 2-Thiobarbituric acid (> 98% purity), ethanol (98% purity), and methanol (> 99.9 purity) were obtained from Sigma-Aldrich (St. Louis, MO, USA). For microbiological tests, buffered peptone water, trypticasein soy broth (TSB), and Man Rogosaand Sharpe agar (MRS) were purchased from Labkem (Barcelona, Spain). Violet red bile agar (VRB) was supplied by Scharlab S.L. (Sentmenat, Spain). Strains of Listeria innocua (CECT 910) and Escherichia coli (CECT 101) were purchased from the Spanish Type Collection (CECT, University of Valencia, Valencia, Spain).

Obtaining and Characterisation of RS Aqueous Extracts

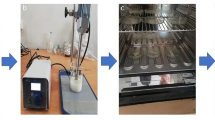

Three aqueous RS extracts were obtained, by applying a previously optimised combined ultrasound-reflux heating treatment (USHT) (Freitas et al., 2020) and subcritical water extraction (SWE) at 160 (SWE160) and 180 (SWE180) °C (Fig. 1). For SWE processes, the RS particles were dispersed in distilled water at a ratio of 1:10 (w/w) and submitted to extraction in a pressure reactor (Model 1-T-A-P-CE, 5 L capacity, Amar Equipment PVT.LTD, Mumbai, India) under two extraction conditions: 160 °C, 7 bars, 150 rpm for 30 min, and 180 °C, 11 bars, 150 rpm for 30 min.

After each extraction step, the RS dispersion was filtered (Filterlab) to obtain the liquid extracts, which were freeze-dried (Telstar, model LyoQuest-55) at −60 °C, 0.8 mbar for 72 h. The obtained freeze-dried extracts were stored in a dark bottle at 0% relativity humidity (RH) (with P2O5) and at 4 ± 2 °C until further use.

The dried extracts were characterised as to their total phenolic content (TPC) and antioxidant capacity. TPC was determined in triplicate for each extract, by using the modified Folin-Ciocalteu method, as described by Menzel et al. (2020). The TPC was determined through the absorbance values and the standard curve (R2 = 0.9991) of gallic acid (2–20 mg L−1). The results were expressed as mg gallic acid equivalent (GAE) per g of dry extract.

The antioxidant activity of the extracts was determined through the ABTS and DPPH radical scavenging capacity. The ABTS assay was carried out as reported by Re et al. (1999). Each extract was analysed in duplicate. The standard curve was prepared using different concentrations of Trolox (0–25 µmol L−1; R2 = 0.9982), and the results were expressed as Trolox equivalent antioxidant capacity (TEAC), in μmol Trolox/mg extract.

The 2,2-diphenyl-1-pikryl-hydroxyl (DPPH) method (Brand-Williams et al., 1995), with some modifications (Freitas et al., 2020), was also used to quantify the antioxidant capacity of the extracts. The antioxidant activity of the different extract was reported as the EC50 value, which is the concentration required to reduce the DPPH concentration by 50% when the reaction is stable, using a standard curve with different concentrations of DPPH (0.08–0.1 mmol L−1; R2 = 0.9992). The time to achieve reaction stability was 12 h for all cases.

The minimal inhibitory concentration (MIC) of the extracts for a Gram + (Listeria innocua) and a Gram − (Escherichia coli) bacteria was analysed in order to assess the potential antibacterial effect of the extracts, as described by Requena et al. (2019a), with the modifications described by Freitas et al. (2020), using a 96‐well disposable sterile microtiter plate (well volume of 200 μL). Stock solutions of each extract and different dilutions, ranging between 20 and 200 mg mL−1 (with 10 mg mL−1 intervals) were obtained with the TSB broth medium. The MIC value of each extract was analysed in duplicate.

Film Preparation and Characterisation

PLA films with the different RS extracts were prepared by melt blending and compression moulding. The amorphous PLA pellets were preconditioned in P2O5 for 2 days to eliminate residual water. On the basis of previous studies (Freitas et al., 2022), PLA samples were hand-mixed with the dried extracts, at 6% with respect to the polymer mass, and melt-blended, using an internal mini-mixer (HAAKETM PolyLabTM QC, Thermo Fisher Scientific, Karlsruhe, Germany), at 160 °C and 50 rpm for 6 min. PLA films without RS extract were also prepared as control films. All films were thermoformed by thermocompression of 3 g of the blend, previously milled (IKA, model M20, Germany), using a heat plate hydraulic press (Model LP20, Labtech Engineering, Thailand) (Freitas et al., 2022). The films were labelled as PLA (control), PLA-USHT, PLA-SWE160, and PLA-SWE180, which indicate the type of active extract incorporated in the PLA film.

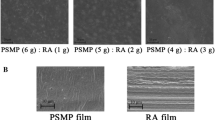

Film Microstructure

The morphologies of the cross-sections of films were evaluated using a field emission scanning electron microscope (ULTRA™ 55, Zeiis, Oxford Instruments, UK). The film samples were cryo-fractured by immersion in liquid nitrogen and then platinum coated, using an EM MED020 sputter coater (Leica BioSystems, Barcelona, Spain). The micrographs were taken at 2.0 kV acceleration voltage.

Colour and Transparency

A spectro-colorimeter (CM-3600d, Minolta Co. Tokyo, Japan) was used to measure the optical properties of the films according to the Kubelka-Munk theory of multiple scattering. The internal transmittance (Ti) and infinite reflectance spectra (R∞) were obtained from the film reflectance (R) on black (R0) and white (Rg) backgrounds, in the range of 400 to 700 nm (Eqs. (1)-(4)), as previously described (Freitas et al., 2023a). The CIEL*a*b* colour coordinates of the films were obtained from the infinite reflectance spectra. Chroma (Cab*) (Eq. (5)) and hue angle (hab*) (Eq. (6)) were also calculated.

A UV-visible spectrophotometer (Evolution 201, Thermo Scientific) operating in light transmission mode was used to determine the UV-vis spectra of the films. For each formulation, the spectra were obtained between 200 and 900 nm, in triplicate.

Tensile Properties

Tensile strength at break (TS), elastic modulus (EM), and elongation at break (E) were determined following the ASTM D882 method (ASTM, 2012) using a universal test machine (TA.XTplus model, Stable Micro Systems, Haslemere, England) (Freitas et al., 2022). Before the analysis, a digital micrometre (Palmer, model COMECTA, Barcelona, accuracy of 0.001 mm) was used to measure the thicknesses of the films at ten random film positions. Eight replicates were evaluated per treatment.

Barrier Properties

The water vapour permeability (WVP) of the films was determined following the gravimetric method ASTM E96/E96M (ASTM, 2005) applying the modification proposed by McHugh et al. (1993). The cups were weighed every 1.5 h with an analytical balance (±0.0001 g) throughout 48 h. Finally, the WVP was calculated from the slope of the weight loss-time curves (Freitas et al., 2021). For each formulation, the analysis was carried out in triplicate.

An oxygen permeation analyser (Model 8101e, Systech Illinois, Illinois, USA) was used to determine the oxygen permeability (OP) of the films at 25 °C and 53% RH, following the ASTM D3985-05 methodology (ASTM, 2010). The oxygen transmission rate (OTR) through the film samples (50 cm2) was measured every 15 min until equilibrium was reached (difference between the last 4 measurements of less than 1%). The OP of the films was calculated according to Eq. (7), and the measurements were taken in duplicate for each formulation.

where \(\Delta p\) is the difference in partial pressure of oxygen between the two sides of the film.

Thermal Behaviour of the Films

Differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) of the films was carried out to analyse the effect of extracts on phase transitions and thermal stability of PLA, respectively. Film samples (5–7 mg) in aluminium-sealed pans were analysed in the calorimeter (Stare System, Mettler-Toledo Inc., Switzerland), under a nitrogen flow (30 mL min−1), by applying a heating scan previously described by Freitas et al. (2022). For TGA, film samples (3–5 mg) was also analysed following the Freitas et al. (2022) methodology. The derivative curves (DTGA) of the thermograms were analysed, and the initial degradation temperature, the temperature at maximum degradation rate, and the mass loss were determined.

Pork Meat Preservation Capacity of the Films

The capacity of the films with different active extracts to preserve fresh pork meat during cold storage was evaluated. To this end, fresh pork meat was obtained from the local market and aseptically cut into fillets of about 22 g. Previously, the control and active films (12 cm × 7 cm) were thermo-sealed using a vacuum sealer (Vacio Press, Saeco) to obtain bags. Then, the fillets were put into the film bags, and thermo-sealed at vacuum conditions. The packaged samples were stored for 16 days at 4 °C. The meat quality parameters, typically pH, mass loss, colour, microbial count, and 2-thiobarbituric acid reactive substances (TBARS) index, were evaluated on days 0, 7, and 16 days of storage, using two different sample bags for each time.

Colour Measurement

The meat CIEL*a*b* colour coordinates were obtained with a spectro-colorimeter (CM-3600d, Minolta Co., Japan) using a D65 illuminant and at 10° observer. The meat colour parameters at initial time (L0*, a0*, b0*) were used to determine the total colour difference of the samples (∆E*) throughout the storage, by applying Eq. (8).

where \(\Delta {L}^{*}=\left({L}^{*}-{L}_{0}^{*}\right)\); \(\Delta {a}^{*}=\left({a}^{*}-{a}_{0}^{*}\right)\); \(\Delta {b}^{*}=\left({b}^{*}-{b}_{0}^{*}\right)\).

Mass Loss and pH Measurement

The pH analysis was performed by immersing an electrode probe (Mettler-Toledo GmbH, Schwerzenbach, Switzerland) into the pork meat fillets (five measurements per sample). In addition, the sample weight loss was determined by weighing each fillet at 0, 7, and 16 days of storage (Eq. (9)).

where w0 and wf are the initial and final weight (on day 7 or 16) of the meat sample

TBARS Assay

The antioxidant capacity of the active films was evaluated by measuring the TBARS index of the meat following the methodology previously described by Siu and Draper (1978) and Freitas et al. (2023b). The absorbance at 532 nm was measured, and the TBARS index were expressed as mg malonaldehyde (MDA) per kg of meat using 1,1,3,3-tetramethoxypropane as standard (0.5–12 µM). The measurements were performed in triplicate.

Microbiological Analysis

Microbial counts, typically total viable (TV), psychrotrophic bacteria (PB), total coliforms (TC), and lactic acid bacteria (LA) were determined in packaged meat throughout storage, as described by Freitas et al. (2023b). For each microorganism and treatment, plates with 25–250 colonies were selected to determine the bacterial count and expressed as log colony-forming units (CFU) per gram of meat (log CFU g−1 sample).

Statistical Analysis

Analysis of variance (ANOVA) and Tukey’s HSD (honestly significant difference) test, considering the least significant difference (α) of 5%, were applied to determine whether there were significant differences among the active extracts and or the film formulations. The statistical analysis was carried out using the Minitab Statistical Software (version 17).

Results and Discussion

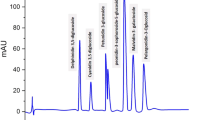

Active Properties of the RS Extracts

Table 1 shows the phenolic content, antioxidant parameters, and MIC values of each active extract. A different phenolic content and antioxidant capacity were obtained via the different extraction processes. SWE was more effective than USHT process at phenolic extraction, the efficiency increasing when the temperature rose. The phenolic content of the extracts was linearly correlated with their ABTS radical scavenging capacity (r = 0.996), but a poor correlation was observed between EC50 values and TPC (r = −0.828). The higher the TPC, the lower the EC50 values (a smaller extract amount was required to reduce the DDPH radical activity by 50%), although SWE extracts seem to exhibit a different tendency with respect to TPC. This suggests that phenolic compounds detected from the Folin-Ciocalteu assay in the extracts did not have the same composition profile in USHT extract as in the SWE extracts and exhibited different DPPH scavenging capacity. In this sense, other antioxidant compounds neo-formed through Maillard and caramelisation reactions at the highest SWE temperature could also contribute to the EC50 values, as described by other authors as regard the SWE of different plant matrices (Plaza et al., 2010a). Plaza et al. (2010b) studied the formation of Maillard and caramelisation products during SWE using glycation model systems with amino acids and glucose, as a function of temperature, and found that the extent of non-enzymatic browning reactions was higher when the temperature increased. Therefore, SWE180 extracts could contain a greater ratio of these kinds of brown compounds.

For comparison purposes, the EC50 values of potent antioxidant compounds, such as ascorbic acid or α-tocopherol, are 0.12 and 0.26 mg compound /mg DPPH, respectively (Brand-Williams et al., 1995), which indicates that the SWE extracts, especially SWE180, exhibited a high DPPH radical scavenging capacity, nearer to that of the strong antioxidants.

As concerns the antimicrobial capacity of the extracts, the MIC values of the extracts for both Gram-positive and Gram-negative bacteria also suggested greater antibacterial activity of the SWE extracts, since lower MIC values were obtained for these extracts. Although in no case were the MIC values of USHT extracts reached at the maximum concentration (200 mg mL−1) used, SWE extracts reached the MIC value of L. innocua at 30 and 50 mg mL−1 for SWE160 and SWE180 extracts, respectively. E coli was less sensitive to these extracts, exhibiting higher MIC values (over 200 mg mL−1, for SWE160 extract). Previous studies with phenolic acids, which are the main phenolic compounds in RS aqueous extracts (Menzel et al., 2020), also pointed to the differences as regards their effectiveness against each bacterium (Ordoñez et al., 2021) Ferulic acid, one of the main constituents of rice straw aqueous extract (Menzel et al., 2020), was also more effective against L. innocua than against E. coli, as observed by other authors (Andrade et al., 2022; Takahashi et al., 2013). Gram-negative bacteria, such as E. coli, are expected to be more resistant to antimicrobials, as their outer membrane limits the crossing of small molecules to a greater degree (Bof et al., 2016; Liu et al., 2020). Therefore, the obtained RS extracts may be used to produce biodegradable active films, as reported for other plant extracts (Bof et al., 2016; Hauser et al., 2016; Requena et al., 2019b).

Properties of the Films

Microstructure and Optical Properties of the Films

Figure 2 shows the cross-sections of PLA films with and without RS extracts obtained by different extraction methods (USHT, SWE160, and SWE180). The control PLA films exhibited a plastic cryofracture, with brittle and rubbery domains, characteristic of this amorphous polymer, as observed by other authors (Muller et al., 2017; Sanyang et al., 2016). The incorporation of RS extracts promoted appreciable differences in the microstructure of the films, according to the new interactions established between the extract components and PLA chains. The phenolic-rich composition of the extracts, including ferulic acid, p-coumaric acid, protocatechuic acid, and caffeic acid (Menzel et al., 2020), may imply the extensive formation of hydrogen bonds between the phenol OH groups and carbonyl of the PLA chains or with the end chain hydroxyl, which could promote a new interchain entanglement. Likewise, the presence of small aggregates, or small holes, in the polymer matrix, depending on the extract incorporated, suggested the lack of total compatibility of the extract compounds and polymer, giving rise to phase separation and a more heterogenous structure. The PLA-USHT film showed a high proportion of small aggregates that were well adhered to the polymer matrix, whereas films with SWE extracts showed small holes that, in some cases, contained loose particles. This suggests a different affinity of non-miscible compounds of the extracts with the polymer, giving rise to differing adhesion forces of dispersed particles with the matrix, depending on their composition. A rough surface pattern of the cross-section of PLA films was also reported by Díaz-Galindo et al. (2020) when the a greater concentration of grapevine cane extract was incorporated (5–15% wt.). The SWE promotes the extraction of less polar compounds, such as phenolic acids (Ong et al., 2006; Plaza et al., 2010a), but also favours the extraction of hemicellulose (Requena et al., 2019b), which could be less compatible with the PLA chains, given their polymeric, hydrophilic nature. Therefore, interchain interactions with miscible compounds of the extracts and dispersion of the non-compatible fractions provoked a structural modification in the PLA matrix that can affect its functional properties as a packaging material, such as its optical, barrier, or mechanical properties.

As concerns the optical characteristics of the films, their visual appearance, colour coordinates, and UV-vis transmittance spectra are shown in Fig. 3a. The incorporation of extracts promoted marked changes in the film colour that becomes reddish, more vivid, and darker than the control PLA film. Active films exhibited a notable decrease in lightness (L*: from 90.7 to 61.0), with a pronounced increase in colour saturation (Cab*: from 2.7 to 49.2), and a significant change in the hue angle (hab*: from 99.0 to 75.2), in which the extract SWE180 promoted the highest changes. The total colour difference (∆E*) of the active films with respect to the control PLA film was higher for PLA-SWE180 films (55.7) than PLA-SWE160 (45.1), while the lowest value was obtained for PLA-USHT films (36.7). This is coherent with a higher ratio of coloured compounds in the extracts, since many chemicals present in the lignin fraction are responsible for the dark colour in plant matrices (Do et al., 2020). Likewise, the high temperatures and pressures applied in the SWE process could promote browning reactions, such as Maillard and caramelisation reactions, giving rise to more coloured/more intensely coloured extracts, mainly at 180 °C, as previously reported (Plaza et al., 2010b).

As concerns the UV-vis transmittance spectra (Fig. 3b), the net PLA film was highly transparent, with 70–80% transmittance in the visible wave-length range, with a slight light-blocking effect in the UV region (400–250 nm). In contrast, the active films exhibited a marked decrease in light transmission in both the visible and UV ranges, due to the presence of the extract compounds in the polymer matrix with the ability to absorb UV light. In fact, phenolic compounds are considered as photo-protective compounds due to their molecular structure, with conjugated double bonds and aromatic rings (Woo et al., 2011). The most intense UV-vis light blocking effect was achieved for the films with SWE extracts (SWE160 and SWE180). These transmitted approximately 20% in the visible light range and exhibited a total blocking effect between 400 and 450 nm. The PLA-USHT film was slightly more transparent than the other active films, especially in the UV region. Wen et al. (2020) also reported an excellent light-blocking effect of poly (vinyl alcohol) films with green tea extract. Thus, the presence of active RS extracts, especially those obtained by SWE, prevented the UV light transmission, which is responsible for promoting the photo-oxidation of the components present in foods, such as vitamins, fatty acids, or pigments.

Thermal, Mechanical, and Barrier Properties of the Films

Thermal analysis of the films obtained by DSC (second heating to delete the polymer thermal history) (Fig. 4b and c) showed the typical glass transition of the amorphous PLA at 55.8 °C, in the previously reported range by other authors (Ordoñez et al., 2022). The incorporation of RS extracts provoked a plasticising effect, reducing the Tg values by about 5 °C, regardless of the kind of extract (Table 2).

Likewise, TGA also revealed the effect of RS extracts on thermal stability of PLA (Fig. 4a and b). The typical degradation curve of amorphous PLA was obtained, with a single thermal event starting at 269 °C (To) and maximum degradation rate at 357 °C (Tp), as reported by other authors (Ordoñez et al., 2022). The incorporation of RS extracts provoked a decrease in both To and Tp of about 50 and 15 °C, respectively, regardless of the extract incorporated, as shown in Table 2. These effects reflected the structural changes in the PLA matrix due to action of some extract components, such as phenolic acids or bonded water. These compounds could promote the partial hydrolyses of PLA during thermal processing, with the subsequent formation of shorter chains. The low molecular weight chains would contribute to a reduction in the Tg and thermal stability of the matrix, whose degradation started at a lower temperature. Similar effects on Tg of PLA matrices have been observed when plant extracts were incorporated (Khakestani et al., 2017).

Figure 5a shows the typical stress–strain curves of the films, whose mean thickness was 0.140 mm, with no significant differences between formulations. The embedded table in Fig. 4a gives the values of the film tensile parameters, typically TS, E, and EM.

a Stress–strain curves and tensile properties (inserted table) (TS: tensile strength at break, E: elongation at break, and EM: elastic modulus) (different subscript letters in the same column indicate significant differences between samples by Tukey test), and b oxygen permeability (OP), and water vapour permeability (WVP) of the PLA films with different RS extracts (for each property, different letters indicate significant differences)

The control PLA films showed TS, E, and EM values in the range found by other authors for PLA films of similar characteristics (Cvek et al., 2022; Muller et al., 2017). Nevertheless, the incorporation of active extracts markedly affected the tensile behaviour of the films, making them less extensible and reducing their resistance to break, as shown in Fig. 5a. Therefore, the active films exhibited a slightly worsened mechanical performance with respect to the neat PLA film, with reductions of about 18 and 36%, respectively, in the TS and E values. This behaviour reflected the weakening effect provoked by the extract compounds in the polymer matrix resulting from the compound interactions with the PLA chains that globally reduced the interchain forces and matrix cohesiveness, as previously observed in PLA films when molecular compounds of different characteristics, such as phenolic acids (Ordoñez et al., 2022) or other antioxidant compounds (Bassani et al., 2019; Freitas et al., 2023a), were incorporated. Additionally, the phenolic acids present in the extracts could promote the hydrolysis of the PLA chains during the film thermo-manufacturing steps to a certain degree, as deduced from the thermal analysis. This would also contribute to the weakening of the PLA network. Nevertheless, the described interactions did not significantly affect the film stiffness since no notable changes were observed in the elastic modulus of the films with extracts.

Figure 5b shows the WVP and OP values of the control PLA film and those containing different RS extracts. The extract-free film exhibited a WVP value of 0.077 g mm kPa−1 h−1 m−2, similar to that reported by other authors for PLA films (Díaz-Galindo et al., 2020; Jamshidian et al., 2012). Nevertheless, the incorporation of the active extract slightly worsened the water vapour barrier capacity of the films, leading to an increase in the WVP values of about 30% (p < 0.05). This could be associated with the presence of hydrophilic components from the RS extracts in the matrix, which would enhance the solubility of water molecules through the polymer network, and with the weakening effect of the compound extracts in the polymer network cohesion forces that enhances molecular mobility and diffusion.

The OP values of the films were also greatly influenced by the incorporation of the active extracts (p < 0.05). All of the active films showed a decrease in the OP values with respect to the control PLA film, which could be attributed to several reasons: (1) the promotion of the hydrophilic nature of the polymer matrix when RS extracts were present that enhances the oxygen solubility in the matrix and (2) the oxygen scavenging capacity of the extract compounds that limits the oxygen transfer in the active films (Bonilla et al., 2013). The PLA-USHT, PLA-SWE160, and PLA-SWE180 films exhibited reductions in the OP values of approximately 16, 20, and 24%, respectively, which correlate with the respective antioxidant capacity of the present extracts. The greater the radical scavenging capacity of the extracts, the more significant the OP reduction in the films. This points to a greater impact of the antioxidant power on the oxygen transfer through the films.

Therefore, despite the slightly worse mechanical properties and water vapour permeability of the films with RS extracts, their oxygen and light barrier capacity as well as their potential active properties could represent a significant improvement in terms of their food packaging potential, as a means of preventing food oxidation reactions during storage.

Pork Meat Preservation Capacity of the Films

The active and control PLA films were used to evaluate their ability to package and preserve fresh pork meat during storage. For this purpose, the quality parameters of packaged meat, namely weight loss, pH, TBARS index, microbial count, and colour, were analysed throughout 16 days of cold storage. Figure 6a shows the weight loss of the meat fillets packaged in the active and control film bags. The samples packaged with the control PLA films exhibited the greatest weight loss, reaching values of about 10% after 16 storage days, in the range reported by other authors (Hernández-García et al., 2022). The active film bags were more effective at preventing the sample weight loss (~4% after 6 storage days), with no significant differences between active bags. The meat water retention capacity may be affected by different processing factors, such as cutting, temperature, salt addition, or grinding, and by the intrinsic characteristics of the meat, such as the pH value that directly affects the water retention capacity of meat proteins (Haque et al., 2016).

Figure 6b shows the pH values of the meat as a function of storage time, where the expected increase can be observed in every sample. The pH increase is associated with the deterioration of proteins through enzymatic reactions or the metabolism of microorganisms that leads to the production of alkaline compounds, such as biogenic amines. The initial pH value of the meat was 5.59, consistent with the values reported by other studies for fresh pork meat (Yang et al., 2019). The meat packaged in the control film bag exhibited a greater increase in pH (pH final value of 5.70) than the samples packaged in active bags, which also coincides with the higher weight loss value of this sample. Meat samples packaged with PLA-SWE160 and PLA-SWE180 films showed the smallest changes in the pH values throughout time, which could be attributed to the active properties of the films, as discussed below for the other quality parameters.

As concerns meat oxidation, the development of malondialdehyde (MDA) levels, one of the end-products originating from hydroperoxide decomposition, as a function of storage time is shown in Fig. 6c for the different treatments. Initially, the meat exhibited a TBARS index of 0.1 mg MDA kg−1 sample, typical of fresh pork meat (Kaczmarek et al., 2017). The storage time and the type of packaging significantly affected the TBARS values. All of the meat samples showed a progressive increase in the TBARS index, but the samples packaged with the control film had a much higher oxidation rate. This indicates that the extracts incorporated into PLA films were efficient at retarding meat oxidation during storage. The ability to slow down the oxidative processes in meat could be associated with the release of antioxidant compounds from the films to the meat surface. Likewise, the lower OP values and the significant UV-light barrier of the active films could produce additional antioxidant effects, since the lower oxygen and UV light exposure of the meat samples prevent meat photo-oxidation. The antioxidant effects were mainly appreciated after 16 storage days and were aligned with the different antioxidant activity of the extracts incorporated into the films (PLA-SWE180 > PLA-SWE160 > PLA-USHT). Therefore, the films with a SWE180 extract with the lowest oxygen permeability, more intense UV light blocking effect, and the highest antioxidant capacity of the extract were the most effective at preserving the meat samples from oxidative deterioration.

Figure 7 shows the microbial counts in the packaged meat, in terms of the TV, LA, TC, and PB bacteria, at the different storage times. As reported by other authors (Kim et al., 2016; Valencia-Sullca, 2018), all the microorganisms tested in the meat samples exhibited progressive microbial growth. The microbial counts in the control sample (packaged in an extract-free PLA bag) were higher than those of the samples packaged in active films, which indicates the capacity of these films to inhibit microbial growth. Of the active films, the PLA-USHT was the least efficient at reducing microbial counts, especially in the case of TV and PB bacteria, with the samples exhibiting similar counts to the control sample. In fact, the samples packaged in PLA and PLA-USHT bags exceeded the acceptability limit of the total viable count in pork meat (6 log CFU g−1, Commission Regulation No 2073/2005) on day 16 of cold storage, whereas the samples packaged in SWE160 and SWE180 films remained below this limit throughout the entire period tested. The PLA-SWE180 film was the most effective at inhibiting microbial growth, exhibiting a log reduction of TV, LA, TC, and PB bacteria of about 1.9, 0.9, 1.1, and 1.4, respectively, after 16 storage days with respect to the control sample. The antibacterial effect of the released phenolic compounds is associated with their ability to inhibit bacterial virulence factors, such as enzymes and toxins, interact with the cytoplasmic membrane, and suppress the formation of bacterial biofilms (Miklasińska-Majdanik et al., 2018).

The colour changes of packaged meat, in terms of the L*, Cab*, and hab* coordinates, and the total colour difference (∆E*) with respect to the initial coordinates are shown in Fig. 8, as a function of storage time at 4 °C. All of the meat samples became darker (L* decrease) and less vivid in colour (Cab*) decrease), with small changes in hue, throughout storage (Fig. 8). However, the samples packaged in the extract-free film exhibited the most significant changes in the colour coordinates, which was reflected in the higher values of ∆E* at each storage time. The colour changes are associated with water loss and pigment oxidation during storage. Water loss modifies the sample surface reflectance and pigment concentration, which affect sample colour (Hernández-García et al., 2022). Myoglobin is the heme protein responsible for meat colour, and the oxidation of the central iron atom within the heme group is responsible for discoloration, producing changes from red OxyMb to brownish MetMb. This oxidation has been linked to lipid oxidation since the oxidation of one of these compounds produces chemical species that can promote the oxidation of the others. Therefore, previous studies reported that meat colour was preserved by the incorporation of antioxidant compounds (Faustman et al., 2010). In fact, active films with antioxidant extracts better preserved the colour of the meat samples, leading to smaller colour differences throughout storage. The colour development was coherent with the sample oxidation pattern reflected in the TBARS analysis and indicates the key role played by the antioxidant extracts in delaying the oxidative decay of the samples that produces both rancidity and colour degradation.

Active PLA films with RS extracts exhibited good preservation capacity to package fresh pork meat, compared to extract free PLA films, maintaining the quality parameters throughout longer times. SWE (especially a 180 °C) produced extracts with greater antioxidant and antibacterial activity, which were reflected in a greater effectiveness of the films containing these extracts to preserve meat from oxidative and microbial spoilage.

Conclusions

Aqueous RS extracts obtained by combined US-reflux heating and SWE exhibited antioxidant and antibacterial activity; this was greater in the SWE extracts, especially at 180 °C. These extracts tended to reduce the extensibility, resistance to break and water barrier capacity of the PLA films when incorporated at 6% wt. Nonetheless, they enhanced the oxygen barrier capacity and the UV light blocking effect of the films. When used for meat packaging, the films with RS extracts were effective at preserving quality parameters for longer, inhibiting meat oxidation, discolouration, and weight loss. The SWE extract obtained at 180 °C was the most effective at obtaining active films for meat preservation. Therefore, the green SWE technique permits active extracts to be obtained from RS, which is useful for producing active PLA films to extend the meat shelf life. These results represent a sustainable alternative to valorise the RS waste for developing biodegradable active materials to preserve food products sensitive to oxidative and microbial deterioration.

Data Availability

The data used to support the findings of this study are included in the article.

References

ASTM. (2005). E96/E96M-05 Standard test methods for water vapor transmission of materials (pp. 1–11). American Society for Testing and Materials.

ASTM. (2010). D3985–05 Oxygen gas transmission rate through plastic film and sheeting using a coulometric sensor (pp. 1–7). Annual Book of ASTM Standards, C. https://doi.org/10.1520/D3985-05.2

ASTM. (2012). ASTM D882–12 Standard test method for tensile properties of thin plastic sheeting (p. 12). American Society for Testing and Materials.

Alara, O. R., Abdurahman, N. H., & Ukaegbu, C. I. (2021). Extraction of phenolic compounds: A review. Current Research in Food Science, 4, 200–214. https://doi.org/10.1016/j.crfs.2021.03.011

Almasi, H., Jahanbakhsh Oskouie, M., & Saleh, A. (2021). A review on techniques utilized for design of controlled release food active packaging. Critical Reviews in Food Science and Nutrition, 61(15), 2601–2621.

Almeida, A. D. R., Brisola Maciel, M. V. D. O., Machado, M. H., Sganzerla, W. G., Teixeira, G. L., da Rosa, C. G., Block, J. M., Nunes, M. R., & Barreto, P. L. M. (2022). Production of chitosan and poly (vinyl alcohol) films functionalized with hop extract (Humulus lupulu L. var. Cascade) for food packaging application. Food Packaging and Shelf Life, 32, 100833. https://doi.org/10.1016/j.fpsl.2022.100833

Andrade, A., González-Martínez, C., & Chiralt, A. (2022). Physical and active properties of poly (vinyl alcohol) films with phenolic acids as affected by the processing method. Food Packaging and Shelf Life, 33, 100855. https://doi.org/10.1016/j.fpsl.2022.100855

Baghi, F., Gharsallaoui, A., Dumas, E., & Ghnimi, S. (2022). Advancements in biodegradable active films for food packaging: Effects of nano/microcapsule incorporation. Foods, 11(5), 760. https://doi.org/10.3390/foods11050760

Bassani, A., Montes, S., Jubete, E., Palenzuela, J., Sanjuán, A. P., & Spigno, G. (2019). Incorporation of waste orange peels extracts into PLA films. Chemical Engineering Transactions, 74(A), 1063–1068.

Bhat, R. (2021). Sustainability challenges in the valorization of agri-food wastes and by-products. Valorization of agri-food wastes and by-products (pp. 1–27). Elsevier. https://doi.org/10.1016/B978-0-12-824044-1.00022-2

Bof, M. J., Jiménez, A., Locaso, D. E., García, M. A., & Chiralt, A. (2016). Grapefruit seed extract and lemon essential oil as active agents in corn-starch-chitosan blend films. Food and Bioprocess Technology, 9, 2033–2045.

Bonilla, J., Talón, E., Atarés, L., Vargas, M., & Chiralt, A. (2013). Effect of the incorporation of antioxidants on physicochemical and antioxidant properties of wheat starch–chitosan films. Journal of Food Engineering, 118(3), 271–278.

Brand-Williams, W., Cuvelier, M. E., & Berset, C. (1995). Use of a free radical method to evaluate antioxidant activity. LWT - Food Science and Technology, 28(1), 25–30. https://doi.org/10.1016/S0023-6438(95)80008-5

Burgos, N., Armentano, I., Fortunati, W., Dominici, F., Luzi, F., Fiori, S., Cristofaro, F., Visai, L., Jiménez, A., & Kenny, J. M. (2017). Functional properties of plasticized bio-based poly (lactic acid)_poly(hydroxybutirate) (PLA_PHB) films for active food packaging. Food and Bioprocess Technology, 10, 770–780.

Campos, C. A., Gerschenson, L. N., & Flores, S. K. (2011). Development of edible films and coatings with antimicrobial activity. Food and Bioprocess Technology, 4, 849–875.

Castro-Puyana, M., Herrero, M., Mendiola, J. A., & Ibáñez, E. (2013). Subcritical water extraction of bioactive components from algae. Functional ingredients from algae for foods and nutraceuticals (pp. 534–560). Elsevier. https://doi.org/10.1533/9780857098689.3.534

Cheung, Y. -C., & Wu, J. -Y. (2013). Kinetic models and process parameters for ultrasound-assisted extraction of water-soluble components and polysaccharides from a medicinal fungus. Biochemical Engineering Journal, 79, 214–220. https://doi.org/10.1016/j.bej.2013.08.009

Collazo-Bigliardi, S., Ortega-Toro, R., & Chiralt, A. (2019). Improving properties of thermoplastic starch films by incorporating active extracts and cellulose fibres isolated from rice or coffee husk. Food Packaging and Shelf Life, 22, 100383. https://doi.org/10.1016/j.fpsl.2019.100383

Cvek, M., Paul, U. C., Zia, J., Mancini, G., Sedlarik, V., & Athanassiou, A. (2022). Biodegradable films of PLA/PPC and curcumin as packaging materials and smart indicators of food spoilage. ACS Applied Materials & Interfaces, 14(12), 14654–14667. https://doi.org/10.1021/acsami.2c02181

Díaz-Galindo, E. P., Nesic, A., Cabrera-Barjas, G., Dublan-García, O., Ventura-Aguilar, R. I., Vázquez-Armenta, F. J., Aguilar-Montes de Oca, S., Mardones, C., & Ayala-Zavala, J. F. (2020). Physico-chemical and antiadhesive properties of poly(lactic acid)/grapevine cane extract films against food pathogenic microorganisms. Polymers, 12(12), 2967. https://doi.org/10.3390/polym12122967

Do, N. H., Pham, H. H., Le, T. M., Lauwaert, J., Diels, L., Verberckmoes, A., Do, N. H. N., Tran, V. T., & Le, P. K. (2020). The novel method to reduce the silica content in lignin recovered from black liquor originating from rice straw. Scientific Reports, 10(1), 21263. https://doi.org/10.1038/s41598-020-77867-5

Faustman, C., Sun, Q., Mancini, R., & Suman, S. P. (2010). Myoglobin and lipid oxidation interactions: Mechanistic bases and control. Meat Science, 86(1), 86–94.

Freitas, P. A. V., Arias, C. I. L. F., Torres-Giner, S., González-Martínez, C., & Chiralt, A. (2021). Valorization of rice straw into cellulose microfibers for the reinforcement of thermoplastic corn starch films. Applied Sciences, 11(18), 8433. https://doi.org/10.3390/app11188433

Freitas, P. A. V., Gil, N. J. B., & González-Martínez, C. (2022). Antioxidant poly (lactic acid) films with rice straw extract for food packaging applications. Food Packaging and Shelf Life, 34, 1001003.

Freitas, P. A. V., González-Martínez, C., & Chiralt, A. (2020). Application of ultrasound pre-treatment for enhancing extraction of bioactive compounds from rice straw. Foods, 9(11), 1657. https://doi.org/10.3390/foods9111657

Freitas, P. A., González-Martínez, C., & Chiralt, A. (2023a). Antioxidant starch composite films containing rice straw extract and cellulose fibres. Food Chemistry, 400, 134073.

Freitas, P. A. V., González-Martínez, C., & Chiralt, Al. (2023b). Using rice straw fractions to develop reinforced, active PLA-starch bilayers for meat preservation. Food Chemistry, 405, 134990.

Goodman, B. A. (2020). Utilization of waste straw and husks from rice production: a review. Journal of Bioresources and Bioproducts, 5(3), 143–162.

Haque, M. A., Timilsena, Y. P., & Adhikari, B. (2016). Food proteins, structure, and function. Reference Module in Food Science. https://doi.org/10.1016/B978-0-08-100596-5.03057-2

Hauser, C., Peñaloza, A., Guarda, A., Galotto, M. J., Bruna, J. E., & Rodríguez, F. J. (2016). Development of an active packaging film based on a methylcellulose coating containing murta (Ugni molinae Turcz) leaf extract. Food and Bioprocess Technology, 9, 298–307.

Han, J. -W., Ruiz-Garcia, L., Qian, J. -P., & Yang, X. -T. (2018). Food packaging: a comprehensive review and future trends: food packaging: review and future trends. Comprehensive Reviews in Food Science and Food Safety, 17(4), 860–877. https://doi.org/10.1111/1541-4337.12343

Hernández-García, E., Vargas, M., & Chiralt, A. (2022). Starch-polyester bilayer films with phenolic acids for pork meat preservation. Food Chemistry, 385, 132650. https://doi.org/10.1016/j.foodchem.2022.132650

Herrero, M., Plaza, M., Cifuentes, A., & Ibáñez, E. (2012). Extraction techniques for the determination of phenolic compounds in food. Comprehensive sampling and sample preparation (pp. 159–180). Elsevier. https://doi.org/10.1016/B978-0-12-381373-2.00132-0

Jamshidian, M., Tehrany, E. A., Imran, M., Akhtar, M. J., Cleymand, F., & Desobry, S. (2012). Structural, mechanical and barrier properties of active PLA–antioxidant films. Journal of Food Engineering, 110(3), 380–389. https://doi.org/10.1016/j.jfoodeng.2011.12.034

Kaczmarek, A. M., Muzolf-Panek, M., Rudzi, M., Szablewski, T., & Cegielska-Radziejewska, R. (2017). The effect of plant extracts on pork quality during storage. Italy Journal of Food Science, 29, 644–656.

Karimi, E., Mehrabanjoubani, P., Keshavarzian, M., Oskoueian, E., Jaafar, H. Z., & Abdolzadeh, A. (2014). Identification and quantification of phenolic and flavonoid components in straw and seed husk of some rice varieties (Oryza sativa L.) and their antioxidant properties: identification and quantification of phenolic and flavonoid. Journal of the Science of Food and Agriculture, 94(11), 2324–2330. https://doi.org/10.1002/jsfa.6567

Khakestani, M., Jafari, S. H., Zahedi, P., Bagheri, R., & Hajiaghaee, R. (2017). Physical, morphological, and biological studies on PLA/n HA composite nanofibrous webs containing E quisetum arvense herbal extract for bone tissue engineering. Journal of Applied Polymer Science, 134(39), 45343.

Kim, H. W., Jeong, J. Y., Seol, K. -H., Seong, P. -N., & Ham, J. -S. (2016). Effects of edible films containing procyanidin on the preservation of pork meat during chilled storage. Korean Journal for Food Science of Animal Resources, 36(2), 230–236. https://doi.org/10.5851/kosfa.2016.36.2.230

Lee, S. E., Hwang, H. J., Ha, J. S., Jeong, H. S., & Kim, J. H. (2003). Screening of medicinal plant extracts for antioxidant activity. Life Sciences, 73(2), 167–179.

Liu, Y., Jia, Y., Yang, K., Li, R., Xiao, X., & Wang, Z. (2020). Anti-HIV agent azidothymidine decreases Tet(X)-mediated bacterial resistance to tigecycline in Escherichia coli. Communications Biology, 3, 162. https://doi.org/10.1038/s42003-020-0877-5

Luque-Garcı́a, J. L., & Luque de Castro, M. D. (2003). Ultrasound: a powerful tool for leaching. Trends in Analytical Chemistry, 22(1), 41–47. https://doi.org/10.1016/S0165-9936(03)00102-X

Makris, D. P., Boskou, G., & Andrikopoulos, N. K. (2007). Polyphenolic content and in vitro antioxidant characteristics of wine industry and other agri-food solid waste extracts. Journal of Food Composition and Analysis, 20(2), 125–132.

Mchugh, T. H., Avena-Bustillos, R., & Krochta, J. M. (1993). Hydrophilic edible films: modified procedure for water vapor permeability and explanation of thickness effects. Journal of Food Science, 58(4), 899–903. https://doi.org/10.1111/j.1365-2621.1993.tb09387.x

Menzel, C., González-Martínez, C., Vilaplana, F., Diretto, G., & Chiralt, A. (2020). Incorporation of natural antioxidants from rice straw into renewable starch films. International Journal of Biological Macromolecules, 146, 976–986. https://doi.org/10.1016/j.ijbiomac.2019.09.222

Merlo, T. C., Contreras-Castillo, C. J., Saldaña, E., Barancelli, G. V., Dargelio, M. D. B., Yoshida, C. M. P., Ribeiro Junior, E. E., Massarioli, A., & Venturini, A. C. (2019). Incorporation of pink pepper residue extract into chitosan film combined with a modified atmosphere packaging: effects on the shelf life of salmon fillets. Food Research International, 125, 108633. https://doi.org/10.1016/j.foodres.2019.108633

Miklasińska-Majdanik, M., Kępa, M., Wojtyczka, R., Idzik, D., & Wąsik, T. (2018). Phenolic compounds diminish antibiotic resistance of Staphylococcus aureus clinical strains. International Journal of Environmental Research and Public Health, 15(10), 2321. https://doi.org/10.3390/ijerph15102321

Moirangthem, K., Ramakrishna, P., Amer, M. H., & Tucker, G. A. (2021). Bioactivity and anthocyanin content of microwave-assisted subcritical water extracts of Manipur black rice (Chakhao) bran and straw. Future Foods, 3, 100030.

Muller, J., González-Martínez, C., & Chiralt, A. (2017). Poly(lactic) acid (PLA) and starch bilayer films, containing cinnamaldehyde, obtained by compression moulding. European Polymer Journal, 95, 56–70. https://doi.org/10.1016/j.eurpolymj.2017.07.019

Nerín, C., Tovar, L., & Salafranca, J. (2008). Behaviour of a new antioxidant active film versus oxidizable model compounds. Journal of Food Engineering, 84(2), 313–320. https://doi.org/10.1016/j.jfoodeng.2007.05.027

Ojha, K. S., Aznar, R., O’Donnell, C., & Tiwari, B. K. (2020). Ultrasound technology for the extraction of biologically active molecules from plant, animal and marine sources. Trends in Analytical Chemistry, 122, 115663. https://doi.org/10.1016/j.trac.2019.115663

Ong, E. S., Cheong, J. S. H., & Goh, D. (2006). Pressurized hot water extraction of bioactive or marker compounds in botanicals and medicinal plant materials. Journal of Chromatography A, 1112(1–2), 92–102. https://doi.org/10.1016/j.chroma.2005.12.052

Ordoñez, R., Atarés, L., & Chiralt, A. (2021). Physicochemical and antimicrobial properties of cassava starch films with ferulic or cinnamic acid. Lwt, 144, 111242.

Ordoñez, R., Atarés, L., & Chiralt, A. (2022). Effect of ferulic and cinnamic acids on the functional and antimicrobial properties in thermo-processed PLA films. Food Packaging and Shelf Life, 33, 100882.

Panzella, L., Moccia, F., Nasti, R., Marzorati, S., Verotta, L., & Napolitano, A. (2020). Bioactive phenolic compounds from agri-food wastes: an update on green and sustainable extraction methodologies. Frontiers in Nutrition, 7, 60.

Peanparkdee, M., & Iwamoto, S. (2019). Bioactive compounds from by-products of rice cultivation and rice processing: extraction and application in the food and pharmaceutical industries. Trends in Food Science & Technology, 86, 109–117. https://doi.org/10.1016/j.tifs.2019.02.041

Plaza, M., Amigo-Benavent, M., del Castillo, M. D., Ibáñez, E., & Herrero, M. (2010a). Facts about the formation of new antioxidants in natural samples after subcritical water extraction. Food Research International, 43(10), 2341–2348. https://doi.org/10.1016/j.foodres.2010.07.036

Plaza, M., Amigo-Benavent, M., del Castillo, M. D., Ibáñez, E., & Herrero, M. (2010b). Neoformation of antioxidants in glycation model systems treated under subcritical water extraction conditions. Food Research International, 43, 1123–1129. https://doi.org/10.1016/j.foodres.2010.02.005

Re, R., Pellegrini, N., Proteggente, A., Pannala, A., Yang, M., & Rice-Evans, C. (1999). Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radical Biology and Medicine, 29, 1231–1237. https://doi.org/10.1016/S0891-5849(98)00315-3

Requena, R., Jiménez-Quero, A., Vargas, M., Moriana, R., Chiralt, A., & Vilaplana, F. (2019a). Integral fractionation of rice husks into bioactive arabinoxylans, cellulose nanocrystals, and silica particles. ACS Sustainable Chemistry & Engineering, 7(6), 6275–6286. https://doi.org/10.1021/acssuschemeng.8b06692

Requena, R., Vargas, M., & Chiralt, A. (2019b). Study of the potential synergistic antibacterial activity of essential oil components using the thiazolyl blue tetrazolium bromide (MTT) assay. Lwt, 101, 183–190.

Sabaghi, M., Tavasoli, S., Jamali, S. N., Katouzian, I., & Esfanjani, A. F. (2022). The pros and cons of incorporating bioactive compounds within food networks and food contact materials: a review. Food and Bioprocess Technology, 15, 2422–2455.

Saeed, N., Khan, M. R., & Shabbir, M. (2012). Antioxidant activity, total phenolic and total flavonoid contents of whole plant extracts Torilis leptophylla L. BMC Complementary and Alternative Medicine, 12(1), 1–12.

Saini, J. K., Saini, R., & Tewari, L. (2015). Lignocellulosic agriculture wastes as biomass feedstocks for second-generation bioethanol production: concepts and recent developments. 3 Biotech, 5(4), 337–353. https://doi.org/10.1007/s13205-014-0246-5

Sanyang, M. L., Sapuan, S. M., Jawaid, M., Ishak, M. R., & Sahari, J. (2016). Development and characterization of sugar palm starch and poly(lactic acid) bilayer films. Carbohydrate Polymers, 146, 36–45. https://doi.org/10.1016/j.carbpol.2016.03.051

Siu, G. M., & Draper, H. H. (1978). A survey of the malonaldehyde content of retail meats and fish. Journal of Food Science, 43(4), 1147–1149. https://doi.org/10.1111/j.1365-2621.1978.tb15256.x

Södergard, A., & Stolt, M. (2002). Properties of lactic acid based polymers and their correlation with composition. Progress in Polymer Science, 27(6), 1123–1163. https://doi.org/10.1016/S0079-6700(02)00012-6

Sofi, S. A., Singh, J., Rafiq, S., Ashraf, U., Dar, B. N., & Nayik, G. A. (2018). A comprehensive review on antimicrobial packaging and its use in food packaging. Current Nutrition & Food Science, 14(4), 305–312.

Sung, S. -Y., Sin, L. T., Tee, T. -T., Bee, S. -T., Rahmat, A. R., Rahman, W. A. W. A., Tan, A. -C., & Vikhraman, M. (2013). Antimicrobial agents for food packaging applications. Trends in Food Science & Technology, 33(2), 110–123. https://doi.org/10.1016/j.tifs.2013.08.001

Takahashi, H., Kashimura, M., Koiso, H., Kuda, T., & Kimura, B. (2013). Use of ferulic acid as a novel candidate of growth inhibiting agent against Listeria monocytogenes in ready-to-eat food. Food Control, 33(1), 244–248. https://doi.org/10.1016/j.foodcont.2013.03.013

Torres-Valenzuela, L. S., Ballesteros-Gómez, A., & Rubio, S. (2020). Green solvents for the extraction of high added-value compounds from agri-food waste. Food Engineering Reviews, 12(1), 83–100.

Valencia-Sullca, C., Atarés, L., Vargas, M., & Chiralt, A. (2018). Physical and antimicrobial properties of compression-molded cassava starch-chitosan films for meat preservation. Food and Bioprocess Technology, 11(7), 1339–1349.

Wen, H., Hsu, Y. -I., Asoh, T. -A., & Uyama, H. (2020). Antioxidant activity and physical properties of pH-sensitive biocomposite using poly(vinyl alcohol) incorporated with green tea extract. Polymer Degradation and Stability, 178, 109215. https://doi.org/10.1016/j.polymdegradstab.2020.109215

Woo, K. K., Ngou, L. S., Soong, W. K., & Tang, P. Y. (2011). Stability of betalain pigment from red dragon fruit (Hylocereus polyrhizus). American Journal of Food Technology, 6(2), 140–148. https://doi.org/10.3923/ajft.2011.140.148

Yang, W., Xie, Y., Jin, J., Liu, H., & Zhang, H. (2019). Development and application of an active plastic multilayer film by coating a plantaricin BM-1 for Chilled Meat Preservation. Journal of Food Science, 84(7), 1864–1870. https://doi.org/10.1111/1750-3841.14608

Zazharskyi, V. V., Davydenko, P., Kulishenko, O., Borovik, I. V., & Brygadyrenko, V. V. (2019). Antimicrobial activity of 50 plant extracts. Biosystems Diversity, 27(2), 163–169.

Zhao, X., Tian, R., Zhou, J., & Liu, Y. (2022). Multifunctional chitosan/grape seed extract/silver nanoparticle composite for food packaging application. International Journal of Biological Macromolecules, 207, 152–160. https://doi.org/10.1016/j.ijbiomac.2022.02.180

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. The authors thank the Agencia Estatal de Investigación (Spain) for the financial support through project PID2019-105207RB-I00/AEI/10. 13039/501100011033 and Generalitat Valenciana through the project CIPROM/2021/071 and funding (grant number GrisoliaP/2019/115).

Author information

Authors and Affiliations

Contributions

Conceptualisation, methodology, formal analysis, investigation, writing–original draft preparation, writing–review and editing: Pedro A. V. Freitas, Chelo González-Martínez, and Amparo Chiralt.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Freitas, P.A.V., González-Martínez, C. & Chiralt, A. Active Poly (Lactic Acid) Films with Rice Straw Aqueous Extracts for Meat Preservation Purposes. Food Bioprocess Technol 16, 2635–2650 (2023). https://doi.org/10.1007/s11947-023-03081-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-023-03081-6