Abstract

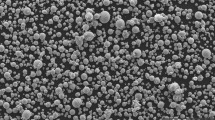

In this paper, the microstructure of Ti-6Al-4V alloy sintered by spark plasma was studied by multi-pass of hot compression experiment, and the influence of different thermal deformation parameters (hot compression temperature deformation: 950°C–20% for one pass, 850°C–20% for two passes and 900°C–10%/20%/30% for three passes) was studied. The results show that the dynamic recrystallization characteristic behavior appears in the three deformation passes. The microstructure after the first and second pass deformation is mainly composed of Widmanstätten structure. With the increase of strain rate, the thickness of lamellar α decreases gradually. In three pass, the grain boundary α phase and the layered α phase are twisted and bent when the deformation amount is 10% and 20%, and the deformation amount increases to 30%. The spheroidization of lamellar α phase occurs, and the size of β grain decreases obviously. The content of equiaxed α phase and grain size decrease with the increase of strain rate.

Similar content being viewed by others

References

R.R.B.J.C. Williams, Metals 10, 705 https://doi.org/10.3390/met10060705 (2020).

Q. Wang, J. Kong, X. Liu, K. Dong, X. Song, Y. Yang, J. Xu, and X. Chen, Vacuum 193, 110554 https://doi.org/10.1016/j.vacuum.2021.110554 (2021).

A. Babapoor, M.S. Asl, Z. Ahmadi, and A.S. Namini, Ceram. Int. 44, 14541 https://doi.org/10.1016/j.ceramint.2018.05.071 (2018).

O.E. Falodun, B.A. Obadele, S.R. Oke, M.E. Maja, and P.A. Olubambi, J. Alloy. Compd. 736, 202 https://doi.org/10.1016/j.jallcom.2017.11.140 (2018).

Z.H. Zhang, L.F. Wang, T.J. Su, and F.C. Wang, Appl. Mech. Mater. 782, 107 (2015).

J. Wu, R. Guo, L. Xu, Z. Lu, Y. Cui, and R. Yang, J. Mater. Sci. Technol. 33, 172 https://doi.org/10.1016/j.jmst.2016.10.004 (2017).

L. Liu and K. Morita, J. Eur. Ceram. Soc. 42, 2487 https://doi.org/10.1016/j.jeurceramsoc.2021.12.045 (2022).

Y.C. Lin, X.-Y. Jiang, C.-J. Shuai, C.-Y. Zhao, D.-G. He, M.-S. Chen, and C. Chen, Mater. Sci. Eng., A 711, 293 https://doi.org/10.1016/j.msea.2017.11.044 (2018).

G. Quan, S. Pu, H. Wen, Z. Zou, and J. Zhou, High Temp. Mater. Process. 34, 549 https://doi.org/10.1515/htmp-2014-0106 (2015).

Z. Yan, H. Liu, X. Dai, L. Li, Z. Zhang, Q. Wang, and Y. Xue, J. Market. Res. 23, 3137 https://doi.org/10.1016/j.jmrt.2023.01.217 (2023).

H. Liu, Z. Zhang, K. Xu, J. Zhang, Y. Xue, and Q. Wang, Mater. Charact. 178, 111263 https://doi.org/10.1016/j.matchar.2021.111263 (2021).

X.Y. Liu Haijun, Z. Zhimin, R. Luying, W. Yaojin, X. Jian, and Y. Jiangpeng, Proc. Manufact. 50, 652 (2020).

X. Jia, L. Wang, Z. Wang, C. Chen, and F. Zhang, J. Mater. Sci. 57, 22140 https://doi.org/10.1007/s10853-022-08014-w (2022).

S. Zhang, W. Zeng, X. Gao, D. Zhou, and Y. Lai, J. Alloys Compd. 684, 201 https://doi.org/10.1016/j.jallcom.2016.05.176 (2016).

K. Majchrowicz, A. Sotniczuk, B. Adamczyk-Cieślak, W. Chromiński, P. Jóźwik, Z. Pakieła, and H. Garbacz, J. Alloys Compd. 948, 169791 https://doi.org/10.1016/j.jallcom.2023.169791 (2023).

S.J. Yang Shengli, L. Xiwu, Y. Xiaodong, Z. Yongan, L. Zhihui, H. Shushuhui, and X. Baiqing, Rare Met. Mater. Eng. (2017)

O. Avwerosuoghene Moses, C. Themba Edmond, T. Thapelo Precious, L. Senzeni Sipho, O. Samuel Ranti, and O. Peter Apata, Mater. Today Proc. 18, 3791 https://doi.org/10.1016/j.matpr.2019.07.317 (2019).

G. Shao, H. Li, X. Zhang, M. Zhan, and Z. Xiang, J. Alloys Compd. 908, 164591 https://doi.org/10.1016/j.jallcom.2022.164591 (2022).

D. Cai, L. Xiong, W. Liu, G. Sun, and M. Yao, Mater. Charact. 58, 941 https://doi.org/10.1016/j.matchar.2006.09.004 (2007).

A. Soltani-Tehrani, M. Habibnejad-Korayem, S. Shao, M. Haghshenas, and N. Shamsaei, Addit. Manuf. 51, 102584 https://doi.org/10.1016/j.addma.2021.102584 (2022).

Z. Hu, X. Zhou, X.-A. Nie, S. Zhao, H. Liu, D. Yi, and X. Zhang, J. Alloys Compd. 788, 136 https://doi.org/10.1016/j.jallcom.2019.02.201 (2019).

Z. Yan, L. Wang, X. Xu, Z. Zhou, A. Liu, and Z. Ning, Mater. Sci. Technol. 38, 1037 https://doi.org/10.1080/02670836.2022.2069317 (2022).

A.L. Rominiyi, M.B. Shongwe, N. Maledi, B.J. Babalola, and P.A. Olubambi, Int. J. Adv. Manuf. Technol. 104, 1041 https://doi.org/10.1007/s00170-019-03950-5 (2019).

Z. Zhang, M. Lin, D.H.L. Seng, S.L. Teo, F. Wei, H.R. Tan, A.K.H. Cheong, S.H. Lim, S. Wang, and J. Pan, Materialia 12, 100813 https://doi.org/10.1016/j.mtla.2020.100813 (2020).

T. Jiao, T. Jiang, G. Dai, Y. Guo, Z. Sun, H. Chang, Y. Han, S. Li, and I.V. Alexandrov, Mater. Charact. 197, 112665 https://doi.org/10.1016/j.matchar.2023.112665 (2023).

O. Molnarova, J. Duchon, E. de Prado, S. Csaki, F. Prusa, and P. Malek, Materials 13, 3756 https://doi.org/10.3390/ma13173756 (2020).

Y.V.R.K.P.O. Sivakesavam, Mater. Sci. Eng. A (2002)

P. Cizek, S.R. Kada, N. Armstrong, R.A. Antoniou, S. Slater, and P.A. Lynch, Mater. Sci. Eng. A 836, 142700 https://doi.org/10.1016/j.msea.2022.142700 (2022).

X. Lin, H. Huang, X. Yuan, Y. Wang, B. Zheng, X. Zuo, and G. Zhou, J. Alloys Compd. 891, 162105 https://doi.org/10.1016/j.jallcom.2021.162105 (2022).

H.X. Zhou, S.W. Jiang, X.T. Li, and C.X. Li, Surf. Interfaces 33, 102237 https://doi.org/10.1016/j.surfin.2022.102237 (2022).

E. Rogoff, M. Antony, and P. Markle, J. Mater. Eng. Perform. 27, 5227 https://doi.org/10.1007/s11665-018-3432-5 (2018).

Z. Hao, Y. Chen, Q. Zhang, P. Wang, Y. Shu, and J. He, Adv. Powder Technol. 33, 103379 https://doi.org/10.1016/j.apt.2021.11.031 (2022).

J.L.L. Zhu, B. Tang, F. Zhao, K. Hua, S. Yan, and H. Kou, Prog. Nat. Sci. Mater. Int. 30, 517 https://doi.org/10.1016/j.pnsc.2020.08.008 (2020).

A. Sarkar, A. Marchattiwar, J.K. Chakravartty, and B.P. Kashyap, J. Nucl. Mater. 432, 9 https://doi.org/10.1016/j.jnucmat.2012.07.020 (2013).

L. Dong, Int. J. Mech. Sci. 173, 105460 https://doi.org/10.1016/j.ijmecsci.2020.105460 (2020).

L.-J. Zhang and X.-P. Guo, Rare Met. 36, 174 https://doi.org/10.1007/s12598-017-0881-1 (2017).

M. Bönisch, A. Panigrahi, M. Calin, T. Waitz, M. Zehetbauer, W. Skrotzki, and J. Eckert, J. Alloys Compd. 697, 300 https://doi.org/10.1016/j.jallcom.2016.12.108 (2017).

X. Chen, B. Tang, Y. Liu, X. Xue, L. Li, H. Kou, and J. Li, Prog. Nat. Sci. Mater. Int. 29, 587 https://doi.org/10.1016/j.pnsc.2019.08.004 (2019).

Y.C. Lin, Y.-W. Xiao, Y.-Q. Jiang, G.-D. Pang, H.-B. Li, X.-Y. Zhang, and K.-C. Zhou, Mater. Sci. Eng. A. https://doi.org/10.1016/j.msea.2020.139282 (2020).

T. Zhang, H. Xu, Z. Li, H. She, D. Du, A. Dong, H. Xing, D. Wang, G. Zhu, and B. Sun, J. Mech. Behav. Biomed. Mater. 109, 103842 https://doi.org/10.1016/j.jmbbm.2020.103842 (2020).

Acknowledgements

The present work was supported by the National Natural Science Foundation of China (Grant no. 51675492).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dai, X., Zhang, Z. & Xue, Y. Effect of Multi-pass Deformation on Microstructure Evolution of Spark Plasma Sintered Ti-6Al-4V Alloy. JOM 76, 1844–1855 (2024). https://doi.org/10.1007/s11837-023-06216-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-06216-4