Abstract

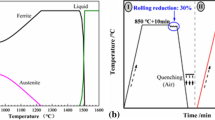

The hydrogen embrittlement behavior of two low-carbon medium manganese steel welding joints was elucidated using a slow strain rate tensile experiment, hydrogen permeation experiment, and hydrogen concentration test. The fracture starting position becomes heat-affected zone (HAZ) after hydrogen charging. The hydrogen concentration of HAZ is higher than weld material (WM) for two welding joints after hydrogen charging for both 1 h and 2 h. The hydrogen embrittlement susceptibility of the welding joint with high hydrogen concentration, which contains about 0.03 Ti in both WM and HAZ, is larger than the welding joint that does not contain Ti. When the hydrogen charging time of the Ti-contained welding joints increases from 1 h to 2 h, the fractography of WM changes from small shallow dimples (hydrogen enhanced localized plasticity) to quasi-cleavage and cleavage (hydrogen enhanced decohesion), and the fractography of HAZ changes from quasi-cleavage (hydrogen enhanced decohesion) to intergranular (hydrogen enhanced decohesion).

Similar content being viewed by others

References

X.K. Jin, L. Xu, W.C. Yu, K.F. Yao, J. Shi, and M.Q. Wang, Corros. Sci. 170, 108421 (2020).

L. Chen, X.L. Xiong, X. Tao, Y.J. Su, and L.J. Qiao, Corros. Sci. 166, 108428 (2020).

T. Das, S.V. Brahimi, J. Song, and S. Yue, Corros. Sci. 190, 109701 (2021).

X.Y. Cheng and H.X. Zhang, Corros. Sci. 174, 108800 (2020).

M. Dadfarnia, P. Novak, D.C. Ahn, J.B. Liu, P. Sofronis, D.D. Johnson, and I.M. Robertson, Adv. Mater. 22, 1128 (2010).

J. Song and W.A. Curtin, Acta Mater. 59, 1557 (2011).

J. Song and W.A. Curtin, Nat. Mater. 12, 145 (2013).

J. Song and W.A. Curtin, Acta Mater. 68, 61 (2014).

R.A. Oriani and P.H. Josephic, Acta Metall. 25, 979 (1977).

J.F. Lessar and W.W. Gerberich, Metall. Trans. A 7, 953 (1976).

S.P. Lynch, Acta Metall. 36, 2639 (1988).

Z. Tarzimoghadam, M. Rohwerder, S.V. Merzlikin, A. Bashir, L. Yedra, S. Eswara, D. Ponge, and D. Raabe, Acta Mater. 109, 69 (2016).

Y. Chen, D. Haley, S.S.A. Gerstl, A.J. London, F. Sweeney, R.A. Wepf, W.M. Rainforth, P.A.J. Bagot, and M.P. Moody, Science 355, 1196 (2017).

J.M. Cairney and H.Z. Lu, Science 367, 171 (2020).

J. Zhao and Z. Jiang, Prog. Mater. Sci. 94, 174 (2018).

D.Z. Zhang, X.H. Gao, L.X. Du, Y. Du, H. Wang, Z.G. Liu, and G.Q. Su, Mater. Sci. Eng. A 765, 138278 (2019).

M.A. Mohtadi-Bonab, J.A. Szpunar, and S.S. Razavi-Tousi, Int. J. Hydrogen Energ. 38, 13831 (2013).

D. Wang, X. Lu, Y. Deng, X. Guo, and A. Barnoush, Acta Mater. 166, 618 (2019).

H. Liu, L.X. Du, J. Hu, H.Y. Wu, X.H. Gao, and R.D.K. Misra, J. Alloys Compd. 695, 2072 (2017).

J. Hu, L.X. Du, W. Xu, J.H. Zhai, Y. Dong, Y.J. Liu, and R.D.K. Misra, Mater. Charact. 136, 20 (2018).

J. Hu, L.X. Du, G.S. Sun, H. Xie, and R.D.K. Misra, Scr. Mater. 104, 87 (2015).

X.Y. Qi, L.X. Du, J. Hu, and R.D.K. Misra, Mater. Sci. Eng. A 718, 471 (2018).

L.Y. Lan, M. Yu, and C.L. Qiu, Mater. Sci. Eng. A 742, 442 (2019).

J.L. Yang, F. Huang, Z.H. Guo, Y. Rong, and N. Chen, Mater. Sci. Eng. A 665, 76 (2016).

X. Zhu, W. Li, H.S. Zhao, and X.J. Jin, Int. J. Hydrogen Energ. 38, 10694 (2013).

X. Zhu, W. Li, H. Zhao, L. Wang, and X. Jin, Int. J. Hydrogen Energ. 39, 13031 (2014).

A.E. Pontini and J.D. Hermida, Scripta Mater. 37, 1831 (1997).

T. Michler, C. San Marchi, J. Naumann, S. Weber, and M. Martin, Int. J. Hydrogen Energ. 37, 16231 (2012).

Y. Du, X.H. Gao, L.Y. Lan, X.Y. Qi, H.Y. Wu, L.X. Du, and R.D.K. Misra, Int. J. Hydrogen Energ. 44, 32292 (2019).

Y. Du, X.H. Gao, Z.W. Du, L.Y. Lan, X.Y. Qi, R.D.K. Misra, H.Y. Wu, and L.X. Du, Int. J. Hydrogen Energ. 46, 8269 (2021).

X.Y. Qi, L.X. Du, J. Hu, and R.D.K. Misra, Steel Res. Int. 89, 1700422 (2018).

J.H. Yoo, K.T. Han, Y.H. Park, and C.H. Lee, Mater. Chem. Phys. 146, 175 (2014).

T.M. Zhang, W.M. Zhao, Q.S. Deng, W. Jiang, Y.L. Wang, Y. Wang, and W.C. Jiang, Int. J. Hydrogen Energ. 42, 25102 (2017).

S.J. Kim, H.G. Jung, and K.Y. Kim, Scripta Mater. 67, 895 (2012).

E. López Martínez, H.J. Vergara Hernández, O. Flores, and B. Campillo, Hydrogen ISIJ Int. 55, 2435 (2015).

L.Y. Lan, X.W. Kong, Z.Y. Hu, C.L. Qiu, D.W. Zhao, and L.X. Du, Corros. Sci. 112, 180 (2016).

Z.H. Fu, T. Li, M.L. Shan, G.Q. Gou, Z.Y. Zhu, C.P. Ma, W. Gao, and Y.C. Hu, Corros. Sci. 148, 272 (2019).

Y.H. Fan, B. Zhang, H.L. Yi, G.S. Hao, Y.Y. Sun, J.Q. Wang, E.H. Han, and W. Ke, Acta Mater. 139, 188 (2017).

T. Hojo, E. Akiyama, H. Saitoh, A. Shiro, R. Yasuda, T. Shobu, J. Kinugasa, and F. Yuse, Corros. Sci. 177, 108957 (2020).

H.Y. Tian, J.C. Xin, Y. Li, X. Wang, and Z.Y. Cui, Corros. Sci. 158, 108089 (2019).

BS EN ISO 17081-2014.

H.H. Johnson, N. Quick, and A.J. Kumnick, Scr. Metall. 13, 67 (1979).

A.M. Brass, F. Guillon, and S. Vivet, Metall. Mate. Trans. A 35A, 1449 (2004).

S.Z. Wang, Z.J. Gao, G.L. Wu, and X.P. Mao, Int. J. Min. Met. Mater. 29, 645 (2022).

Y. Han, J. Shi, L. Xu, W.Q. Cao, and H. Dong, Mater. Des. 34, 427 (2012).

C.D. Beachem, Metall. Trans. A 3, 441 (1972).

Acknowledgements

The authors gratefully appreciate the financial support from the National Natural Science Foundation of China (No. 51975391) and the National High-tech R&D Program (863 Program) (No. 2015AA03A501).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Du, Y., Gao, X.H., Wang, X.N. et al. Hydrogen Embrittlement Behavior and Mechanism of Low Carbon Medium Manganese Steel Gas Metal Arc Welding Joints. JOM 75, 4407–4420 (2023). https://doi.org/10.1007/s11837-023-06064-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-06064-2