Abstract

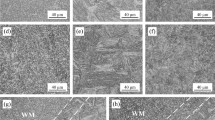

Spectacular failure cases of fossil power stations in the recent years exhibited severe cracking in T24 welds. The results show that hydrogen-assisted cracking up to 200 °C cannot be excluded. Hence, it is important to gain a basic understanding on how hydrogen might affect the basic material properties in the respective weld microstructures. The present study focuses on hydrogen degradation of the respective weld microstructures, i.e., the weld metal and the coarse grained heat affected zone, where actually cracking appeared in practice. Tensile tests were carried out for coarse grain heat-affected zone (CGHAZ) and the weld metal in uncharged and electrochemically hydrogen-charged condition. It turned out that both microstructures show distinct tendency for gradual degradation of mechanical properties in the presence of increasing hydrogen concentration. Already for a hydrogen concentration about and above 2 ml/100 g Fe, a significant ductility reduction has been observed. SEM investigations revealed that the fracture topography changes from ductile topography in uncharged condition to intergranular topography for the CGHAZ and to ductile-brittle mix for the weld metal (WM) in hydrogen charged condition. Ti-rich inclusions were identified as central regions of quasi-cleavage fracture areas in the WM. An approximation procedure is applied to quantify the degradation intensity.

Similar content being viewed by others

References

Hahn B, Bendick W (2008) Rohrstaehle fuer moderne Hochleistungskraftwerke. 3R Int 47:3–12

Heuser H, Jochum C, Lecomte-Beckers J, Carton M, Schubert F, Ennis PJ (2002) Characterization of matching filler metals for new ferritic-bainitic steels like T/P 23 and T/P 24, Materials for Advanced Power Engineering 2002. Forschungszentrum Jülich, Jülich

Dhooge A, Vekeman J (2005) New generation 21/4Cr steels T/P 23 and T/P 24 weldabiltiy and high temperature properties. Weld World 49:75–93. doi:10.1007/bf03266492

Garet M, Brass AM, Haut C, Guttierez-Solana F (1998) Hydrogen trapping on non-metallic inclusions in Cr-Mo low alloyed steels. Corros Sci 40:1073–1086. doi:10.1016/S0010-938x(98)00008-0

Albert SK, Ramasubbu V, Parvathavarthini N, Gill TPS (2003) Influence of alloying on hydrogen-assisted cracking and diffusible hydrogen content in Cr-Mo steel welds. Sadhana 28:383–393. doi:10.1007/bf02706439

Coudreuse L, Bocquet P, Cheviet L (1992) Hydrogen trapping in Cr-Mo steels for hydro processing reactors. PVP-Vol. 239/ MPC- Vol. 33, Serviceability of Petroleum, Process and Power Equipment, ASME

Brouwer RC (1993) Hydrogen concentration distribution in the wall of pressure vessels made of conventional and V-modified steels. Int J Pres Ves Pip 56:133–148. doi:10.1016/0308-0161(93)90091-7

Brouwer RC (1992) Hydrogen diffusion and solubility in vanadium modified pressure vessel steels. Scripta Metall Mater 27:353–358. doi:10.1016/0956-716x(92)90525-j

Nowack R, Goette C, Heckmann S (2011) Quality management at RWE using T24 boiler material as an example (in German). VGB Powertech J 11:1–5

Boewe J, Becker M (2013) Modified commissioning procedure for USC boilers using material T24., Hitachi Power Europe GmbH Germany, http://pennwell.websds.net/2013/vienna/pge/papers/T4S5O3-paper.pdf. Accessed on 27 November 2014

Husemann RU, Devrient S, Kilian R (2012) Cracking mechanism in high temperature water-T24 Root cause analysis program. In: NN 38th VDI-Jahrestagung Schadensanalyse in Kraftwerken. VDI-Wissensforum, Düsseldorf, pp 87–103

Luedenbach G (2012) Stress corrosion cracking of T24. VGB Powertech. http://www.vgb.org/en/hv_12_presentations-dfid-47601.html. Accessed on 24 Mai 2014

Hoffmeister H, Boellinghaus T (2014) Modeling of combined anodic dissolution/hydrogen-assisted stress corrosion cracking of low- alloyed power plant steels in high-temperature water environments. Corros Sci 70:563–578. doi:10.5006/1048

Baeumel A, Drotden P, Pirchner H, Wagner G (1983) Study of stress corrosion cracking on welded high-strength fine grained structural steels in boiled feed water. Stahl Eisen 103:1091–1096

Nevasmaa P, Laukanen A (2005) Assessment of hydrogen cracking risk in multipass weld metal of 2.25Cr-1Mo-0.25V-TiB (T24) boiler steel. Weld World 49:45–58. doi:10.1007/bf03263423

Mohyla P, Foldyna V (2009) Improvement of reliability and creep resistance in advanced low-alloy steels. Mat Sci Eng A-Struct 510–511:234–237. doi:10.1016/j.msea.2008.05.056

Blach J, Falat F, Sevc P (2011) The influence of hydrogen charging on the notch tensile properties and fracture behavior on dissimilar weld joints of advanced Cr-Mo-V and Cr-Ni-Mo creep resistant steels. Eng Fail Anal 18:485–491. doi:10.1016/j.engfailanal.2010.09.043

Dayal RK, Parvathavarthini N (2003) Hydrogen embrittlement in power plant steels. Sadhana 28:431–451. doi:10.1007/bf02706442

Zimmer P, Seeger DM, Boellinghaus T, Cerjak H (2005) Hydrogen permeation and related material properties of high strength steels, High strength steels for hydropower plants - Proceedings. Institute for Materials Science, Welding and Forming, Graz, pp 1–18, paper-no 17

Heuser H (2009) Schweißtechnische Verarbeitung neuer Kraftwerkstähle. Forum-Schweißtechnik im Kraftwerksbau (SLV München). http://www.bayern-innovativ.de/schweisstechnik2009/download/heuser.pdf. Accessed 20 May 2014

Michler T, Naumann J (2010) Microstructure aspects upon hydrogen environment embrittlement of various bcc steels. Int J Hydrog Energ 35:821–832. doi:10.1016/j.ijhydene.2009.10.092

Salmi S, Rhode M, Juettner S, Zinke M (2015) Hydrogen determination in 22MnB5 steel grade by use of carrier gas hot extraction technique. Weld World 59:137–144. doi:10.1007/s40194-014-0186-z

Kannengiesser T, Tiersch N (2010) Measurements of diffusible hydrogen contents at elevated temperatures using different hot extraction techniques - an international round robin test. Weld World 54(5):R115–R122. doi:10.1007/BF03263497

Coudreuse L, Bocquet P (1995) Hydrogen diffusion and trapping in Cr-Mo steels for hydrotreating reactors. In: Turnbull A (ed) Hydrogen cracking in metals. The Institute of Materials, London, pp 227–239

Brass AM, Guillon F, Vivet S (2004) Quantification of hydrogen diffusion and trapping in 2.25Cr-1Mo and 3Cr-1Mo-V steels with electrochemical permeation technique and melt extraction. Metall Mater Trans A 35:1449–1464. doi:10.1007/s11661-004-0253-y

Takahashia J, Kawakamia K, Taruib T (2012) Direct observation of hydrogen-trapping sites in vanadium carbide precipitation steel by atom probe tomography. Scripta Mater 67:213–216. doi:10.1016/j.scriptamat.2012.04.022

Depover T, Monbaliu O, Wallaert E, Verbeken K (2015) Effect of Ti, Mo and Cr based precipitates on the hydrogen trapping and embrittlement of Fe-C-X Q&T alloys. Int J Hydrog Energ. doi:10.1016/j.ijhydene.2015.06.157, In Press, Corrected proof

Parvathavarthini N, Saroja S, Dayal RK, Khatak HS (2001) Studies on hydrogen permeability of 2.25%Cr-1%Mo ferritic steel: correlation with microstructure. J Nucl Mater 288:187–196. doi:10.1016/S0022-3115(00)00706-6

Mohyla P, Foldyna V (2009) Improvement of reliability and creep resistance in advanced low-alloy steels. Mater Sci Eng A 510(511):234–237. doi:10.1016/j.msea.2008.05.056

Boellinghaus T, Hoffmeister H, Dangeleit A (1995) A scatterband for hydrogen diffusion coefficients in micro-alloyed low carbon structural steels. Weld World 35(2):83–96

Liu Y, Wang M, Liu G (2013) Hydrogen trapping in high strength martensitic steel after austenitized at different temperatures. Int J Hydrog Energ 38:14364–14368. doi:10.1016/j.ijhydene.2013.08.121

Matsuoka S, Homma N, Tanaka H, Fukushima Y, Murakami Y (2006) Effect of hydrogen on the tensile properties of 900MPa-class JIS-SCM435 low-alloy-steel for use in storage cylinder of hydrogen station. J Jpn Inst Metals 70:1002–1011. doi:10.2320/jinstmet.70.1002

Birnbaum HK, Sofronis P (1994) Hydrogen-enhanced localized plasticity - a mechanism for hydrogen-related fracture. Mat Sci Eng A-Struct 176:191–202. doi:10.1016/0921-5093(94)90975-X

Coleman KK, Newell WF (2007) P91 and Beyond -Welding the new-generation Cr-Mo alloys for high-temperature service. Weld J 86:29–33

Xu H, Xia X, Hua L, Sun Y, Dai Y (2012) Evaluation of hydrogen embrittlement susceptibility of temper embrittled 2.25Cr-1Mo steel by SSRT method. Eng Fail Anal. doi:10.1016/j.engfailanal.2011.08.008

Depover T, Perez Escobar D, Wallaert E, Zermout Z, Verbeken K (2014) Effect of hydrogen charging on the mechanical properties of advanced high strength steels. Int J Hydrog Energ 39:4647–4656. doi:10.1016/j.ijhydene.2013.12.190

Eliaz N, Shachar A, Tal B, Eliezer D (2002) Characteristics of hydrogen embrittlement, stress corrosion cracking and tempered martensite embrittlement in high-strength steels. Eng Fail Anal 9:167–184. doi:10.1016/S1350-6307(01)00009-7

Gojic M, Kosec L, Matkovic P (2003) Embrittlement damage of low alloy Mn-V steel. Eng Fail Anal 10:93–102. doi:10.1016/s1350-6307(02)00038-9

Nelson HG (1983) Hydrogen embrittlement. In: Briant CL, Banerji SK (eds) Treatise on materials science and technology, vol 25. Academic Press, New York, pp 275–359

Beghini M, Benamati G, Bertini L, Valentini R (1998) Effect of hydrogen on tensile properties of martensitic steels for fusion application. J Nucl Mater 9:1295–1299. doi:10.1016/S0022-3115(98)00162-7

Lynch SP (1984) A fractographic study of gaseous hydrogen embrittlement and liquid-metal embrittlement in a tempered-martensitic steel. Acta Metall Mater 32:79–90. doi:10.1016/0001-6160(84)90204-9

Martin ML, Fenske JA, Liu GS, Sofronis P, Robertson IM (2011) On the formation and nature of quasi-cleavage fracture surfaces in hydrogen embrittled steels. Acta Mater 59:1601–1605. doi:10.1016/j.actamat.2010.11.024

Liua Q, Irwantob B, Atrensa A (2013) The influence of hydrogen on 3.5NiCrMoV steel studied using the linearly increasing stress test. Corros Sci 67:193–202. doi:10.1016/j.corsci.2012.10.019

Pancikiewicz K, Zielinska-Lipiec A, Tasak E (2013) Cracking of high-strength steel welded joints. Adv Mater Sci 13(3):76–85. doi:10.2478/adms-2013-0013

Davies JR (2004) Tensile testing. ASM-International, Materials Park, Ohio, USA

Wongpanya P, Boellinghaus T, Lothongkum G, Hoffmeister H (2009) Numerical modeling of cold cracking initiation and propagation in S 1100 QL steel root welds. Weld World 53:R34–R43. doi:10.1007/bf03266701

Mente T, Boellinghaus T, Schmitz-Niederau M (2012) Heat treatment effects on the reduction of hydrogen in multi-layer high-strength weld joints. Weld World 56:26–36. doi:10.1007/bf03321362

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission IX - Behaviour of Metals Subjected to Welding

Rights and permissions

About this article

Cite this article

Rhode, M., Steger, J., Boellinghaus, T. et al. Hydrogen degradation effects on mechanical properties in T24 weld microstructures. Weld World 60, 201–216 (2016). https://doi.org/10.1007/s40194-015-0285-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-015-0285-5