Abstract

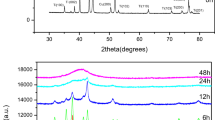

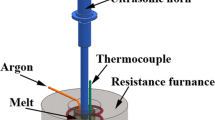

In this paper, TiCx particles were prepared by an in situ process and added to an Al-Bi alloy, and the effects of TiCx particles on the homogenization preparation and refinement mechanism of Al-Bi alloys were studied. The TiCx particle size can be greatly reduced by decreasing graphite particle size, and the TiCx particle size was further reduced after changing C source from graphite to MLG. The TiCx particle gradually changed from angular octahedral to truncated octahedral and then became round with the C/Ti ratio increasing from 0.4 to 1.0. After the TiCx particles being added to the Al-Bi alloy, it was found that TiCx had a significant inhibitory effect on the macrosegregation and coarsening of Bi phase. The average diameter of the Bi phase decreased from 4.32 μm to 3.45 μm with the TiCx particle size decreased, and the distribution became more dispersed and uniform, contributing to the heterogeneous nucleation and self-assembly behavior of TiCx particle. With the decreasing of TiCx particle size, the refinement mechanism evolved from heterogeneous nucleation to self-assembly.

Similar content being viewed by others

References

L. Ratke, and S. Diefenbach, Mater. Sci. Eng. R 15(7), 263 (1995).

J. He, J.Z. Zhao, and R. Lorenz, Acta Mater. 54(7), 1749 (2006).

J.Z. Zhao, S. Drees, and L. Ratke, Mater. Sci. Eng. A 282(1), 262 (2000).

J. Koo, C. Lee, S.J. Hong, K. Kim, and H.M. Lee, J. Alloys Compd. 650, 106 (2015).

K. Qiu, R. Wang, C.Q. Peng, N.G. Wang, Z.Y. Cai, and C. Zhang, Trans. Nonferrous Met. Soc. China 25(12), 3886 (2015).

F. Bertelli, E.S. Freitas, N. Cheung, M.A. Arenas, A. Conde, J.D. Damborenea, and A. Garcia, J. Alloys Compd. 695, 3621 (2017).

Z.C. Lu, M.Q. Zeng, J.Q. Xing, and M. Zhu, Wear 364–365, 122 (2016).

C.Z. Cao, L.Y. Chen, J.Q. Xu, H. Choi, and X.C. Li, Mater. Sci. Eng. A 651, 332 (2016).

W.Q. Lu, S.G. Zhang, W. Zhang, and J.G. Li, J. Mater. Sci. Technol. 32(12), 1321–1325 (2016).

W.Q. Lu, S.G. Zhang, W. Zhang, and J.G. Li, Scripta Mater. 102, 19–22 (2015).

R. Dai, S.J. Zhang, Y.S. Li, X.K. Guo, and J.G. Li, J. Alloys Compd. 509(5), 2289–2293 (2011).

A.P. Silva, J.E. Spinelli, N. Mangelinck-Noël, and A. Garcia, Mater. Des. 31(10), 4584 (2010).

H.X. Jiang, J.Z. Zhao, and J. He, J. Mater. Sci. Technol. 30(10), 1027 (2014).

S. Yang, W.J. Liu, and J. Jia, J. Mater. Sci. 36(22), 5351 (2001).

T.M. Man, L. Zhang, Z.L. Xiang, W.B. Wang, J.W. Gao, and E.G. Wang, Acta Phys. Sin. 67(03), 195 (2018).

P. Jia, J.Y. Zhang, H.R. Geng, X.Y. Teng, D.G. Zhao, Z.X. Yang, Y. Wang, S. Hu, J. Xiang, and X. Hu, Met. Mater. Int. 24(6), 1262 (2018).

L. Zhang, T.N. Man, and E.G. Wang, Acta Metall. Sin. 55(03), 399 (2018).

Q. Sun, H.X. Jiang, J.Z. Zhao, and J. He, Acta Mater. 129, 321 (2017).

K. Zhang, X.F. Bian, Y.M. Li, C.C. Yang, H.B. Yang, and Y. Zhang, J. Alloys Compd. 639, 563 (2015).

S.Q. Cao, W.Q. Lu, Q.D. Hu, P.F. Yu, X. Ge, P.S. Lai, and J.G. Li, Scr. Mater. 209, 114365 (2022).

L.Y. Chen, J.Q. Xu, H. Choi, H. Konishi, S. Jin, and X.C. Li, Nat. Commun. 15, 3879 (2014).

C.Z. Cao, W.Q. Liu, Z.W. Liu, J.Q. Xu, I. Hwang, I.M.D. Rosa, and X.C. Li, Mater. Des. 146, 163 (2018).

J.F. Nie, X.F. Liu, and Y.Y. Wu, J. Alloys Compd. 48(4), 1645 (2013).

Z.J. Wang, Z.X. Qiu, H. Sun, and W.C. Liu, J. Alloys Compd. 806, 788 (2019).

K. Zhao, T. Gao, H.B. Yang, K.Q. Hu, G.L. Liu, Q.Q. Sun, J.F. Nie, and X.F. Liu, Mater. Sci. Eng. A. 806, 140852 (2021).

K. Vasanthakumar, and R.B. Srinivasa, Ceram. Int. 44(1), 484 (2018).

B.X. Dong, H.Y. Yang, F. Qiu, Q. Li, S.L. Shu, B.Q. Zhang, and Q.C. Jiang, Mater. Des. 181, 107951 (2019).

C.M. Li, Y.G. Yin, G. Cao, M. Xu, C. Liu, R.R. Li, G.T. Zhang, Q. Chen, and B.X. Yang, J. Mater. Eng. Perform. 31, 524 (2021).

C.M. Li, Y.G. Yin, M. Xu, J.F. Cheng, L. Shen, G.T. Zhang, Q. Chen, and B.X. Yang, Int. J. Mater. Res. 111(7), 607 (2020).

J.B. Holt, and Z.A. Munir, J. Mater. Sci. 21(1), 251 (1986).

Y. Dong, M.J. Wang, G.W. Zhang, and H. Xu, Results Phys. 23, 104000 (2021).

J.F. Zhang, D.S. Zhang, H.G. Zhu, and Z.H. Xie, Mater. Sci. Eng. A. 794, 139946 (2020).

Y. Birol, J. Alloys Compd. 454, 110 (2008).

R.R. Wang, M. Wang, S.Y. Gao, Z.L. Wang, T.Z. Xin, M. Liu, and Y.P. Bao, J. Clean. Prod. 378, 134548 (2022).

K. Vasanthakumar, and S.R. Bakshi, Ceram. Int. 44, 484 (2018).

Y.X. Li, J.D. Hu, Y.H. Liu, Y. Yang, and Z.X. Guo, Mater. Lett. 61(22), 4366 (2007).

Y. Dong, M.J. Wang, G.W. Zhang, and H. Xu, Results. Phys. 23, 104000 (2021).

H.B. Yang, T. Gao, H.C. Wang, J.F. Nie, and X.F. Liu, J. Mater. Sci. Technol. 33, 616 (2017).

J. Li, Y.Q. Yang, L.L. Li, J.H. Lou, X. Luo, and B. Huang, J. Appl. Phys. 113, 023516 (2013).

G. Yi, H. Li, C.Y. Zang, W.L. Xiao, and C.L. Ma, Mater. Sci. Eng. A 855, 143903 (2022).

X.J. Zhang, W.J. Yu, J. Wang, P. Wang, Z.H. Liu, M. He, and Z.R. Yang, Vacuum 207, 111635 (2023).

Y.Y. Gao, F. Qiu, Q. Zou, J.G. Chu, B.X. Dong, X. Han, H.Y. Yang, B. Jiang, and Q.C. Jiang, Ceram. Int. 47(20), 28584 (2021).

M.S. Song, M.X. Zhang, S.G. Zhang, B. Huang, and J.G. Li, Mater. Sci. Eng. A. 473, 166 (2008).

H.X. Jiang, Q. Sun, L.L. Zhang, and J.Z. Zhao, J. Alloys Compd. 748, 774 (2018).

W.Q. Lu, S.G. Zhang, Q.D. Hu, and J.G. Li, Mater. Lett. 182, 351 (2016).

E.E. Michaelides, Int. J. Heat Mass Transf. 81, 179 (2015).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 51575151 and 51775158) and Natural Science Foundation of Anhui Province (No. 1908085QE195)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

On behalf of all authors, the corresponding author states that there is no conflict of interest. All authors of this paper claim that the paper is original and have not been copyrighted or published previously.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, C., Yin, Y., Xu, M. et al. In Situ Preparation of TiCx Particles with Different Sizes and Self-Assembly Behavior Analysis of TiCx/Al-Bi Alloy. JOM 75, 2828–2840 (2023). https://doi.org/10.1007/s11837-023-05836-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05836-0