Abstract

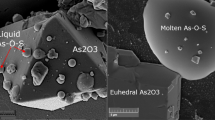

The phase transformation mechanism of antimony sulfide in the oxygen-enriched smelting system was investigated. The standard Gibbs free energy change (ΔGθ) of reactions in the smelting system at 100 ~ 1400°C were calculated, indicating that the reaction between Sb2S3 and oxygen was liable to occur first, and that the high-valent antimony oxide decomposed at high temperatures. The thermodynamic analysis of the Sb-S–O system at different temperatures indicated that the phase transformation of antimony was feasible, and that the increase in temperature was beneficial to the existence of Sb2O3. Equilibrium calculation of Sb2S3 and oxygen showed that the antimony mainly volatilized into the gas phase, and that a small amount of antimony formed non-volatile antimony oxides. Thermogravimetric analysis of antimony oxide verified the accuracy of the thermodynamic analysis. A conceptual oxidation model in the oxygen-enriched smelting process is proposed, combined with the thermodynamic analysis, equilibrium calculation, and thermogravimetry–differential scanning calorimetry (TG-DSC) analysis of the oxygen-enriched smelting system.

Similar content being viewed by others

References

C.G. Anderson, Chem. Erde-Geochem. 72, 3 (2012).

T. Liu and K. Qiu, J. Hazard. Mater. 347, 334 (2018).

B. Ren, Y. Zhou, H. Ma, and R. Deng, P, Zhang, B, Hou. J. Mater. Cycles Waste Manage. 20, 193 (2018).

L. Ye, Z. Ouyang, Y. Chen, Y. Chen, and L. Xiao, Miner. Eng. 144, 106049 (2019).

X. Guo, M. Tian, S. Wang, S. Yan, Q. Wang, Z. Yuan, Q. Tian, D. Tang, and Z. Li, JOM. 71, 3941 (2019).

W. Gao, C. Wang, F. Yin, Y. Chen, and W. Yang, Adv. Mater. Res. 2044, 904 (2012).

H. Luo, W. Liu, W. Qin, Y. Zheng, and K. Yang, Rare Met. 38, 800 (2019).

W. Liu, H. Luo, W. Qing, Y. Zheng, K. Yang, and J. Han, Metall. Mater. Trans. B. 45, 1281 (2014).

M. Chen and X. Dai, JOM. 70, 41 (2018).

T. Lager and K.S.E. Forssberg, Miner. Eng. 2, 543 (1989).

D. Orosela, P. Baloga, H. Liu, J. Qian, and M. Jansena, J. Solid State Chem. 178, 2602 (2005).

Z. Zhang and X. Dai, Trans. Nonferrous Met. Soc. China. 30, 501 (2020).

K. ZHOU, Cent South Univ. 2014. (in Chinese)

Z. Zhang, X. Dai, and W. Zhang, JOM. 69, 2671 (2017).

J. Zhang, X. Yang, W. Deng, Y. Chen, and C. Wang, Non. Metall. (Extra Metall). 3, 1. (in Chinese) (2019).

Y. Hua, Y. Yang, and F. Zhu, J. Mater. Sci. Technol. 19, 619 (2003).

W. Qin, H. Luo, W. Liu, Y. Zheng, K. Yang, J. Han, and J. Cent, South Univ. 22, 868 (2015).

R. Padilla, A. Aracena, M.C. Ruiz, J. Min. Metall., Sect. B 50, 127 (2014).

R. Padilla, R. Gustavo, and C.R. Maria, Metall. Mater. Trans. B. 41B, 1284 (2010).

C.A. Cody, L. DiCarlo, and R.K. Darlington, Inorg. Chem. 18, 1572 (1979).

A. Aracena, O. Jerez, and C. Antonucci, Trans. Nonferrous Met. Soc. China. 26, 294 (2016).

P. Zhao, C. Liu, S. Chandrasekar, L. Zhang, F. Wang, and J. Gao, Powder Technol. 379, 630 (2021).

Acknowledgements

The authors acknowledge financial support from the National Natural Science Foundation of China (No. U20A20273 and No. 51904351), National Key R&D Program of China (No. 2019YFC1907401), Natural Science Foundation for Distinguished Young Scholar of Hunan Province (No. 2022JJ10078), Science and Technology Innovation Program of Hunan Province (No. 2021RC3005), Innovation Driven Projects of Central South University (No. 2020CX028).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, M., Wang, Q., Wang, S. et al. Analysis of Antimony Sulfide Oxidation Mechanism in Oxygen-Enriched Smelting Furnace. JOM 75, 506–514 (2023). https://doi.org/10.1007/s11837-022-05609-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05609-1