Abstract

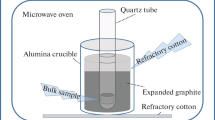

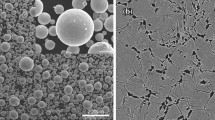

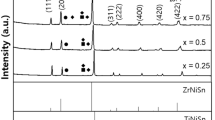

In this study, effects of different pressing processes on the microstructure and thermoelectric properties of TiNiSn1-xTex Half-Heusler alloy prepared by microwave method were investigated. TiNiSn1-xTex Half-Heusler alloys prepared by microwave synthesis-warm pressing-microwave sintering process had relatively higher density than those of samples prepared by microwave synthesis-cold pressing-microwave sintering (MCM) process. The XRD results showed that the diffraction peaks of TiNiSn1-xTex samples slightly shifted to the large angle direction because of the Te substitution on the Sn sites, and the intensity of impurity peak decreased after microwave sintering. Although the density of TiNiSn1-xTex samples prepared by MCM process was lower, the thermoelectric performance of TiNiSn0.99Te0.01 sample was significantly improved, which resulted from the decrease of resistivity and thermal conductivity due to the Te-doping. The thermal conductivity of TiNiSn0.99Te0.01 was within 1.21–1.61 \({\text{W}}{\text{m}}^{-1}{\text{K}}^{-1}\) over the whole temperature range, and its thermoelectric figure of merit ZT was the best.

Similar content being viewed by others

References

G.J. Snyder and E.S. Toberer, Nat Mater. 7, 105. (2008).

Y. Lei, Y. Li, L. Xu, J. Yang, R. Wan, and H. Long, J. Alloys Compd. 660, 166. (2016).

H. Goldsmid, Thermoelectric refrigeration (Springer, Boston, 2013), p 10.

P. Maji, N.J. Takas, D.K. Misra, H. Gabrisch, K. Stokes, and P.F. Poudeu, J. Solid State Chem. 183, 1120. (2010).

S. Chen and Z. Ren, Mater. Today. 16, 387. (2013).

S.B. Riffat and X. Ma, Appl. Therm. Eng. 23, 913. (2003).

C. Uher, J. Yang, S. Hu, D. Morelli, and G. Meisner, Phys. Rev. B. 59, 8615. (1999).

J. He and T.M. Tritt, Science. 357, eaak9997. (2017).

Y. Sun, W. Qiu, L. Zhao, H. He, L. Yang, L. Chen, H. Deng, X. Shi, and J. Tang, Chem. Phys. Lett. 755, 137770. (2020).

R.A. Downie, D.A. MacLaren, R.I. Smith, and J.W. Bos, Chem Commun (Camb). 49, 4184. (2013).

E. Lkhagvasuren, S. Ouardi, G.H. Fecher, G. Auffermann, G. Kreiner, W. Schnelle, and C. Felser, AIP Adv. 7, 045010. (2017).

H. Ma, C.L. Yang, M.S. Wang, X.G. Ma, and Y.G. Yi, J. Phys. D: Appl. Phys. 52, 255501. (2019).

F. Aliev, N. Brandt, V. Moshchalkov, V. Kozyrkov, R. Skolozdra, and A. Belogorokhov, Z. Physik B Condens. Matter. 75, 167. (1989).

F. Aliev, V. Kozyrkov, V. Moshchalkov, R. Scolozdra, and K. Durczewski, Z. Physik B Condens. Matter. 80, 353. (1990).

K. Kurosaki, T. Maekawa, H. Muta, and S. Yamanaka, J. Alloys Compd. 397, 296. (2005).

T. Berry, C. Fu, G. Auffermann, G.H. Fecher, W. Schnelle, F. Serrano-Sanchez, Y. Yue, H. Liang, and C. Felser, Chem. Mater. 29, 7042. (2017).

R. Downie, D. MacLaren, and J.W. Bos, J. Mater. Chem. A. 2, 6107. (2014).

A. Karati, M. Nagini, S. Ghosh, R. Shabadi, K. Pradeep, R.C. Mallik, B. Murty, and U. Varadaraju, Sci. Rep. 9, 1. (2019).

S.W. Kim, Y. Kimura, and Y. Mishima, Intermetallics 15, 349. (2007).

J.P. Makongo, D.K. Misra, X. Zhou, A. Pant, M.R. Shabetai, X. Su, C. Uher, K.L. Stokes, and P.F. Poudeu, J. Am. Chem. Soc. 133, 18843. (2011).

Y. Gelbstein, N. Tal, A. Yarmek, Y. Rosenberg, M.P. Dariel, S. Ouardi, B. Balke, C. Felser, and M. Köhne, J. Mater. Res. 26, 1919. (2011).

B. Balke, J. Barth, M. Schwall, G.H. Fecher, and C. Felser, J. Electron. Mater. 40, 702. (2011).

H. Xie, H. Wang, C. Fu, Y. Liu, G.J. Snyder, X. Zhao, and T. Zhu, Sci. Rep. 4, 1. (2014).

A. Karati, S. Mukherjee, R.C. Mallik, R. Shabadi, B. Murty, and U. Varadaraju, Materialia. 7, 100410. (2019).

A. Karati and B. Murty, Mater. Lett. 205, 114. (2017).

D. Baghurst, A. Chippindale, and D.M.P. Mingos, Nature 332, 311. (1988).

W.L.E. Wong, S. Karthik, and M. Gupta, Mater. Sci. Technol. 21, 1063. (2005).

J.W. Lekse, T.J. Stagger, and J.A. Aitken, Chem. Mater. 19, 3601. (2007).

K. Biswas, S. Muir, and M.A. Subramanian, Mater. Res. Bull. 46, 2288. (2011).

C.S. Birkel, W.G. Zeier, J.E. Douglas, B.R. Lettiere, C.E. Mills, G. Seward, A. Birkel, M.L. Snedaker, Y. Zhang, and G.J. Snyder, Chem. Mater. 24, 2558. (2012).

J.E. Douglas, C.S. Birkel, M.S. Miao, C.J. Torbet, G.D. Stucky, T.M. Pollock, and R. Seshadri, Appl. Phys. Lett. 101, 183902. (2012).

K. Chen, C. Nuttall, E. Stefanaki, K. Placha, R. Tuley, K. Simpson, J.W.G. Bos, and M.J. Reece, Scr. Mater. 191, 71. (2021).

Y. Lei, C. Cheng, Y. Li, R. Wan, and M. Wang, Ceram. Int. 43, 9343. (2017).

Z. Dong, J. Luo, C. Wang, Y. Jiang, S. Tan, Y. Zhang, Y. Grin, Z. Yu, K. Guo, and J. Zhang, Nat. Commun. 13, 1. (2022).

F. Aversano, M. Palumbo, A. Ferrario, S. Boldrini, C. Fanciulli, M. Baricco, and A. Castellero, Intermetallics 127, 106988. (2020).

X. Yang, D. Liu, J. Li, R. Min, H. Kang, L. Li, Z. Chen, E. Guo, and T. Wang, J. Mater. Sci. Technol. 87, 39. (2021).

D.Y. Jung, K. Kurosaki, C.E. Kim, H. Muta, and S. Yamanaka, J. Alloys Compd. 489, 328. (2010).

J.N. Kahiu, S.K. Kihoi, and H.S. Lee, J. Mater. Chem. C. 9, 12374. (2021).

K. Gałązka, W. Xie, S. Populoh, M.H. Aguirre, S. Yoon, G. Büttner, and A. Weidenkaff, Rare Met. 39, 659. (2020).

J.L. Chen, H. Yang, C. Liu, J. Liang, L. Miao, Z. Zhang, P. Liu, K. Yoshida, C. Chen, Q. Zhang, and A.C.S. Appl, Mater. Interfaces. 13, 48801. (2021).

N. Jia, J. Cao, X.Y. Tan, J. Dong, H. Liu, C.K.I. Tan, J. Xu, Q. Yan, X.J. Loh, and A. Suwardi, Mater. Today Phys. 21, 100519. (2021).

R.F. Wang, S. Li, W.H. Xue, C. Chen, Y.M. Wang, X.J. Liu, and Q. Zhang, Rare Met. 40, 40. (2021).

J.M. Mena and T. Gruhn, J. Mater. Chem. A. 9, 21111. (2021).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 51772132); Shandong Province Higher Educational Youth Innovative Science and Technology Program (Grant No. 2019KJA018); the leader of scientific research studio program of Jinan (Grant No. 2021GXRC082); and Natural Science Foundation of Shandong Province (Grant No. ZR2019MEM019). The authors would like to thank Yanzhong Pei Group at Tongji University for the partial measurement of TE properties.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, L., Zhang, R., Bo, L. et al. Effects of Different Pressing Process on the Microstructure and Thermoelectric Properties of TiNiSn1-xTex Half-Heusler Alloy Prepared by Microwave Method. JOM 74, 4250–4257 (2022). https://doi.org/10.1007/s11837-022-05464-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05464-0