Abstract

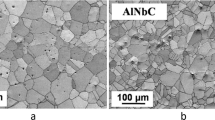

The initial corrosion behaviors of Fe20Cr25NiNb austenitic stainless steel are investigated at 1000°C in helium environment with different relative humidity values. Results show that thin chromia film and small nodules are formed for all oxidation conditions, and some white-colored large nodules are developed for the conditions with ≥ 20% relative humidity. The number and size of these large nodules increase slightly with the increase of relative humidity. These small nodules are primarily composed of the pre-formed chromia film and new-generated chromia phases, and their formation is strongly related to the oxidation of intergranular Fe2Nb phases. The white-colored large nodules mainly consist of three oxide layers: outer magnetite layer, inner spinel layer and (Cr, O)-rich healing layer. An accelerated oxidation is observed after the transition point for the conditions with ≥ 20% relative humidity, which is attributed to the formation of large nodules. The oxide growth primarily follows the linear law before the transition point and obeys the parabolic law after the transition point for higher relative humidity.

Similar content being viewed by others

References

P.C. Rowlands, J.C.P. Garrett, L.A. Popple, A. Whittaker, and A. Hoaskey, Nucl. Energy 25, 267 (1986).

A. Shin, M. Chevalier, E. Laney, and J. Pearson, Mater. High Temp. 35, 30 (2018).

A. Rudge, Mater. High Temp. 22, 11 (2005).

R.N. Clark, Mapping of corrosion sites in advanced gas-cooled reactor fuel cladding in long term pond storage. Dissertation, Swansea University, (2018).

C. Degueldre, R.J. Wilbraham, J. Fahy, and S.M. Green, J. Nucl. Mater. 543, 152633 (2021).

C. Cabet and B. Duprey, Nucl. Eng. Des. 251, 139 (2012).

R.N. Clark, J. Searle, T.L. Martin, W.S. Walters, and G. Williams, Corros. Sci. 165, 108365 (2020).

IAEA, Review of Fuel Failures in Water Cooled Reactors, (IAEA Nuclear Energy Series No. NF-T-2.1, Vienna, 2010), pp. 1–2.

R.B. Rebak, W.P. Gassmann and K.A. Terrani, Managing nuclear power plant safety with FeCrAl alloy fuel cladding. Paper presented at Top Safe 2017, IAEA Safety in Reactor Operation, Vienna, Austria, 12–16 February (2017).

D.R. Olander, Fundamental Aspects of Nuclear Reactor Fuel Elements (Technical Information Center, Springfield, Virginia, 1976), pp 373–462.

E. Nonbol, Description of the Advanced Gas Cooled Type of Reactor (AGR), (Risø National Laboratory, Roskilde, Denmark, NKS/RAK-2(96)TR-C2, 1996), pp. 10–12.

D. Hambley, Technical basis for extending storage of the UK’s advanced gas-cooled reactor fuel. Paper presented at Proceedings of GLOBAL 2013: International Nuclear Fuel Cycle Conference, Salt Lake City, UT, 29 Sep–3 Oct 2013.

H. Chen, H. Wang, Q. Sun, C. Long, T. Wei, S.H. Kim, and C. Jang, Corros. Sci. 145, 90 (2018).

J.W. Tyler, Oxid. Met. 24, 149 (1985).

P.K. Madden and V.M. Callen, J. Nucl. Mater. 113, 46 (1983).

C. Degueldre, J. Fahy, O. Kolosov, R.J. Wilbraham, M. Döbeli, N. Renevier, and S. Ritter, J. Mater. Eng. Perform. 27, 2081 (2018).

C. Barcellini, Microstructural Evolution of AGR Steel Cladding During Processing and Proton Irradiation. Dissertation, University of Manchester, (2019).

G.C. Allen, P.A. Tempest, J.W. Tyler, and R.K. Wild, Oxid. Met. 21, 187 (1984).

W.M. Pragnell and H.E. Evans, Oxid. Met. 66, 209 (2006).

R.C. Lobb and H.E. Evans, Corros. Sci. 24, 385 (1984).

H.E. Evans, Mater. Sci. Tech. 4, 414 (1988).

R.W. Swindeman, Development of a modified 310 stainless steel. Fossil Energy Program Annual Progress Report for April 1996 Through March 1997, Oak Ridge National Laboratory Report ORNL-6924, (1997).

C.S. Tedmon, D.A. Vermilyea, and J.H. Rosolowski, J. Electrochem. Soc. 118, 192 (1971).

B. Shassere, Y. Yamamoto, J. Poplawsky, W. Guo, and S.S. Babu, Metall. Mater. Trans. A 48, 4598 (2017).

N. Takata, H. Ghassemi-Armaki, M. Takeyama, and S. Kumar, Intermetallics 70, 7 (2016).

H. Chen, S.H. Kim, and C. Jang, J. Mater. Sci. 55, 3652 (2020).

H. Sakai, T. Tsuji, and K. Naito, J. Nucl. Sci. Tech. 21, 844 (1984).

D.J. Young, High Temperature Oxidation and Corrosion of Metals (Elsevier, Oxford, 2008), pp 315–356.

H. Yin, W.Y.D. Yuen, and D.J. Young, Mater. Corros. 63, 869 (2012).

T.P. Li, High Temperature Oxidation and Hot Corrosion of Metals (Chemical Industry Press, Beijing, 2003), pp 29–62.

C. Nico, T. Monteiro, and M.P.F. Graça, Prog. Mater. Sci. 80, 1 (2016).

T. Wei, J. Lin, C. Long, and H. Chen, Acta Metall. Sin. 52, 209 (2015).

H. Chen, S.H. Kim, C. Kim, J. Chen, and C. Jang, Corros. Sci. 156, 16 (2019).

A.S. Khanna, High Temperature Corrosion (World Scientific, Singapore, 2016), pp 1–32.

K. Zhao, S. Ouyang, Y. Liu, B. Liu, X. Liang, and Y. Wang, Trans. Nonferrous Met. Soc. China 29, 526 (2019).

J. Yuan, W. Wang, H. Zhang, L. Zhu, S. Zhu, and F. Wang, Corros. Sci. 109, 36 (2016).

S.R.J. Saunders, M. Monteiro, and F. Rizzo, Prog. Mater. Sci. 53, 775 (2008).

F.W. Murray, J. Appl. Meteorol. 6, 203 (1967).

M. Michalik, M. Hänsel, J. Zurek, L. Singheiser, and W.J. Quadakkers, Mater. High Temp. 22, 213 (2005).

Acknowledgements

The authors are grateful for the financial support of Guangdong Basic and Applied Basic Research Foundation (2021A1515012411) and Sichuan Science and Technology Program (2018JY0155, 2019YJ0685).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, H., Wang, H., Sun, Q. et al. Initial Corrosion Behaviors of Fe20Cr25NiNb Stainless Steel in High Temperature Environment with Different Relative Humidity Values. JOM 74, 3921–3934 (2022). https://doi.org/10.1007/s11837-022-05425-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05425-7