Abstract

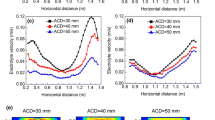

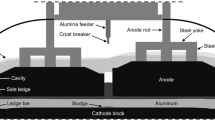

The quantitative description and theoretical research on the stability of the electromagnetic field interfacial wave in aluminum electrolysis cells are the key to achieving high energy efficiency and operational safety. The magneto-hydrodynamics equations were established based on the theory of electromagnetics and hydrodynamics and applied to a 500-kA cell. The Fourier series expansion and finite element methods were used for modeling and simulation of interfacial stability. Detailed analysis was conducted on wave mode coupling regimes by custom code in MATLAB. Based on the characteristics of total modulus, a modal analysis method was proposed to clarify how anode–cathode distance (ACD) and length-width ratio of cells affected interfacial stability. The results indicate that the stability is enhanced as the increase of ACD for a 500-kA electrolysis cell and the critical ACD is derived as 0.041 m, which is preferable for stabilizing the cell and reducing energy consumption.

Similar content being viewed by others

References

A. Gupta and B. Basu, Trans. Indian Inst. Met. 72, 2135 (2019).

Y. Yang, Y.Q. Guo, W.S. Zhu, and J.B. Huang, Trans. Nonferrous Met. Soc. China 29, 1784 (2019).

W. Liu, D.F. Zhou, and Z.B. Zhao, JOM 71, 2420 (2019).

B. Bardet, T. Foetisch, S. Renaudier, J. Rappaz, M. Flueck, and M. Picasso, in Light Metals 2016 (TMS, Warrendale, 2016), pp 315–319.

W. Herreman, C. Nore, J.-L. Guermond, L. Cappanera, N. Weber, and G.M. Horstmann, J. Fluid Mech. 122, 598 (2019).

T. Sele, Metall. Trans. B 8, 613 (1977).

N. Urata, K. Mori, and H. Ikeuchi, J. Jpn. Inst. Light Met. 26, 573 (1976).

N. Urata, in Light Metals 1985 (TMS, Warrendale, 1985), pp 581–591.

A.D. Sneyd, J. Fluid Mech. 156, 223 (1985).

P.A. Davidson, and R.I. Lindsay, in Light Metals 1997 (TMS, Warrendale, 1997), pp 437–442.

O. Zikanov, A. Thess, P.A. Davidson, and D.P. Ziegler, Metall. Mater. Trans. B 31, 1541 (2000).

T. Weyens, J.M. Reynolds-Barredo, and A. Loarte, Comput. Phys. Commun. 242, 60 (2019).

J.L. Ding, J. Li, H.L. Zhang, Y.J. Xu, S. Yang, and Y.X. Liu, Cent. South Univ. 21, 4097 (2014).

M. Dupuis and M. Page, in Light Metals 2016 (TMS, Warrendale, 2016), pp 909–914.

M. Dupuis and M. Page, in Light Metals 2016 (TMS, Warrendale, 2016), pp 58–62.

V. Bojarevics and M. Romerio, Eur. J. Mech. B 13, 33 (1994).

V. Bojarevics and S. Sira, in Light Metals 2014 (TMS, Warrendale, 2014), pp 685–690.

V. Bojarevics and K. Pericleous, in Light Metals 2006 (TMS, Warrendale, 2006), pp 347–352.

V. Bojarevics, in Light Metals 2013 (TMS, TMS, Warrendale, 2013), pp 609–614.

V. Bojarevics and A. Tucs, in Light Metals 2017 (TMS, Warrendale, 2013), pp 677–686.

V. Bojarevics and M. Dupuis, in Light Metals 2021 (TMS, Warrendale, 2021), pp 565–571.

M. Dupuis and V. Bojarevics, in Light Metals 2020 (TMS, Warrendale, 2020), pp 495–509.

H.J. Sun, O. Zikanov, and D.P. Ziegler, Fluid Dyn. Res. 35, 255 (2004).

M. Kadkhodabeigi and Y. Saboohi, in Light Metals 2007 (TMS, Warrendale, 2007), pp 345–351.

S. Molokov, G. El, and A. Lukyanov, Theor. Comput. Fluid Dyn. 122, 6 (2019).

S. Molokov, Europhys. Lett. 121, 44001 (2018).

A. Pedcenko, S. Molokov, and B. Bardet, Metall. Mater. Trans. B 48, 6 (2017).

S.Y. Ruan, F.Y. Van, M. Dupuis, V. Bojarevics, and J.F. Zhou, in Light Metals 2013 (TMS, Warrendale, 2013), pp 603–607.

Y. Yang, S.H. Yao, and X.B. Yi, in Light Metals 2014 (TMS, Warrendale, 2014), pp 703–708.

B.K. Li, F. Wang, X.B. Zhang, F.S. Qi, and N.X. Feng, in AIP Conference Proceedings ( American Institute of Physics, Melville, 2012), pp 865–868.

Q. Wang, B.K. Li, F. Wang, and N.X. Feng, in Light Metals 2013 (TMS, Warrendale, 2013), pp 615–619.

Y.F. Tian, Nonferrous Met. 25, 23 (2009).

Y.F. Tian, Light Met. 2, 31 (2011).

Y.J. Xu, J. Li, H.L. Zhang, and Y.Q. Lai, Chin. J. Nonferrous Met. 21, 191 (2011).

H.L. Zhang, J. Li, Z.G. Wang, Y.J. Xu, and Y.Q. Lai, JOM 62, 26 (2010).

X.J. Lu, H.X. Zhang, Z.X. Han, K.J. Wang, C.H. Guan, Q.D. Sun, W.W. Wang, and M.R. Wei, Trans. Nonferrous Met. Soc. China 30, 1124 (2020).

J.S. Hua, M. Rudshaug, C. Droste, and R. Jorgensen, Metall. Mater. Trans. B 49, 1246 (2018).

A. Tucs, V. Bojarevics, and K. Pericleous, J. Fluid Mech. 852, 453 (2018).

A. Tucs, V. Bojarevics, and K. Pericleous, Europhys. Lett. 124, 24001 (2018).

N. Weber, P. Beckstein, W. Herreman, G.M. Horstmann, C. Nore, F. Stefani, and T. Weier, Phys. Fluids 29, 54101 (2017).

G.M. Horstmann, N. Weber, and T. Weier, J. Fluid Mech. 845, 1 (2018).

O. Zikanov, Theor. Comput. Fluid Dyn. 32, 325 (2018).

M. Segatz and C. Droste, in EMC 2001: European Metallurgical Conference (GDMB, Clausthal-Zellerfeld, 2001), pp. 117–128.

N. Urata, in Light Metals 2005 (TMS, Warrendale, 2005), pp 455–460.

H.S. Li, W.Y. Hou, and Q.H. Li (Central South University, Changsha, 2019).

Acknowledgements

This research was funded by the High Technology Research and Development Program of China (2010AA065201), the Fundamental Research Funds for the Central Universities of Central South University (2018zzts157, 2021zzts0668). The authors also thank the anonymous referees for valuable comments and useful suggestions that helped us to improve the quality of present and future work.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, M., Ma, S., Li, H. et al. Mode Coupling Analysis of Interfacial Stability and Critical Anode–Cathode Distance in a 500-kA Aluminum Electrolysis Cell. JOM 73, 2741–2751 (2021). https://doi.org/10.1007/s11837-021-04799-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04799-4