Abstract

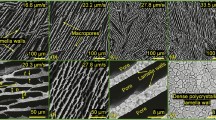

Polymer-ceramic composites are widely used in biomedical applications. This paper presents the results of an experimental investigation on the crack extension inside epoxy-alumina. Specimens with 5 vol.%, 10 vol.%, …, 25 vol.% fillers fractions were fabricated. Three-point bending on single-edge notched bend specimens were performed using conventional mechanical tester and in situ mechanical tester coupled with micro-CT, respectively. Fracture toughness was measured to be 2.10–2.51 \({\text{MPa}}\sqrt {\text{m}} \), and it decreased with increasing filler fraction. When cracks were shorter than 0.88 mm, crack resistance for 5 and 25 vol.% epoxy-alumina was similar. Beyond 0.88 mm, 25 vol.% epoxy-alumina exhibited no crack resistance, whereas stress intensity factor kept increasing in 5 vol.% epoxy-alumina. The matrix-particle interfaces were the weakest link, where cracks often initiated from. Crack bridging by uncracked ligament and crack deflection were commonly observed toughening mechanisms. To design robust epoxy-alumina composites, increasing matrix-particle interface strength is recommended for future work.

Similar content being viewed by others

References

D. Mohamad Yunos, O. Bretcanu, and A.R. Boccaccini, J. Mater. Sci. 43, 4433. (2008).

H. Qiu, J. Yang, P. Kodali, J. Koh, and G.A. Ameer, Biomaterials 27, 5845. (2006).

V. Mouriño, J.P. Cattalini, J.A. Roether, P. Dubey, I. Roy, and A.R. Boccaccini, Expert Opin. Drug Deliv. 10, 1353. (2013).

J. Du, X. Niu, N. Rahbar, and W. Soboyejo, Acta Biomater. 9, 5273. (2013).

J. Du, X. Niu, and W. Soboyejo, J. Mech. Behav. Biomed. Mater. 46, 41. (2015).

J.J. Kruzic, R.K. Nalla, J.H. Kinney, and R.O. Ritchie, Biomaterials 24, 5209. (2003).

R.K. Nalla, J.J. Kruzic, J.H. Kinney, and R.O. Ritchie, Biomaterials 26, 217. (2005).

P.J. Schilling, B.R. Karedla, A.K. Tatiparthi, M.A. Verges, and P.D. Herrington, Compos. Sci. Technol. 65, 2071. (2005).

A.J. Moffat, P. Wright, J.Y. Buffière, I. Sinclair, and S.M. Spearing, Scr. Mater. 59, 1043. (2008).

B. Croom, W.M. Wang, J. Li, and X. Li, Exp. Mech. 56, 999. (2016).

Y. Zhou, C. Gong, G.S. Lewis, A.D. Armstrong, and J. Du, Extrem. Mech. Lett. 35, 100614. (2020).

Y. Zhou, C. Gong, M. Hossaini-Zadeh, and J. Du, J. Mech. Behav. Biomed. Mater. 110, 103858. (2020).

D.K. Shukla, and V. Parameswaran, J. Mater. Sci. 42, 5964. (2007).

ASTM E399, Standard Test Method for Linear-Elastic Plane-Strain Fracture Toughness K1C of Metallic Material (2013).

J.E. Srawley, Int. J. Fract. 12, 475. (1976).

L.M. McGrath, R.S. Parnas, S.H. King, J.L. Schroeder, D.A. Fischer, and J.L. Lenhart, Polymer (Guildf). 49, 999. (2008).

S. Zhao, L. Schadler, R. Duncan, H. Hillborg, and T. Auletta, Compos. Sci. Technol. 68, 2965. (2008).

D. Shukla, S. Kasisomayajula, and V. Parameswaran, Compos. Sci. Technol. 68, 3055. (2008).

P.R. Marur, R.C. Batra, G. Garcia, and A.C. Loos, J. Mater. Sci. 39, 1437. (2004).

A. Omrani, L.C. Simon, and A.A. Rostami, Mater. Chem. Phys. 114, 145. (2009).

O. Jin, Y. Li, and W.O. Soboyejo, Appl. Compos. Mater. 5, 25. (1998).

B. Wetzel, P. Rosso, F. Haupert, and K. Friedrich, Eng. Fract. Mech. 73, 2375. (2006).

J. Douce, J.P. Boilot, J. Biteau, L. Scodellaro, and A. Jimenez, Thin Solid Films 466, 114. (2004).

M.C. Kuo, C.M. Tsai, J.C. Huang, and M. Chen, Mater. Chem. Phys. 90, 185. (2005).

L. Jiang, J. Zhang, and M.P. Wolcott, Polymer (Guildf). 48, 7632. (2007).

Y. Chen, S. Zhou, H. Yang, and L. Wu, J. Appl. Polym. Sci. 95, 1032. (2005).

Acknowledgements

This research is supported by the National Science Foundation (#1826221). The authors are grateful to the program manager, Dr. Siddiq Qidwai, for his encouragement and support. Appreciation is extended to Dr. Timothy Stecko of Penn State Center for Quantitative Imaging for technical assistance with micro-CT scanning.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tang, Y., Su, K., Man, R. et al. Investigation of Internal Cracks in Epoxy-Alumina Using In Situ Mechanical Testing Coupled with Micro-CT. JOM 73, 2452–2459 (2021). https://doi.org/10.1007/s11837-021-04714-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04714-x