Abstract

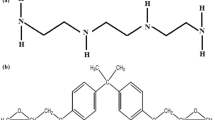

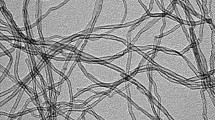

Alumina nanoparticles of two shapes (spherical and rod) were dispersed in epoxy resin by sonication technique to synthesize functionally graded polymer nanocomposites (FGPNC). Weight percentage (wt%) of nanoparticles was varied in the thickness direction to achieve the gradation in samples. In a vertical acrylic mould, nanocomposite layers containing 0, 0.25, 0.5, 0.75 and 1 wt% of nanoparticles were sequentially cast to prepare the samples of FGPNC. Transmission electron micrographs and in situ EDX mapping showed the uniform dispersion of alumina nanoparticles. Fracture toughness of FGPNC samples was evaluated for three different orientations of crack by three-point bending method. In two cases, the crack was created along the thickness direction, while the load was applied from either nanocomposite side or epoxy side. Crack was introduced in the perpendicular direction to gradation in the third case. In the case of nanocomposite side loading, FGPNC (spherical) and FGPNC (nanorods) had 38% and 25% higher fracture toughness, respectively, compared to that of neat epoxy (layered). 25% and 8% of improvement in fracture toughness were observed for FGPNC having nanorods and spherical particles, respectively, for the sample with the crack in the perpendicular direction to the direction of gradation.

Similar content being viewed by others

References

Deng S, Ye L, Friedrich K (2007) Fracture behaviours of epoxy nanocomposites with nano-silica at low and elevated temperatures. J Mater Sci 42:2766–2774. https://doi.org/10.1007/s10853-006-1420-x

Baskaran R, Sarojadevi M, Vijayakumar CT (2011) Unsaturated polyester nanocomposites filled with nano alumina. J Mater Sci 46:4864–4871. https://doi.org/10.1007/s10853-011-5398-7

Zhang H, Zhang Z, Friedrich K, Eger C (2006) Property improvements of in situ epoxy nanocomposites with reduced interparticle distance at high nanosilica content. Acta Mater 54:1833–1842. https://doi.org/10.1016/j.actamat.2005.12.009

Naous W, Yu XY, Zhang QX, Naito K, Kagawa Y (2006) Morphology, tensile properties, and fracture toughness of epoxy/Al2O3 nanocomposites. J PolymSci B Polym Phys 44:1466–1473. https://doi.org/10.1002/polb.20800

Shukla DK, Parameswaran V (2007) Epoxy composites with 200 nm thick alumina platelets as reinforcements. J Mater Sci 42:5964–5972. https://doi.org/10.1007/s10853-006-1110-8

Hiremath V, Shukla DK (2016) Effect of particle morphology on viscoelastic and flexural properties of epoxy-alumina polymer nanocomposites. Plast Rubber Compos 45:199–206. https://doi.org/10.1080/14658011.2016.1159778

Hirano T, Yamada T, Teraki J, Niino M, Kumakawa A (1988) A study on a functionally graded material design system for a thrust chamber. In: Proceedings 16th international symposium on space technology and science, Tokyo, Japan, pp 375–380.

Butcher RJ, Rousseau CE, Tippur HV (1999) A functionally graded particulate composite: preparation, measurement and failure analysis. Acta Mater 47(1):259–268. https://doi.org/10.1016/S1359-6454(98)00305-X

Kommana R, Parameswaran V (2009) Experimental and numerical investigation of a cracked transversely graded plate subjected to in plane bending. Int J Solids Struct 46:2420–2428. https://doi.org/10.1016/j.ijsolstr.2009.01.026

Kurd SH, Hassanifard S, Hartmann S (2017) Fracture toughness of epoxy-based stepped functionally graded materials reinforced with carbon nanotubes. Iran Polym J 26:253–260. https://doi.org/10.1007/s13726-017-0512-6

Mishra SK, Shukla DK, Patel RK (2019) Effect of particle morphology on flexural properties of functionally graded epoxy-alumina polymer nanocomposite. Mater Res Exp 6:1250i9. https://doi.org/10.1088/2053-1591/ab70e2

Chung H, Das S (2008) Functionally graded nylon-11/silica nanocomposites produced by selective laser sintering. Mater Sci Eng A 487:251–257. https://doi.org/10.1016/j.msea.2007.10.082

Lee NJ, Jang J, Park M, Choe CR (1997) Characterization of functionally gradient epoxy/carbon fibre composite prepared under centrifugal force. J Mater Sci 32:2013–2020. https://doi.org/10.1023/A:1018502201000

Tsotra P, Friedrich K (2003) Electrical and mechanical properties of functionally graded epoxy-resin/carbon fibre composites. Compos Part A Appl Sci Manuf 34:75–82. https://doi.org/10.1016/S1359-835X(02)00181-1

Bafekrpour E, Yang C, Fox B (2013) Bending behaviour of step-wise graded carbon nanofiber/polymer nanocomposites. Int J AdvEngAppl 6:47–52

Wen B, Wu G, Yu J (2004) A flat polymeric gradient material: preparation, structure and property. Polymer 45:3359–3365. https://doi.org/10.1016/j.polymer.2004.03.023

Doddamani M, Kishore SVC, Gupta N, Vijayakumar HB (2015) Compressive and flexural properties of functionally graded cenosphere-epoxy resin synthetic foams. Polym Compos 36:685–693. https://doi.org/10.1002/pc.22987

Jin X, Wu L, Guo L, Hongjun Y, Yuguo S (2009) Experimental investigation of the mixed-mode crack propagation in ZrO2/NiCr functionally graded materials. Eng Fract Mech 76:1800–1810. https://doi.org/10.1016/j.engfracmech.2009.04.003

Koohbor B, Mallon S, Kidane A, Anand A, Parameswaran V (2015) Through thickness elastic profile determination of functionally graded materials. ExpMech 55:1427–1440. https://doi.org/10.1007/s11340-015-0043-z

ASTM D5045-99. Standard Test Methods forPlane-Strain Fracture Toughness and Strain Energy ReleaseRate of Plastic Materials. ASTM International, West Conshohocken, PA, United States.

Zhang H, Zhang H, Tang L, Liu G, Zhang D, Zhou L, Zhang Z (2010) The effects of alumina nanofillers on mechanical properties of high-performance epoxy resin. J Nanosci Nanotechnol 10:7526–7532. https://doi.org/10.1166/jnn.2010.2791

Lim SH, Zeng KY, He CB (2010) Morphology, tensile and fracture characteristics of epoxy-alumina nanocomposites. Mater Sci Eng A 527:5670–5676. https://doi.org/10.1016/j.msea.2010.05.038

Verma V, Sayyed AHM, Sharma C, Shukla DK (2020) Tensile and fracture properties of epoxy alumina composite: role of particle size and morphology. J Polym Res 27:388. https://doi.org/10.1007/s10965-020-2359-z

Wetzel B, Rosso P, Haupert F, Friedrich K (2006) Epoxy nanocomposites – fracture and toughening mechanisms. Eng Fract Mech 73:2375–2398. https://doi.org/10.1016/j.engfracmech.2006.05.018

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mishra, S.K., Shukla, D.K. & Patel, R.K. Fracture toughness of functionally graded nanocomposite in quasi-static loading. Polym. Bull. 79, 1787–1801 (2022). https://doi.org/10.1007/s00289-021-03594-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-021-03594-0