Abstract

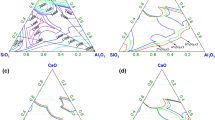

The use of recycled wastes and fluxing agents in hot metal desulfurizing mixtures aims to recover potential abilities from residues and to improve the reaction kinetics. Therefore, this work’s aim is to propose calcitic lime partial replacement by limestone waste and slag from desulfurization in the Kambara Reactor. Likewise, it is proposed that fluorspar (CaF2) is replaced by boron oxide (B2O3), sodalite and aluminum dross. Experimental tests were carried out in a resistance furnace at 1350°C in an inert atmosphere with constant stirring. Simulations were carried out with the FactSage software in order to obtain the phases present in each mixture at the working temperature. The most efficient mixtures formed a liquid phase above 20 wt.%, indicating that the dissolved CaO also desulfurizes hot metal. Limestone waste and the fluxes generated a positive effect on the desulfurization kinetics. It was possible to develop an empirical parameter called the global desulfurization factor (FGDeS).

Similar content being viewed by others

References

H.M. Ahmed, E.A. Mousa, M. Larsson, and N.N. Viswanathan, Ironmaking and Steelmaking Processes - Greenhouse Emissions, Control, and Reduction, ed. P. Cavaliere (Lecce: Springer, 2016), p. 101.

A. Matsui, Y. Uchida, N. Kikuchi, and Y. Miki, ISIJ Int. 57, 1012. (2017).

Y. Nakai, N. Kikuchi, M. Iwasa, S. Nabeshima, and Y. Kishimoto, Steel Res. Int. 80, 727. (2009).

Z. Tong, G. Ma, X. Cai, Z. Xue, W. Wang, and X. Zhang, Waste Biomass Valorization 7, 1. (2016).

M.A. Latif, S. Naganathan, H.A. Razak, and K.N. Mustapha, Procedia Eng. 125, 780. (2015).

V. Seshadri, A.C. Silva, and I.A. Silva, Mater. Manuf. Processes 17, 693. (2002).

T. Vuolio, V.V. Visuri, S. Tuomikoski, T. Paananen, and T. Fabritius, Metall. Mater. Trans B 49, 2692. (2018).

L.B. McFeaters, and R.J. Fruehan, Metall. Mater. Trans. B 24B, 441. (1993).

D. Lindström, and D. Sichen, Metall. Mater. Trans. B 46, 83. (2015).

J.C. Niedringhaus, and R.J. Fruehan, Metall. Mater. Trans. B 19, 261. (1988).

E. Oktay, and R.J. Fruehan, Steel Res. Int. 66, 93. (1995).

T. W. Miller, J. Jimenez, A. Sharan, and D. A. Goldstein, The Making, Shaping and Treating of Steel: Steelmaking and Refining Volume, ed. R. J. Fruehan (Pittsburgh: The AISE Steel Foundation, 1998), p. 475.

F.F. Grillo, R.A. Sampaio, J.F. Viana, D.C.R. Espinosa, and J.R. Oliveira, REM. Rev. Esc. Minas 66, 461. (2013).

T. Mitsuo, T. Shoji, Y. Hatta, H. Ono, H. Mori, and T. Kai, Trans. Jpn. Inst. Met. 23, 768. (1982).

Y. Yang, P. Wu, G. Men, and A. McLean, High Temp. Mater. Proc. 31, 519. (2012).

A.S.B. Moreira, C.A. Silva, and I.A. Silva, REM. Int. Eng. J. 71, 261. (2018).

H. Wang, T. Zhang, H. Zhu, G. Li, Y. Yan, and J. Wang, ISIJ Int. 51, 702. (2011).

K.H. Zhang, Y.L. Zhang, and T. Wu, J. Iron Steel Res. Int. 26, 1041. (2018).

Z. Tong, J. Qiao, and X. Jiang, ISIJ Int. 57, 245. (2017).

Y. Nakai, I. Sumi, H. Matsuno, N. Kikuchi, and Y. Kishimoto, ISIJ Int. 50, 403. (2010).

J.Y. Choi, D.J. Kim, and H.G. Lee, ISIJ Int. 41, 218. (2001).

K. Takahashi, K. Utagawa, H. Shibata, S.Y. Kitamura, N. Kikuchi, and Y. Kishimoto, ISIJ Int. 52, 10. (2012).

F.C. Broseghini, H.C.C. Oliveira, S.G. Soares, F.F. Grillo, and J.R. Oliveira, REM. Int. Eng. J. 71, 217. (2018).

R.O. Pezzin, A.P.L. Berger, F.F. Grillo, E. Junca, H.S. Furtado, and J.R. Oliveira, J. Mater. Res. Technol. 9, 838. (2020).

P.K. Iwamasa, and R.J. Fruehan, Metall. Mater. Trans. B 28, 47. (1997).

Acknowledgements

Thanks to Coordenação de Aperfeiçoamento de Pessoal de nível Superior, Fundação de Amparo à Pesquisa e Inovação do Espírito Santo, Conselho Nacional de Desenvolvimento Científico e Tecnológico, and Programa de Pós-Graduação em Engenharia Metalúrgica e de Materiais for technical and laboratory support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

do Espírito Santo, E.V., Soares, S.G., de Oliveira, H.C.C. et al. Influence of Industrial Wastes and Different Fluxes on Hot Metal Desulfurization Efficiency. JOM 73, 1909–1918 (2021). https://doi.org/10.1007/s11837-021-04673-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04673-3