Abstract

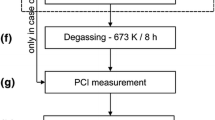

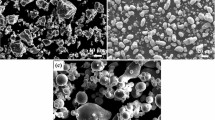

In this work, a novel thermochemical method was introduced to produce fine titanium alloy powders with low oxygen content by utilizing hydrogenated titanium alloy powders mixed with Ca and CaCl2 powders. The stability of Ti-O solid solution decreased when the hydrogen was released in situ during the thermochemical process. Hydrogen could increase the oxygen potentials of Ti-O solid solution alloys, and the average particle size could be mainly preserved at 35.23 μm after the heat treatment. Experimental results reveal that the oxygen content in final products could be remarkably decreased to 0.146 wt.% at low temperature of 680°C compared to the results of 0.67 wt.% when utilizing pre-dehydrogenated powders instead. Moreover, hydrogen can be easily reduced by heat treatment, and the experimental results show the remaining hydrogen concentration is 0.078 wt.%. This work is expected to provide a one-step solution by integrating the dehydrogenation with the deoxygenation process in to produce fine metal powders with low oxygen content.

Similar content being viewed by others

References

W. Chen, Y. Yamamoto, W.H. Peter, S.B. Gorti, A.S. Sabau, M.B. Clark, S.D. Nunn, J.O. Kiggans, C.A. Blue, J.C. Williams, B. Fuller, and K. Akhtar, Powder Technol. 214, 194. (2011).

A.T. Sidambe, I.A. Figueroa, H.G.C. Hamilton, and I. Todd, J. Mater. Process. Technol. 212, 1591. (2012).

S. Yang, J.N. Gwak, T.S. Lim, Y.J. Kim, and J.Y. Yun, Mater. Trans. 54, 2313. (2013).

C.Y. Yap, C.K. Chua, Z.L. Dong, Z.H. Liu, D.Q. Zhang, L.E. Loh, and S.L. Sing, Appl. Phys. Rev. 2, 041101. (2015).

H.H. Nersisyan, B.U. Yoo, Y.M. Kim, H.T. Son, K.Y. Lee, and J.H. Lee, Chem. Eng. J. 304, 232. (2016).

C. Zheng, T. Ouchi, A. Iizuka, Y.K. Taninouchi, and T.H. Okabe, Metall. Mater. Trans. B 50, 622. (2019).

S. Liu, Z. Zhang, S. Xiao, and Y. Chen, J. Alloys Compd. 781, 1139. (2019).

M. Yan, W. Xu, M.S. Dargusch, H.P. Tang, M. Brandt, and M. Qian, Powder Metall. 57, 251. (2014).

M.L. Wasz, F.R. Brotzen, R.B. McLellan, and A.J. Griffin, Inter. Mater. Rev. 41, 1. (1996).

J.M. Oh, B.G. Lee, S.W. Cho, S.W. Lee, G.S. Choi, and J.W. Lim, Met. Mater. Int. 17, 733. (2011).

ASTM F2924-14, West Conshohocken, PA: ASTM, 2014.

J.W. Lim, J.M. Oh, B.K. Lee, C.Y. Suh, S.W. Cho, US patent, 8449813 B1, 2013.

J.M. Oh, B.K. Lee, C.Y. Suh, S.W. Cho, and J.W. Lim, Powder Metall. 55, 402. (2012).

T.H. Okabe, T. Oishi, and K. Ono, Metall. Trans. B 23, 583. (1992).

R.O. Suzuki, M. Aizawa, and K. Ono, J. Alloys Compd. 288, 173. (1999).

T.H. Okabe, T. Oishi, and K. Ono, J. Alloys Compd. 184, 43. (1992).

J.M. Oh, K.M. Roh, B.K. Lee, C.Y. Suh, W. Kim, H. Kwon, and J.W. Lim, J. Alloys Compd. 593, 61. (2014).

J.M. Oh, C.I. Hong, and J.W. Lim, Adv. Powder Technol. 30, 1. (2019).

C.I. Hong, J.M. Oh, J. Park, J.M. Yoon, and J.W. Lim, Adv. Powder Technol. 29, 1640. (2018).

T.H. Okabe, T. Oda, and Y. Mitsuda, J. Alloys Compd. 364, 156. (2004).

B. Xu, B. Yang, J. Jia, D. Liu, H. Xiong, and Y. Deng, J. Alloys Compd. 576, 208. (2013).

R.O. Suzuki, K. Teranuma, and K. Ono, Metall. Mater. Trans. B 34B, 287. (2003).

R.O. Suzuki, and S. Inoue, Metall. Mater. Trans. B 34B, 277. (2003).

R.O. Suzuki, JOM 59, 68. (2007).

J. Jia, B. Xu, B. Yang, D. Wang, and D. Liu, JOM 65, 630. (2013).

Y. Zhang, Z.Z. Fang, P. Sun, T. Zhang, Y. Xia, C. Zhou, and Z. Huang, J. Am. Chem. Soc. 138, 6916. (2016).

Y. Zhang, Z.Z. Fang, Y. Xia, P. Sun, B.V. Devener, M. Free, H. Lefler, and S. Zheng, Chem. Eng. J. 308, 299. (2017).

Y. Xia, Z.Z. Fang, D. Fan, P. Sun, Y. Zhang, and J. Zhu, Int. J. Hydrogen Energy 43, 11939. (2018).

L. Luo, Y. Su, J. Guo, and H. Fu, J. Alloys Compd. 425, 140. (2006).

R. Sridharan, K.H. Mahendran, T. Gnanasekaran, G. Periaswami, U.V. Varadaraju, and C.K. Mathews, J. Nucl. Mater. 223, 72. (1995).

J. Yang, M. Kuwabara, T. Sawada, and M. Sano, ISIJ Int. 46, 1130. (2006).

H. Wang, Z. Fang, and K. Hwang, Metall. Mater. Trans. A 42, 3534. (2011).

M. Nie, Y. Yang, Z. Zhang, C. Yan, X. Wang, H. Li, and W. Dong, Chem. Eng. J. 246, 373. (2014).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (NSFC no. 11535003) and the Fund of State Key Laboratory of Multiphase Complex Systems (no. Y525021140).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, B., Hou, G., Jin, H. et al. The Deep Deoxygenation Behavior of Fine Hydrogenated Ti Alloy Powders. JOM 73, 1188–1195 (2021). https://doi.org/10.1007/s11837-021-04571-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04571-8