Abstract

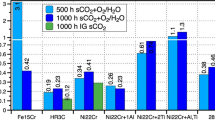

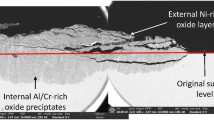

Future power plants will require Ni-based superalloys resistant to high-temperature corrosion in CO2-rich environments containing impurities. In this work, several commercially available Ni-based alloys (617, 230, 625, 263, 740H) were exposed at 600°C, 650°C, 750°C and 1 atm to 95% CO2, 4% H2O, 1% O2 without/with 0.1% SO2 to simulate compositions expected in a direct-fired supercritical CO2 power cycle. The results indicate no effect of SO2 at 750°C, a small negative effect at 650°C, and a large negative effect at 600°C. Alloys exposed at the higher temperatures (650–750°C) formed thin Cr-rich oxide scales, whereas the lowest temperature (600°C) resulted in thicker scales consisting of non-protective oxides and sulfates. Thermodynamic analysis indicates this increased corrosion is associated with a transition in the stable compounds in contact with the gas. Understanding the factors that affect this transition will aid in the selection or design of alloys for future CO2-based power systems.

Similar content being viewed by others

References

R. Viswanathan, J. Shingledecker, and R. Purgert, Power 154, 41 (2010).

K. Brun, P. Friedman, and R. Dennis, Fundamentals and Applications of Supercritical Carbon Dioxide (sCO2) Based Power Cycles (Sawston: Woodhead Publishing, 2017).

N.T. Weiland and C.W. White, Fuel 212, 613 (2018).

B.J.P. Buhre, L.K. Elliott, C.D. Sheng, R.P. Gupta, and T.F. Wall, Prog. Energy Combust. Sci. 31, 283 (2005).

R. Allam, S. Martin, B. Forrest, J. Fetvedt, X. Lu, D. Freed, G.W. Brown, T. Sasaki, M. Itoh, and J. Manning, Energy Procedia 114, 5948 (2017).

J.P. Shingledecker, S.C. Kung, and I.G. Wright, Predicting the Oxidation/Corrosion Performance of Structural Alloys in Supercritical CO2, Report No. DE-FE0024120, Electric Power Research Institute (2017).

V. Firouzdor, K. Sridharan, G. Cao, M. Anderson, and T.R. Allen, Corros. Sci. 69, 281 (2013).

B.A. Pint and J.R. Keiser, JOM 67, 2615 (2015).

H.J. Lee, H. Kim, S.H. Kim, and C. Jang, Corros. Sci. 99, 227 (2015).

G.R. Holcomb, C. Carney, and Ö.N. Doğan, Corros. Sci. 109, 22 (2016).

T.D. Nguyen, Y. Xie, S. Ding, J. Zhang, and D.J. Young, Oxid. Met. 87, 605 (2017).

R.P. Oleksak, J.P. Baltrus, J. Nakano, A. Nakano, G.R. Holcomb, and Ö.N. Doğan, Corros. Sci. 125, 77 (2017).

R.I. Olivares, D.J. Young, T.D. Nguyen, and P. Marvig, Oxid. Met. 90, 1 (2018).

A. Hjörnhede, M. Montgomery, M. Bjurman, P. Henderson, and A. Gerhardt, in Proceedings of the 9th Liege Conference on Materials for Advanced Power Engineering. Liege, Belgium (2010).

M. Gagliano, A. Seltzer, H. Agarwal, A. Robertson, and L. Wang, Oxy-Combustion Boiler Material Development, Report No. DE-NT0005262, Foster Wheeler North America Corp. (2012).

S.C. Kung, Proceedings of the 7th International Conference on Advances in Materials Technology for Fossil Power Plants. Waikoloa, Hawaii (2013).

B.S. Lutz, G.R. Holcomb, and G.H. Meier, Oxid. Met. 84, 353 (2015).

J. Pirón Abellán, T. Olszewski, H.J. Penkalla, G.H. Meier, L. Singheiser, and W.J. Quadakkers, Mater. High Temp. 26, 63 (2009).

W.J. Quadakkers, T. Olszewski, J. Piron-Abellan, V. Shemet, and L. Singheiser, Mater. Sci. Forum 696, 194 (2011).

P. Huczkowski, T. Olszewski, M. Schiek, B. Lutz, G. Holcomb, V. Shemet, W. Nowak, G. Meier, L. Singheiser, and W.J. Quadakkers, Mater. Corros. 65, 121 (2014).

R.P. Oleksak, J.H. Tylczak, C.S. Carney, G.R. Holcomb, and Ö.N. Doğan, JOM 70, 1527 (2018).

R.P. Oleksak, J.H. Tylczak, G.R. Holcomb, and Ö.N. Doğan, Corros. Sci. 157, 20 (2019).

B.A. Pint, J. Lehmusto, M.J. Lance, and J.R. Keiser, Mater. Corros. 70, 1400 (2019).

B.A. Pint, R.G. Brese, and J.R. Keiser, in Proceedings of the 2018 NACE CORROSION Conference. Phoenix, AZ (2018).

P. Huczkowski, D.J. Young, T. Olszewski, A. Chyrkin, and W.J. Quadakkers, Oxid. Met. 89, 651 (2018).

J. Mahaffey, A. Schroeder, D. Adam, A. Brittan, M. Anderson, A. Couet, and K. Sridharan, Metall. Mater. Trans. A 49, 3703 (2018).

Y. Xie, T.D. Nguyen, J. Zhang, and D.J. Young, Corros. Sci. 146, 28 (2019).

T. Lolla, J. Shingledecker, S. Kung, M. Gagliano, I. Wright, and A. Sabau, in Proceedings of the 6th International Supercritical CO2Power Cycles Symposium. Pittsburgh, PA (2018).

C.B. Alcock, M.G. Hocking, and S. Zador, Corros. Sci. 9, 111 (1969).

R.P. Oleksak, C.S. Carney, G.R. Holcomb, and Ö.N. Doğan, Oxid. Met. 90, 27 (2017).

R.P. Oleksak, M. Kapoor, D.E. Perea, G.R. Holcomb, and Ö.N. Doğan, npj Mater. Degr. 2, 1 (2018).

D.J. Young, High Temperature Oxidation and Corrosion of Metals, 2nd ed. (Amsterdam: Elsevier, 2016).

K.R. Peters, D.P. Whittle, and J. Stringer, Corros. Sci. 16, 791 (1976).

A. Jalowicka, W. Nowak, D. Naumenko, L. Singheiser, and W.J. Quadakkers, Mater. Corros. 65, 178 (2014).

R.P. Oleksak, J.H. Tylczak, G.R. Holcomb, and O.N. Dogan, Corros. Sci. 164, 108316 (2020).

Acknowledgements

This work was performed in support of the US Department of Energy’s Fossil Energy Crosscutting Technology Research Program. The Research was executed through the NETL Research and Innovation Center’s Advanced Alloy Development Field Work Proposal. Research performed by Leidos Research Support Team staff was conducted under the RSS contract 89243318CFE000003. We thank Christopher McKaig (NETL) for preparing the sample cross sections, Keith Collins (NETL) for performing the WDS analysis, and Richard Chinn (NETL) for performing the XRD analysis.

Disclaimer

This work was funded by the Department of Energy, National Energy Technology Laboratory, an agency of the United States Government, through a support contract with Leidos Research Support Team (LRST). Neither the United States Government nor any agency thereof, nor any of their employees, nor LRST, nor any of their employees, makes any warranty, expressed or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise, does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.

Funding

Funding was provided by Clean Coal.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Oleksak, R.P., Tylczak, J.H., Holcomb, G.R. et al. Temperature-Dependence of Corrosion of Ni-Based Superalloys in Hot CO2-Rich Gases Containing SO2 Impurities. JOM 72, 1822–1829 (2020). https://doi.org/10.1007/s11837-020-04081-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04081-z