Abstract

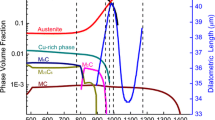

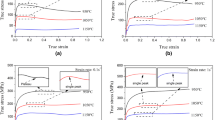

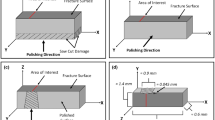

The evolution of stress during damage initiation and accumulation in a two-phase alloy consisting of a ductile copper (Cu) matrix with a randomly dispersed brittle tungsten (W) phase was studied using multiple non-destructive experimental probes. Neutron diffraction measurements were performed to examine the macroscopic strain partitioning between the two phases during a uniaxial tension test. The same material was then examined with high-energy x-ray diffraction microscopy (HEDM) and micro-computed tomography (\(\mu \hbox {-CT}\)) measurements to monitor micromechanical field evolution. The neutron diffraction data indicated a redistribution of load between the Cu and W phases as deformation proceeds. Using HEDM to monitor individual grain micromechanical behavior, an increase followed by decrease in hydrostatic stress and a similar stress triaxiality behavior were found to occur in a subset of W grains. These same W grains were found to be in close proximity to voids observed via tomography at later stages of deformation. From these observations, we conclude that high stress triaxiality development in the W particles leads to decohesion of the interface between the Cu and W phases. The debonded regions eventually grew and coalesced with neighboring voids leading to material failure.

Similar content being viewed by others

References

D. Lassance, D. Fabregue, F. Delannay, and T. Pardoen, Progr. Mater. Sci. 52, 62 (2007).

H. Li, M.W. Fu, J. Lu, and H. Yang, Int. J. Plast. 27, 147 (2011).

J. Lemaitre, A Course on Damage Mechanics (Springer, 2012).

G.M. Castelluccio, W.D. Musinski, and D.L. McDowell, Curr. Opin. Solid State Mater. Sci. 18, 180 (2014).

A. Patra and D.L. McDowell, J. Mech. Phys. Solids, 74, 111 (2015).

T.R. Bieler, P. Eisenlohr, F. Roters, D. Kumar, D.E. Mason, M.A. Crimp, and D. Raabe, Int. J. Plast. 25, 1655 (2009).

D.L. McDowell, Int. J. Solids Struct. 37, 293 (2000).

H.F. Poulsen, Three-dimensional X-ray Diffraction Microscopy: Mapping Polycrystals and their Dynamics, vol. 2015 (Springer, 2004).

M.P. Miller, R.M. Suter, U. Lienert, A.J. Beaudoin, E. Fontes, J. Almer, and J.C. Schuren, Synchrotron Radiat. News 25, 18 (2012).

R. Pokharel, Materials Discovery and Design, ed. T. Lookman, S. Eidenbenz, F. Alexander, and C. Barnes (Cham: Springer, 2018)

E.M. Lauridsen, S.R. Dey, R.W. Fonda, and D.J. Jensen, JOM 58, 40 (2006).

E. Maire, O. Bouaziz, M. Di Michiel, and C. Verdu, Acta Mater. 56, 4954 (2008).

C.M. Hefferan, J. Lind, S.F. Li, U. Lienert, A.D. Rollett, and R.M. Suter, Acta Mater. 60, 4311 (2012).

R. Pokharel, J. Lind, A.K. Kanjarla, R.A. Lebensohn, S.F. Li, P. Kenesei, R.M. Suter, and A.D. Rollett, Annu. Rev. Condens. Matter Phys. 5, 317 (2014).

M. Obstalecki, S.L. Wong, P.R. Dawson, and M.P. Miller, Acta Mater. 75, 259 (2014).

J.C. Schuren, P.A. Shade, J.V. Bernier, S.F. Li, B. Blank, J. Lind, P. Kenesei, U. Lienert, R.M. Suter, T.J. Turner, and D.M. Dimiduk, Curr. Opin. Solid State Mater. Sci. 19, 235 (2015).

K. Chatterjee, A. Venkataraman, T. Garbaciak, J. Rotella, M.D. Sangid, A.J. Beaudoin, P. Kenesei, J.S. Park, and A.L. Pilchak, Int. J. Solids Struct. 94, 35 (2016).

D.C. Pagan, P.A. Shade, N.R. Barton, J.S. Park, P. Kenesei, D.B. Menasche, and J.V. Bernier, Acta Mater. 128, 406 (2017).

D. Naragani, M.D. Sangid, P. Shade, J.C. Schuren, H. Sharma, J.S. Park, P. Kenesei, J.V. Bernier, T.J. Turner, and I. Parr, Acta Mater. 137, 71 (2017).

V. Tari, R.A. Lebensohn, R. Pokharel, T.J. Turner, P.A. Shade, J.V. Bernier, and A.D. Rollett, Acta Mater. 154, 273 (2018).

A.N. Bucsek, D. Dale, J.Y.P. Ko, Y. Chumlyakov, and A.P. Stebner, Acta Crystallogr. Sect. A Found. Adv. 74, 425 (2018).

C.F. Chen, R. Pokharel, M.J. Brand, E.L. Tegtmeier, B. Clausen, D.E. Dombrowski, T.L. Ickes, and R.A. Lebensohn, J. Mater. Sci. 52, 1172 (2017).

H.F. Poulsen, Appl. Phys. A 74, 1673 (2002).

A.C. Larson, R.B. Von Dreele, Los Alamos National Lab.(LANL), Los Alamos, NM (United States), LAUR 86-748 (1994).

J.V. Bernier, N.R. Barton, U. Lienert, and M.P. Miller, J. Strain Anal. Eng. Des.46, 527 (2011).

N.Y. Juul, G. Winther, D. Dale, M.K.A. Koker, P. Shade, and J. Oddershede, Scripta Mater. 120, 1 (2016).

D.E. Boyce and J.V. Bernier, Lawrence Livermore National Lab.(LLNL), Livermore, CA (United States), Tech Report (2013).

J.F. Hunter, Los Alamos National Lab.(LANL), Los Alamos, NM (United States), Tech Report (2011).

S.G. Epstein and O.N. Carlson, Acta Metall., 13, 487 (1965).

F.H. Featherston and J.R. Neighbours, Phys. Rev. 130, 1324 (1963).

F.A. McClintock, J. Appl. Mech. 35, 363 (1968).

J.R. Rice and D.M. Tracey, J. Mech. Phys. Solids 17, 201 (1969).

R.C. Hurley, E.B. Herbold, and D.C. Pagan, J. Appl. Crystallogr. 51, 1021 (2018).

C. Chu and A. Needleman, J. Eng. Mater. Technol. 102, 249 (1980).

A. Needleman and V. Tvergaard, Int. J. Fract. 101, 1 (2000).

R.A. Lebensohn, A.K. Kanjarla, and P. Eisenlohr, Int. J. Plast. 32, 59 (2012).

R.A. Lebensohn, J.P. Escobedo, E.K. Cerreta, D. Dennis-Koller, C.A. Bronkhorst, and J.F. Bingert, Acta Mater. 61, 6918 (2013).

Acknowledgements

This work was supported by the US Department of Energy through the Los Alamos National Laboratory. Los Alamos National Laboratory is operated by Triad National Security, LLC for the National Nuclear Security Administration of the US Department of Energy (contract no. 89233218CNA000001), specifically the Laboratory Directed Research and Development (LDRD) program (Project 20140114DR) and Science Campaign 2. The use of F2 Beamline at CHESS and SMARTS Beamline at LANSCE is also acknowledged. CHESS is supported by the NSF award DMR-1332208.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pokharel, R., Lebensohn, R.A., Pagan, D.C. et al. In-Situ Grain Resolved Stress Characterization During Damage Initiation in Cu-10%W Alloy. JOM 72, 48–56 (2020). https://doi.org/10.1007/s11837-019-03692-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03692-5