Abstract

An innovative and environmentally friendly lead-acid battery paste recycling method is proposed. The reductive sulfur-fixing recycling technique was used to simultaneously extract lead and immobilize sulfur. SO2 emissions and pollution were significantly eliminated. In this work, the detailed lead extraction and sulfur-fixing mechanisms in the PbSO4-Fe3O4-Na2CO3-C system were investigated thermodynamically and experimentally, and the phase transformation and microstructural evolution processes characterized. In addition, a series of bench-scale pilot experiments were carried out to confirm the feasibility of the technique. The results show that the lead extraction and sulfur-fixing reactions followed the shrinking unreacted-core model. The recycling products were separated into three distinct layers: slag, matte, and crude lead bullion. Primary recoveries of 96.2% for lead and 98.9% for sulfur were obtained. The purity of the crude lead bullion was 98.6 wt.%. Sulfur was fixed in the solidified matte as FeS and NaFeS2.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Spent lead-acid batteries (LABs) are widely scrapped from automobiles and electric bicycles in urban areas. The reported amounts of scrap LAB annually in China total more than 2.6 million metric tons.1,2 LABs are a solid waste and classified as hazardous materials in many countries. Their disposal has become a significant environmental concern.3 Recycling and reuse of LABs are attracting great attention from both the public and materials processing industry. At the same time, the depletion of high-quality lead ores resulting in rising extraction costs presents critical challenges for the lead extractive metallurgical industry. As a result, scrap LABs have become a significant secondary lead source worldwide.1 Secondary lead produced by recycling is gradually dominating the world’s lead market.4 Typically, a spent LAB consists of four components: waste electrolyte (11–30%), polymeric materials (22–30%), lead alloy grids (24–30%), and lead paste (30–40%). Of these, lead paste is the most difficult part to deal with.5 However, it is a high-quality secondary lead-bearing material. Around 80–85% of the total secondary lead is recycled from lead paste.6

Currently, the worldwide LAB recycling technology can be divided into traditional routes such as pyrometallurgy and hydrometallurgy, and advanced approaches including electrowinning,7 biological techniques,8,9 and vacuum methods.5 Pyrometallurgy is presently the predominant route worldwide for recycling LAB,10 in which high-temperature treatment of spent LABs in a blast, electric, reverberatory, or rotary furnace without pre-desulfurization is employed.11,12 In the hydrometallurgical process,13,14 a pre-desulfurization step15 is necessary. Na2CO3, NaOH, and K2CO3 solutions or citric acid and citrate salts are usually adopted as desulfurization reagents. However, the treatment of spent LABs involves a potential health and environmental risk.16,17 At the same time, existing LAB pyrometallurgical processes operated at high temperatures are usually associated with high atmospheric emissions, since dioxins, chloride compounds, and mercury can be generated in the process. Meanwhile, hydrometallurgical processes are accompanied by laborious procedures, generation of large amounts of problematic waste water, and high electricity consumption.18 As a result, the stringent environmental requirements are increasingly difficult to meet with current pyro- and hydrometallurgical recycling technologies. Therefore, the lead industry is keen to seek advanced technologies19 which are more economical, minimize environmental pollution,20 and reduce energy usage and production costs.

In this article, an innovative and environmentally friendly lead-acid battery paste recycling method is proposed. The reductive sulfur-fixing21,22,23 technique was used to simultaneously extract lead and immobilize sulfur. This novel technique is distinguished from conventional pyrometallurgy techniques such as oxidizing matte smelting and reductive smelting by the use of a reducing atmosphere in the processing combined with sulfur transformation and fixation as a sulfide matte. Iron-containing wastes are also employed as sulfur-fixing agents to immobilize sulfur as FeS. The smelting products obtained contain three products, namely crude metal bullion, matte, and slag. The novelty of this process is the treatment of various iron/lead-bearing wastes, SO2-free sulfur fixation, a much shorter flowsheet, absence of harmful byproducts, and wide adaptability for different secondary materials.12 This work investigated the detailed lead extraction and sulfur-fixing mechanisms in the PbSO4-Fe3O4-Na2CO3-C system, thermodynamically and experimentally. The phase transformations and microstructural evolution processes were characterized, and the lead extraction and sulfur-fixing reaction mechanisms proposed. Furthermore, bench-scale experiments were carried out to confirm the feasibility and reliability of the new technique.

Experimental Procedures

Materials

In the reaction mechanism investigation, PbSO4, Na2CO3, Fe3O4, and carbon powder with purity of ≥ 99% were employed to ensure high experimental accuracy. In the batch tests, lead paste separated from LAB scrap was used as raw material. Hematite and coke obtained from Jiuquan Iron & Steel Co., Ltd., Gansu, China were applied as sulfur-fixing agent and reductant, respectively. Their chemical compositions were analyzed by inductively coupled plasma-atomic emission spectrometry (ICP-AES, PerkinElmer, Optima 3000, Norwalk, USA) and are shown in Supplementary Table S-I (Online Supplementary Material). The phase compositions of the lead paste and hematite were characterized by x-ray diffraction (XRD) analysis (D/max 2550PC, Rigaku Co., Ltd., Japan). The results are presented in Supplementary Fig. S-1, showing that the lead paste comprised 56.3% PbSO4, 18.9% PbO2, 13.7% Pb, and 11.1% PbO. Lead sulfate (anglesite) is the main substance in the lead paste. Hematite mainly contains Fe2O3 and (Mg,Al)6(Si,Al)4O10(OH)8, SiO2, and Ca(Al,Si)2O4.

Methods

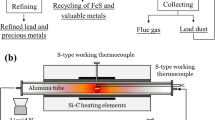

PbSO4 was selected as a model compound in the reaction mechanism investigation, since it is the major as well as the most difficult component to deal with in spent lead paste. At the same time, to reveal the reaction paths that may take place in each raw material component, the PbSO4-Fe3O4-Na2CO3-C system was divided into the PbSO4-Na2CO3, PbSO4-Na2CO3-C, PbSO4-Fe3O4, and PbSO4-Fe3O4-C subsystems. The specimens were mixed carefully and pressed uniaxially under 15 MPa into cylindrical samples of 10 mm diameter. Each specimen was placed in an alumina crucible and pushed slowly into the constant-temperature zone of a horizontal tube furnace (Supplementary Fig. S-2). The temperature was measured using a Pt-Rh thermocouple and controlled using a SHIMADEN SR25 intelligent temperature controller (accuracy ± 1°C). Nitrogen with purity of 99% was applied as protective gas in the reaction mechanism investigations. The N2 gas flow during the reaction was fixed at 0.5 L/min. After the preset smelting time, the sample was removed rapidly from the furnace and quenched in liquid nitrogen.

In the bench-pilot confirmation experiments, 2000 g LAB paste was mixed thoroughly with a desired proportion of hematite, coke, Na2CO3, and other fluxes (CaO and SiO2). The specimen was loaded into an alumina crucible and put into a chamber furnace. After the required smelting time, the sample was taken out and cooled down at room temperature. Next, the crucible was broken to carefully separate and weigh the end products obtained, i.e., crude lead, ferrous matte, and slag. Each product was prepared for ICP-AES analysis. The direct recovery rate of Pb (η) and the sulfur-fixing rate (γ) were calculated based on Eqs. 1 and 2, respectively:

The phases and microstructure of the samples were characterized by XRD using Cu Kα radiation and scanning electron microscope with energy-dispersive spectroscopy (SEM–EDS, Carl Zeiss LEO 1450, Germany; EDS, INCA Wave 8570, Oxford Instruments, UK). XRD data were collected in the 2θ range from 10° to 80° in steps of 1°. The recorded patterns were evaluated using the PDF-2 powder XRD database.24 Samples for SEM–EDS analysis were mounted in epoxy resin and polished using conventional metallographic grinding and polishing techniques.

Thermodynamic Calculations

Figure 1 illustrates the equilibrium compositions of the PbSO4-Fe3O4-Na2CO3-C reaction system for different carbon additions as simulated using HSC Chemistry software, version 9.2.6, and its database;25 the phase diagrams of the Al2O3-SiO2-CaO-10 wt.%Na2O and Fe-Fe3O4-FeS systems were calculated using MTDATA version 6.026 and MTOX database 8.2.27 Figure 1a suggests that, without carbon addition, PbSO4 prefers to react with Na2CO3 to produce Na2SO4 and PbO, even below 200°C. As the temperature is increased above 500°C, some PbO decomposes to metallic lead. In a weakly reductive atmosphere, as shown in Fig. 1b, PbSO4 is reduced to PbS. At the same time, as the temperature increases, PbS prefers to react further with Fe3O4, instead of Na2CO3, generating metallic Pb and FeS. However, when the temperature reaches around 630°C, Na2CO3 gradually reacts with FeS as well as PbS. Thus, the amounts of Pb, Na2S, and Fe3O4 products increase, while those of PbS, Na2CO3, and FeS decrease. However, some PbS remains due to insufficient addition of carbon.

Equilibrium compositions (a)–(c) of the PbSO4-Fe3O4-Na2CO3-C reaction system calculated for different carbon additions; data taken from HSC 9.2.6 and its database;25 and liquidus contour diagrams of (d) the Al2O3-SiO2-CaO-10 wt.%Na2O system and (e) the Fe-Fe3O4-FeS system calculated using MTDATA version 6.0 and MTOX database 8.227

Figure 1c indicates that, at equilibrium conditions, all the lead can be extracted from PbSO4 and PbS before 800°C when the carbon addition is sufficient. However, when the temperature is increased from 700°C to 800°C, the equilibrium amount of FeS remains steady while the amounts of metallic Pb and Na2S increase and, at the same time, those of Na2CO3 as well as PbS decrease. This indicates that Na2CO3 is partly involved in the lead extraction reactions from PbS. When the temperature exceeds 800°C, some FeS will also react with Na2CO3 to generate Na2S and Fe3O4.

The above thermodynamic equilibrium composition calculations reveal that, in the absence of a reducing agent and below 200°C, PbSO4 prefers to react with Na2CO3 rather than Fe3O4 to generate PbO and Na2SO4. Once the temperature is increased and the atmosphere is sufficiently reducing, PbSO4 will be reduced to PbS. At that point, PbS will prefer to react with Fe3O4 rather than Na2CO3 to produce FeS and PbO. When the temperature exceeds 800°C, the excess Na2CO3 will continue to react with FeS. Thus, the sulfur transfers from the initial PbSO4 to PbS and then FeS, and finally to Na2S. As a result, the presence of Na2CO3, and a reductant as well as sulfur-fixing agent Fe3O4, can ensure efficient sulfur fixation and lead extraction at both low and high temperature. No gaseous SO2 or SO3 is generated throughout the whole reaction process. All lead can thus be extracted from PbSO4 and PbS.

The phase diagrams of the Al2O3-SiO2-CaO-10 wt.%Na2O system shown in Fig. 1d indicate that the first liquid slag appeared below around 975°C (1248 K), surrounded by liquid wollastonite [(Ca,Fe)SiO3], tridymite (SiO2), and feldspar [(AlCa,NaSi)AlO8]. At that point, PbS, FeS, metallic Pb, Na2SO4, and Na2S were generated in the smelting system, as shown in Fig. 1a–c. They stayed in liquid form, together with the remaining Fe3O4 and liquid Na2CO3. As the temperature was increased further, more liquid was formed from (Ca,Fe)SiO3 and other solid smelting materials. When the temperature reached 1200°C (1473 K), more tridymite (SiO2) and feldspar [(AlCa,NaSi)AlO8] also dissolved in the melt, and the liquid slag region expanded.

Figure 1e further reveals that pyrrhotite FeS melts may come into contact with spinel Fe3O4, halite FeO, or/and FCC-A1 Fe before 1000°C (1273 K). A eutectic iron sulfide–oxide liquid appeared and gradually expanded along with the temperature. At 1200°C (1473 K), FeS was in liquid form. This promoted the generation of FeS and its settling from the smelting system as a separate sulfide melt layer.

Results and Discussion

Thermogravimetric Behavior of PbSO4-Fe3O4-Na2CO3-C Mixtures

The thermogravimetric behavior of the reactants and their mixtures was characterized using a thermogravimetric analyzer (TG–DTA, STA 494 F3; Netzsch, Germany) at heating rate of 10°C/min in N2 flow of 100 mL/min, from 25 to 1000°C. The results are shown in Fig. 2.

It can be observed from Fig. 2a that the weight loss in the PbSO4-C, PbSO4-Na2CO3-C, and PbSO4-Fe3O4-C subsystems was greater than that in the PbSO4, PbSO4-Fe3O4, and PbSO4-Na2CO3 subsystems. This implies that the presence of carbon promoted the conversion of PbSO4. Figure 2b further illustrates that T1 (around 82°C) is associated with loss of crystallographic water from Na2CO3. T2 (406°C) is ascribed to the transformation of Fe3O4 into crystal form. T3 (443°C) corresponds to preliminary decomposition of PbSO4. T4 (563°C) and T5 (717°C) are associated with the conversion reactions between PbSO4 and Na2CO3. The pronounced endothermic peaks detected at T6 (around 875°C) can be attributed to further decomposition of PbSO4. The last obvious endothermic peaks recorded at T7 (around 980°C) are assumed to be linked with the generation of metallic lead.

Experimental Reaction Mechanisms in the PbSO4-Na2CO3-C Mixture

The experimental phase transformation paths in the different reaction systems and at different temperatures and reaction times were characterized by XRD and SEM–EDS analyses. The results for the PbSO4-Na2CO3-C system are shown in Fig. 3. It was observed that the reactions between PbSO4 and Na2CO3 took place below 650°C. PbO and Na2SO4 were detected at 650°C within a 30-min duration. At the same time, when the temperature was increased, more intermediate products were detected, e.g., PbO·PbSO4, 2PbO·PbSO4, and 4PbO·PbSO4. This indicates that the reactions between PbSO4 and Na2CO3 are a multistage process and follow the shrinking unreacted-core model. The unreacted PbSO4 core is surrounded by liquid Na2CO3. The products xPbO·PbSO4 (x = 1, 2, or 4) form a boundary layer. When the temperature exceeded 1000°C, the reactions were completed and the final products were stable in PbO and Na2SO4. No metallic Pb was detected due to the absence of reductant. These results agree well with the thermodynamic calculations presented in Fig. 1. Figure 3b further reveals that the exchange reactions between PbSO4 and Na2CO3 favorably occur at 850°C quickly, within as little as 5 min. Thus, SO3 in PbSO4 was transformed and fixed to Na2SO4, instead of being emitted to the furnace atmosphere. The presence of Na2CO3 inhibited self-decomposition of PbSO4.

Phase transformation paths in (a) the PbSO4-Na2CO3 (mole ratio 1:1) reaction system at different smelting temperature after 30 min reaction time; (b) the PbSO4-Na2CO3 (mole ratio 1:1) reaction system at 850°C for different reaction times; (c) the PbSO4-Na2CO3-C (mole ratio 1:1:6) reaction system at different smelting temperatures after 30 min reaction time; (d) the PbSO4-Na2CO3-C (mole ratio 1:1:6) reaction system at 850°C for different reaction times

Once a reductant was present, as shown in Fig. 3c and d, PbSO4 was reduced to PbS when the temperature was higher than 750°C. Metallic Pb was also detected. This implies that PbO had been reduced by carbon. Furthermore, as the temperature was increased to 1000°C, the stable sodium-bearing product after 30 min reaction time was Na2S, rather than Na2SO4. This indicates that Na2SO4 had been reduced to Na2S. The final products were PbS, Pb, and Na2S.

The reaction paths in the PbSO4-Na2CO3-C system at 850°C after different reaction times, which are illustrated in Fig. 3d, further reveal that the PbSO4 and PbO reduction reactions can occur rapidly. PbS and metallic Pb appeared within 5 min reaction time. The presence of carbon thus changes the reaction paths in the PbSO4-Na2CO3 system. Only very weak diffraction peaks of PbO, Na4CO3SO4, and Na2SO4 were detected in the reaction products. The reduction of PbSO4 to PbS dominated the reaction path at 850°C. The sulfur in PbSO4 would be converted mainly to PbS rather than Na2SO4.

Experimental Reaction Mechanisms in the PbSO4-Fe3O4-C Mixtures

Figure 4 presents the phase evolutions in the PbSO4-Fe3O4-C system. It can be observed in Fig. 4a and b that no reactions took place between PbSO4 and Fe3O4 in the absence of reductant, as only a decomposition product, viz. PbO·PbSO4 from PbSO4, was detected. With the addition of a reductant, as illustrated in Fig. 4c, below 650°C, PbSO4 was still not involved in any reaction with iron oxide during the first 30 min. However, at 750°C, PbS was detected, and PbSO4 also converted to PbO·PbSO4 and further to 2PbO·PbSO4, and metallic Pb emerged. This implies that, without Na2CO3, PbSO4 self-decomposition intensified. As the temperature increased to 850°C, the product after 30 min reaction time consisted of PbS, Pb, and Fe3O4. Figure 4d further illustrates that the PbSO4 reduction reactions to PbS could take place instantaneously. PbSO4 disappeared before it was involved in any reaction with Fe3O4. FeS did not emerge until 1000°C after 30 min reaction time, and was generated by the exchange reactions between PbS and Fe3O4. PbSO4 did not directly react with the sulfur-fixing agent, iron oxide. The sulfur-fixation reactions occurred with the help of exchange reactions between PbSO4 and Na2CO3, as well as PbS and Fe3O4. The reaction mechanism proposed is consistent with the thermodynamic results above.

Phase transformation paths in (a) the PbSO4-Fe3O4 (mole ratio 3:1) reaction system at different smelting temperatures after 30 min reaction time; (b) the PbSO4-Fe3O4 (mole ratio 3:1) reaction system at 850°C for different reaction times; (c) the PbSO4-Fe3O4-C (mole ratio 3:1:18) reaction system at different smelting temperatures after 30 min reaction time; (d) the PbSO4-Fe3O4-C (mole ratio 3:1:18) reaction system at 850°C for different reaction times

Microstructural Evolution Mechanisms

Selected samples, produced from simulated smelting systems at different temperatures and reaction times, were further characterized by SEM–EDS analysis. The results are presented in Fig. 5. Figure 5a shows the SEM–EDS results for the PbSO4-Na2CO3-C system at 750°C for 30 min reactions. It was observed that (PbO)x·PbSO4 (x = 1, 2, or 4) was close to Na2SO4 particles and a part of PbSO4 had reduced to PbS. Moreover, PbSO4 and Na2SO4 were surrounded by PbO and metallic Pb. This confirms that the reactions between PbSO4 and Na2CO3 follow the shrinking unreacted-core model. PbSO4 first reacts with Na2CO3 to generate Na2SO4 and PbO. Na2CO3 surrounds and gradually “erodes” the PbSO4 unreacted core, then the PbSO4 core is disintegrated by molten Na2SO4. At the same time, the reaction product PbO gradually diffuses out from the unreacted PbSO4 core.

Figure 5b illustrates the SEM–EDS results for the PbSO4-Fe3O4-C system at 850°C after 5 min reaction time. It reveals that PbS was surrounded by FeS. Metallic Pb was located in the center of the PbS particle. A PbFexOy boundary layer was detected between the metallic Pb and PbS layers. This demonstrates that the reactions between PbS and FexOy also follow the shrinking unreacted-core model. A possible phase transformation and microstructural evolution mechanism for the entire PbSO4-Na2CO3-Fe3O4-C reaction system is summarized and presented graphically in Fig. 6.

Confirmation Experiments and Characterization of Products

Two bench-scale pilot confirmation experiments with 1800 g lead paste were carried out to determine the reliability of this novel process under the following conditions: \( W_{{{\text{lead}}\,{\text{paste}}}} :W_{\text{hematite}} :W_{{{\text{Na}}_{ 2} {\text{CO}}_{ 3} }} :W_{\text{coke}} \) = 100 g:20 g:4 g:12 g. FeO/SiO2 = 1.3, CaO/SiO2 = 0.4, smelting temperature of 1200°C, and smelting time of 1.5 h. A physical macrograph and corresponding XRD patterns of the smelting products are presented in Fig. 7a and b. It can be observed that three products were obtained, visibly separated as distinct layers by settling, i.e., slag, ferrous matte, and crude lead bullion. The chemical compositions of the different products obtained and the element distribution behavior is presented in Fig. 7c and Table S-II (Supplementary Material).

(a) Macrograph of smelting products in bench-scale pilot experiments; (b) XRD patterns of matte and slag; (c) element distribution behavior (\( W_{{{\text{lead}}\,{\text{paste}}}} :W_{\text{hematite}} :W_{{{\text{Na}}_{ 2} {\text{CO}}_{ 3} }} :W_{\text{coke}} \) = 1800 g:360 g:72 g: 216 g. FeO/SiO2 = 1.3, CaO/SiO2 = 0.4, 1200°C, 1.5 h)

The above results validate the reductive sulfur-fixing technique as being experimentally feasible for recycling LAB paste. More than 96.2% of the lead and 98.9% of the sulfur (89.6% in the matte and 9.3% in the slag) in the raw materials were extracted and fixed within 1.5 h at 1200°C. Crude lead bullion with purity of 98.6 wt.% Pb was obtained. The lead content in the matte and slag were 2.6 wt.% and 0.5 wt.%, respectively. The major constituent in the matte was FeS. Some CaS, Fe3O4, and unreacted PbS as well as entrained gangue materials such as Ca3Al2(SiO4)3, FeSiO3, Ca2(Al(AlSi)O7, and CaSiO3 were also detected. The solidified slag comprised Ca2(Al(AlSi)O7, Fe2SiO4, CaFe4O7, NaAlSiO4, Na2Si2O5, CaSiO3, Fe3O4, Ca2Al2(SiO4)3, and some entrained FeS.

The matte and slag that were obtained were further characterized by SEM–EDS analysis. The results are shown in Fig. 8. Figure 8a–d shows that, in the matte, mackinawite mineral FeS was bonded to magnetite Fe3O4. Sodium iron sulfide NaFeS2 and galena PbS filled the gaps between the magnetite minerals. Metallic Pb was detected, embedded in the FeS and NaFeS2 minerals. In the slag, as shown in Fig. 8e–h, sodium aluminosilicate (NaAlSiO4) and sodium disilicate (Na2Si2O5) dissolved in fayalite Fe2SiO4 and gehlenite Ca2(Al(AlSi)O7. Mackinawite FeS was entrained in the magnetite Fe3O4 and calcium iron oxide CaFe4O7 minerals, and magnetite had separated out from the fayalite matrix. These results agree well with the thermodynamic phase diagram calculations above.

Conclusion

Effective lead extraction from LAB paste by a reductive sulfur-fixing recycling technique was shown to be feasible, thermodynamically and experimentally. The reaction mechanism investigations revealed that the presence of Na2CO3 helped to transform SO3 from PbSO4 to Na2SO4 at low temperatures and in weakly reductive atmospheres. This ensures the conservation of sulfur in the smelting system without emitting gaseous SO2 to the atmosphere. Once the atmosphere was sufficiently reductive, PbSO4 was reduced to PbS. Thus, the sulfur-fixing agent Fe3O4 reacted with PbS to transfer sulfur to iron matte. Finally, metallic lead was extracted from PbO, and sulfur was fixed as FeS and NaFeS2. The lead extraction and sulfur-fixing reactions followed the shrinking unreacted-core model. Furthermore, bench-scale experiments using lead paste as raw material validated the fact that three recycling products were obtained: slag, matte, and crude lead bullion. More than 96.2% of the lead and 98.9% of the sulfur in the raw materials were extracted and fixed. The purity of the crude lead bullion was 98.6% Pb. The lead content in the matte and slag was decreased to 2.6% and 0.5% in the one-step treatment, respectively. This new process can be used for cotreating various iron-containing solid wastes and residues, and for comprehensive recycling of a variety of valuable metals compatible with iron matte and metallic lead.

References

Q. Zhang, Int. J. Electrochem. Sci. 8, 6457 (2013).

X. Tian, Y. Wu, Y. Gong, and T. Zuo, Waste Manag. Res. 33, 986 (2015).

Z. Sun, H. Cao, X. Zhang, X. Lin, W. Zheng, G. Cao, Y. Sun, and Y. Zhang, Waste Manag. 64, 190 (2017).

T.W. Ellis and A.H. Mirza, J. Power Sources 195, 4525 (2010).

D. Lin and K. Qiu, Waste Manag. 31, 1547 (2011).

R.A. Huggins, Lead-Acid Batteries (US: Springer, 2016).

D. Andrews, A. Raychaudhuri, and C. Frias, J. Power Sources 88, 124 (2000).

J. Weijma, K. de Hoop, W. Bosma, and H. Dijkman, Biotechnol. Prog. 18, 770 (2002).

A. Schröder-Wolthoorn, S. Kuitert, H. Dijkman, and J.L. Huisman, Hydrometallurgy 94, 105 (2008).

M.A. Kreusch, M.J.J.S. Ponte, H.A. Ponte, N.M.S. Kaminari, C.E.B. Marino, and V. Mymrin, Resour. Conserv. Recycl. 52, 368 (2007).

X. Zhang, L. Li, E. Fan, Q. Xue, Y. Bian, F. Wu, and R. Chen, Chem. Soc. Rev. 47, 7239 (2018).

Y. Li, S. Yang, W. Lin, P. Taskinen, J. He, Y. Wang, J. Shi, Y. Chen, C. Tang, and A. Jokilaakso, Minerals 9, 119 (2019).

R. Prengaman and A. Mirza, Lead-Acid Batteries for Future Automobiles (Amsterdam: Elsevier, 2017), p. 575.

E. Kim, J. Roosen, L. Horckmans, J. Spooren, K. Broos, K. Binnemans, K.C. Vrancken, and M. Quaghebeur, Hydrometallurgy 169, 589 (2017).

A. Singh and P. Karandikar, Microsyst. Technol. 23, 2263 (2017).

T.J. Van der Kuijp, L. Huang, and C.R. Cherry, Environ. Health 12, 61 (2013).

X. Tian, Y. Wu, P. Hou, S. Liang, S. Qu, M. Xu, and T. Zuo, J. Clean. Prod. 144, 142 (2017).

A.D. Ballantyne, J.P. Hallett, D.J. Riley, N. Shah, D.J. Payne, and R. Soc, Open Sci. 5, 171368 (2018).

Y. Li, S. Yang, P. Taskinen, J. He, F. Liao, R. Zhu, Y. Chen, C. Tang, Y. Wang, and A. Jokilaakso, J. Clean. Prod. 217, 162 (2019).

M. L. Jaeck, in Primary and Secondary Lead Processing: Proceedings of the International Symposium on Primary and Secondary Lead Processing, Halifax, Nova Scotia, Canada, August 20–24, Elsevier, Amsterdam (2013), p. 113.

Y. Hu, C. Tang, M. Tang, Y. Chen, J. Yang, S. Yang, and J. He, China Nonferr. Metall. 43, 75 (2014).

L. Ye, C. Tang, Y. Chen, S. Yang, J. Yang, and W. Zhang, J. Clean. Prod. 93, 134 (2015).

Y. Li, C. Tang, Y. Chen, S. Yang, L. Guo, J. He, and M. Tang, in 8th International Symposium on High-Temperature Metallurgical Processing, TMS, San Diego, CA, US, March 23–26 (Springer, Cham, 2017), p. 767.

B. Toby, J. Appl. Crystallogr. 38, 1040 (2005).

A. Roine, HSC Chemistry for Windows, vers. 9.2.6 (Outotec Research, Pori, Finland, 2019). www.hsc-chemistry.com.

MTDATA ver. 8.2. (NPL, Teddington, 2015). https://mtdata.com.au/.

J. Gisby, P. Taskinen, J. Pihlasalo, Z. Li, M. Tyrer, J. Pearce, K. Avarmaa, P. Björklund, H. Davies, M. Korpi, S. Martin, L. Pesonen, and J. Robinson, Metall. Mater. Trans. B 48B, 91 (2017).

Acknowledgements

Open access funding provided by Aalto University. This work is supported by the Specialized Research Project of Guangdong Provincial Applied Science and Technology, China (Grant No. 2016B020242001), Hunan Provincial Science Fund for Distinguished Young Scholars, China (Grant No. 2018JJ1044), National Natural Science Foundation of China (Grant Nos. 51234009 and 51604105), CMEco by Business Finland (Grant No. 2116781), National Natural Science Foundation for Less Developed Regions of China (Grant No. 51664013), Program for Young Talents of Science and Technology in Universities of the Inner Mongolia, China (Grant No. NJYT-17-B35), and Bayannur Science and Technology Project from Bayannur Bureau of Science and Technology for Wang Yuejun, China (Grant No. K201509).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Li, Y., Yang, S., Taskinen, P. et al. Spent Lead-Acid Battery Recycling via Reductive Sulfur-Fixing Smelting and Its Reaction Mechanism in the PbSO4-Fe3O4-Na2CO3-C System. JOM 71, 2368–2379 (2019). https://doi.org/10.1007/s11837-019-03529-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03529-1