Abstract

Austenitic stainless steels are cost-effective materials for high-temperature applications if they have the oxidation and creep resistance to withstand prolonged exposure at such conditions. Since 1990, Oak Ridge National Laboratory (ORNL) has developed advanced austenitic stainless steels with creep resistance comparable to Ni-based superalloy 617 at 800–900°C based on specially designed “engineered microstructures” utilizing a microstructure/composition database derived from about 20 years of radiation effect data on steels. The wrought high temperature-ultrafine precipitate strengthened (HT-UPS) steels with outstanding creep resistance at 700–800°C were developed for supercritical boiler and superheater tubing for fossil power plants in the early 1990s, the cast CF8C-Plus steels were developed in 1999–2001 for land-based gas turbine casing and diesel engine exhaust manifold and turbocharger applications at 700–900°C, and, in 2015–2017, new Al-modified cast stainless steels with oxidation and creep resistance capabilities up to 950–1000°C were developed for automotive exhaust manifold and turbocharger applications. This article reviews and summarizes their development and their properties and applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The Oak Ridge National Laboratory (ORNL) has a history of developing new or modified austenitic stainless steel advanced nuclear reactor or high-temperature creep-resistant applications.1,2,3 The void-swelling-resistant D9 and Path A Prime Candidate Alloy (PCA) of the fast breeder reactor and magnetic fusion reactor programs, respectively, in the 1970s and 1980s led to development of high temperature-ultrafine precipitate strengthened (HT-UPS) steel, which was the most void-swelling-resistant steel to date and the steel with the highest creep resistance.3,4,5 The HT-UPS steel won a 1990 R&D100 Award for having creep resistance equivalent to solid-solution Ni-based alloys like 617. In 1999, a new cast stainless steel was developed as a laboratory scale casting (15 lb) and then scaled up to commercial cast heats (500 lb) based on outstanding creep-rupture behavior at 850°C in 2001. This new steel was designated CF8C-Plus steel and won an R&D100 Award in 2003.6 It was commercialized by Caterpillar for regeneration of the diesel particulate filters on all heavy-duty on-highway diesel engines from late 2006 to 2011 (550 tons), and of 45,000 units deployed for this application, none have been reported failed to date. This achievement received the Federal Laboratory Consortium Award in 2009. Recently, an aluminum-modified CF8C-Plus steel has been developed, which has outstanding creep resistance comparable to CF8C-Plus steel (700–1000°C), but has oxidation resistance in air + 10% water vapor at 800–950°C. All of these steels were designed for specific microstructural behavior before they were tested for other properties, and all have shown very good properties from the first heat melted. This article reviews their development and summarizes their properties tested to date.

Alloy Development Results—HT-UPS Steels

In the late 1970s, the US Fusion Materials (FM) Program selected a swelling-resistant modified 316 stainless steel called the Path A prime candidate alloy (PCA), which was a titanium-modified austenitic stainless steel quite similar to the D9 alloy of the US Fast Breeder Reactor (FBR) program.7,8,9 As shown in Table I, they were 14Cr-16Ni2.5Mo-2Mn steels with Ti and C additions. In the US FM program, more void-swelling resistance was needed because of the higher He/dpa ratio. Special alloying effects and microstructural engineering work were undertaken at ORNL to further modify the PCA alloy for improved swelling and helium embrittlement resistance.10 The result was a triply stabilized steel with added Ti, Nb and V in addition to small increases in B and P, and the result was a microstructurally stable steel termed HT-UPS steel with extremely stable nanoscale complex MC carbides during both reactor irradiation and high-temperature thermal aging. Although initially designed for irradiation effect applications, these steels also had creep-rupture resistance for fossil energy power applications at 650–800°C.11,12,13

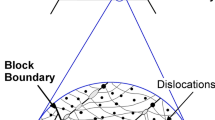

The goal for the HT-UPS steels was to achieve 100,000 h creep rupture life at 700°C and 100 MPa, which the strongest steels at the time, 17-14CuMo and NF709, were not quite able to meet. Figure 1 shows the data used to win the 1990 R&D 100 Award and achieve a patent for the HT-UPS steel.14 The plot shows the American Society of Mechanical Engineers (ASME) allowable stresses for 347H, modified 310, NF709 and the HT-UPS steels, and clearly the HT-UPS steel is significantly stronger. HT-UPS steel was designed using specific rules to control precipitation, including the (1) reactant effects, (2) catalytic effects, (3) inhibitor effects and (4) interference effects.1 , 2 In the cold-worked condition, the HT-UPS steel had nanodispersions of complex MC carbides that were incredibly stable to dissolution or coarsening for creep strength and no formation of detrimental intermetallic compounds such as Laves and sigma phases for long-term creep resistance (Figs. 2 and 3). Figure 2 shows the robust nano-MC with the bright field image of analytical electron microscopy (AEM) of the phase particle composition after 18,000 h at 700°C, and Fig. 3 shows no intermetallics or even creep voids after > 60,000 h at 700°C.

(Reprinted from Ref. 11)

A plot of the ASME allowable stress (67% of the average strength needed for 100,000 h creep life) versus creep temperature for the HT-UPS steel and 347H, 310CbN and NF709 and the corresponding boiler tubing. Note that the weakest tube made from 347H stainless steel has a larger wall thickness than the other tubes, which exhibit higher creep strength.11

(Reprinted from Ref. 12)

A TEM bright field image of HT-UPS stainless steel mill-annealed commercial tubing (AX-8) after creep rupture testing at 700°C and 170 MPa to 18,000 h showing the fine, stable nanostructure of MC carbides and FeTiP needles. AEM on carbon extraction replicas shows the MC carbides to be a complex Ti, V and Nb-rich phase.12

Therefore, the engineered microstructure design for the HT-UPS steel relies on several different creep-related microstructural mechanisms: (1) the formation of nanoscale dispersions of precipitates during creep to effectively pin dislocations against climb/glide, (2) the stability of the nanoscale dispersions to dissolution or coarsening during creep, (3) the resistance to creep-void formation, (4) the resistance of the alloy to the formation of embrittling intermetallic phases such as Laves or sigma, and (5) for wrought materials such as HT-UPS steel the resistance to recovery or recrystallization.

Commercial heats of HT-UPS tubing were made by AMEX and by Combustion Engineering (now Alstom/GE), and it was found to exhibit optimum creep behavior tubes needing to be solution annealed for 1 h at 1150–1200°C and then “mill annealed,” which produces 5–15% cold work (CW). The HT-UPS steels had only 14 Cr, so they had oxidation problems at 750–800°C or above and had to be clad with a higher Cr alloy, as shown in Fig. 1 with alloy 671. Lessons learned were applied to the next generations of ORNL-modified austenitic stainless steels.

Alloy Development Results—Cast CF8C-Plus Steels

In 1998, ORNL formed a Cooperative Research and Development Agreement (CRADA) project with Caterpillar, Inc., and Solar Turbines (a Caterpillar Company) to develop a cost-effective improved version of standard CF8C cast austenitic stainless steel, and in 1999, they jointly developed CF8C-Plus stainless steel with added Mn and N. Caterpillar needed a more heat-resistant alloy to use for diesel exhaust components (manifolds, turbochargers, Fig. 4) than SiMo cast iron that could operate at 750–800°C, while Solar Turbines needed a material better than CF8C for the end-cover of the engine (Fig. 4) for its Mercury 50 gas turbine engine. In 2001, ORNL had developed laboratory heats, and then Caterpillar produced commercial heats of CF8C-Plus, which showed outstanding creep-rupture resistance at 850°C and 35 MPa and excellent tensile, creep and fatigue resistance at 600–900°C, and won the R&D 100 Award in 2003.6 The Mn addition gives CF8C-Plus good metal fluidity and castability, and the cast steel is used as-cast, with no additional heat treatments necessary.

(a) An actual photo of a Caterpillar C-15 heavy-duty 14.6 L on-highway diesel engine and (b) the conceptual drawing of a Solar Turbines 4.6 MW Mercury 50 recuperated low NOx gas turbine engine. The diesel engine would use CF8C-Plus steel for the exhaust manifold and turbocharger components, while the gas turbine engine would use CF8C-Plus for the end-cover component

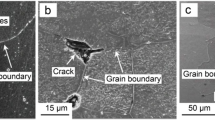

The excellent creep-rupture resistance of the CF8C-Plus steel is shown in Figs. 5 and 6, and the extraordinary microstructure that imparts these properties is shown in Fig. 7. Extremely fine and dense distributions of Nb-rich MC carbides and M2N nitrides that remain stable for very long times are the basis for the excellent creep properties of CF8C-Plus steel (Fig. 7). The microstructures in Fig. 7 correlate directly with the creep strain curves in Fig. 5. The durability of the nanoscale microstructure is remarkable, and the difference between the CF8C-Plus steel and the standard CF8C steel is dramatic.

The CF8C-Plus also forms no sigma phase at 700–850°C, while the CF8C steel does form sigma phase readily from the delta ferrite in the latter, while the CF8C-Plus has no delta ferrite and is 100% austenitic. Creep rupture data for CF8C-Plus steel are given in Figs. 6 and 8 and compared to cast irons and CF8C steel and to various solid-solution Ni-based superalloys, respectively. CF8C-Plus steel is orders of magnitude stronger than cast irons such as SiMo cast iron and Ni-resist (D5S) cast iron and is twice as strong as standard CF8C steel (Fig. 6). When compared with solid-solution Ni-based superalloys, CF8C-Plus steel has creep strength comparable to alloys such as 625, 617 and 230 that are 5–7 times more expensive.15,16,17

A plot of creep stress versus the Larson-Miller parameter for cast CF8C-Plus and a variety of solid-solution Ni-based superalloys. The creep strengths of these alloys are similar17

There have been several commercial applications of CF8C-Plus steel. One of the first large cast component trials for the CF8C-Plus steel in 2005 was centrifugally casting the end cover for the Solar Turbines Mercury 50 gas turbine engine (6700 lbs) (Fig. 9 top). This component was cut up and inspected for casting defects and cracks, and none were found. The mechanical properties including creep rupture fell in line with other property studies of this material.15,16,17 In 2011, two more end cover components were centrifugally cast, and one was installed on a Mercury 50 gas turbine engine that was deployed to the 29 Palms Marine Base in California in 2013.18 The gas turbine engine is running well to date. Another much larger commercial application was the Caterpillar Regeneration System (CRS) burner housings that were investment cast by IMPRO in China (Fig. 10) beginning in the fall of 2006. The CRS units cleaned the ceramic diesel particulate filters (DPF) that were downstream in the exhaust gas path. The CRS units experienced very severe thermal cycling as diesel fuel was added to the turbocharger outlet gas, heated up to 900°C for 20 min and then cooled. The CRS units were deployed on every heavy-duty on-highway diesel engine produced by Caterpillar from 2006 to 2011; 550 tons of steel was used to make the CRS units, and at a unit weight of 25–29 lb, about 45,000 CRS units were made. All of them are still in the field with no failures. This successful commercialization of CF8C-Plus cast steel for the CRS application won a Federal Laboratory Consortium Award for Excellence in Technology Transfer for ORNL and Caterpillar in 2009.

(Reprinted from Ref. 18)

A Mercury 50 gas turbine engine end cover (6700 lb) cast in 2005 by MetalTek International for Solar Turbines and sent to the Caterpillar Technical Center for destructive analysis and then a second end cover cast for deployment on a Mercury 50 gas turbine in 2011 and installation (29 Palms Marine Base in California) in 2013, which has operated successfully since 2014.18

A photograph of CRS housing made of CF8C-Plus attached to the turbocharger of a Caterpillar C-15 heavy-duty diesel engine to regenerate the ceramic diesel particulate filter (DPF). Deployed on all on-highway diesel engines from the fall of 2006 to the end of 2011, these housings see severe thermal cycling with a 20-min burn cycle at about 900°C. Over 550 tons of steel was used to produce about 45,000 units, all of which are still in service and none of which have failed16 , 17

Development of Aluminum-Modified CF8C-Plus Steel

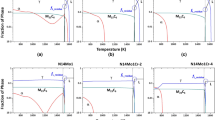

Wrought aluminum forming austenitic (AFA) alloys were developed at ORNL in 2006, based on the matrix composition of the HT-UPS steels described earlier19,20,21 (Table II). The AFA alloys won an R&D 100 Award in 2009. Recently, cast AFA alloys (CAFA) have been developed.22 , 23 These AFA alloys were initially based on Fe-25Ni-(14-15)Cr alloys for operation around 700–850°C, with Hf and Y additions also needed for long-term operation in the 900°C range. All AFA alloys have an upper temperature limit to their oxidation and protective alumina scale formation because of the need to balance mechanical properties and austenite stability with oxidation resistance.24 Cast AFA alloys capable of 1100°C operation have also been identified, although they are based on Fe-35Ni-25Cr alloys with Hf and Y additions, which increase alloy costs.24 Fe-25Ni-18Cr alloys based on wrought AFA compositions have also been reported.25 In 2015, aluminum-modified CF8C-Plus alloys were pursued and developed at ORNL that have a different chemistry, including lower Ni and higher Cr, W, Cu and C levels than the previous wrought AFA and CAFA alloys and were intended to be more cost-effective and have higher creep strength and oxidation resistance at 950–1000°C for automotive exhaust component (manifold and turbocharger) applications (Table II).

The CF8C-Plus steel has reasonable oxidation resistance in dry air at 800°C, but has poor oxidation resistance in air + 10% water vapor at 800°C and higher, so an alloy with more oxidation resistance with added aluminum to form a protective Al2O3 oxide scale was needed for higher temperature applications, particularly exhaust environments with moisture. The Al-mod. CF8C-Plus base alloy (PJMAl-2) is a 20Cr-20Ni alloy with added Mn for metal fluidity, Si for oxidation resistance, Nb and W for carbide stability and strengthening, Cu for austenite stability, C for austenite stability and carbide strengthening, and 3.5Al for alumina scale formation and oxidation resistance (Fig. 11).

Small heats of all the PJMAl2 alloys (Table II) were cast as small ingots in the ORNL arc melter, and one of the heats (PJMAl2 base) was cast as a larger heat by the University of Missouri-Rolla facilities to generate oxidation and mechanical properties data.

Oxidation data with 1-h cycles in air + 10% water vapor at 950°C and 900°C are shown in Fig. 12. In both cases, the Al-mod. CF8C-Plus with the base PJMAl2 (3.5% Al) or PJMAl2.33 (4.0% Al) shows excellent behavior, better than exhaust alloys based on chromia formation or other CAFA alloys. Preliminary oxidation testing at 1000°C shows good oxidation resistance of the PJMAl2 alloy as well. This oxidation resistance compares well with Ni-based alloys that contain Al, but costs 5–9 times more. The tensile properties of the Al-mod. CF8C-Plus alloys are shown in Fig. 13 [yield strength (YS) and total elongation (TE)], and clearly the Al-mod CF8C-Plus steels have more strength than the standard CF8C-Plus steel and 10% or more TE over the temperature ranges of interest. The YS at 700–800°C compares well with that of the solid-solution Ni-based alloy 617, and preliminary creep data show that the rupture life of the Al-mod. CF8C-Plus steel is 2–3 times more than standard CF8C-Plus steel at 850–950°C (Fig. 14).

Plots of yield strength (YS) and total elongation (TE) as functions of tensile test temperature for two specimens from a 2-lb ingot made at ORNL of PJM-Al2 and many specimens of PJM-Al2 from > 100 melt made by the University of Missouri-Rolla. Standard CF8C-Plus steel is included for comparison. All specimens are in the as-cast condition without any additional heat treatment

Currently, ORNL is scaling up heats PJM-Al2 and PJM-Al2.33 at MetalTek International to produce about 500-lb heats to make keel bars for tensile/creep/fatigue testing, weld plates for welding tests and molds to test the metal fluidity to measure the castability for future component trials. Applications for the Al-modified CF8C-Plus should include (but are not limited to) automotive and diesel exhaust components, including exhaust manifolds and turbocharger components, gas-turbine components, including turbine end covers and other exhaust hot-gas path pieces, fuel cell balance of plant and heat exchanger cover components, A-USC steam turbine parts, including turbine casing and steam valve components, and heat-recovery steam generators for combine cycle gas/steam turbine systems. External, protective alumina scale formation should be beneficial for resistance to carburizing, coking and metal dusting environments including chemical and petrochemical tubing and piping, as well as supercritical CO2 turbine systems.

Summary

A methodology exists that enables one to design alloys with significantly improved heat resistance and long-term durability by carefully engineering the microstructure so that the stainless steels and alloys can successfully perform in various extreme environments. The rules that govern precipitation behavior in the alloy matrix include (1) reactant effects, (2) catalytic effects, (3) inhibitor effects and (d) interference effects of the various alloying element additions. These in turn produce an alloy matrix with (1) nanoscale precipitation of carbide and/or nitride phases, (2) robust nanodispersions that are resistant to dissolution or coarsening, (3) resistance to embrittling intermetallic phases such as sigma, chi and Laves, (4) resistance to radiation-induced or thermal creep voids and (5) for wrought materials, resistance to recovery or recrystallization. This engineered microstructure method produced the 14Cr-16Ni HT-UPS steel with creep strength equivalent to Ni-based superalloy 617 at 600–800°C because of triply stabilized MC carbides, but lacked oxidation resistance at those temperatures. It also produced the CF8C-Plus cast austenitic stainless steel modified with Mn and N to produce a matrix resistant to the adverse effects of aging and creep strength at 600–900°C similar to superalloys 617 and 230 because of nanodispersions of Nb-rich MC carbides and M2N nitrides. However, CF8C-Plus lacked moisture-enhanced oxidation resistance at 800°C and above. Finally, recent application of the engineered microstructure method produced the 20Cr-20Ni aluminum-modified CF8C-Plus cast steels with more creep strength and outstanding oxidation resistance in air plus moisture at 900–950°C and above. Alloy design of cost-effective stainless steels has transformed steels that usually cannot perform in extreme environments into materials with performance and durability that cannot fail.

Notice of Copyright

This manuscript has been authored by UT-Battelle, LLC, under Contract No. DE-AC05-00OR22725 with the US Department of Energy. The United States Government retains and the publisher, by accepting the article for publication, acknowledges that the United States Government retains a non-exclusive, paid-up, irrevocable, worldwide license to publish or reproduce the published form of this manuscript, or allow others to do so, for United States Government purposes. The Department of Energy will provide public access to these results of federally sponsored research in accordance with the DOE Public Access Plan (http://energy.gov/downloads/doe-public-access-plan).

References

P.J. Maziasz, JOM 41, 14 (1989).

P.J. Maziasz, R.L. Klueh, and A.F. Rowcliffe, MRS Bull. XIV, 36 (1989).

P.J. Maziasz and J.T. Busby, Compr. Nucl. Mater. 2, 267 (2012).

P.J. Maziasz, J. Nucl. Mater. 205, 118 (1993).

P.J. Maziasz, J. Nucl. Mater. 200, 90 (1993).

P.J. Maziasz and M.P. Pollard, Adv. Mater. Process. 116, 57 (2003).

P.J. Maziasz, J. Nucl. Mater. 108&109, 359 (1982).

P.J. Maziasz and D.N. Braski, J. Nucl. Mater. 141–143, 973 (1986).

B.J. Makenas, Radiation-Induced Changes in Microstructure: 13th Internat. Symp. (Part I), ASTP-STP-955 (ASTM: Philadelphia, PA, 1987), p. 146.

P.J. Maziasz, MiCon 86: Optimization of Processing, Properties and Service Performance Through Microstructural Control, ASTM STP 979 (Philadelphia, PA: ASTM, 1988), p. 116.

P.J. Maziasz and R.W. Swindeman, Proceedings International Conference on Technology and Technology Exchange—Appendix A (International Technology Exchange, Pittsburgh, PA, 1990).

R.W. Swindeman and P.J. Maziasz, Creep: Characterization, Damage, and Life Assessment (Materials Park, OH: ASM-International, 1992).

R.W. Swindeman and P.J. Maziasz, Pressure Vessel Technology (7-ICPVT) (Vereine e V Essen: Verband der Technischen Uberwachungs, 1992).

P.J. Maziasz, D.N. Braski, and A.F. Rowcliffe, US Patent 4,818,485 (April 1989).

P.J. Maziasz, J.P. Shingledecker, N.D. Evans, and M.J. Pollard, J. Press. Vessel Technol. 131, 051404-1 (2009).

J.P. Shingledecker, P.J. Maziasz, N.D. Evans, and M.J. Pollard, Int. J. Press. Vessels Pip. 84, 21 (2007).

P.J. Maziasz and B.A. Pint, J. Eng. Gas Turbines Power 133, 092102-1 (2011).

B.A. Pint, Deployment of CF8C-Plus Cast Stainless Steels, ORNL TM-2013, 277, Oak Ridge National Laboratory Report, Oak Ridge, TN (2013).

Y. Yamamoto, M.P. Brady, Z.P. Lu, P.J. Maziasz, C.T. Liu, B.A. Pint, K.L. More, H.M. Meyer, and E.A. Pyzant, Science 316, 433 (2007).

Y. Yamamoto, M.P. Brady, Z.P. Lu, C.T. Liu, M. Takeyama, P.J. Maziasz, and P.A. Pint, Metall. Mater. Trans. A 38A, 2737 (2007).

Y. Yamamoto, M.P. Brady, M.L. Santella, H. Bei, P.J. Maziasz, and B.A. Pint, Metall. Mater. Trans. A 42A, 922 (2011).

G. Muralidharan, Y. Yamamoto, M.P. Brady, B.A. Pint, D. Voke, and R.I. Pankiw, Corrosion 2015, Paper 6114 (Houston, TX: NACE International, 2015).

G. Muralidharan, Y. Yamamoto, M.P. Brady, L.R. Walker, H.M. Meyer III, and D.N. Leonard, JOM 68, 2803 (2016).

M.P. Brady, G. Muralidharan, D.N. Leonard, J.A. Haynes, R.G. Weldon, and R.D. England, Oxid. Met. 82, 359 (2014).

X. Xu, X. Zhang, G. Chen, and Z. Lu, Mater. Lett. 65, 3285 (2011).

Acknowledgements

Thanks to Dr. Bruce Pint at ORNL for being a co-inventor of the Al-mod. CF8C-Plus steels and for generating the oxidation data at ORNL. Thanks to Christopher Stevens and Jeremy Moser at ORNL for tensile and creep testing of the CF8C-Plus and Al-modified CF8C steels. Thanks to Dr. Yukinori Yamamoto and Dr. Michael Brady at ORNL for reviewing the manuscript. Thanks to the US DOE Office of Energy Efficiency and Renewable Energy, Vehicle Technologies Office, Propulsion Materials Program and the ORNL Technology Transfer and Maturation Funds for funding this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Maziasz, P.J. Development of Creep-Resistant and Oxidation-Resistant Austenitic Stainless Steels for High Temperature Applications. JOM 70, 66–75 (2018). https://doi.org/10.1007/s11837-017-2642-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-017-2642-x