Abstract

Heat-resistant ferritic stainless steels are widely used in many high-temperature applications such as power plants, automotive exhaust manifolds and solid oxide fuel cell interconnects due to their low price, low coefficient of thermal expansion, high thermal conductivity, high thermal fatigue resistance, high creep performance and excellent corrosion resistance. High-temperature strength, formability, high-temperature oxidation resistance and creep performance are the main evaluation criteria for the application. With the development of relevant industries, higher requirements are proposed for the performance of ferritic stainless steels. Therefore, the development of a new generation of heat-resistant ferritic stainless steel has received extensive attention. In this presentation, we summarized the research progress of heat-resistant ferritic stainless steels including high-temperature strength, formability, high-temperature oxidation resistance and creep performance. Meanwhile, some suggestions are given for alloy composition design and microstructure optimization. The future research direction of heat-resistant ferritic stainless steels also prospected.

Reproduced with permission from Ref. [20]. Copyright 2020 Elsevier

Reproduced with permission from Ref. [25]. Copyright 1996 Elsevier

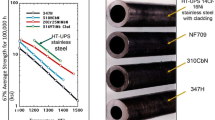

Reproduced with permission from Ref. [10]. Copyright 2003 Elsevier

Reproduced with permission from Ref. [10]. Copyright 2003 Elsevier

Reproduced with permission from Ref. [20]. Copyright 2020 Elsevier

Reproduced with permission from Ref. [11]. Copyright 2012 Elsevier

Reproduced with permission from Ref. [42]. Copyright 2013 Elsevier

Reproduced with permission from Ref. [16]. Copyright 2020 Springer Nature

Reproduced with permission from Ref. [74]. Copyright 2018 Elsevier

Reproduced with permission from Ref. [74]. Copyright 2018 Elsevier

Reproduced with permission from Ref. [79]. Copyright 2007 Elsevier

Reproduced with permission from Ref. [87]. Copyright 2011 Elsevier

Similar content being viewed by others

References

Gao F, Liu ZY, Liu HT, Wang GD. Evolution of through-thickness texture in ultra-purified 17%Cr ferritic stainless steels. J Iron Steel Res Int. 2013;20(4):31.

Zhang X, Fan LJ, Xu YL, Li J, Xiao XH, Jiang LZ. Texture, microstructure and mechanical properties of aluminum modified ultra-pure 429 ferritic stainless steels. Mater Des. 2013;89:626.

Lu HH, Guo HK, Liang W, Li JC, Zhang GW, Li TT. High-temperature Laves precipitation and its effects on recrystallisation behaviour and Lüders deformation in super ferritic stainless steels. Mater Charact. 2020;188:108477.

Liu HL, Ma MY, Liu LL, Wei LL, Chen LQ. Effect of hot band annealing processes on texture and formability of 19Cr2Mo1W ferritic stainless steel. Acta Metall Sin. 2019;55(5):566 (in Chinese).

Ma MY, He CL, Chen LQ, Wei LL, Misra RDK. Effect of W and Ce additions on the electrochemical corrosion behaviour of 444-type ferritic stainless steel. Corros Eng Sci Tech. 2018;53(3):199.

Fu JW, Li F, Sun JJ, Wu YC. Texture, orientation, and mechanical properties of Ti-stabilized Fe-17Cr ferritic stainless steel. Mater Sci Eng A. 2018;738:335.

Khorrami MS, Mostafaei MA, Pouraliakbar H, Kokabi AH. Study on microstructure and mechanical characteristics of low-carbon steel and ferritic stainless steel joints. Mater Sci Eng A. 2014;608:35.

Bai Y, He T, Liu Y. Effects of Sn microalloying on cold rolling and recrystallization textures and microstructure of a ferritic stainless steel. Mater Charact. 2018;137:142.

Wei LL, Zheng JH, Chen LQ, Misra RDK. High temperature oxidation behavior of ferritic stainless steel containing W and Ce. Corros Sci. 2018;142:79.

Fujita N, Ohmura K, Yamamoto A. Changes of microstructures and high temperature properties during high temperature service of Niobium added ferritic stainless steels. Mater Sci Eng A. 2003;351(1–2):272.

Chiu YT, Lin CK. Effects of Nb and W additions on high-temperature creep properties of ferritic stainless steels for solid oxide fuel cell interconnect. J Power Sources. 2012;198:149.

Froitzheim J, Meier GH, Niewolak L, Ennis PJ, Hattendorf H, Singheiser L, Quadakkers WJ. Development of high strength ferritic steel for interconnect application in SOFCs. J Power Sources. 2008;178(1):163.

Kuhn B, Asensio Jimenez C, Niewolak L, Hüttel T, Beck T, Hattendorf H, Singheiser L, Quadakkersa WJ. Effect of Laves phase strengthening on the mechanical properties of high Cr ferritic steels for solid oxide fuel cell interconnect application. Mater Sci Eng A. 2011;528(18):5888.

N’Dah E, Tsipas S, Hierro MP, Pérez FJ. Study of the cyclic oxidation resistance of Al coated ferritic steels with 9 and 12%Cr. Corros Sci. 2007;49(10):3850.

Han J, Li H, Zhu Z, Jiang L, Xu H, Ma L. Effects of processing optimisation on microstructure, texture, grain boundary and mechanical properties of Fe–17Cr ferritic stainless steel thick plates. Mater Sci Eng A. 2014;616:20.

Wei LL, Chen LQ, Liu HL, Han LQ, Gong N, Misra RDK. Precipitation behavior of Laves phase in the vicinity of oxide film of ferritic stainless steel: selective oxidation-induced precipitation. Oxid Met. 2020;93(1–2):195.

Tetsui T, Shindo K, Kobayashi S, Takeyama M. Strengthening a high-strength TiAl alloy by hot-forging. Intermetallic. 2003;11(4):299.

Bhowmik S, McWilliams BA, Knezevic M. Effect of powder reuse on tensile, compressive, and creep strength of Inconel 718 fabricated via laser powder bed fusion. Mater Charact. 2022;190:112023.

Guo R, Liu B, Xu R, Cao Y, Qiu J, Chen F, Yan Z, Liu Y. Microstructure and mechanical properties of powder metallurgy high temperature titanium alloy with high Si content. Mater Sci Eng A. 2020;777:138993.

Liu H, Wei L, Ma M, Zheng J, Chen L, Misra RDK. Laves phase precipitation behavior and high-temperature strength of W-containing ferritic stainless steels. J Mater Res Technol. 2020;9(2):2127.

Wang J, Zhang Y, Ma J, Li J, Zhang Z. Microcrack nucleation and propagation investigation of Inconel 740H alloy under in situ high temperature tensile test. Acta Metall Sin. 2017;53(12):1627.

Juuti T, Rovatti L, Porter D, Angella G, Kömi J. Factors controlling ambient and high temperature yield strength of ferritic stainless steel susceptible to intermetallic phase formation. Mater Sci Eng A. 2018;726:45.

Zhang Y. Numerical study of creep behavior of P91 steel at elevated temperature. Northwest Univ. 2019;48:446 ((in Chinese)).

Masuyama F. History of power plants and progress in heat resistant steels. ISIJ Int. 2001;41(6):612.

Fujita N, Ohmura K, Kikuchi M, Suzuki T, Funaki S, Hiroshige I. Effect of Nb on high-temperature properties for ferritic stainless steel. Scripta Mater. 1996;35(6):705.

Miyazaki A, Takao K, Furukimi O. Effect of Nb on the proof strength of ferritic stainless steels at elevated temperatures. ISIJ Int. 2002;42(8):916.

Sim GM, Ahn JC, Hong SC, Lee KJ, Lee KS. Effect of Nb precipitate coarsening on the high temperature strength in Nb containing ferritic stainless steels. Mater Sci Eng A. 2005;396(1–2):159.

Nabiran N, Klein S, Weber S, Theisen W. Evolution of the Laves phase in ferritic heat-resistant steels during long-term annealing and its influence on the high-temperature strength. Metall Mater Trans A. 2014;46(1):102.

Miyazaki A, Hirasawa J, Furukimi O. Ferritic stainless steel for automotive exhaust systems–High heat-resistant ferritic stainless steel with high formability for automotive exhaust manifolds: “JFE-MH1.” JFE Technical Report. 2004;4:61.

Miyazaki A, Gunzi M, Yoshioka K. High formability R429EX and heat-resistant R444EX stainless steels for automotive exhaust manifold. Kawasaki Steel Technical Report. 1994;31:21.

Liu T, Chen L, Bi H, Che X. Effect of Mo on high-temperature fatigue behavior of 15CrNbTi ferritic stainless steel. Acta Metall Sin (EngL Lett). 2017;27(3):452.

Abe F. Creep rates and strengthening mechanisms in tungsten-strengthened 9Cr steels. Mater Sci Eng A. 2001;319–321:770.

Yazawa Y, Ozaki Y, Kato Y, Furukimi O. Development of ferritic stainless steel sheets with excellent deep drawability by {111} recrystallization texture control. JASE Rev. 2003;24(4):483.

Yan H, Bi H, Lin X, Xu Z. Microstructure, texture and grain boundaries character distribution evolution of ferritic stainless steel during rolling process. J Mater Process Tech. 2009;209(5):2627.

Hamada JI, Ono N, Inoue H. Effect of texture on r-value of ferritic stainless steel sheets. ISIJ Int. 2011;51(10):1740.

Yazawa Y, Kato Y, Kobayashi M. Development of Ti-bearing high performance ferritic stainless steels R430XT and RSX-1. Kawasaki Steel Technical Report. 1999;40:23.

Fu J, Cui K, Li F, Wang J, Wu Y. Texture and anisotropic mechanical properties of ferritic stainless steel stabilized with Ti and Nb. Mater Charact. 2020;159:110027.

Kang Y, Mao WM, Chen YJ, Jing J, Cheng M. Effect of Ti content on grain size and mechanical properties of UNS S44100 ferritic stainless steel. Mater Sci Eng A. 2016;677:211.

Du W, Jiang LZ, Sun QS, Liu ZY, Zhang X. Microstructure, texture, and formability of Nb+Ti stabilized high purity ferritic stainless steel. J Iron Steel Res Int. 2010;17(6):47.

Zhang C, Liu Z, Wang G. Effects of hot rolled shear bands on formability and surface ridging of an ultra purified 21%Cr ferritic stainless steel. J Mater Process Tech. 2011;211(6):1051.

Liu HL, Liu LL, Ma MY, Chen LQ. Influence of finish rolling temperature on microstructure and mechanical properties of a 19Cr1.5Mo0.5W ferritic stainless steel. Acta Metall Sin (EngL Lett). 2020;33(7):991.

Gao F, Liu Z, Liu H, Wang G. Texture evolution and formability under different hot rolling conditions in ultra purified 17%Cr ferritic stainless steels. Mater Charact. 2013;75:93.

Davison RM. Formability of low-interstitial 18 Pct Cr-2 Pct Mo ferritic stainless steel. Metall Mater Trans B. 1974;5(11):2287.

Wang WT, Zhang J, Sui FL, Zhang ZX, Bi HY. A comparison of deformation, microstructure, mechanical properties and formability of SUS436L stainless steel in tandem and reversible cold rolling processes. J Iron Steel Res Int. 2019;26(5):442.

Shu J, Bi H, Li X, Xu Z. Effect of hot band annealing on forming limit diagrams of ultra-pure ferritic stainless steel. J Mater Eng Perform. 2014;23(3):982.

Bai Y, He T, Guo D, Liu XT, Shao FY, Liu YD. Texture evolution, formability and ridging resistance of a Sn-bearing ferritic stainless steel under different hot band annealing temperatures. Acta Metall Sin (EngL Lett). 2019;32(11):1362.

Čížek J, Janeček M, Krajňák T, Stráská J, Hruška P, Gubicza J, Kim HS. Structural characterization of ultrafine-grained interstitial-free steel prepared by severe plastic deformation. Acta Mater. 2016;105:258.

Ma X, Zhao J, Du W, Zhang X, Jiang L, Jiang Z. An analysis of ridging of ferritic stainless steel 430. Mater Sci Eng A. 2017;658:358.

Zhang C, Zhang LW, Liu ZY. Improvement of surface ridging resistance of an ultra-purified ferritic stainless steel by optimizing hot rolling condition. Acta Metall Sin (EngL Lett). 2016;29(6):561.

Shu J, Bi H, Li X, Xu Z. Effect of Ti addition on forming limit diagrams of Nb-bearing ferritic stainless steel. J Mater Process Tech. 2012;212(1):59.

Tanure L, de Alcântara CM, Santos DB, de Oliveira TR, Gonzalez BM, Verbeken K. Microstructural characterization and mechanical behavior during recrystallization annealing of Nb-stabilized type ASTM 430 and Nb-Ti-stabilized ASTM 439 ferritic stainless steels. J Mater Res Tech. 2019;8(5):4048.

Villafuerte JC, Pardo E, Kerr HW. The effect of alloy composition and welding conditions on columnar-equiaxed transitions in ferritic stainless steel gas-tungsten arc welds. Metall Trans A. 1990;21(7):2009.

Yazawa Y, Muraki M, Kato Y, Furukimi O. Effect of chromium content on relationship between r-value and 111 recrystallization texture in ferritic steel. ISIJ Int. 2003;43(10):1647.

Liu H, Zheng J, Ma M, Wei L, Chen L. Structure-mechanical property-formability relationships for 444-type W-containing ferritic stainless steels. J Mater Eng Perform. 2021;30(1):467.

Huh MY, Engler O. Effect of intermediate annealing on texture, formability and ridging of 17%Cr ferritic stainless steel sheet. Mater Sci Eng A. 2001;308(1–2):74.

Brady MP, Tortorelli PF. Alloy design of intermetallics for protective scale formation and for use as precursors for complex ceramic phase surfaces. Intermetallics. 2004;12(7–9):779.

Alnegren P, Sattari M, Froitzheim J, Svensson JE. Degradation of ferritic stainless steels under conditions used for solid oxide fuel cells and electrolyzers at varying oxygen pressures. Corros Sci. 2016;110:200.

Cheng X, Jiang Z, Wei D, Zhao J, Monaghan BJ, Longbottom RJ, Jiang L. Characteristics of oxide scale formed on ferritic stainless steels in simulated reheating atmosphere. Surf Coat Technol. 2015;258:257.

Galerie A, Henry S, Wouters Y, Mermoux M, Petit JP, Antoni L. Mechanisms of chromia scale failure during the course of 15–18Cr ferritic stainless steel oxidation in water vapour. Mater High Temp. 2005;22(1–2):105.

Chen X, Hou PY, Jacobson CP, Visco SJ, De Jonghe LC. Protective coating on stainless steel interconnect for SOFCs: oxidation kinetics and electrical properties. Solid State Ionics. 2005;176(5–6):425.

Inoue Y, Hiraide N, Hayashi A, Ushioda K. Effect of titanium on oxidation behavior of high-purity ferritic stainless steel. Mater Trans. 2019;60(9):1968.

Seo HS, Yun DW, Kim KY. Effect of Ti addition on the electric and ionic property of the oxide scale formed on the ferritic stainless steel for SOFC interconnect. Int J Hydrogen Energ. 2012;37(21):16151.

Xu Y, Zhang X, Fan L, Li J, Yu X, Xiao X, Jiang L. Improved oxidation resistance of 15 wt.% Cr ferritic stainless steels containing 008–2.45 wt.% Al at 1000 °C in air. Corros Sci. 2015;100:311.

Swaminathan S, Lee YS, Kim DI. Long term high temperature oxidation characteristics of La and Cu alloyed ferritic stainless steels for solid oxide fuel cell interconnects. J Power Sources. 2016;327:104.

Yun DW, Seo HS, Jun JH, Lee JM, Kim KY. Molybdenum effect on oxidation resistance and electric conduction of ferritic stainless steel for SOFC interconnect. Int J Hydrogen Energ. 2012;37(13):10328.

Shu J, Bi H, Li X, Xu Z. The effects of molybdenum addition on high temperature oxidation behavior at 1000 °C of type 444 ferritic stainless steel. Oxid Met. 2012;78(3–4):253.

Safikhani A, Esmailian M, Tinatiseresht T, Darband GB. High temperature cyclic oxidation behavior of ferritic stainless steel with addition of alloying elements Nb and Ti for use in SOFCs interconnect. Int J Hydrogen Energ. 2016;41(14):6045.

Ali-Löytty H, Hannula M, Juuti T, Niu Y, Zakharov AA, Valden M. The role of (FeCrSi)2(MoNb)-type Laves phase on the formation of Mn-rich protective oxide scale on ferritic stainless steel. Corros Sci. 2018;132:214.

Pint BA. Experimental observations in support of the dynamic-segregation theory to explain the reactive-element effect. Oxid Met. 1996;45(1–2):1–37.

Cheng X, Jiang Z, Monaghan BJ, Wei D, Longbottom RJ, Zhao J, Peng J, Luo M, Ma L, Luo S, Jiang L. Breakaway oxidation behaviour of ferritic stainless steels at 1150 °C in humid air. Corros Sci. 2016;108:11.

Gindorf C, Singheiser L, Hilpert K. Vaporisation of chromia in humid air. J Phys Chem Solids. 2005;66(2–4):384.

Yoon YS, Lee J, Hwang HJ, Whang CM, Moon JW, Kim DH. Lanthanum oxide-coated stainless steel for bipolar plates in solid oxide fuel cells (SOFCs). J Power Sources. 2008;181(2):281.

Yang Z, Xia GG, Li XH, Stevenson JW. (Mn, Co)3O4 spinel coatings on ferritic stainless steels for SOFC interconnect applications. Int J Hydrogen Energ. 2007;32(16):3648.

Wei LL, Chen LQ, Ma MY, Liu HL, Misra RDK. Oxidation behavior of ferritic stainless steels in simulated automotive exhaust gas containing 5 vol.% water vapor. Mater Chem Phys. 2018;205:508.

Holzer I, Kozeschnik E, Cerjak H. New approach to predict the long-term creep behaviour and evolution of precipitate back-stress of 9–12% chromium steels. Trans Indian Inst Met. 2010;63:137.

Paul VT, Saroja S, Vijayalakshmi M. Microstructural stability of modified 9Cr–1Mo steel during long term exposures at elevated temperatures. J Nucl Mater. 2008;378(3):273.

Wang H, Yan W, van Zwaag S, Shi Q, Wang W, Yang K, Shan Y. On the 650 °C thermostability of 9–12Cr heat resistant steels containing different precipitates. Acta Mater. 2017;134(1):143.

Abe F. Precipitate design for creep strengthening of 9% Cr tempered martensitic steel for ultra-supercritical power plants. Sci Technol Adv Mater. 2008;9(1):013002.

Abe F, Taneike M, Sawada K. Alloy design of creep resistant 9Cr steel using a dispersion of nano-sized carbonitrides. Int J Pres Ves Pip. 2007;84(1–2):3.

Abe F, Nakazawa S. The effect of tungsten on creep behavior of tempered martensitic 9Cr steel. Metall Mater Trans A. 1992;23(11):3025.

Lee KH, Suh JY, Hong SM, Huh JY, Jung WS. Microstructural evolution and creep-rupture life estimation of high-Cr martensitic heat-resistant steels. Mater Charact. 2015;106:266.

Pešička J, Aghajani A, Somsen C, Hartmaier A, Eggeler G. How dislocation substructures evolve during long-term creep of a 12% Cr tempered martensitic ferritic steel. Scr Mater. 2010;62(6):353.

Varin RA, Haftek J. Structural changes in a ferritic heat-resistant steel after long-term service. Mater Sci Eng. 1984;62(1):129.

Pöpperlová J, Fan X, Kuhn B, Bleck W, Krupp U. Impact of tungsten on thermomechanically induced precipitation of Laves phase in high performance ferritic (HiperFer) stainless steels. Appl Sci. 2020;10(13):4472.

Toda Y, Tohyama H, Kushima H, Kimura K, Abe F. Improvement in creep strength of precipitation strengthened 15Cr ferritic steel by controlling carbon and nitrogen contents. JSME Int J. 2005;48(1):35.

Toda Y, Seki K, Kimura K, Abe F. Effect of W and Co on long-term creep strength of precipitation strengthened 15Cr ferritic heat resistant steels. ISIJ Int J. 2003;43(1):112.

Shibuya M, Toda Y, Sawada K, Kushima H, Kimura K. Effect of nickel and cobalt addition on the precipitation-strength of 15Cr ferritic steels. Mater Sci Eng A. 2011;528:5387.

Toda Y, Tohyama H, Kushima H, Kimura K, Abe F. Influence of chemical composition and heat treatment condition on impact toughness of 15Cr ferritic creep resistant steel. JSME Int J. 2005;48(3):125.

Kuhn B, Talik M, Niewolak L, Zurek J, Hattendorf H, Ennis PJ, Quadakkers WJ, Beck T, Singheiser L. Development of high chromium ferritic steels strengthened by intermetallic phases. Mater Sci Eng A. 2014;594:372.

Fan X, Kuhn B, Pöpperlová J, Bleck W, Krupp U. Compositional optimization of high-performance ferritic (HiperFer) steels—Effect of niobium and tungsten content. Metals. 2020;10(10):1300.

Pöpperlová J, Fan X, Kuhn B, Krupp U. Up-scaling of thermomechanically induced Laves phase precipitation in high performance ferritic (HiperFer) stainless steels. Materials. 2021;14(7):1635.

Kuhn B, Talik M, Fischer T, Fan X, Yamamoto Y, Barrilao JL. Science and technology of high performance ferritic (HiperFer) stainless steels. Metals. 2020;10(4):463.

Barrilao JL, Kuhn B, Wessel E. Microstructure evolution and dislocation behaviour in high chromium, fully ferritic steels strengthened by intermetallic Laves phases. Micron. 2018;108:11.

Acknowledgements

The authors gratefully acknowledge the joint financial support from the National Natural Science Foundation of China and Baowu Steel Group Co., Ltd. (Grant No. U1660205) as well as the financial support from the Fundamental Research Funds for the Central Universities (No. N2002024).

Author information

Authors and Affiliations

Contributions

YZ: wrote the draft, LC: contributed to conceived the idea of the study, HL and LW: collected the data. All authors contributed to the writing and revisions.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, Y., Liu, HL., Wei, LL. et al. An overview on the novel heat-resistant ferritic stainless steels. Tungsten 5, 467–480 (2023). https://doi.org/10.1007/s42864-022-00171-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42864-022-00171-4