Abstract

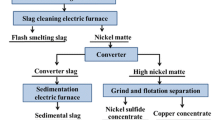

In this study, a new technique was proposed for the economical and environmentally friendly recovery of valuable metals from copper smelting slag while simultaneously upgrading nickel laterite through a co-reduction followed by wet magnetic separation process. Copper slag with a high FeO content can decrease the liquidus temperature of the SiO2-Al2O3-CaO-MgO system and facilitate formation of liquid phase in a co-reduction process with nickel laterite, which is beneficial for metallic particle growth. As a result, the recovery of Ni, Cu, and Fe was notably increased. A crude Fe-Ni-Cu alloy with 2.5% Ni, 1.1% Cu, and 87.9% Fe was produced, which can replace part of scrap steel, electrolytic copper, and nickel as the burden in the production of weathering steel by an electric arc furnace. The study further found that an appropriate proportion of copper slag and nickel laterite in the mixture is essential to enhance the reduction, acquire appropriate amounts of the liquid phase, and improve the growth of the metallic alloy grains. As a result, the liberation of alloy particles in the grinding process was effectively promoted and the metal recovery was increased significantly in the subsequent magnetic separation process.

Similar content being viewed by others

References

M. Morcillo, I. Díaz, B. Chico, H. Cano, and D. de la Fuente, Corros. Sci. 83, 6 (2014).

M. Morcillo, B. Chico, I. Díaz, H. Cano, and D. De la Fuente, Corros. Sci. 77, 6 (2013).

M. Sánchez and M. Sudbury, J. Min. Metall. B 49, 161 (2013).

B. Gorai, R.K. Jana, and Premchand, Resour. Conserv. Recy. 39, 299 (2003).

I. Muravyov, V. Fomchenko, V. Usoltsev, A. Vasilyev, and F. Kondrateva, Hydrometallurgy 119, 40 (2012).

S. Panda, S. Mishra, D.S. Rao, N. Pradhan, U. Mohapatra, S. Angadi, and B.K. Mishra, Korean J. Chem. Eng. 32, 667 (2015).

K. Mawejaa, T. Mukongob, and I. Mutomboc, J. Hazard. Mater. 164, 856 (2009).

A. Sarrafi, B. Rahmati, and H.R. Hassani, Miner. Eng. 17, 457 (2004).

Z.Q. Guo, D.Q. Zhu, J. Pan, and T.J. Wu, Metals 86, 6 (2016).

Z.Q. Guo, D.Q. Zhu, J. Pan, and F. Zhang, JOM 69, 2341 (2016).

X.L. Zhou, D.Q. Zhu, J. Pan, and T.J. Wu, Int. ISIJ 55, 1347 (2015).

B. Su Kim, S. Ki Jo, D. Shin, J.C. Lee, and S.B. Jeong, Int. J. Miner. Process. 43, 143 (2015).

R.R. Moskalyk and A.M. Alfantazi, Miner. Eng. 15, 593 (2002).

M. Jiang, T. Sun, Z. Liu, J.Liu. Kou, and N.S. Zhang, Int. J. Miner. Process. 32, 123 (2013).

M.J. Rao, G.H. Li, X. Zhang, J. Luo, Z.W. Peng, and T. Jiang, Separa. Sci. Technol. 51, 1727 (2016).

D.Q. Zhu, Y. Cui, K. Vining, S. Hapugoda, J. Douglas, J. Pan, and G.L. Zheng, Int. J. Miner. Process. 1, 106 (2012).

G.H. Li, T.M. Shi, M.J. Rao, T. Kiang, and Y.B. Zhang, Miner. Eng. 19, 32 (2012).

R.M. German, P. Suri, and S.J. Park, J. Mater. Sci. 39, 44 (2009).

H. Tsuji, ISIJ Int. 52, 1000 (2012).

Y. Kobayashi, H. Todoroki, and H. Tsuji, ISIJ Int. 35, 51 (2011).

J. Luo, G.H. Li, Z.W. Peng, M.J. Rao, Y.B. Zhang, and T. Jiang, JOM 68, 3015 (2016).

GB/T 219-2008, Determination of Fusibility of Coal Ash (National Standards of the People’s Republic of China, 2008); (in Chinese)

Acknowledgements

The authors wish to express their thanks to the National Key Technology R&D Program of China (No. 2013BAB03B04) for the financial support of this research and would like to thank the Co-Innovation Center for Clean and Efficient Utilization of Strategic Metal Mineral Resources of Hunan Province, which supplied us the facilities and funds to complete the experiments.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Guo, Z., Pan, J., Zhu, D. et al. Co-reduction of Copper Smelting Slag and Nickel Laterite to Prepare Fe-Ni-Cu Alloy for Weathering Steel. JOM 70, 150–154 (2018). https://doi.org/10.1007/s11837-017-2641-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-017-2641-y