Abstract

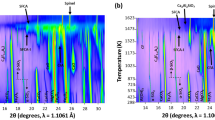

The correlations between phase evolution, fusion behavior, and Ni-Fe granules growth of laterite ore–CaO mixtures during reductive roasting have been investigated. The minimum melting point of 1220°C of the CaO-MgO-Al2O3-SiO2 system with 17–36 wt.% CaO is demonstrated via phase diagram analysis, and this point is decreased in the presence of FeO. This reveals that the fusion behavior in close association with the Fe-Ni granular growth can be regulated by altering the contents of CaO and FeO. Promoting the generation of diopside (CaMgSi2O6) may reduce the operating temperature from 1300–1350°C to 1150–1200°C, which ensures sufficient melting phase content. Moreover, reducing the CO partial fraction lowers the fusion temperature but hinders the growth of Ni-Fe grains. The average size of Ni-Fe granules in the reduced mixture with 17 wt.% CaO reaches nearly 20 μm at 1200°C for 1 h in a 100 vol.% CO atmosphere.

Similar content being viewed by others

References

U.S.G.S., Mineral commodity summaries 2016. doi:10.3133/70140094.

M. Rao, G. Li, T. Jiang, J. Luo, Y. Zhang, and X. Fan, JOM 65, 1573 (2013).

R.R. Moskalyk and A.M. Alfantazi, Miner. Eng. 15, 593 (2002).

Z. Peng and J.Y. Hwang, Int. Mater. Rev. 60, 30 (2015).

G. Li, T. Shi, M. Rao, T. Jiang, and Y. Zhang, Miner. Eng. 32, 19 (2012).

A. Bunjaku, M. Kekkonen, K.K. Pietilä, and P. Taskinen, Trans. Inst. Min. Metall. C 121, 155 (2012).

B. Li, H. Wang, and Y. Wei, Miner. Eng. 24, 1556 (2011).

T. Watanabe, S. Ono, H. Arai, and T. Matsumori, Int. J. Miner. Process. 19, 173 (1987).

S. Yamasaki, M. Noda, and N. Tachino, J. MMIJ 123, 689 (2007).

T. Matsumori, J. MMIJ 115, 448 (1999).

G. Tao, F. Xiao, and W. Jiang, Nonferr. Metal. (Ext. Met.) 8, 51 (2014).

H. Tsuji, ISIJ Int. 52, 1000 (2012).

Y. Kobayashi, H. Todoroki, and H. Tsuji, ISIJ Int. 51, 35 (2011).

H. Tsuji, ISIJ Int. 52, 333 (2012).

H. Tsuji and N. Tachino, ISIJ Int. 52, 1951 (2012).

H. Tsuji and N. Tachino, ISIJ Int. 52, 1724 (2012).

M. Valix and W.H. Cheung, Miner. Eng. 15, 607 (2002).

M.A. Rhamdhani, P.C. Hayes, and E. Jak, Trans. Inst. Min. Metall. C 118, 146 (2009).

I. Halikia, K. Skartados, and P. Neou-Syngouna, Trans. Inst. Min. Metall. C 111, 135 (2002).

E.N. Zevgolis, C. Zografidis, T. Perraki, and E. Devlin, J. Therm. Anal. Calorim. 100, 133 (2010).

M. Rao, G. Li, X. Zhang, J. Luo, Z. Peng, and T. Jiang, Sep. Sci. Technol. 51, 1408 (2016).

M. Rao, G. Li, X. Zhang, J. Luo, Z. Peng, and T. Jiang, Sep. Sci. Technol. 51, 1727 (2016).

G. Li, J. Luo, Z. Peng, Y. Zhang, M. Rao, and T. Jiang, ISIJ Int. 55, 1828 (2015).

J. Luo, G. Li, M. Rao, Y. Zhang, Z. Peng, Q. Zhi, and T. Jiang, JOM 67, 1966 (2015).

Acknowledgements

The authors wish to express their thanks to the National Natural Science Foundation of China (Nos. 51234008 and 51174230), the Co-Innovation Center for Clean and Efficient Utilization of Strategic Metal Mineral Resources and the Open-End Fund for the Valuable and Precision Instruments of Central South University for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Luo, J., Li, G., Peng, Z. et al. Phase Evolution and Ni-Fe Granular Growth of Saprolitic Laterite Ore–CaO Mixtures during Reductive Roasting. JOM 68, 3015–3021 (2016). https://doi.org/10.1007/s11837-016-2118-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-016-2118-4