Abstract

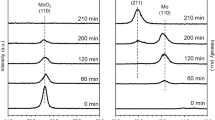

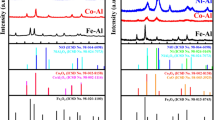

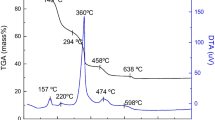

Methane and hydrogen reduction has emerged as promising technology for clean and efficient metallurgy. To understand the reduction process of MnO2 by CH4-H2 gas mixture, the effects of various CH4/(CH4 + H2) molar ratios (0–1) and temperatures (1100°C–1250°C) on the reduction of pure MnO2 were researched. Characterization of the solid carbon derived from the decomposition of CH4 gas was also determined. Thermodynamic analysis indicated that the MnO2 was first reduced to MnO by CH4-H2 gas mixture, and then MnO was reduced to Mn7C3 according to this reaction, 7MnO(s) + 10CH4(g) = Mn7C3(s) + 7CO(g) + 20H2(g). Experimental results showed that under the CH4/(CH4 + H2) molar ratio of 0.2, the reduction extent of MnO2 increased with the rising of temperatures. Nevertheless, the deep reduction of MnO to Mn7C3 was retarded even by increasing the temperature and prolonging the time, which was a result of the formation of deposited solid carbon. The free carbon contents in the reduced samples increased with the increasing of the CH4/(CH4 + H2) molar ratio and reduction time. The reduction of MnO2 and formation of carbon can be regulated by adjusting the CH4/(CH4 + H2) molar ratio in a gas mixture. For example, when MnO2 was reduced by 50 vol.%CH4-50%N2, large amounts of MnO and Mn7C3 particles were wrapped by the platelike and rodlike carbon with nanoscale. Yet, the wrapping phenomenon cannot be observed under 10 vol.%CH4-40 vol.%H2-50 vol.%N2.

Similar content being viewed by others

References

R.H. Eriç, Min. Proc. Ext. Met. Rev. 15, 191 (1995).

Z. Cai, Y. Feng, H. Li, X. Liu, and Z. Yang, JOM 64, 1296 (2012).

Y. Wu, B. Shi, W. Ge, C. Yan, and X. Yang, JOM 67, 361 (2015).

Y. Nasiri, M. Panjepour, and M. Ahmadian, Int. J. Miner. Process. 153, 17 (2016).

S. Hayashi and Y. Iguchi, ISIJ Int. 37, 345 (1997).

M.C. Altay and S. Eroglu, Int. J. Miner. Process. 149, 50 (2016).

S. Cetinkaya and S. Eroglu, Int. J. Miner. Process. 110–111, 71 (2012).

N. Anacleto and O. Ostrovski, Metall. Mater. Trans. B 35B, 609 (2004).

X. Li, G. Zhang, R. Tronstad, and O. Ostrovski, Metall. Mater. Trans. B 47B, 2197 (2016).

M. Ksiazek, M. Tangstad, H. Dalaker, and E. Ringdalen, Metall. Mater. Trans. E 1E, 272 (2014).

N. Anacleto, O. Ostrovski, and S. Ganguly, ISIJ Int. 44, 1615 (2004).

O. Ostrovski and G. Zhang, AIChE J. 52, 300 (2006).

B. Liu, Y. Zhang, Z. Su, G. Li, and T. Jiang, Powder Technol. 301, 102 (2016).

H. Zhang, Chemical Phase Analysis of Ores and Industrial Products (Beijing: Metallurgical Industry Press, 1992), pp. 74–76.

W.O. Touhey and J.C. Redmond, Anal. Chem. 20, 202 (1948).

W.C. Bowden, W.O. Toehey, and J.C. Redmond, Anal. Chem. 20, 989 (1948).

Acknowledgements

The authors wish to express their thanks to the Teachers’ Research Fund of Central South University (No. 2013JSJJ028) and the Doctorial Research Innovation Project of Hunan Province (No. CX2016B053).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Liu, B., Zhang, Y., Su, Z. et al. Thermodynamic Analysis and Reduction of MnO2 by Methane–Hydrogen Gas Mixture. JOM 69, 1669–1675 (2017). https://doi.org/10.1007/s11837-017-2456-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-017-2456-x