Abstract

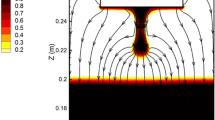

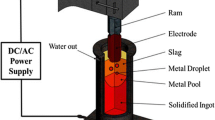

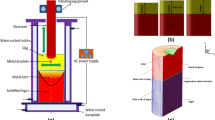

A transient three-dimensional (3D) coupled mathematical model of electroslag remelting (ESR) furnace has been developed to investigate the impact of power control function on the heat transfer and magnetohydrodynamic (MHD) two-phase flow. Maxwell’s equations are solved by electrical potential method. The volume of fluid (VOF) approach is implemented to describe the two phase flow. The Lorentz force and the Joule heating are updated at each iteration as a function of phase distribution. The solidification is modeled by enthalpy-porosity formulation. A reasonable agreement between the experiment and simulation is obtained. The melt rate increases 15.83% in the remelting process with a constant current of 1600 A. With the power control function, the current would be reduced if the melt rate is 1.05 times larger than its initial value. The fluctuation range of the melt rate therefore decreases to 7.23%. Moreover, the fluctuation is limited within 5.12% if we start the power control program when the melt rate is 1.03 times higher than its initial value. Not only the metal pool depth but also the input power decreases under the effect of the current control function.

Similar content being viewed by others

Abbreviations

- \( \vec{A} \) :

-

magnetic potential vector ((V s)/m)

- \( A_{\rm electrode} \) :

-

cross sectional area of electrode (m2)

- \( A_{\rm mush} \) :

-

mushy zone constant

- \( \vec{B} \) :

-

magnetic flux density (T)

- \( c_{\rm p} \) :

-

specific heat (J/(kg K))

- \( \vec{F}_{\rm e} \) :

-

Lorentz force (N/m3)

- \( \vec{F}_{\rm b} \) :

-

buoyancy force (N/m3)

- \( \vec{F}_{\rm d} \) :

-

damping force (N/m3)

- \( f_{\rm H} \) :

-

current frequency (Hz)

- \( f_{\ell } \) :

-

liquid fraction

- \( H \) :

-

enthalpy (J/kg)

- \( h \) :

-

sensible enthalpy (J/kg)

- \( h_{\rm ref} \) :

-

reference sensible enthalpy (J/kg)

- \( I_{\rm rms} \) :

-

root mean square current (A)

- \( I_{\rm rms0} \) :

-

root mean square current at the beginning of the process (A)

- \( \vec{J} \) :

-

current density (A/m2)

- \( k_{\rm eff} \) :

-

effective thermal conductivity (W/(m K))

- L :

-

latent heat (J/kg)

- \( \dot{m} \) :

-

melt rate (kg/s)

- \( \dot{m}_{0} \) :

-

melt rate at the beginning of the process (kg/s)

- \( p \) :

-

pressure (Pa)

- \( Q \) :

-

Joule heating (W/m3)

- \( R \) :

-

radius (m)

- \( R_{\hbox{max} } \) :

-

mold radius (m)

- T :

-

temperature (K)

- T ref :

-

reference temperature (K)

- \( t \) :

-

time (s)

- \( \vec{u} \) :

-

velocity (m/s)

- \( \vec{u}_{\rm cast} \) :

-

casting velocity (m/s)

- \( \delta \) :

-

electromagnetic skin thickness (m)

- \( \eta \) :

-

coefficient used in Eq. 10

- \( \mu_{0} \) :

-

vacuum permittivity (N/A2)

- \( \mu_{\rm eff} \) :

-

effective viscosity (Pa s)

- \( \xi \) :

-

power efficiency

- \( \rho \) :

-

density (kg/m3)

- \( \rho_{\text{e}} \) :

-

electrical resistance (Ω m)

- \( \sigma \) :

-

electrical conductivity (1/(Ω m))

- \( \phi \) :

-

electrical potential (V)

References

B. Hernandez-Morales and A. Mitchell, Ironmaing Steelmaking 26, 423 (1999).

A. Ludwig, A. Kharicha, and M. Wu, Metall. Mater. Trans. B 45B, 36 (2014).

W.Z. Li, W.Y. Wang, Y.C. Hu, and Y.X. Chen, Metall. Mater. Trans. B 43B, 276 (2012).

A. Mitchell, Mater. Sci. Eng. A 413, 10 (2005).

D.K. Melgaard, J.J. Beaman, and G. Shelmidine (Paper Presented at Sohn Int. Symp. Advanced Processing of Metals and Materials, San Diego, USA, 2006), pp. 435–439.

N. Wang and J. Tu, Acta Automatica Sinica 19, 3 (1993).

W. Li and J. Wang, Acta Automatica Sinica 32, 5 (2006).

Q. Wang, Z. He, B.K. Li, and F. Tsukihashi, Metall. Mater. Trans. B 45B, 2425 (2014).

V. Weber, A. Jardy, B. Dussoubs, D. Ablitzer, S. Rybéron, V. Schmitt, S. Hans, and H. Poisson, Metall. Mater. Trans. B 42B, 271 (2009).

A. Kharicha, A. Mackenbrock, A. Ludwig, W. Schützenhöfer, V. Maronnier, M. Wu, and O. Köser (Paper Presented at Proc. 2007 Int. Symp. on Liquid Metal Processing and Casting, Nancy, French, 2007), pp. 113–120.

A. Kharicha, W. Schützenhöfer, A. Ludwig, G. Reiter, and M. Wu, Int. J. Cast Metals Res. 22, 155 (2009).

M. Hugo, B. Dussoubs, A. Jardy, J. Escaffre, and H. Poisson (Paper Presented at Proc. of the 2013 Int. Symp. on Liquid Metal Processing & Casting, Austin, Texas, 2013), pp. 79–85.

M. Choudhary and J. Szekely, Metall. Mater. Trans. B 12B, 418 (1981).

Q. Wang, L. Gosselin, and B.K. Li, ISIJ Int. 54, 2821 (2014).

A.H. Dilawari, J. Szekely, and T.W. Eagar, Metall. Mater. Trans. B 9B, 371 (1978).

B.K. Li, B. Wang, and F. Tsukihashi, Metall. Mater. Trans. B 45B, 1122 (2014).

M. Choudhary and J. Szekely, Metall. Mater. Trans. B 11B, 439 (1980).

K. Fezi, J. Yanke, and M.J.M Krane (Paper Presented at Proc. 2013 Int. Symp. on Liquid Metal Processing & Casting, Austin, Texas, 2013), pp. 151–158.

Acknowledgements

The authors’ gratitude goes to National Natural Science Foundation of China (51210007) and Fundamental Research Funds of People’s Republic of China for the Central Universities (N140206002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Q., Rong, W. & Li, B. Effect of Power Control Function on Heat Transfer and Magnetohydrodynamic Two-Phase Flow in Electroslag Remelting Furnace. JOM 67, 2705–2713 (2015). https://doi.org/10.1007/s11837-015-1621-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1621-3