Abstract

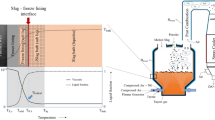

Slag freeze linings, the formation of protective deposit layers on the inner walls of furnaces and reactors, are increasingly used in industrial pyrometallurgical processes to ensure that furnace integrity is maintained in these aggressive, high-temperature environments. Most previous studies of freeze-linings have analyzed the formation of slag deposits based solely on heat transfer considerations. These thermal models have assumed that the interface between the stationary frozen layer and the agitated molten bath at steady-state deposit thickness consists of the primary phase, which stays in contact with the bulk liquid at the liquidus temperature. Recent experimental studies, however, have clearly demonstrated that the temperature of the deposit/liquid bath interface can be lower than the liquidus temperature of the bulk liquid. A conceptual framework has been proposed to explain the observations and the factors influencing the microstructure and the temperature of the interface at steady-state conditions. The observations are consistent with a dynamic steady state that is a balance between (I) the rate of nucleation and growth of solids on detached crystals in a subliquidus layer as this fluid material moves toward the stagnant deposit interface and (II) the dissolution of these detached crystals as they are transported away from the interface by turbulent eddies. It is argued that the assumption that the interface temperature is the liquidus of the bulk material represents only a limiting condition, and that the interface temperature can be between T liquidus and T solidus depending on the process conditions and bath chemistry. These findings have implications for the modeling approach and boundary conditions required to accurately describe these systems. They also indicate the opportunity to integrate considerations of heat and mass flows with the selection of melt chemistries in the design of future high temperature industrial reactors.

Similar content being viewed by others

References

M. Goto, S. Kawakita, N. Kikumoto, and O. Iida, JOM 38 (9), 43 (1986).

J.A. Aseljoki, L.K. Bailey, D.B. George, and D.W. Rodolff, JOM 37 (5), 20 (1985).

C.J. Newmann, M.M. Weaver, in Conference on Sulphide Smelting, ed. R.L. Stephens, H.Y. Sohn (Warrendale, PA: TMS, 2002), pp. 317–328.

D.G. Tisdale, C.G. Ransom, Symposium on Ni-Cobalt, 36th Conference of Metallurgists (Montreal: CIM, 1997), pp. 35–43.

R. Veenstra, N. Voermann, B. Wasmund, Proceedings of International Symposium on Ni-Cobalt, 36th Conference of Metallurgists (Montreal: CIM, 1997).

N. Voermann, F. Ham, J. Merry, R. Veens, K. Hutchinson, in Proceedings of Copper 99-Cobre 99, International Conference on Smelting Operations and Advances, ed. D.B. George, W.J. Chen, P.J. Mackey, A.J. Weddick (Warrendale, PA: TMS, 1999), pp. 573–582.

J. Sarvinis, N. Voermann, C. Crowe, J. Bianchini, and B. Wasmund, Metallurgical Plant Design and Operating Strategies (Sydney: AusIMM, 2002), pp. 318–331.

P.L. Duncanson and J.D. Toth, INFACON X (Cape Town: SAIMM, 2004), pp. 488–499.

L.R. Nelson, R. Sullivan, P. Jacobs, E. Munnik, P. Lewarns, E. Roos, M.J.N. Uys, B. Salt, M. de Vries, K. McKenna, N. Voermann, B.O. Wesmund, INFACON X (Cape Town: SAIMM, 2004), pp. 508–521.

A.M. Hearn, A.S.J.V. Rensburg, and J.R. Henning, Infaconx (Cape Town: SAIMM, 2004), pp. 500–507.

N. Voermann, T. Gerritsen, I. Candy, F. Stober, A. Matyas, Proceedings of 10th International Ferroalloys Congress, INFACON X, ‘Transformation through Technology’ (Cape Town: SAIMM, 2004).

A.K. Kyllo and N.B. Gray, EMC 2005 (Dresden: GDMB, 2005), pp. 1027–1034.

K. Verscheure, A.K. Kyllo, A. Filzwieser, B. Blanpain, P. Wollants, Advanced Processing of Metals and Materials (Sohn International Symposium), ed. F. Kongolli, R.G. Reddy (Warrendale, PA: TMS, 2006), pp. 139–154.

K. Verscheure, M. Van Camp, B. Blanpain, P. Wollants, P. Hayes, and E. Jak, Metall. Mater. Trans. B 38B, 21 (2007).

K. Verscheure, M. Van Camp, B. Blanpain, P. Wollants, P. Hayes, and E. Jak, Metall. Mater. Trans. B 38B, 13 (2007).

K. Grjotheim, Aluminium Electrolysis: Fundamentals of the Hall–Héroult Process, 2nd ed. (Düsseldorf: Aluminium-Verlag, 1984).

K. Grjotheim, C. Krohn, M. Malinovsky, K. Matiasovsky, and J. Thonstad, Aluminium Electrolysis: The Chemistry of the Hall–Héroult Process (Düsseldorf: Aluminium-Verlag, 1977).

K. Grjotheim and B. Welch, Aluminium Smelter Technology (Düsseldorf: Aluminium Verlag, 1980).

P.C. Pistorius, JSAIMM 108, 35 (2008).

Y.K. Rao and J.H. Haberman, Can. Metall. Q. 23, 123 (1984).

G. Bisio, G. Rubatto, and R. Martini, Energy 25, 1047 (2000).

Q. Liang, X. Guo, Z. Dai, H. Liu, and X. Gong, Fuel 102, 491 (2012).

N. Kimura, J. Jpn. Inst. Energy 87, 236 (2008).

C.B. Solnordal, F.R.A. Jorgensen, and R.N. Taylor, Metall. Mater. Trans. B 29, 485 (1998).

L.R. Nelson, R.J. Hundermark, Proceedings of Furnace Tapping Conference (Johannesburg: SAIMM, 2014), pp. 1–32.

F. Guevara and G. Irons, Metall. Mater. Trans. B 42B, 652 (2011).

F. Guevara and G. Irons, Metall. Mater. Trans. B 42B, 664 (2011).

S. Kolås, JOM 59, 55 (2007).

A. Solheim, L.I.R. Støen, Light Metals 1997, ed. R. Huglen (Warrendale, PA: TMS, 1997), pp. 325–332.

K. Verscheure, Ph.D. Dissertation, Katholieke Universiteit Leuven, 2007.

K. Verscheure, F. Verhaeghe, E. Boydens, M. Van Camp, B. Blanpain, and P. Wollants, Metall. Mater. Trans. B 37B, 929 (2006).

G. Plascencia, T.A. Utigard, and D. Jaramillo, JOM 57, 44 (2005).

D.G.C. Robertson, S. Kang, Fluid Flow Phenomena in Minerals Processing, ed. N. El-Kaddah (Warrendale, PA: TMS, 1999), pp. 157–168.

H. Joubert, Proceedings of 6th International Conference on Molten Slags and Fluxes, ed. E.S. Seetharaman, D. Sichen (Trite Met 85, CD-ROM, 2000).

P.C. Pistorius, JSAIMM 103, 509 (2003).

P.C. Pistorius, JSAIMM 104, 417 (2004).

J.H. Zietsman and C. Pistorius, Miner. Eng. 19, 262 (2005).

M.P. Taylor. (Ph.D. Dissertation, The University of Auckland, 1984).

M.P. Taylor and B.J. Welch, Metall. Trans. B 18B, 391 (1987).

F.J. Guevara, G.A. Irons, Symposium on Pyrometallurgy, Copper 2007 (Toronto, Canada, 2007), pp. 481–493.

B. Henning, M. Shaprio, L.A. Grange, Proceedings of 10th International Ferroalloys Congress, INFACON X: ‘Transformation through Technology’ (Cape Town: SAIMM, 2004), pp. 565–574.

S. Jana, S. Ray, and F. Durst, Appl. Math. Model. 31, 93 (2007).

M. Campforts, B. Blanpain, and P. Wollants, Metall. Mater. Trans. B 40B, 643 (2009).

M. Campforts, E. Jak, B. Blanpain, and P. Wollants, Metall. Mater. Trans. B 40B, 619 (2009).

M. Campforts, E. Jak, B. Blanpain, and P. Wollants, Metall. Mater. Trans. B 40B, 632 (2009).

M. Campforts, K. Verscheure, E. Boydens, T. Van Rompaey, B. Blanpain, and P. Wollants, Metall. Mater. Trans. B 39B, 408 (2008).

M. Campforts, K. Verscheure, T. Van Rompaey, E. Boydens, B. Blanpain, and P. Wollants, Metall. Mater. Trans. B 38B, 841 (2007).

P. Taskinen, M. Kaskiala, P. Hietanen, K. Miettinen, and A. Forsström, Trans. Inst. Min. Metall. C 120, 147 (2011).

A. Fallah-Mehrjardi, P.C. Hayes, and E. Jak, Metall. Mater. Trans. B 44B, 534 (2013).

A. Fallah-Mehrjardi, P.C. Hayes, and E. Jak, Metall. Mater. Trans. B 44B, 549 (2013).

A. Fallah-Mehrjardi, P.C. Hayes, and E. Jak, Metall. Mater. Trans. B 44B, 1337 (2013).

A. Fallah-Mehrjardi, P.C. Hayes, S. Vervynckt, and E. Jak, Metall. Mater. Trans. B 45B, 850 (2014).

A. Fallah-Mehrjardi, P.C. Hayes, and E. Jak, Metall. Mater. Trans. B 45B, 1232 (2014).

A. Fallah-Mehrjardi, J. Jansson, P. Taskinen, P.C. Hayes, and E. Jak, Metall. Mater. Trans. B 45B, 864 (2014).

J. Jansson, P. Taskinen, and M. Kaskiala, Can. Metall. Q. 53, 1 (2014).

P. Taskinen, M. Kaskiala, K. Miettinen, J. Jansson. (Paper presented at the International Conference on Molten Slags and Fluxes, Beijing, China, 2012).

A. Fallah-Mehrjardi, P.C. Hayes, E. Jak, Celebrating the Megascale: Proceedings of the Extraction and Processing Division Symposium on Pyrometallurgy in Honor of David G.C. Robertson, ed. P.J. Mackey, E.J. Grimsey, R.T. Jones, G.A. Brooks (Warrendale, PA: TMS; and New York: Wiley and Sons, Inc., 2014), pp. 259–266.

A. Fallah-Mehrjardi, P.C. Hayes, E. Jak. (Paper presented at Copper 2013, Santiago, Chile, 2013).

P.V. Danckwerts, Ind. Eng. Chem. 43, 1460 (1951).

Acknowledgements

The authors would like to thank the Australian Research Council Linkage program, Rio Tinto Kennecott Utah Copper Corp., Xstrata Technology, Xstrata Copper, BHP Billiton Olympic Dam Operation, and Outotec Finland Oy for their financial support for the project. Thanks are also given to Lloyd Nelson (Anglo American Platinum), Phil Mackey (P.J. Mackey Technology), and Rodney Jones (MINTEK) for their valuable suggestions on industrial applications of freeze linings.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fallah-Mehrjardi, A., Hayes, P.C. & Jak, E. Understanding Slag Freeze Linings. JOM 66, 1654–1663 (2014). https://doi.org/10.1007/s11837-014-1127-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-014-1127-4