Abstract

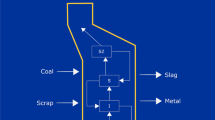

The disposal of zinc-containing residues is an important sustainability issue currently facing the metallurgical industry. These residues can be treated by using zinc slag-fuming processes in which heavy metals are chemically reduced and evaporated from a molten slag bath. Continuous operation of these processes requires high zinc-fuming rates while retaining vessel integrity. To meet these challenges, a new generation of technologies is being developed that depends on the formation of a freeze lining on the internal reactor walls. A general zinc-fuming process model that simultaneously describes the chemical reactions, phase equilibria, and thermal- and heat-transfer outcomes of these processes has been developed using the FactSage thermodynamic databank system and the ChemApp programmer’s library for thermochemical applications. This simultaneous description of these processes allows the model to be used as part of a new approach to the design of freeze linings, namely, the use of slag engineering and composition adjustment to obtain optimum process efficiency and freeze lining behavior.

Similar content being viewed by others

Abbreviations

- A bath :

-

surface area of the bath/postcombustor interface (m2)

- A bottom :

-

total area of the bottom of the furnace (m2)

- A fl :

-

total area of the hot face of the freeze lining (m2)

- A roof :

-

total area of the roof of the furnace (m2)

- h bath :

-

convection coefficient from the bath to the freeze lining (W m−2 K−1)

- h pc→roof :

-

total heat-transfer coefficient from the postcombustion gas to the roof (W m−2 K−1)

- h pc→sw :

-

total heat-transfer coefficient from the postcombustion gas to the vertical idewalls (W m−2 K−1)

- h pc→zf :

-

total heat-transfer coefficient from the postcombustion gas to the bath (W m−2 K−1)

- h water :

-

convection coefficient from the water to the furnace shell (W m−2 K−1)

- ΔH m :

-

enthalpy change resulting from the change of temperature, phase transformations, dissolution, and chemical reactions in the mixer (W)

- ΔH pc :

-

enthalpy change resulting from the change of temperature, phase transformations, dissolution, and chemical reactions in the postcombustor (W)

- ΔH ph :

-

enthalpy change resulting from the change of temperature, phase transformations, dissolution, and chemical reactions in the preheater (W)

- ΔH zf :

-

enthalpy change resulting from the change of temperature, phase transformations, dissolution, and chemical reactions in the zinc fumer (W)

- ΔH M,tot :

-

total enthalpy change of the mixer (W)

- ΔH PC,tot :

-

total enthalpy change of the postcombustor (W)

- ΔH PH,tot :

-

total enthalpy change of the preheater (W)

- ΔH ZF,tot :

-

total enthalpy change of the zinc fumer (W)

- k fl :

-

thermal conductivity of the freeze lining (W m−1 K−1)

- k ins,bottom :

-

thermal conductivity of the insulation layer of the furnace bottom (W m−1 K-1)

- k refr,bottom :

-

thermal conductivity of the refractory layer of the furnace bottom (W m−1 K−1)

- k refr,roof :

-

thermal conductivity of the refractory deposit on the postcombustor roof (W m−1 K−1)

- k refr,sw :

-

thermal conductivity of the refractory deposit on the postcombustor sidewalls (W m−1 K−1)

- k shell :

-

thermal conductivity of the furnace shell (W m−1 K−1)

- Q bottom :

-

heat losses through the bottom of the furnace (W)

- Q el :

-

electrical heat input in the preheater (W)

- Q fl :

-

heat losses through the freeze lining (W)

- Q hs :

-

heat input from the other heat sources in the preheater (W)

- Q pc→zf :

-

heat exchange from the postcombustor to the zinc fumer (W)

- Q walls :

-

heat losses through the walls of the postcombustor (W)

- r fl :

-

inner radius of the freeze lining (m)

- r refr,sw :

-

inner radius of the refractory sidewalls of the postcombustor (m)

- r shell,in :

-

inner radius of the furnace shell (m)

- r shell,out :

-

outer radius of the furnace shell (m)

- R bottom :

-

total thermal resistance of the furnace bottom (K W−1)

- R sidewall :

-

total thermal resistance of the postcombustor sidewalls (K W−1)

- R roof :

-

total thermal resistance of the postcombustor roof (K W−1)

- T bath :

-

bath temperature (K)

- T liquidus :

-

liquidus temperature of the bath (K)

- T pc :

-

postcombustor temperature (K)

- T water :

-

water temperature in the furnace jackets (K)

- t ins,bottom :

-

thickness of the insulation layer in the furnace bottom (m)

- t refr,bottom :

-

thickness of the refractory layer in the furnace bottom (m)

- t refr,roof :

-

thickness of the refractory layer in the furnace bottom (m)

- t shell :

-

thickness of the furnace shell (m)

- z bath :

-

height of the slag bath (m)

- z pc :

-

height of the postcombustor (m)

References

S.E. James, J.L. Watson, and J. Peter: Lead-Zinc 2000, J.E. Dutrizac et al., eds., Pittsburgh, PA, 2000, TMS, Warrendale, PA, 2000, pp. 205–25

Richards G.G., Brimacombe K., Toop G.W. 1985 Metall. Trans. B, 16B:513–27

E. Jak, S. Degterov, P.C. Hayes, and A.D. Pelton: Proc. 5th Int. Symp. Metallurgical Slags and Fluxes, G.R. Belton, ed., Sydney, 1997, ISS, Warrendale, PA, 1997, pp. 621–28

Jak E., Degterov S., Zhao B., Pelton A.D., Hayes P.C. 2000 Metall. Mater. Trans. B, 31B:621–30

E. Jak, B. Zhao, and P.C. Hayes: MINPREX, Int. Congr. on Mineral Processing and Extractive Metallurgy, Melbourne, Oct. 2000, AusIMM, Carlton, Victoria, Australia, 2000, pp. 479–84

D.G.C. Robertson and S. Kang: Fluid Flow Phenomena in Metals Processing, N. El Kaddah, ed., San Diego, CA, 1999, TMS, Warrendale, PA, 1999, pp. 157–68

S. Kang: Ph.D. Thesis, University of Missouri–Rolla, Rolla, MO, 1991

C.C. Wei, J.J.J. Chen, B.J. Welch, and V.R. Voller: Light Metals 1997, R. Huglen, ed., TMS, Warrendale, PA, 1997, pp. 309–16

A. Solheim: 12th Aluminium Symp., Bratislava, Slovakia, Slovalco, 2003, Proc. on CD-ROM

K.E. Scholey, G.G. Richards, and I.V. Samarasekera: Metall. Trans. B, 1991, vol. 22B, pp. 163–75

A.P. Campbell: Ph.D. Thesis, Centre for Numerical Modelling and Process analysis, School of Computing and Mathematical Sciences, University of Greenwich, London, United Kingdom, 2002

H. Pfundt, D. Vogelsang, and U. Gerling: Light Metals 1989, P.G. Campbell, ed., TMS, Warrendale, PA, 1989, pp. 371–77

J.N. Bruggeman and D.J. Danka: Light Metals 1990, C.M. Bickert, ed., TMS, Warrendale, PA, 1990, 203–09

A. Vallés, V. Lenis, and M. Rao: Light Metals 1995, J.W. Evans, ed., TMS, Warrendale, PA, 1995, pp. 309–13

H.A. Ahmed, S.M. El-Raghy, F.A. Elrefaie, S. Reda, and Z. Bassuny: Light Metals 1994, U. Mannweiler, ed., TMS, Warrendale, PA, 1994, pp. 333–38

P.C. Pistorius: Proc. VII Int. Conf. on Molten Slags, Fluxes and Salts, Cape Town, South Africa, 2004, SAIMM, Johannesburg, 2004, pp. 237–42

J.H. Zietsman: Ph.D. Thesis, University of Pretoria, Pretoria, South Africa, 2004

D. Ward: MINPREX, Int. Congr. Mineral Processing and Extractive Metallurgy, Melbourne, Oct. 2000, AusIMM, Carlton, Victoria, Australia, 2000, pp. 471–78

R.M. Grant: Proc. Australia/Japan Extractive Metallurgy Symp., Sydney, 1980, AusIMM, Melbourne, Australia, 1980, pp. 75–93

Jak E., Hayes P.C. 2002 Can. Met. Q., 41(2):163–74

C.W. Bale, P. Chartrand, S.A. Degterov, G. Eriksson, K. Hack, R. Ben Mahfoud, J. Melancon, A.D. Pelton, and S. Petersen: Calphad., 2002, vol. 26(2), pp. 189–228, www.factsage.com.

S. Degterov, I.H. Jung, E. Jak, P.C. Hayes, and A.D. Pelton: VII Int. Conf. on Molten Slags, Fluxes and Salts, Capetown, 2004, SAIMM, Johannesburg, South Africa, 2004, pp. 839–50

G. Eriksson, K. Hack, and S. Petersen: Werkstoff Woche ‘96, Symposium 8, Simulation, Modellierung, Informationssysteme, J. Hirsch, ed., DGM Informationsgesellschaft Verlag, Frankfurt, Germany, 1997, pp. 47–51

K. Verscheure, M. Van Camp, B. Blanpain, P. Wollants, P.C. Hayes, and E. Jak: Lead and Zinc ‘05, T. Fujisawa, MMIJ, Kyoto, Japan, Tokyo, 2005, pp. 943–60

Verscheure K., Van Camp M., Blanpain B., Wollants P., Hayes P.C., Jak E.: 2007 Metall. Mater. Trans. B, vol. 38B, doi: 10.1007/s11663-006-9010-5

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 25, 2006.

Rights and permissions

About this article

Cite this article

Verscheure, K., Van Camp, M., Blanpain, B. et al. Continuous Fuming of Zinc-Bearing Residues: Part I. Model Development. Metall Mater Trans B 38, 13–20 (2007). https://doi.org/10.1007/s11663-006-9009-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-006-9009-y