Abstract

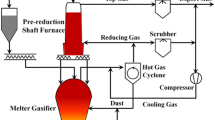

In recent years, two parallel pipes of areal gas distribution (AGD) were installed into the COREX shaft furnace to improve the furnace efficiency. A three-dimensional mathematical model at steady state, which takes a modified three-interface unreacted core model into consideration, is developed in the current work to describe the effect of the AGD pipe on the inner characteristics of shaft furnace. The accuracy of the model is evaluated using the plant operational data. The AGD pipe effectively improves the uniformity of reducing gas distribution, which leads to an increase in gas temperature and concentration of CO or H2 around the AGD pipe, and hence it further contributes to the iron oxide reduction. As a result, the top gas utilization rate and the solid metallization rate (MR) at the bottom outlet are increased by 0.015 and 0.11, respectively. In addition, the optimizations of the flow volume ratio (FVR) of the reducing gas fed through the AGD inlet and the AGD pipe arrangement are further discussed based on the gas flow distribution and the solid MR. Despite the relative suitability of the current FVR (60%), it is still meaningful to enable a manual adjustment of FVR, instead of having it driven by pressure difference, to solve certain production problems. On the other hand, considering the flatter distribution of gas flow, the higher solid MR, and easy installation and replacement, the cross distribution arrangement of AGD pipe with a length of 3 m is recommended to replace the current AGD pipe arrangement.

Similar content being viewed by others

Abbreviations

- A s :

-

Surface area of solid particle (m2/m3)

- a n,m :

-

Variable explained in Ref. 18

- C P,j :

-

Heat capacity of phase j (J/kg K)

- D 1, D 2 :

-

Diameter of inner and outer wall (m)

- D i :

-

Mass diffusion coefficient of specie i (m2/s)

- d s :

-

Solid particle diameter (m)

- \( \vec{F}_{\text{gs}} \) :

-

Gas-solid drag force (N/m2)

- \( \vec{F}_{\text{w}} \) :

-

Wall friction force (N/m2)

- f s :

-

Friction coefficient (−)

- \( \vec{g} \) :

-

Gravitational acceleration (m/s2)

- H j :

-

Enthalpy of phase j (J/kg)

- ΔH n :

-

Interphase heat source for reaction n (J/kmol)

- ΔH T i,j :

-

Formation heat for species i in phase j at temperature T (J/kg)

- h gs :

-

Heat-transfer coefficient (W/m2 K)

- h wall :

-

Heat-transfer coefficient of wall (W/m2 K)

- K n :

-

Equilibrium constant of reaction n (−)

- k n :

-

Kinetic constant of reaction n (various)

- M :

-

Molecular weight (kg/kmol)

- P :

-

Pressure (Pa)

- P atm :

-

Standard atmospheric pressure (101325 Pa)

- P i :

-

Partial pressure of specie i (Pa)

- q wall :

-

Wall heat flux (W/m2)

- R n :

-

Rate of reaction n (kmol/m3 s)

- S ψ :

-

Source term for variable ψ in Eq. 1 (various)

- T j :

-

Temperature of phase j (K)

- T wall :

-

Temperature of wall (K)

- \( \vec{v}_{j} \) :

-

Physical velocity of phase j (m/s)

- v g,ave, v g,max, v g,min :

-

Average, maximum, and minimum velocity of gas (m/s)

- v s :

-

Solid velocity (m/s)

- W :

-

Variable explained in Ref. 18 (various)

- Y i,j :

-

Mass fraction of species i in phase j (−)

- α wall :

-

Weighting factor (−)

- ɛ j :

-

Volume fraction of phase j (−)

- λ j :

-

Thermal conductivity of phase j (W/m K)

- ρ j :

-

Density of phase j (kg/m3)

- ϕ s :

-

Solid particle shape factor (−)

- Γ ψ :

-

Diffusion coefficient for variable ψ in Eq. 1 (various)

- ψ :

-

General dependent variable in Eq. 1 (various)

- φ i,j :

-

Volume fraction of species i in phase j (−)

- \( \overline{\overline{\tau }}_{j} \) :

-

Stress tensor of phase j (Pa)

- g:

-

Gas

- s:

-

Solid

- AGD:

-

Areal gas distribution

- FVR:

-

Flow volume ratio of the reducing gas fed through the AGD inlet

- MR:

-

Metallization rate

- GFD:

-

Gas flow deviation

References

W.G. Li, Paper presented at the 3rd Baosteel Biennial Academic Conference, Shanghai, China, 2008, p. A75.

S.L. Wu, H.F. Xu, Z.Y. Li, Q. Zhang, and J.J. Lin, Paper presented at the 3rd Baosteel Biennial Academic Conference, Shanghai, China, 2008, p. A102.

Q. Zhang and L. Guo, Paper presented at the 3rd Baosteel Biennial Academic Conference, Shanghai, China, 2008, p. A219.

Y. Hara, M. Sakawa, and S. Kondō, Tetsu-to-Hagané 62, 315 (1976).

Y. Hara, M. Sakawa, and S. Kondō, Tetsu-to-Hagané 62, 324 (1976).

A. Ajbar, K. Alhumaizi, and M. Soliman, Ironmaking Steelmaking 38, 401 (2011).

S.L. Wu, J. Xu, Q. Zhou, S.D. Yang, and L.H. Zhang, Paper presented at the 5th International Conference on the Science and Technology of Ironmaking, Shanghai, China, 2009, p. 1250.

S.L. Wu, J. Xu, S.D. Yang, Q. Zhou, and L.H. Zhang, ISIJ Int. 50, 1032 (2010).

X.Y. Guo, S.L. Wu, J. Xu, and K.P. Du, Proc. Eng. 15, 4702 (2011).

S.L. Wu, J. Xu, J. Yagi, X.Y. Guo, and L.H. Zhang, ISIJ Int. 51, 1344 (2011).

J. Xu, S.L. Wu, M.Y. Kou, and K.P. Du, ISIJ Int. 53, 576 (2013).

C. Böhm, W. Grill, and H. Heckmann, Paper presented at the 4th Baosteel Biennial Academic Conference, Shanghai, China, 2010, p. A60.

J.J. Lin, W.G. Song, and W.Y. Xia, Paper presented at the 5th Baosteel Biennial Academic Conference, Shanghai, China, 2013, p. A499.

H. Xu, X.Q. Li, J.J. Lin, and J.M. Zhu, World Iron Steel, 15 (2012).

H. Zhou, Z.G. Luo, T. Zhang, J.J. Sun, L.H. Han, X.R. Liu, and Z.S. Zou, Adv. Mater. Res. 712, 1268 (2013).

P.R. Austin, H. Nogami, and J. Yagi, ISIJ Int. 37, 458 (1997).

P.R. Austin, H. Nogami, and J. Yagi, ISIJ Int. 37, 748 (1997).

Y. Hara, M. Tsuchiya, and S. Kondō, Tetsu-to-Hagané 60, 1261 (1974).

R. Takahashi, Y. Takahashi, J. Yagi, and Y. Omori, Paper presented at the 43rd Ironmaking Conference, Warrendale, PA, 1984, p. 485.

R. Takahashi, Y. Takahashi, J. Yagi, and Y. Omori, Trans. ISIJ 26, 765 (1986).

J.Z. Chen, T. Akiyama, H. Nogami, J. Yagi, and H. Takahashi, ISIJ Int. 33, 664 (1993).

R.H. Perry, D.W. Green, and J.O. Maloney, Perry’s Chemical Engineers’ Handbook, 7th ed. (New York: McGraw-Hill, 1997), pp. 1–2.

S.V. Patankar, Numerical Heat Transfer and Fluid Flow (Washington, DC: Hemisphere, 1980), p. 126.

J.D. Anderson, Computational Fluid Dynamics: The Basics with Application (Beijing, China: Tsinghua University Press, 2002), p. 179.

Acknowledgements

The authors would like to thank the financial support from the National Natural Science Foundation of China (No. U1260202) and Specialized Research Fund for Doctoral Program of Higher Education (No. 20120006110002). The authors are thankful for linguistic corrections from Mr. Siming Chen and the improvement of this work from the anonymous reviewers.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, S., Du, K., Xu, J. et al. Numerical Analysis on Effect of Areal Gas Distribution Pipe on Characteristics Inside COREX Shaft Furnace. JOM 66, 1265–1276 (2014). https://doi.org/10.1007/s11837-014-1019-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-014-1019-7