Abstract

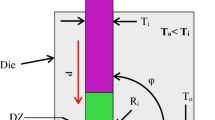

Equal-channel angular pressing (ECAP) is a very interesting method for modifying the microstructure in producing ultrafine-grained materials and nanomaterials. It consists mainly of pressing test samples through a die containing two channels that are equal in cross section and intersect at a certain angle. As a result of pressing, the sample theoretically deforms by simple shear and retains the same cross-sectional area to allow repeat pressing for several cycles. A 6063-T1 aluminum alloy was investigated in this study. The specimens were processed for up to nine passes (one, three, six, and nine ECAP passes, respectively) using a die channel angle of 90°. After ECAP, the samples were cut from each specimen and prepared for metallographic analysis and mechanical testing. The microstructures of the ECAP treated and as-received material were investigated using both optical microscopy and scanning electron microscopy. All samples (ECAP processed and as-received) were mechanically investigated in compression tests. Ultimate compressive strength, yield strength, and compression modulus were obtained. Also, all ECAP processed specimens were investigated for microhardness and compared with the as-received material.

Similar content being viewed by others

References

J.G. Kaufman, Properties of Aluminum Alloys—Tensile, Creep and Fatigue Data at High and Low Temperatures (Materials Park, OH: ASM International and The Aluminum Association, 2000).

R.Z. Valiev, K. Islamgaliev, and V. Alexandrov, Prog. Mater. Sci. 45, 103 (2000).

R.Z. Valiev and T.G. Langdon, Prog. Mater. Sci. 51, 881 (2006).

N. Serban, R. Saban, N. Ghiban, B. Ghiban, and R.I. Iacobescu, Metall. Int. XIV, 67 (2009).

S. Ferrasse and V.M. Segal, Metall. Mater. Trans. A 28A, 1047 (1997).

Z. Horita and T. Fujinami, Metall. Mater. Trans. A 31A, 691 (2000).

U. Chakkingal, A.B. Suriadi, and P.F. Thomson, Mater. Sci. Eng. A 266, 241 (1999).

M. Furukawa, Y. Iwahashi, Z. Horita, M. Nemoto, and T.G. Langdon, Mater. Sci. Eng. A 257, 328 (1998).

V.V. Stolyarov, Y.T. Zhu, T.C. Lowe, and R.Z. Valiev, Mater. Sci. Eng. A 303, 82 (2001).

M. Mukai, M. Yamanoi, H. Watanabe, and K. Higashi, Scr. Mater. 45, 89 (2001).

W.J. Kim, C.W. An, Y.S. Kim, and S.I. Hong, Scr. Mater. 47, 39 (2002).

N. Ghiban, N. Serban, R. Saban, V.D. Cojocaru, B. Ghiban, and A. Ghiban (Paper presented at the Annals of DAAAM for 2009 & Proceedings of the 20th International DAAAM Symposium, Vienna, Austria, 25–28 November 2009, vol. 20, no. 1), pp. 1547–1548.

Y. Iwahashi, Z. Horita, M. Nemoto, and T.G. Langdon, Acta Mater. 45, 4733 (1997).

Y. Iwahashi, J. Wang, Z. Horita, M. Nemoto, and T.G. Langdon, Scr. Mater. 35, 143 (1996).

N. Llorca-Isern, C. Luis-Perez, P.A. Gonzalez, L. Laborde, and D. Patino, Rev. Adv. Mater. Sci. 10, 473 (2005).

A.P. Zhilyaev, D.L. Swisher, K. Oh-ishi, T.G. Langdon, and T.R. McNelley, Mater. Sci. Eng. A 429, 137 (2006).

M. Reihanian, R. Ebrahimi, M.M. Moshksar, D. Terada, and N. Tsuji, Mater. Charact. 59, 1312 (2008).

E.A. El-Danaf, Mater. Sci. Eng. A 487, 189 (2008).

J.C. Werenskiold and H.J. Roven, Mater. Sci. Eng. A 410–411, 174 (2005).

E.A. El-Danaf, M.S. Soliman, A.A. Almajid, and M.M. El-Rayes, Mater. Sci. Eng. A 458, 226 (2007).

K. Oh-ishi, A.P. Zhilyaev, and T.R. McNelley, Mater. Sci. Eng. A 410–411, 183 (2005).

J. Lian, B. Baudelet, and A.A. Nazarov, Mater. Sci. Eng. A 172, 23 (1993).

J.P. Hirth and J. Lothe, Theory of Dislocations, 2nd ed. (New York: Wiley, 1982).

D. Kuhlmann-Wilsdorf, Mater. Sci. Eng. A 113, 1 (1989).

N. Hansen, X. Huang, and D.A. Hughes, Mater. Sci. Eng. A 317, 3 (2001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Serban, N., Cojocaru, VD. & Butu, M. Mechanical Behavior and Microstructural Development of 6063-T1 Aluminum Alloy Processed by Equal-Channel Angular Pressing (ECAP): Pass Number Influence. JOM 64, 607–614 (2012). https://doi.org/10.1007/s11837-012-0311-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-012-0311-7