Abstract

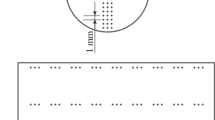

A technique invented in the former Soviet Union and recently introduced in the United States, called equal channel angular extrusion (ECAE), produces intense and uniform deformation by simple shear and is applied to 25 × 25 × 152-mm billets of Cu 101 and Al 3003. Microcrystalline structures with a grain size of 0.2 to 0.4 µm are created during room-temperature multipass ECAE deformation for true strains lying in the range ε=2.31 to 9.24. Evidence shows that intense simple shear deformation promotes dynamic or continuous recrystallization by subgrain rotation. The effects of the number of extrusion passes and deformation route for Cu 101, and the deformation route after four passes for Al 3003, are studied. Increasing the number of ECAE passes in Cu 101 causes strength to reach saturation and grain refinement stabilization after four passes (true strain of 4.68), and subgrain misorientation to increase as the number of passes increases. For multipass ECAE with billet orientation constant (route A) or rotated 90 deg between all passes (route B), two levels of structures are created inside the original grains: shear bands (first level) and very fine subgrains (second level) within the shear bands. For a billet rotation of 180 deg between passes (route C), an unusual event is observed. At each even numbered pass, shear bands nearly disappear and only subgrains are present inside the original grains. Route B gives the highest strength, whereas route C produces a more equiaxed and stable microstructure. Subsequent static recrystallization increases the average grain size to 5 to 10 µm.

Similar content being viewed by others

References

C. Suryanarayana: Bull. Mater. Sci., 1994, vol. 17, pp. 307–46.

R.Z. Valiev, A.V. Kornikov, and R.R. Mulyokov: Mater. Sci. Eng., 1993, vol. A168, pp. 141–48.

V.Y. Gertsman, R. Birringer, R.Z. Valiev, and H. Gleiter: Scripta Metall., 1994, vol. 30, pp. 229–34.

I. Saunders and J. Nutting: Met. Sci., 1984, vol. 18, pp. 571–75.

H.J. Zughaer and J. Nutting: Mater. Sci. Technol., 1992, vol. 8, pp. 1104–07.

V. Andrade, M.A. Meyers, K.S. Vecchio, and A.H. Chokshi: Acta Metall. Mater., 1994, vol. 42, pp. 3183–95.

V.M. Segal: Patent of the USSR, No. 575,892, 1977.

V.M. Segal, V.I. Reznikov, A.E. Drobyshevkiy, and V.I. Kopylov: Russ. Metall., 1981, vol. 1, pp. 99–105 (English translation).

V.M. Segal, K.T. Hartwig, and R.E. Goforth: First International Conference on Processing Materials for Properties, H. Henein and T. Oki, eds., TMS, Honolulu, HI, 1993, pp. 971–74.

A.K. Fedotov, V.M. Segal, V.I. Kopylov, V.M. Anischik, and I.I. Gerys: Dokl. Acad. Sci., BSSR, 1983, vol. 27, pp. 630–33.

V.M. Segal: Proceedings of the Fifth International Aluminum Technology Seminar, 1992, vol. 2, pp. 403–07.

V.M. Segal: Mater. Sci. Eng., 1995, vol. A197, pp. 157–64.

R.Z. Valiev, E.V. Kozlov, Y.F. Ivanov, J. Lian, A.A. Nazarov, and B. Baudelet: Acta Metall. Mater., 1994, vol. 42, pp. 2467–75.

N.A. Akhmadeev, N.P. Kobelev, R.R. Mulyokov, YA.M. Soifer, and R.Z. Valiev: Acta Metall. Mater., 1993, vol. 41, pp. 1041–46.

V.M. Segal: First International Conference on Processing Materials for Properties, H. Henein and T. Oki, eds., TMS, Honolulu, HI, 1993, pp. 947–50.

P.J. Goodhew: Specimen Preparation for Transmission Electron Microscopy of Materials, Oxford University Press, Oxford, United Kingdom, 1984.

Stephane Ferrasse: Master’s Thesis, Texas A&M University, College Station, TX, 1995.

R.R. Mulyokov, N.A. Akhmadeev, S.B. Mikhailov, and R.Z. Valiev: Mater. Sci. Eng., 1993, vol. A171, pp. 143–49.

R.Z. Valiev, N.A. Krasilnikov, and N.K. Tsenev: Mater. Sci. Eng., 1991, vol. A137, pp. 35–40.

M.T. Lyttle and J.A. Wert: J. Mater. Sci., 1994, vol. 29, pp. 3342–50.

Metals Handbook, 10th ed., vol. 2, Metallography and Microstructures, ASM, Materials Park, OH, 1990, pp. 84–85 and 266–68.

H. Gudmunsson, D. Brooks, and J.A. Wert: Acta. Metall. Mater., 1991, vol. 39, pp. 19–35.

R. DeWitt: J. Phys., 1972, vol. C5, pp. 529–39.

A.E. Romanov and V.I. Vladimirov: Phys. Status Solidi, 1983, vol. 78, pp. 11–34.

T.R. McNelley, E.W. Lee, and A. Garg: Aluminum Alloys—Physical and Mechanical Properties, Engineering Materials Advisory Services Ltd., West Midlands, England, 1986.

J.D. Embury, A. Korbel, V.S. Raghunathan, and J. Rys: Acta Metall., 1984, vol. 32, pp. 1883–94.

J. Hirsh, K. Lucke, and M. Hatherly: Acta Metall., 1988, vol. 36, pp. 2905–27.

A.S. Malin and M. Hatherly: Met. Sci., 1979, vol. 13, pp. 463–72.

M. Blicharski and S. Gorczyca: Met. Sci., 1978, vol. 12, pp. 303–12.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ferrasse, S., Hartwig, K.T., Goforth, R.E. et al. Microstructure and properties of copper and aluminum alloy 3003 heavily worked by equal channel angular extrusion. Metall Mater Trans A 28, 1047–1057 (1997). https://doi.org/10.1007/s11661-997-0234-z

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-997-0234-z