Abstract

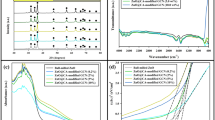

Ferric ion was introduced to the commercial photocatalyst P25 (Degussa) by ultrasonic wet impregnation technique. The concentration of the dopant was varied from 0.0 to 3.0% Fe/Ti ratio. The doped TiO2 was then loaded to alumina balls using mechanical coating technique and followed by calcination in air at 400, 450, 500 and 550 °C. The fabricated photocatalyst was characterized by X-ray diffraction, N2 adsorption-desorption isotherms, scanning electron microscopy, UV-Vis diffuse reflectance spectroscopy, X-ray adsorption near edge structure and photoluminescence spectroscopy. The photocatalytic activity was tested by following the degradation of methylene blue (MB). It was found that the Fe3+ doped TiO2/Al2O3 has a combination of anatase and rutile phase and free of iron oxide phases. The optimum calcination temperature is 400 °C with 0.1% Fe3+ concentration. The catalyst addresses the entrainment in photocatalytic reactors, eliminating the need for a post filtration process.

Similar content being viewed by others

References

Y. Long, Y. Lu, Y. Huang, Y. Peng, Y. Lu, S.-Z. Kang and J. Mu, J. Phys. Chem. C., 113, 13899 (2009).

W. S. Nam and G.Y. Han, Korean. J. Chem. Eng., 20, 180 (2003).

S. Artkla, K. Wantala, B. Srinameb, N. Grisdanurak, W. Klysubun and J. Wittayakun, Korean. J. Chem. Eng., 26, 1556 (2009).

M. Zhou, J. Yu and B. Cheng, J. Hazard. Mater., 137, 1838 (2006).

S. Yin, M. Komatsu, Q. Zhang, F. Saito and T. Sato, J. Mater. Sci., 42, 2399 (2007).

W. Choi, A. Termin and M. Hoffmann, J. Phys. Chem., 98, 13669 (1994).

J.-W. Shi, J.-T. Zheng, Y. Hu and Y.-C. Zhao, Mater. Chem. Phys., 106, 247 (2007).

H. Yoshida, Y. Lu, H. Nakayama and M. Hirohashi, J. Alloy. Compd., 475, 383 (2009).

M. I. Litter and J. A. Navío, J. Photoch. Photobio. A., 98, 171 (1996).

F. R. Feret, D. Roy and C. Boulanger, Spectro. Acta. B., 55, 1051 (2000).

Z. Li, W. Shen, W. He and X. Zu, J. Hazard. Mater., 155, 590 (2008).

M. Zhou, J. Yu and B. Cheng, J. Hazard. Mater., 137, 1838 (2006).

P. Bouras, E. Stathatos and P. Lianos, Appl. Catal. B-Environ., 73, 51 (2007).

B. Liu, L. Wen and X. Zhao, Mater. Chem. Phys., 106, 350 (2007).

T. L. Thompson and J. T. Yates, Top. Catal., 35, 197 (2005).

T.-F. Hsu, T.-L. Hsiung, J. Wang, C.-H. Huang and H. P. Wang, Nucl. Instrum. Methods Phys. Res. A., 619, 98 (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bajamundi, C.J.E., Dalida, M.L.P., Wantala, K. et al. Effect of Fe3+ doping on the performance of TiO2 mechanocoated alumina bead photocatalysts. Korean J. Chem. Eng. 28, 1688–1692 (2011). https://doi.org/10.1007/s11814-011-0031-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-011-0031-7