Abstract

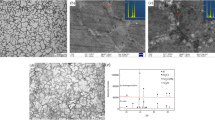

The mechanical properties and microstructure of Al-Cu-Li alloy sheets subjected to cryorolling (−100 °C, −190 °C) or hot rolling (400 °C) and subsequent aging at 160 °C for different times were investigated. The dynamic precipitation and dislocation characterizations were examined via transmission electron microscopy and X-ray diffraction. The grain morphologies and the fracture-surface morphologies were studied via optical microscopy and scanning electron microscopy. Samples subjected to cryorolling followed by aging exhibited relatively high dislocation densities and a large number of precipitates compared with hot-rolled samples. The samples cryorolled at −190 °C and then aged for 15 h presented the highest ultimate tensile strength (586 MPa), while the alloy processed via hot rolling followed by 10 h aging exhibited the highest uniform elongation rate (11.5%). The size of precipitates increased with the aging time, which has significant effects on the interaction mechanism between dislocations and precipitates. Bowing is the main interaction method between the deformation-induced dislocations and coarsened precipitates during tensile tests, leading to the decline of the mechanical properties of the alloy during overaging. These interesting findings can provide significant insights into the development of materials possessing both excellent strength and high ductility.

摘要

研究了深冷轧制(−100 °C, −190 °C)和热轧(400 °C)并随后在 160 °C 时效不同时间的Al-Cu-Li 合金带材的力学性能和显微组织。通过透射电子显微镜和X 射线衍射检查了动态析出和位错特征。通过超景深显微镜和扫描电子显微镜研究了微观组织和断口表面形貌。与热轧样品相比, 经过深冷轧制和时效的样品表现出较高的位错密度和大量的析出物。在 −190 °C 深冷轧制后时效15 h 的样品表现出最高的极限抗拉强度(586 MPa), 而通过热轧随后5 h 时效处理的合金则表现出最高的均匀延展性(11.5%)。析出物的尺寸随着时效时间的增加而增加, 这对位错与析出物之间的相互作用机理具有重要影响。过时效时, 析出物尺寸比较粗大, 拉伸变形过程中位错会绕过析出物进行运动, 进而力学性能下降。

Similar content being viewed by others

References

TRIÓLO A, LIN J S, TRIÓLO R. Early and late stages of demixing of a commercial Al-Li alloy [J]. Journal of Materials Science, 2002, 37(6): 1207–1213. DOI: https://doi.org/10.1023/A:1014327824507.

YUAN Shun, LI Yi-bo, HUANG Ming-hui, LI Jian. Determination of key parameters of Al — Li alloy adhesively bonded joints using cohesive zone model [J]. Journal of Central South University, 2018, 25(9): 2049–2057. DOI: https://doi.org/10.1007/s11771-018-3894-5.

LIU F, LIU Z Y, LIU M, HU Y C, CHEN Y, BAI S. Analysis of empirical relation between microstructure, texture evolution and fatigue properties of an Al-Cu-Li alloy during different pre-deformation processes [J]. Materials Science and Engineering A, 2018, 726: 309–319. DOI: https://doi.org/10.1016/j.msea.2018.04.047.

MUNOZ MORRIS M A, GUTIERREZ URRUTIA I, CALDERON N, MORRIS D G. Refinement of precipitates and deformation substructure in an Al-Cu-Li alloy during heavy rolling at elevated temperatures[J]. Materials Science and Engineering A, 2008, 492(1, 2): 268–275. DOI: https://doi.org/10.1016/j.msea.2008.03.036.

DECRES B, DESCHAMPS A, DE GEUSER F, DONNADIEU P, SIGLI C, WEYLAND M. The influence of Cu/Li ratio on precipitation in Al-Cu-Li-X alloys [J]. Acta Materialia, 2013, 61(6): 2207–2218. DOI: https://doi.org/10.1016/j.actamat.2012.12.041.

SIDHAR H, MISHRA R S. Aging kinetics of friction stir welded Al-Cu-Li-Mg-Ag and Al-Cu-Li-Mg alloys [J]. Materials and Design, 2016, 110: 60–71. DOI: https://doi.org/10.1016/j.matdes.2016.07.126.

LI Y, SHI Z, LIN J. Experimental investigation and modelling of yield strength and work hardening behaviour of artificially aged Al-Cu-Li alloy [J]. Materials and Design, 2019, 183: 108121. DOI: https://doi.org/10.1016/j.matdes.2019.108121.

RODGERS B I, PRANGNELL P B. Quantification of the influence of increased pre-stretching on microstructure-strength relationships in the Al-Cu-Li alloy AA2195 [J]. Acta Materialia, 2016, 108: 55–67. DOI: https://doi.org/10.1016/j.actamat.2016.02.017.

TSIVOULAS D, PRANGNELL P B. Comparison of the effect of individual and combined Zr and Mn additions on the fracture behavior of Al-Cu-Li alloy AA2198 rolled sheet [J]. Metallurgical and Materials Transactions A, 2014, 45(3): 1338–1351. DOI: https://doi.org/10.1007/s11661-013-2103-2.

MA P, ZHAN L, LIU C, WANG Q, LI H, LIU D, HU Z. Prestrain-dependent natural ageing and its effect on subsequent artificial ageing of an Al-Cu-Li alloy [J]. Journal of Alloys and Compounds, 2019, 790: 8–19. DOI: https://doi.org/10.1016/j.jallcom.2019.03.072.

NAYAN N, MISHRA S, PRAKASH A, MURTY S V S N, PRASAD M J N V, SAMAJDAR I. Effect of cross-rolling on microstructure and texture evolution and tensile behavior of aluminium-copper-lithium (AA2195) alloy [J]. Materials Science and Engineering A, 2019, 740–741: 252–261. DOI: https://doi.org/10.1016/j.msea.2018.10.089.

ZHILYAEV A P, LANGDON T G. Using high-pressure torsion for metal processing: Fundamentals and applications [J]. Progress in Materials Science, 2008, 53(6): 893–979. DOI: https://doi.org/10.1016/j.pmatsci.2008.03.002.

VORHAUER A, PIPPAN R. On the homogeneity of deformation by high pressure torsion [J]. Scripta Materialia, 2004, 51(9): 921–925. DOI: https://doi.org/10.1016/j.scriptamat.2004.04.025.

SUN Y, AINDOW M, HEBERT R J, LANGDON T G, LAVERNIA E J. High-pressure torsion-induced phase transformations and grain refinement in Al/Ti composites [J]. Journal of Materials Science, 2017, 52(20): 12170–12184. DOI: https://doi.org/10.1007/s10853-017-1331-z.

VALIEV R Z, LANGDON T G. Principles of equal-channel angular pressing as a processing tool for grain refinement [J]. Progress in Materials Science, 2006, 51(7): 881–981. DOI: https://doi.org/10.1016/j.pmatsci.2006.02.003.

DENG G Y, LU C, SU L H, TIEU A K, YU H L, LIU X H. Investigation of sample size effect on the deformation heterogeneity and texture development during equal channel angular pressing [J]. Computational Materials Science, 2013, 74: 75–85. DOI: https://doi.org/10.1016/j.commatsci.2013.03.007.

LIU F, YUAN H, GOEL S, LIU Y, WANG J T. Bulk nanolaminated nickel: Preparation, microstructure, mechanical property, and thermal stability [J]. Metallurgical and Materials Transactions A, 2018, 49(2): 576–594. DOI: https://doi.org/10.1007/s11661-017-4394-1.

TSUJI N, SAITO Y, LEE S H, MINAMINO Y. ARB (Accumulative Roll-Bonding) and other new techniques to produce bulk ultrafine grained materials [J]. Advanced Engineering Materials, 2003, 5(5): 338–344. DOI: https://doi.org/10.1002/adem.200310077.

YU H, LU C, TIEU K, KONG C. Fabrication of nanostructured Aluminum sheets using four-layer accumulative roll bonding [J]. Materials and Manufacturing Processes, 2014, 29(4): 448–453. DOI: https://doi.org/10.1080/10426914.2013.872259.

WANG H, SU L, YU H, LU C, TIEU K, LIU Y, ZHANG J. A new finite element model for multi-cycle accumulative roll bonding process and experiment verification[J]. Materials Science and Engineering A, 2018, 726: 93–101. DOI: https://doi.org/10.1016/j.msea.2018.04.040.

YU H, DU Q, GODBOLE A, LU C, KONG C. Improvement in strength and ductility of asymmetric-cryorolled copper sheets under low-temperature annealing [J]. Metallurgical and Materials Transactions A, 2018, 49(10): 4398–4403. DOI: https://doi.org/10.1007/s11661-018-4700-6.

YU H, YAN M, LI J, GODBOLE A, LU C, TIEU K, LI H, KONG C. Mechanical properties and microstructure of a Ti-6Al-4V alloy subjected to cold rolling, asymmetric rolling and asymmetric cryorolling [J]. Materials Science and Engineering A, 2018, 710: 10–16. DOI: https://doi.org/10.1016/j.msea.2017.10.075.

PANIGRAHI S K, JAYAGANTHAN R. A study on the mechanical properties of cryorolled Al-Mg-Si alloy [J]. Materials Science and Engineering A, 2008, 480(1, 2): 299–305. DOI: https://doi.org/10.1016/j.msea.2007.07.024.

PANIGRAHI S K, JAYAGANTHAN R. Effect of ageing on microstructure and mechanical properties of bulk, cryorolled, and room temperature rolled Al 7075 alloy [J]. Journal of Alloys and Compounds, 2011, 509(40): 9609–9616. DOI: https://doi.org/10.1016/j.jallcom.2011.07.028.

PANIGRAHI S K, JAYAGANTHAN R. Effect of annealing on precipitation, microstructural stability, and mechanical properties of cryorolled Al 6063 alloy [J]. Journal of Materials Science, 2010, 45(20): 5624–5636. DOI: https://doi.org/10.1007/s10853-010-4627-9.

UI G G, SANG H L, WON J N. The evolution of microstructure and mechanical properties of a 5052 aluminum alloy by the application of cryogenic rolling and warm rolling [J]. Materials Transactions, 2009, 50(1): 82–86. DOI: https://doi.org/10.2320/matertrans.MD200801.

YU H, LU C, TIEU K, LI H, GODBOLE A, ZHANG S. Special rolling techniques for improvement of mechanical properties of ultrafine-grained metal sheets: A review [J]. Advanced Engineering Materials, 2016, 18(5): 754–769. DOI: https://doi.org/10.1002/adem.201500369.

GHOLINIA A. Processing to ultrafine grain structures by conventional routes [J]. Materials Science and Technology, 2000, 16(11, 12): 1251–1255. DOI: https://doi.org/10.1179/026708300101507316.

XIONG H, SU L, KONG C, YU H. Development of high performance of Al alloys via cryo-forming: A review [J]. Advanced Engineering Materials, 2021, DOI: https://doi.org/10.1002/adem.202001533.

HUGHES D A, HANSEN N, BAMMANN D J. Geometrically necessary boundaries, incidental dislocation boundaries and geometrically necessary dislocations [J]. Scripta Materialia, 2003, 48(22): 147–153. DOI: https://doi.org/10.1016/S1359-6462(02)00358-5.

FU W, ZHENG W, HUANG Y, GUO F, JIANG S, XUE P, REN Y, FAN H, NING Z, SUN J. Cryogenic mechanical behaviors of CrMnFeCoNi high-entropy alloy [J]. Materials Science and Engineering A, 2020, 789: 139579. DOI: https://doi.org/10.1016/j.msea.2020.139579.

YOKOYAMA H, UMEZAWA O, NAGAL K, SUZUKI T, KOKUBO K. Cyclic deformation, dislocation structure, and internal fatigue crack generation in a Ti-Fe-O alloy at liquid nitrogen temperature [J]. Metallurgical and Materials Transactions A, 2000, 31(11): 2793–2805. DOI: https://doi.org/10.1007/BF02830339.

YU H, WANG H, LU C, TIEU A K, LI H, GODBOLE A, LIU X, KONG C, ZHAO X. Microstructure evolution of accumulative roll bonding processed pure aluminum during cryorolling [J]. Journal of Materials Research, 2016, 31(6): 797–805. DOI: https://doi.org/10.1557/jmr.2016.70.

WANG Z J, MA M, QIU Z X, ZHANG J X, LIU W C. Microstructure, texture and mechanical properties of AA 1060 aluminum alloy processed by cryogenic accumulative roll bonding [J]. Materials Characterization, 2018, 139: 269–278. DOI: https://doi.org/10.1016/j.matchar.2018.03.016.

TOPLOSKY V J, HAN K. Mechanical properties of cold-rolled and aged MP35N alloys for cryogenic magnet applications [J]. Advances in Cryogenic Engineering, 2012, 1435: 125–132. DOI: https://doi.org/10.1063/1.4712088.

ZHOU C, ZHAN L H, SHEN R L, ZHAO X, YU H L, HUANG M H, LI H, YANG Y L, HU L B, LIU D B, HU Z G. Creep behavior and mechanical properties of Al-Li-S4 alloy at different aging temperatures [J]. Journal of Central South University, 2020, 27(4): 1168–1175. DOI: https://doi.org/10.1007/s11771-020-4357-3.

XIE Yuan-kang, DENG Yun-lai, WANG Yu, GUO Xiao-bin. Effect of asymmetric rolling and subsequent ageing on the microstructure, texture and mechanical properties of the Al-Cu-Li alloy [J]. Journal of Alloys and Compounds, 2020, 836: 155445. DOI: https://doi.org/10.1016/j.jallcom.2020.155445.

LIU Dan-yang, LI Jin-feng, LIU Tian-le, MA Yun-long, IWAOKA H, HIROSAWA S, ZHANG Kai, ZHANG Ruifeng. Microstructure evolution and mechanical properties of Al-Cu-Li alloys with different rolling schedules and subsequent artificial ageing heat treatment [J]. Materials Characterization, 2020, 170: 110676. DOI: https://doi.org/10.1016/j.matchar.2020.110676.

MEI L, CHEN X P, HUANG G J, LIU Q. Improvement of mechanical properties of a cryorolled Al-Mg-Si alloy through warm rolling and aging [J]. Journal of Alloy and Compounds, 2019, 777: 259–263. DOI: https://doi.org/10.1016/j.jallcom.2018.11.012.

SHANMUGASUNDARAM T, MURTY B S, SUBRAMANYA SARMA V. Development of ultrafine grained high strength Al-Cu alloy by cryorolling [J]. Scripta Materialia, 2006, 54(12): 2013–2017. DOI: https://doi.org/10.1016/j.scriptamat.2006.03.012.

HIROSAWA S, HAMAOKA T, HORITA Z, LEE S, MATSUDA K, TERADA D. Methods for designing concurrently strengthened severely deformed age-hardenable aluminum alloys by ultrafine-grained and precipitation hardenings [J]. Metallurgical and Materials Transactions A, 2013, 44(8): 3921–3933. DOI: https://doi.org/10.1007/s11661-013-1730-y.

ZHANG C, LIU M, MENG Z, ZHANG Q, ZHAO G, CHEN L, ZHANG H, WANG J. Microstructure evolution and precipitation characteristics of spray-formed and subsequently extruded 2195 Al-Li alloy plate during solution and aging process[J]. Journal of Materials Processing Technology, 2020, 283: 116718. DOI: https://doi.org/10.1016/j.jmatprotec.2020.116718.

DENG Yan-jun, HUANG Guang-jie, CAO Ling-fei, WU Xiao-dong, HUANG Li, XIA Ming-yong, LIU Qing. Improvement of strength and ductility of Al-Cu-Li alloy through cryogenic rolling followed by aging [J]. Transactions of Nonferrous Metals Society of China, 2017, 27(9): 1920–1927. DOI: https://doi.org/10.1016/S1003-6326(17)60216-4.

LEE Y, DE-COOMAN B C. Characterization of compound particles formed during thin slab direct rolling of Ti-added Nb HSLA steel [J]. ISIJ International, 2014, 54(4): 893–899. DOI: https://doi.org/10.2355/isijinternational.54.893.

SARKAR A, BHAWMIK A, SUWAS S. Microstructural characterization of ultrafine-grain interstitial-free steel by X-ray diffraction line profile analysis [J]. Applied Physics A, 2009, 94(4): 943–948. DOI: https://doi.org/10.1007/s00339-008-4870-y.

JASEEM I, IMMANUEL J R, RAO P N, KHAN F, SAHOO B N, PANIGRAHI S K, KAMARAJ M. Synergetic effect of cryorolling and postroll aging on simultaneous increase in wear resistance and mechanical properties of an Al-Cu alloy [J]. Journal of Tribology, 2018, 140: 061607. DOI: https://doi.org/10.1115/1.4040162.

GUPTA C, KUMAWAT B, CHAKRAVARTTY J K. Descriptors of temporal signatures of serrations in a low alloy steel [J]. Materials Science and Engineering A, 2015, 620: 407–410. DOI: https://doi.org/10.1016/j.msea.2014.10.032.

KARAMOUZ M, AZARBARMAS M, EMAMY M, ALIPOUR M. Microstructure, hardness and tensile properties of A380 aluminum alloy with and without Li additions [J]. Materials Science and Engineering A, 2013, 582: 409–414. DOI: https://doi.org/10.1016/j.msea.2013.05.088.

SHE X, JIANG X, ZHANG R, WANG P, TANG B, DU W. Study on microstructure and fracture characteristics of 5083 aluminum alloy thick plate [J]. Journal of Alloys and Compounds, 2020, 825: 153960. DOI: https://doi.org/10.1016/j.jallcom.2020.153960.

CHANGELA K, NAIK H B, DESAI K P, RAVAL H K. Effect of rolling temperatures on mechanical and fracture behavior of AA 3003 alloy and pure Cu [J]. Applied Science, 2020, 2: 1109. DOI: https://doi.org/10.1007/s42452-020-2903-0.

SRINIVAS B, PANIGRAHI S K. A phenomenological model based on nanostructured dislocation cluster interactions to predict the work hardening behavior of cryodeformed materials [J]. International Journal of Plasticity, 2020, 133: 102772. DOI: https://doi.org/10.1016/j.ijplas.2020.102772.

GAIROLA S, JOSHI A, GANGIL B, RAWAT P, VERMA R. Correlation of tensile properties and fracture toughness with microstructural features for Al-Li 8090 alloy processed by cryorolling and post-rolled annealing [J]. Transactions of the Indian Institute of Metals, 2019, 72(7): 1743–1755. DOI: https://doi.org/10.1007/s12666-019-01641-z.

DHAL A, PANIGRAHI S K, SHUNMUGAM M S. Precipitation phenomena, thermal stability and grain growth kinetics in an ultra-fine grained Al 2014 alloy after annealing treatment [J]. Journal of Alloys and Compounds, 2015, 649: 229–238. DOI: https://doi.org/10.1016/j.jallcom.2015.07.098.

WANG Z, CHEN M, JIANG H, LI H, LI S. Effect of artificial ageing on strength and ductility of an Al-Cu-Mg-Mn alloy subjected to solutionizing and room-temperature rolling [J]. Materials Characterization, 2020, 165: 110383. DOI: https://doi.org/10.1016/j.matchar.2020.110383.

WANG Y, GUO F, HE Q, SONG L, WANG M, HUANG A, LI Y, HUANG C. Synergetic deformation-induced extraordinary softening and hardening in gradient copper [J]. Materials Science and Engineering A, 2019, 752: 217–222. DOI: https://doi.org/10.1016/j.msea.2019.03.020.

LI J, LU W, CHEN S, LIU C. Revealing extra strengthening and strain hardening in heterogeneous two-phase nanostructures [J]. International Journal of Plasticity, 2020, 126: 102626. DOI: https://doi.org/10.1016/j.ijplas.2019.11.005.

SELVAN C C, NARAYANAN C S, RAVISANKAR B, NARAYANASAMY R, VALLIAMMAI C T. The dependence of the strain path on the microstructure, texture and mechanical properties of the cryogenic rolled Al-Cu alloy [J]. Materials Research Express, 2020, 7(3): 036525. DOI: https://doi.org/10.1088/2053-1591/ab7f9a.

ROESCH L, HENRY G. Relationship between precipitation and dimple fracture in an 18 percent nickel maraging steel [C]//West Conshohocken, PA: ASTM, 1969: 3–32. DOI: https://doi.org/10.1520/STP47354S.

JIANG H J, LIU C Y, ZHANG B, XUE P, MA Z Y, LUO K, MA M Z, LIU R P. Simultaneously improving mechanical properties and damping capacity of Al-Mg-Si alloy through friction stir processing [J]. Materials Characterization, 2017, 131: 425–430. DOI: https://doi.org/10.1016/j.matchar.2017.07.037.

CHEN Y, LIU C Y, ZHANG B, QIN F C, HOU Y F. Precipitation behavior and mechanical properties of Al-Zn-Mg alloy with high Zn concentration [J]. Journal of Alloys and Compounds, 2020, 825: 154005. DOI: https://doi.org/10.1016/j.jallcom.2020.154005.

Funding

Project(2019YFB2006500) supported by the National Key Research and Development Program, China; Project (51674303) supported by the National Natural Science Foundation of China; Project(2020GK2032) supported by Hunan High-tech Industry Science and Technology Innovation Leading Plan, China; Project (2018RS3015) supported by the Huxiang High-level Talent Gathering Project of Hunan Province, China; Project(2017YFA0700700) supported by the Ministry of Science & Technology of China; Project(2019CX006) supported by Innovation Driven Program of Central South University, China

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, L., Bhatta, L., Xiong, Hq. et al. Mechanical properties and microstructure evolution of an Al-Cu-Li alloy subjected to rolling and aging. J. Cent. South Univ. 28, 3800–3817 (2021). https://doi.org/10.1007/s11771-021-4764-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4764-0

Key words

- Al-Cu-Li alloy

- cryorolling

- artificial aging

- dynamic precipitation

- dislocation density

- mechanical property