Abstract

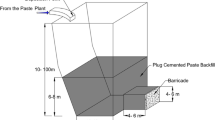

A step-by-step load was utilized to mimic the load history of the backfill column in the in-situ curing process. The inner damage of the specimen during curing and uniaxial compressive testing was monitored by electrical resistivity and ultrasonic equipment. Results show that: 1) Uniaxial compressive strength (UCS) and elastic modulus (EM) of the samples curing under pressure are higher than those of the control samples without pressure, ranging in ratio from 0.5% to 20.2% and 7.1% to 52.3%, respectively, and are influenced by the initial loading age (ILA) and stress strength ratio (SSR). The SSR during curing should not exceed 80%. 2) The earlier the ILA is, the higher the total strain becomes. The higher the SSR applies, the larger the total strain gets. The creep strain increases with the increase of SSR and can be described by Burger’s viscoelastic creep model. When SSR is less than 80%, the earlier the ILA is, the smaller the creep strain becomes after the last step-loading. 3) The stability of the early age backfill column under pressure can be monitored based on the change of ultrasonic pulse velocity (UPV) and electrical resistivity.

摘要

利用分级加载来模拟采空区矸石胶结充填柱硬化过程中的加载历史。通过电阻率和超声设备监 测试件在硬化期间和单轴压缩测试期间的内部损伤。结果表明 1)加压硬化试件32 d 的单轴抗压强 度和弹性模量高于无压力硬化的对照试件, 分别为对照试件的0.5%∼20.2%和7.1%∼52.3%, 且受初始 加载龄期和应力-强度比的影响; 硬化期间施加在矸石胶结充填柱上的应力-强度比不应超过80%。2) 初始加载龄期越早, 总变形越大, 应力-强度比越高, 总应变越大; 蠕变应变随着应力-强度比的增加 而增加, 且可以用Burgers 黏弹性蠕变模型来描述; 当应力-强度比小于80%时, 初始加载龄期越早, 最后一步加载后的蠕变应变就越小。3)可以根据超声波脉冲速度和电阻率的变化来监测早龄期矸石胶 结充填柱在压力下的稳定性。

Similar content being viewed by others

References

ZHANG Qin-li, WANG Xin-min. Performance of cemented coal gangue backfill [J]. Journal of Central South University of Technology, 2007, 14(2): 216–219. DOI: https://doi.org/10.1007/s11771-007-0043-y.

WU Di, YANG Bao-gui, LIU Yu-cheng. Pressure drop in loop pipe flow of fresh cemented coal gangue-fly ash slurry: Experiment and simulation [J]. Advanced Powder Technology, 2015, 26(3): 920–927. DOI: https://doi.org/10.1016/j.apt.2015.03.009.

WU D, ZHANG Y, WANG C. Modeling the thermal response of hydrating cemented gangue backfill with admixture of fly ash [J]. Thermochimica Acta, 2016, 623: 86–94. DOI: https://doi.org/10.1016/j.tca.2015.11.007.

BENZAAZOUA M, OUELLET J, SERVANT S, NEWMAN P, VERBURG R. Cementitious backfill with high sulfur content physical, chemical, and mineralogical characterization [J]. Cement and Concrete Research, 1999, 29(5): 719–725. DOI: https://doi.org/10.1016/S0008-8846(99)00023-X.

BENZAAZOUA M, FALL M, BELEM T. A contribution to understanding the hardening process of cemented pastefill [J]. Minerals Engineering, 2004, 17(2): 141–152. DOI: https://doi.org/10.1016/j.mineng.2003.10.022.

YILMAZ E. Advances in reducing large volumes of environmentally harmful mine waste rocks and tailings [J]. Gospodarka Surowcami Mineralnymi-Mineral Resources Managemen, 2011, 27: 89–112. DOI: https://doi.org/10.1016/j.ijrmms.2010.08.005.

YAO Yuan, SUN Heng-hu. A novel silica alumina-based backfill material composed of coal refuse and fly ash [J]. Journal of Hazardous Materials, 2012, 213-214: 71–82. DOI: https://doi.org/10.1016/j.jhazmat.2012.01.059.

ZHANG Xin-guo, LIN Jia, LIU Jin-xiao, LI Fei, PANG Zhen-zhong. Investigation of hydraulic-mechanical properties of paste backfill containing coal gangue-fly ash and its application in an underground coal mine [J]. Energies, 2017, 10(9): 1309. DOI: https://doi.org/10.3390/en10091309.

FENG Guo-rui, DU Xian-jie, GUO Yu-xia, QI Ting-ye, WANG Ze-hua, LI Qing-dong, LI Hua-yun, KANG Li-xun. Basic theory of constructional backfill mining and the underground space utilization concept [J]. Journal of China Coal Society, 2019, 44(1): 74–84. DOI: https://doi.org/10.13225/j.cnki.jccs.2018.1598. (in Chinese)

XIE Jian-lin, ZHU Wei-bing, XU Jia-lin, WEN Jia-hui, LIU Chuan-zhen. A study on the bearing effect of pier column backfilling in the goaf of a thin coal seam [J]. Geosciences Journal, 2016, 20(3): 361–369. DOI: https://doi.org/10.1007/s12303-015-0047-9.

ZHU Wei-bing, XU Jing-min, XU Jia-lin, CHEN Da-yong, SHI Jian-xin. Pier-column backfill mining technology for controlling surface subsidence [J]. International Journal of Rock Mechanics and Mining Sciences, 2017, 96: 58–65. DOI: https://doi.org/10.1016/j.ijrmms.2017.04.014.

DU Xian-jie, FENG Guo-rui, GUO Yu-xia, QI Ting-ye, ZHANG Yu-jiang, GUO Jun. Failure analyses of unconfined CCWBM body in uniaxial compression based on central pressure variation [J]. Waste Management & Research, 2018, 36(2): 159–168. DOI: https://doi.org/10.1177/0734242X17748365.

DU Xian-jie, FENG Guo-rui, QI Ting-ye, GUO Yu-xia, ZHANG Yu-jiang, WANG Ze-hua. Failure characteristics of large unconfined cemented gangue backfill structure in partial backfill mining [J]. Construction and Building Materials, 2019, 194: 257–265. DOI: https://doi.org/10.1016/j.conbuildmat.2018.11.038.

DU Xian-jie, FENG Guo-rui, ZHANG Yu-jiang, WANG Ze-hua, GUO Yu-xia, QI Ting-ye. Bearing mechanism and stability monitoring of cemented gangue backfill column with stirrups in partial backfill engineering [J]. Engineering Structures, 2019, 188: 603–612. DOI: https://doi.org/10.1016/j.engstruct.2019.03.061.

POKHAREL M, FALL M. Coupled thermochemical effects on the strength development of slag-paste backfill materials [J]. Journal of Materials in Civil Engineering, 2010, 23(5): 511–525. DOI: https://doi.org/10.1061/(asce)mt.1943-5533.0000192.

SUN Qi, LI Bing, TIAN Shuo, CAI Chang, XIA Ya-jie. Creep properties of geopolymer cemented coal gangue backfill under dynamic disturbance [J]. Construction and Building Materials, 2018, 191: 644–654. DOI: https://doi.org/10.1016/j.conbuildmat.2018.10.055.

SUN Qi, CAI Chang, ZHANG Shu-kun, TIAN Shuo, LI Bing, XIA Ya-jie, SUN Qing-wei. Study of localized deformation in geopolymer cemented coal gangue backfill based on the digital speckle correlation method [J]. Construction and Building Materials, 2019, 215: 321–331. DOI: https://doi.org/10.1016/j.conbuildmat.2019.04.208.

FALL M, BELEM T, SAMB S, BENZAAZOUA M. Experimental characterization of the stress-strain behaviour of cemented paste backfill in compression [J]. Journal of Materials Science, 2007, 42(11): 3914–3922. DOI: https://doi.org/10.1007/s10853-006-0403-2.

FALL M, CÉLESTIN J C, POKHAREL M, TOURÉ M. A contribution to understanding the effects of curing temperature on the mechanical properties of mine cemented tailings backfill [J]. Engineering Geology, 2010, 114(3, 4): 397–413. DOI: https://doi.org/10.1016/j.enggeo.2010.05.016.

FALL M, POKHAREL M. Coupled effects of sulphate and temperature on the strength development of cemented tailings backfills: Portland cement-paste backfill [J]. Cement & Concrete Composites, 2010, 32(10): 819–828. DOI: https://doi.org/10.1016/j.cemconcomp.2010.08.002.

FALL M, BENZAAZOUA M, SAA E G. Mix proportioning of underground cemented tailings backfill [J]. Tunnelling and Underground Space Technology, 2008, 23(1): 80–90. DOI: https://doi.org/10.1016/j.tust.2006.08.005.

CAO Shuai, SONG Wei-dong, YILMAZ E. Influence of structural factors on uniaxial compressive strength of cemented tailings backfill [J]. Construction and Building Materials, 2018, 174: 190–201. DOI: https://doi.org/10.1016/j.conbuildmat.2018.04.126.

OREJARENA L, FALL M. The use of artificial neural networks to predict the effect of sulphate attack on the strength of cemented paste backfill [J]. Bulletin of Engineering Geology and the Environment, 2010, 69(4): 659–670. DOI: https://doi.org/10.1007/s10064-010-0326-7.

LI Wen-chen, FALL M. Sulphate effect on the early age strength and self-desiccation of cemented paste backfill [J]. Construction and Building Materials, 2016, 106: 296–304. DOI: https://doi.org/10.1016/j.conbuildmat.2015.12.124.

OREJARENA L, FALL M. Mechanical response of a mine composite material to extreme heat [J]. Bulletin of Engineering Geology and the Environment, 2008, 67(3): 387–396. DOI: https://doi.org/10.1007/s10064-008-0148-z.

YILMAZ E, BELEM T, BENZAAZOUA M. Specimen size effect on strength behavior of cemented paste backfills subjected to different placement conditions [J]. Engineering Geology, 2015, 185: 52–62. DOI: https://doi.org/10.1016/j.enggeo.2014.11.015.

WU Di, DENG Teng-fei, ZHAO Run-kang. A coupled THMC modeling application of cemented coal gangue backfill [J]. Construction and Building Materials, 2018, 158: 326–336. DOI: https://doi.org/10.1016/j.conbuildmat.2017.10.009.

WU Di, HOU Yun-bing, DENG Teng-fei, CHEN Yi-zhou, ZHAO Xiao-long. Thermal, hydraulic and mechanical performances of cemented coal gangue backfill [J]. International Journal of Mineral Processing, 2017, 162: 12–18. DOI: https://doi.org/10.1016/j.minpro.2017.03.001.

XU Wen-bin, HOU Yun-bin, SONG Wei-dong, ZHOU Yi-pei, YIN Tian-jun. Resistivity and thermal infrared precursors associated with cemented backfill mass [J]. Journal of Central South University, 2016, 23(9): 2329–2335. DOI: https://doi.org/10.1007/s11771-016-3291-x.

LIU L, ZHU C, QI C, WANG M, HUAN C, ZHANG B, SONG K I.. Effects of curing time and ice-to-water ratio on performance of cemented paste backfill containing ice slag [J]. Construction and Building Materials, 2019, 228: 116639. DOI: https://doi.org/10.1016/j.conbuildmat.2019.08.020.

ZHENG Juan-rong, ZHU Ya-lan, ZHAO Zhen-bo. Utilization of limestone powder and water-reducing admixture in cemented paste backfill of coarse copper mine tailings [J]. Construction and Building Materials, 2016, 124: 31–36. DOI: https://doi.org/10.1016/j.conbuildmat.2016.07.055.

OUATTARA D, BELEM T, MBONIMPA M, YAHIA A. Effect of superplasticizers on the consistency and unconfined compressive strength of cemented paste backfills [J]. Construction and Building Materials, 2018, 181: 59–72. DOI: https://doi.org/10.1016/j.conbuildmat.2018.05.288.

MANGANE M B C, ARGANE R, TRAUCHESSEC R, LECOMTE A, BENZAAZOUA M. Influence of superplasticizers on mechanical properties and workability of cemented paste backfill [J]. Minerals Engineering, 2018, 116: 3–14. DOI: https://doi.org/10.1016/j.mineng.2017.11.006.

CAO S, YILMAZ E, SONG W, YILMAZ E, XUE G L. Loading rate effect on uniaxial compressive strength behavior and acoustic emission properties of cemented tailings backfill [J]. Construction and Building Materials, 2019, 213: 313–324. DOI: https://doi.org/10.1016/j.conbuildmat.2019.04.082.

QI Ting-ye, FENG Guo-rui, LI Yan-rong, GUO Yu-xia, GUO Jun, ZHANG Yu-jiang. Effects of fine gangue on strength, resistivity, and microscopic properties of cemented coal gangue backfill for coal mining [J]. Shock and Vibration, 2015, 2015: 1–11. DOI: https://doi.org/10.1155/2015/752678.

QI Ting-ye, FENG Guo-rui, ZHANG Yu-jiang, GUO Jun, GUO Yu-xia. Effects of fly ash content on properties of cement paste backfilling [J]. Journal of Residuals Science & Technology, 2015, 12(3): 133–141. DOI: https://doi.org/10.12783/issn.1544-8053/12/3/3.

CHEN Shao-jie, DU Zhao-wen, ZHANG Zhen, YIN Da-wei, FENG Fan, MA Jun-biao. Effects of red mud additions on gangue-cemented paste backfill properties [J]. Powder Technology, 2020, 367: 833–840. DOI: https://doi.org/10.1016/j.powtec.2020.03.055.

CHEN Shao-jie, DU Zhao-wen, ZHANG Zhen, ZHANG Hua-wei, XIA Zhi-guo, FENG Fan. Effects of chloride on the early mechanical properties and microstructure of gangue-cemented paste backfill [J]. Construction and Building Materials, 2020, 235: 117504. DOI: https://doi.org/10.1016/j.conbuildmat.2019.117504.

SERVANT S. Détermination des paramètres mécaniques des remblais miniers faits de résidus ciments [D]. Montreal, Quebec: McGill University, 2001.

YILMAZ E, BELEM T, BENZAAZOUA M. Effects of curing and stress conditions on hydromechanical, geotechnical and geochemical properties of cemented paste backfill [J]. Engineering Geology, 2014, 168: 23–37. DOI: https://doi.org/10.1016/j.enggeo.2013.10.024.

YILMAZ E, BENZAAZOUA M, BELEM T, BUSSIÈRE B. Effect of curing under pressure on compressive strength development of cemented paste backfill [J]. Minerals Engineering, 2009, 22(9, 10): 772–785. DOI: https://doi.org/10.1016/j.mineng.2009.02.002.

YILMAZ E, BELEM T, BUSSIÈRE B, MBONIMPA M, BENZAAZOUA M. Curing time effect on consolidation behaviour of cemented paste backfill containing different cement types and contents [J]. Construction and Building Materials, 2015, 75: 99–111. DOI: https://doi.org/10.1016/j.conbuildmat.2014.11.008.

GHIRIAN A, FALL M. Strength evolution and deformation behaviour of cemented paste backfill at early ages: Effect of curing stress, filling strategy and drainage [J]. International Journal of Mining Science and Technology, 2016, 26(5): 809–817. DOI: https://doi.org/10.1016/j.ijmst.2016.05.039.

LIU Qiong, WU Wen-xin, XIAO Jian-zhuang, TIAN Yu-ting, CHEN Jin-yi, SINGH A. Correlation between damage evolution and resistivity reaction of concrete in-filled with graphene nanoplatelets [J]. Construction and Building Materials, 2019, 208: 482–491. DOI: https://doi.org/10.1016/j.conbuildmat.2019.03.036.

CHU Hong-yan, CHEN Jian-kang. The experimental study on the correlation of resistivity and damage for conductive concrete [J]. Cement & Concrete Composites, 2016, 67: 12–19. DOI: https://doi.org/10.1016/j.cemconcomp.2015.12.005.

HUYNH T P, HWANG C L, LIMONGAN A H. The long-term creep and shrinkage behaviors of green concrete designed for bridge girder using a densified mixture design algorithm [J]. Cement and Concrete Composites, 2018, 87: 79–88. DOI: https://doi.org/10.1016/j.cemconcomp.2017.12.004.

DU Cheng-cheng, LIU Tie-jun, ZOU Du-jian, TENG Jun. Time dependent strain development of early age concrete under step-by-step load history [J]. Construction and Building Materials, 2015, 86: 133–139. DOI: https://doi.org/10.1016/j.conbuildmat.2015.03.116.

BAI Jin-wen, FENG Guo-rui, WANG Ze-hua, WANG Shang-yong, QI Ting-ye, WANG Peng-fei. Experimental investigations on the progressive failure characteristics of a sandwiched coal-rock system under uniaxial compression [J]. Applied Sciences-Basel, 2019, 9(6): 1195. DOI: https://doi.org/10.3390/app9061195.

RUSATI P K, SONG K I. Magnesium chloride and sulfate attacks on gravel-sand-cement-inorganic binder mixture [J]. Construction and Building Materials, 2018, 187: 565–571. DOI: https://doi.org/10.1016/j.conbuildmat.2018.07.149.

XU Wen-bin, TIAN Xi-chun, QIU Yu, DANG Peng, YIN Tian-jun. Experiment of the resistivity characteristic of cemented backfill mass during the whole consolidation process [J]. Journal of China University of Mining & Technology, 2017, 46(2): 265–272, 344. DOI: https://doi.org/10.13247/j.cnki.jcumt.000648. (in Chinese)

WU Di, ZHANG Yong-liang, LIU Yu-cheng. Mechanical performance and ultrasonic properties of cemented gangue backfill with admixture of fly ash [J]. Ultrasonics, 2016, 64: 89–96. DOI: https://doi.org/10.1016/j.ultras.2015.08.004.

FENG G, DU X, ZHANG Y. ‘Optical-acoustic-stress’ responses in failure progress of cemented gangue-fly ash backfill material under uniaxial compression [J]. Nondestructive Testing and Evolution, 2019, 34(2): 135–146. DOI: https://doi.org/10.1080/10589759.2019.1576175.

AL-MUFTI R L, FRIED A N. Pulse velocity assessment of early age creep of concrete [J]. Construction and Building Materials, 2016, 121: 622–628. DOI: https://doi.org/10.1016/j.conbuildmat.2016.06.015.

FARAH M, GRONDIN F, ALAM S Y, LOUKILI A. Experimental approach to investigate creep-damage bilateral effects in concrete at early age [J]. Cement & Concrete Composites, 2019, 96: 128–137. DOI: https://doi.org/10.1016/j.cemconcomp.2018.11.022.

MEHTA P K, MONTEIRO P J M. Concrete microstructure, properties and materials [M]. Third ed. New York: McGraw-Hill, 2006: 38–41.

MONTEIRO P J M, MASO J C, OLLIVIER J P. The aggregate-mortar interface [J]. Cement and Concrete Research, 1985, 15(6): 953–958. DOI: https://doi.org/10.1016/0008-8846(85)90084-5.

AL-MUFTI R L, FRIED A N. The early age non-destructive testing of concrete made with recycled concrete aggregate [J]. Construction and Building Materials, 2012, 37: 379–386. DOI: https://doi.org/10.1016/j.conbuildmat.2012.07.058.

YIM H J, KIM J H, KWAK H G, KIM J K. Evaluation of internal bleeding in concrete using a self-weight bleeding test [J]. Cement and Concrete Research, 2013, 53: 18–24. DOI: https://doi.org/10.1016/j.cemconres.2013.05.015.

SHOKOUHI P, ZOËGA A, WIGGENHAUSER H. Nondestructive investigation of stress-induced damage in concrete [J]. Advances in Civil Engineering, 2010, 2010(5): 1–9. DOI: https://doi.org/10.1155/2010/740189.

YILMAZ E, BELEM T, BUSSIÈRE B, BENZAAZOUA M. Relationships between microstructural properties and compressive strength of consolidated and unconsolidated cemented paste backfills [J]. Cement and Concrete Composites, 2011, 33(6): 702–715. DOI: https://doi.org/10.1016/j.cemconcomp.2011.03.01349.

WANG Dao-lin, ZHANG Qin-li, CHEN Qiu-song, QI Chong-chong, FENG Yan, XIAO Chong-chun. Temperature variation characteristics in flocculation settlement of tailings and its mechanism [J]. International Journal of Minerals, Metallurgy and Materials, 2020. DOI: https://doi.org/10.1007/s12613-020-2022-3

YANG Yi-xuan, ZHAO Tong-qian, JIAO Hua-zhe, WANG Yun-fei, LI Hai-yan. Potential effect of porosity evolution of cemented paste backfill on selective solidification of heavy metal ions [J]. International Journal of Environmental Research and Public Health, 2020, 17(3): 814. DOI: https://doi.org/10.3390/ijerph17030814.

MANSOURI H, AJALLOEIAN R. Mechanical behavior of salt rock under uniaxial compression and creep tests [J]. International Journal of Rock Mechanics and Mining Sciences, 2018, 110: 19–27. DOI: https://doi.org/10.1016/j.ijrmms.2018.07.006.

DERAEMAEKER A, DUMOULIN C. Embedding ultrasonic transducers in concrete: A lifelong monitoring technology [J]. Construction and Building Materials, 2019, 194: 42–50. DOI: https://doi.org/10.1016/j.conbuildmat.2018.11.013.

Author information

Authors and Affiliations

Contributions

The overarching research goals were developed by GUO Yu-xia, FENG Guo-rui and RAN Hong-yu. RAN Hong-yu and GUO Yu-xia did the experiment and the analyzed the experimental data. The initial draft of the manuscript was written by GUO Yu-xia and RAN Hong-yu. FENG Guo-rui, DU Xian-jie, QI Ting-ye and WANG Ze-hua revised the original manuscript. All authors replied to reviewers’ comments and revised the final version.

Corresponding author

Additional information

Conflict of interest

GUO Yu-xia, RAN Hong-yu, FENG Guo-rui, DU Xian-jie, QI Ting-ye and WANG Ze-hua declare that they have no conflict of interest.

Foundation item

Project(51974192) supported by the National Natural Science Foundation of China; Project(201803D31044) supported by the Program for Key Research Project of Shanxi Province in the Field of Social Development, China; Project(201801D121092) supported by the Applied Basic Research Project of Shanxi Province, China

Rights and permissions

About this article

Cite this article

Guo, Yx., Ran, Hy., Feng, Gr. et al. Effects of curing under step-by-step load on mechanical and deformation properties of cemented gangue backfill column. J. Cent. South Univ. 27, 3417–3435 (2020). https://doi.org/10.1007/s11771-020-4556-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-020-4556-y

Key words

- cemented gangue backfill column

- curing under step-by-step load

- compressive strength

- elastic modulus

- deformation

- electrical resistivity