Abstract

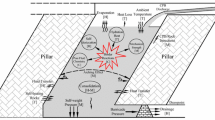

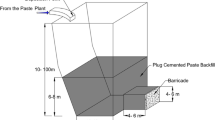

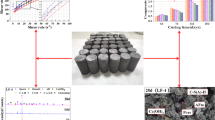

The use of cemented paste backfills (CPB, a mine composite tailings material) in underground mining is currently increasing in importance globally. However, despite the tremendous progress made in understanding the factors affecting the performance of CPB, little attention has been devoted to the impact of high temperatures on its mechanical properties. This article presents the results of experimental investigations into the mechanical responses of CPB when subjected to high thermal loads. Samples made with silicate and pure cement or a mix of 50/50 cement and slag or fly ash were heated at 100, 200, 400 and 600°C, and the unconfined compressive strength, tensile strength, modulus of elasticity, stress–strain behaviour and microstructure evaluated by laboratory tests. The results show that high temperatures have a significant influence on the mechanical properties of CPB, which should be taken into account when determining an appropriate mix for the binder.

Résumé

L’utilisation de remblais en pâte cimenté dans l’exploitation minière prend aujourd’hui beaucoup d’importance dans le monde et particulièrement au Canada. Cependant, malgré d’énormes progrès établis dans la compréhension des facteurs pouvant affecter les propriétés mécaniques ou la performance de ces remblais, peu d’études ont été consacrées à l’évaluation de l’impact des hautes températures sur les propriétés mécaniques des remblais. Pour cette raison, cet article présente les résultats d’études expérimentales sur la réponse mécanique des remblais en pâte cimenté soumis à des chargements thermiques. Plusieurs types de remblais en pâte cimentés ont été d’abord chauffés à différentes températures (100°C, 200°C, 400°C and 600°C). La résistance à la compression uniaxiale, la résistance à la traction indirecte, le module d’élasticité, le comportement contrainte-déformation et la microstructure des remblais chauffés ont été déterminés en conduisant des essais de laboratoire. Les résultats montrent que les hautes températures ont une influence significative sur les propriétés mécaniques des remblais en pâte cimentés.

Similar content being viewed by others

References

ACI Committee 201 (1997) Guide to durable concrete, ACI 201.2R-92 (Reapproved 1997). In: ACI (ed), Manual of Concrete Practice 1, Michigan, 41 pp

Anderberg Y (1997) Spalling phenomena of HPC and OC. In: Proceedings of the International Workshop on Fire Performance of High-Strength Concrete, NIST, Gaithersburg

Benz DP, Ehlen MA, Ferraris CF, Winpigler JA (2002) Service life prediction based on sorptivity for highway concrete exposed to sulfate attack and freeze-thaw conditions. Report no. FHWA-RD-01- 162, US Department of Transportation, 2002, 62 pp

Bernier LR, Li M (2003) High temperature oxidation (heating) of sulfide paste backfill: a mineralogical and chemical perspective. In: Mining and the environment conference, Sudbury, CD ROM

Brackebusch F, Shillabeer J (1998) Use of paste for tailings disposal. In: Proceedings of the 6th international symposium on mining with backfill (Minefill 98). AusIMM, Publication no.1/98, pp 53–58

Chan SYN, Peng GF, Anson M (1999) Residual strength and pore structure of high-strength concrete and normal-strength concrete after exposure to high temperatures. Cem Concr Compos 21:23–27

Cheng F-P, Kodur VKR, Wang TC (2004) Stress–strain curves for high strength concrete at elevated temperatures. J Mater Civil Eng 16(1):84–94

Diederichs U, Jumppanen UM, Penttala V (1989) Behavior of high strength concrete at high temperatures. Report No. 92, Department of Structural Engineering, Helsinki University of Technology

Fall M, Benzaazoua M (2005) Modeling the effect of sulphate on strength development of paste backfill and binder mixture optimization. J Cem Concr Res 35(2):301–314

Fall M, Samb S (2006a) Impact of high temperature on the performance properties of underground cemented paste backfill. In: 59th Canadian Geotechnical Conference, Vancouver, 2006, CD-ROM

Fall M, Samb S (2006b) Influence of curing temperature on strength, deformation behaviour and pore structure of cemented paste backfill at early ages. Constr Build Mater (in press)

Fall M, Samb S (2007) Pore structure of cemented tailings materials under natural or accidental thermal loads. J Mater Charact (in press)

Fall M, Benzaazoua M, Ouellet S (2005) Experimental characterization of the influence of tailings fineness and density on the quality of cemented paste backfill. Miner Eng 18:41–44

Fall M, Benzaazoua M, Sae E (2007a) Mix proportioning of underground cemented paste backfill. Int J Tunn Undergr Constr 23:80–90

Fall M, Belem T, Samb S, Benzaazoua M (2007b). Experimental characterization of the stress–strain behaviour of cemented paste backfill in compression. J Mater Sci 42(11):3914–3992

Hassani F, Archibald J (1998) Mine backfill, CD-ROM. Canadian Institute of Mine, Metallurgy and Petroleum, 262 p

Lasser FP (2001) Thermal stability and decomposition mechanisms of ettringite at <120°. Cem Concr Res 31(9):1333–1339

Mitchel RJ, Wong BC (1982) Behaviour of cemented tailings sand. Can Geotech J 19:289–295

Mitchell RJ, Olsen RS, Smith JD (1982) Model studies on cemented tailings used in mine backfill. Can Geotech J 19(1):14–28

Nasser KW, Marzouk HM (1979) Properties of mass concrete containing fly ash at high temperatures. ACI J 76(4):537–551

Noumowé A (1995) Effet des hautes températures (20°C–600°C) sur le béton, PhD Thesis. Institut National des Sciences Appliquées

Platret G (2002) Suivi de l’hydratation du ciment et de l’évolution des phases solides dans les bétons par analyse thermique. Caractéristiques microstructurales et propriétés relatives à la durabilité des bétons. Méthodes de mesure et d’essai de laboratoire. Méthodes d’essai No. 58, Laboratoire Central des Ponts et Chaussées, Février (2002)

Sofrá F, Boger D (2001) Environmental rheology for waste minimization in the minerals industry. Particulate Fluids Processing Centre, Department of Chemical Engineering, The University of Melbourne, Parkville, Vic 3010, Australia

Vedalakshmi R (2003) Quantification of hydrated cement products of blended cements in low and medium strength concrete using TG and DTA technique. Thermochim Acta 407:49–60

Vergne J (2000) Rules of thumb for the hard rock mining industry. In: Hard rock miner’s handbook, 3rd edn. McIntosh Engineering Inc. USA, 42 pp

Willam K, Rhee I, Xi Y (2002) Thermal degradation of heterogeneous concrete materials. University of Colorado at Boulder, USA. ASCE Mater J 17(3):276–285

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Orejarena, L., Fall, M. Mechanical response of a mine composite material to extreme heat. Bull Eng Geol Environ 67, 387–396 (2008). https://doi.org/10.1007/s10064-008-0148-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-008-0148-z