Abstract

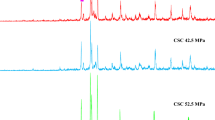

The strength of cement-based materials, such as mortar, concrete and cement paste backfill (CPB), depends on its microstructures (e.g. pore structure and arrangement of particles and skeleton). Numerous studies on the relationship between strength and pore structure (e.g., pore size and its distribution) were performed, but the micro-morphology characteristics have been rarely concerned. Texture describing the surface properties of the sample is a global feature, which is an effective way to quantify the micro-morphological properties. In statistical analysis, GLCM features and Tamura texture are the most representative methods for characterizing the texture features. The mechanical strength and section image of the backfill sample prepared from three different solid concentrations of paste were obtained by uniaxial compressive strength test and scanning electron microscope, respectively. The texture features of different SEM images were calculated based on image analysis technology, and then the correlation between these parameters and the strength was analyzed. It was proved that the method is effective in the quantitative analysis on the micro-morphology characteristics of CPB. There is a significant correlation between the texture features and the unconfined compressive strength, and the prediction of strength is feasible using texture parameters of the CPB microstructure.

摘要

胶结充填膏体 (CPB)、 砂浆及混凝土等水泥基材料的力学强度取决于其微观结构, 如孔隙数量、 孔径及结构, 颗粒及骨架的排列形态等。 对于该类材料的力学强度与其孔隙结构 (如孔径及其分布) 的关系研究目前已有很多, 但与微观形态特征或纹理特性的相关性研究较少。 纹理是一种反映图像中同质现象的视觉特征, 体现了物体表面共有的内在属性, 包含了物体表面结构组织排列以及它们与周围环境的联系, 是量化微观形态特性的有效方法。 在统计分析中, 灰度共生矩阵 (GLCM) 纹理和 Tamura 纹理是表征纹理特征的最具代表性方法。 本研究以 3 种不同质量浓度膏体制备的充填体试块为样本, 养护至指定龄期后经单轴抗压强度试验获得其力学强度, 再对试块断面进行电镜扫描 (SEM) 获得其微观结构图像; 基于图像识别/分析技术提取 SEM 图像的纹理特征参数, 分析纹理特性与 SEM 图像参数(放大倍数)间的关系, 筛选出有效的 SEM 图像样品; 分析各纹理参数与膏体浓度的相关性, 识别出与膏体浓度呈正相关的纹理参数, 并验证该纹理参数与力学强度存在严格的相关关系。

Similar content being viewed by others

References

ARGANE R, BENZAAZOUA M, HAKKOU R, BOUAMRANE A. Reuse of base-metal tailings as aggregates for rendering mortars: Assessment of immobilization performances and environmental behavior [J]. Construction and Building Materials, 2015, 96: 296–306. DOI: https://doi.org/10.1016/j.conbuildmat.2015.08.029.

POKHAREL M, FALL M. Combined influence of sulphate and temperature on the saturated hydraulic conductivity of hardened cemented paste backfill [J]. Cement and Concrete Composites, 2013, 38: 21–28. DOI: https://doi.org/10.1016/j.cemconcomp.2013.03.015.

WU Di, CAI Si-jing. Coupled effect of cement hydration and temperature on hydraulic behavior of cemented tailings backfill [J]. Journal of Central South University, 2015, 22(5): 1956–1964. DOI: https://doi.org/10.1007/s11771-015-2715-3.

LI Xi-bing, DU Jing, GAO Li, HE Su-ya, GAN Lei, SUN Cheng, SHI Ying. Immobilization of phosphogypsum for cemented paste backfill and its environmental effect [J]. Journal of Cleaner Production, 2017, 156: 137–146. DOI: https://doi.org/10.1016/j.jclepro.2017.04.046.

YILMAZ E, FALL M. Paste tailings management [M]. Berlin: Springer International Publishing, 2017: 7–32. DOI: https://doi.org/10.1007/978-3-319-39682-8_4.

ERCIKDI B, KULEKCI G, YILMZA T. Utilization of granulated marble wastes and waste bricks as mineral admixture in cemented paste backfill of sulphide-rich tailings [J]. Construction and Building Materials, 2015, 93: 573–583. DOI: https://doi.org/10.1016/j.conbuildmat.2015.06.042.

YIN Sheng-hua, WU Ai-xiang, HU Kai-jian, WANG Yong, ZHANG Yan-kai. The effect of solid components on the rheological and mechanical properties of cemented paste backfill [J]. Minerals Engineering. 2012, 35: 61–66. DOI: 1 https://doi.org/10.1016/j.mineng.2012.04.008.

KE Xing, HOU Hao-bo, ZHOU Min, WANG Yan, ZHOU Xian. Effect of particle gradation on properties of fresh and hardened cemented paste backfill [J]. Construction and Building Materials, 2015, 96: 378–382. DOI: https://doi.org/10.1016/j.conbuildmat.2015.08.057.

FALL M, CELESTIN J C, POKHAREL M, TOURE M. A contribution to understanding the effects of curing temperature on the mechanical properties of mine cemented tailings backfill [J]. Engineering Geology, 2010, 114(3, 4): 397–413. https://doi.org/10.1016/j.enggeo.2010.05.016.

YILMAZ E, BELEM T, BENZAAZOUA M, KESIMAL A, ERCIKDI B, CIHANGIR F. Use of high-density paste backfill for safe disposal of copper/zinc mine tailings [J]. Gospodarka Surowcami Mineralnymi, 2011, 27(3): 81–94. DOI: https://doi.org/yadda.icm.edu.pl/yadda/element/bwmeta1.element.baztech-article-BPZ1-0068-0025.

WU Ai-xiang, HUANG Ming-qing, HAN Bin, WANG Yi-ming, YU Shao-feng, MIAO Xiu-xiu. Orthogonal design and numerical simulation of room and pillar configurations in fractured stopes [J]. Journal of Central South University, 2014, 21(8): 3338–3344. DOI: https://doi.org/10.1007/s11771-014-2307-7.

FALL M, SAMB S S. Effect of high temperature on strength and microstructural properties of cemented paste backfill [J]. Fire Safety Journal, 2009, 44(4): 642–651. DOI: https://doi.org/10.1016/j.firesaf.2008.12.004.

YILMAZ T, ERCIKDI B. Predicting the uniaxial compressive strength of cemented paste backfill from ultrasonic pulse velocity test [J]. Nondestructive Testing & Evaluation, 2015, 31(3): 247–266. DOI: https://doi.org/10.1080/10589759.2015.1111891.

XU Wen-bin, TIAN Xi-chun, CAO Pei-wang. Assessment of hydration process and mechanical properties of cemented paste backfill by electrical resistivity measurement [J]. Nondestructive Testing & Evaluation, 2017, (3): 1–15. DOI: https://doi.org/10.1080/10589759.2017.1353983.

ERCIKDI B, YILMAZ T, KULEKCI G. Strength and ultrasonic properties of cemented paste backfill [J]. Ultrasonics, 2014, 54(1): 195–204. DOI: https://doi.org/10.1016/j.ultras.2013.04.013.

YILMAZ E, BELEM T, BUSSIERE B, BENZAAZOUA M. Relationships between microstructural properties and compressive strength of consolidated and unconsolidated cemented paste backfills [J]. Cement and Concrete Composites, 2011, 33(6): 702–715. DOI: https://doi.org/10.1016/j.cemconcomp.2011.03.013.

HE Yong-jia, MOTE J, LANGE D A. Characterization of microstructure evolution of cement paste by micro computed tomography [J]. Journal of Central South University, 2013, 20(4): 1115–1121. DOI: https://doi.org/10.1007/s11771-013-1592-x.

CIHANGIR F, AKYOL Y. Mechanical, hydrological and microstructural assessment of the durability of cemented paste backfill containing alkali-activated slag [J]. International Journal of Mining, Reclamation and Environment, 2016, 32(2): 1–21. DOI: https://doi.org/10.1080/17480930.2016.1242183.

JIN Shan-shan, ZHANG Jin-xi, HAN Song. Fractal analysis of relation between strength and pore structure of hardened mortar [J]. Construction and Building Materials. 2017, 135: 1–7. DOI: https://doi.org/10.1016/j.conbuildmat.2016.12.152.

YILMAZ E. Investigating the hydrogeotechnical and microstrural properties of cemented paste backfill using the CUAPS apparetus [D] Quebec, Canada: University du Quebec en Abitibi-Temiscamingue, 2010. https://doi.org/depositum.uqat.ca/34/.

YILMAZ E, BELEM T, BUSSIERE B, MBONIMPA M, BENZAAZOUA M. Curing time effect on consolidation behaviour of cemented paste backfill containing different cement types and contents [J]. Construction and Building Materials, 2015, 75: 99–111. DOI: https://doi.org/10.1016/j.conbuildmat.2014.11.008.

GHIRIAN A, FALL M. Coupled thermo-hydro-mechanicalchemical behaviour of cemented paste backfill in column experiments [J]. Engineering Geology, 2014, 170: 11–23. DOI: https://doi.org/10.1016/j.enggeo.2013.12.004.

YU Hai-peng, LIU Yi-xiang, LIU Zhen-bo. Wood species restrieval on base of image textural festure [J]. Scientia Silvae Sinicae, 2007(4): 77–81. DOI: https://doi.org/10.3321/ j.issn: 1001–1488. 2007.04.013. (in Chinese)

TOWNSEND A, SENIN N, BLUNT L, LEACH R K, TAYLOR J S. Surface texture metrology for metal additive manufacturing: A review [J]. Precision Engineering, 2016, 46: 34–47. DOI: https://doi.org/10.1016/j.precisioneng.2016.06.001.

AZAMI H, ESCUDERO J, HUMEAU-HEURTIER A. Bidimensional distribution entropy to analyze the irregularity of small-sized textures [J]. IEEE Signal Processing Letters, 2017, 24(9): 1338–1342. DOI: https://doi.org/10.1109/lsp.2017.2723505.

SADOWSKI L, MATHIA T G. Multi-scale metrology of concrete surface morphology: Fundamentals and specificity [J]. Construction and Building Materials, 2016, 113: 613–621. DOI: https://doi.org/10.1016/j.conbuildmat.2016.03.099.

STOLZ C M, MASUERO A B, PAGNUSSAT D T, KIRCHHEIM A P. Influence of substrate texture on the tensile and shear bond strength of rendering mortars [J]. Construction and Building Materials, 2016, 128: 298–307. DOI: https://doi.org/10.1016/j.conbuildmat.2016.10.097.

UKAR E, LAUBACH S E. Syn-and postkinematic cement textures in fractured carbonate rocks: Insights from advanced cathodoluminescence imaging [J]. Tectonophysics, 2016, 690: 190–205. DOI: https://doi.org/10.1016/j.tecto.2016.05.001.

ZAMRI M I A P, CORDOVA F, KHAIRUDDIN A S M, MOKHTAR N, YUSOF R. Tree species classification based on image analysis using Improved-Basic Gray Level Aura Matrix [J]. Computers and Electronics in Agriculture, 2016, 124: 227–233. DOI: https://doi.org/10.1016/j.compag.2016.04.004.

ASTM. D2487-11 standard practice for classification of soils for engineering purposes (unified soil classification system) [S]. 2011. DOI: https://doi.org/www.astm.org/Standards/D2487.htm.

ASTM. C143-90 standard test method for slump of hydraulic-cement concrete [S]. 2015. https://doi.org/www.astm.org/Standards/C143.htm.

RAO Yun-zhang, SHAO Ya-jian, XIAO Guang-zhe, SUN Xiang, HUANG Yong-gang. Effect of polycarboxylatebased superplasticizer on performances of super fine tailings paste backfill [J]. The Chinese Journal of Nonferrous Metals, 2016, 26(12): 2647–1655. DOI: https://doi.org/10.19476/j.ysxb.1004.0609.2016.12.021. (in Chinese)

FELIPE-SOTELO M, HINCHLIFF J, EANS N D M, READ D. Solubility constraints affecting the migration of selenium through the cementitious backfill of a geological disposal facility [J]. Journal of Hazardous Materials, 2016, 305: 21–29. DOI: https://doi.org/10.1016/j.jhazmat.2015.11.024.

CIHANGIR F, ERCIKDI B, KESIMAL A, DEVECI H, ERDEMIR F. Paste backfill of high-sulphide mill tailings using alkali-activated blast furnace slag: Effect of activator nature, concentration and slag properties [J]. Minerals Engineering, 2015, 83: 117–127. DOI: https://doi.org/10.1016/j.enggeo.2014.11.015.

TAMURA H, MORI S, YAMAWAKI T. Textural features corresponding to visual perception [J]. IEEE Transactions on Systems, Man, and Cybernetics, 1978, 8(6): 460–473. DOI: https://doi.org/10.1109/tsmc.1978.4309999.

XIE Yong-hua, WANG Jin-cong. Study on the identification of the wood surface defects based on texture features [J]. Optik-International Journal for Light and Electron Optics, 2015, 126(19): 2231–2235. DOI: https://doi.org/10.1016/j.ijleo.2015.05.101.

TIEN Chuen-lin, LYU You-ru, JYU Shiao-shan. Surface flatness of optical thin films evaluated by gray level co-occurrence matrix and entropy [J]. Applied Surface Science, 2008, 254(15): 4762–4767. DOI: https://doi.org/10.1016/j.apsusc.2008.01.088.

SUN Wei, WU Ai-xiang, HOU Ke-peng, YANG Yi, LIU Lei, WEN Yi-ming. Real-time observation of meso-fracture process in backfill body during mine subsidence using X-ray CT under uniaxial compressive conditions [J]. Construction and Building Materials, 2016, 113: 153–162. DOI: https://doi.org/10.1016/j.conbuildmat.2016.03.050.

PIA G, SILIGARDI C, CASNEDI L, SANNA U. Pore size distribution and porosity influence on Sorptivity of ceramic tiles: From experimental data to fractal modelling [J]. Ceramics International, 2016, 42(8): 9583–9590. DOI: https://doi.org/10.1016/j.conbuildmat.2016.05.037.

TANG S W, CAI X H, HE Z, ZHOU W, SHAO H Y, LI Z J, WU T, CHEN E. The review of pore structure evaluation in cementitious materials by electrical methods [J]. Construction and Building Materials, 2016, 117: 273–284. DOI: https://doi.org/10.1016/j.ceramint.2016.03.041.

YILMAZ E, BELEM T, BENZAAZOUA M. Specimen size effect on strength behavior of cemented paste backfills subjected to different placement conditions [J]. Engineering Geology, 2015, 185: 52–62. DOI: https://doi.org/10.1016/j.mineng.2015.08.022.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51722401) supported by the National Natural Science Foundation for Excellent Young Scholars of China; Project(FRF-TP-18-003C1) supported by the Fundamental Research Funds for the Central Universities, China; Project(51734001) supported by the Key Program of National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Yin, Sh., Shao, Yj., Wu, Ax. et al. Texture features analysis on micro-structure of paste backfill based on image analysis technology. J. Cent. South Univ. 25, 2360–2372 (2018). https://doi.org/10.1007/s11771-018-3920-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-018-3920-7

Key words

- microstructure

- texture feature

- Tamura texture

- GLCM feature

- unconfined compressive strength

- quantitative analysis

- cement paste backfill