Abstract

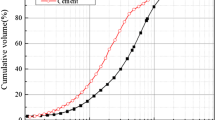

The mechanical properties of cemented paste backfill (CPB) depend heavily on its pore structural characteristics and micro-structural changes. In order to explore the variation mechanisms of macro-mechanical characteristics and micro-structure of CPB. CPB specimens with different mass concentrations prepared from the full tailings of Xianglushan Tungsten Ore were micro-tests. Moreover, acquired pore digital images were processed by using the pores (particles) and cracks analysis system (PCAS), and a sensitivity analysis was performed. The results show that as the mass concentration of CPB increases from 70% to 78%, the porosity, the average pore area and the number of pores drop overall, leading to a decline in the pores opening degree and enhancing the mechanical characteristics. As the mass concentration of CPB increases, the trend of fractal dimension, probability entropy and roundness is reduced, constant and increased, which can result in an enhancement of the uniformity, an unchanged directionality and more round pores. According to the definition of sensitivity, the sensitivities of various micro-parameters were calculated and can be ranked as porosity > average pore area > number of pores > roundness > fractal dimension > probability entropy.

摘要

胶结充填体的力学性能很大程度上取决于其孔隙结构特征及微观结构的变化. 为探究胶结充填体的宏观力学特性和微观结构的变化机理, 以香炉山钨矿的全尾砂为试验材料, 通过对不同质量浓度的胶结充填体开展微观试验, 获得的孔隙数字图像采用颗粒及孔隙识别与分析系统(PCAS)进行处理并进行敏感度分析. 结果表明: 随着胶结充填体质量浓度的增大(由70%增大到78%), 孔隙率、平均孔隙面积、孔隙数的总体变化趋势减小, 导致孔隙张开的程度变小使其力学特征增强; 随着胶结充填体的质量浓度对分形维数、概率熵和圆形度总体的趋势是减小、不变和增大导致均一化程度提高、定向性保持不变和孔隙更接近圆形. 按照敏感度的定义, 计算微观参数敏感度, 其敏感度排序为孔隙率>平均孔隙面积>孔隙数>圆形度>分形维数>概率熵.

Similar content being viewed by others

References

SUN Guang-hua, WEI Sha-sha, SU Dong-liang. Optimal matching scheme for the full tailings-cemented filling based on the orthogonal experiment [J]. Metal Mine, 2015(4): 111–113. (in Chinese)

HUANG Q X, HE Y P. Research on overburden movement characteristics of large mining height working face in shallow buried thin bedrock [J]. Energies, 2019, 12: 4208. DOI: https://doi.org/10.3390/en12214208.

LIU Lang, XIN Jie, HUAN Chao, QI Chong-chong, ZHOU Wen-wu, SONG KI-IL. Pore and strength characteristics of cemented paste backfill using sulphide tailings: Effect of sulphur content [J]. Construction and Building Materials, 2020, 237: 117452. DOI: https://doi.org/10.1016/j.conbuildmat.2019.117452.

LIU Lang, FANG Zhi-yu, WU Yong-ping, LAI Xing-ping, WANG Pai, SONG Ki-il. Experimental investigation of solid-liquid two-phase flow in cemented rock-tailings backfill using electrical resistance tomography [J]. Construction and Building Materials, 2018, 175: 267–276. DOI: https://doi.org/10.1016/j.conbuildmat.2018.04.139.

ER OL Y, MOSTAFA B, TIKOU B, BRUNO B. Effect of curing under pressure on compressive strength development of cemented paste backfill [J]. Minerals Engineering, 2012, 22(9): 772–785. DOI: https://doi.org/10.1016/j.mineng.2009.02.002.

QI Chong-chong, CHEN Qiu-song, FOURIEA A, ZHAO Jian-wen, ZHANG Qin-li. Pressure drop in pipe flow of cemented paste backfill: Experimental and modeling study [J]. Powder Technology, 2018. DOI: https://doi.org/10.1016/j.powtec.2018.03.070.

QI Chong-chong, FOURIEA A, CHEN Qiu-song. Data-driven modelling of the flocculation process on mineral processing tailings treatment [J]. Journal of Cleaner Production, 2018, 196: 505–516. DOI: https://doi.org/10.1016/j.jclepro.2018.06.054.

YILMAZ T, ERCIKDI B. Predicting the UCS of CPB from ultrasonic pulse velocity test [J]. Nondestructive Testing and Evaluation, 2016 31(3): 247–266. DOI: https://doi.org/10.1080/10589759.2015.1111891

LIU Lang, ZHU Chao, QI Chong-chong, WANG Mei, HUAN Chao, ZHANG Bo, SONG Ki-il. Effects of curing time and ice-to-water ratio on performance of cemented paste backfill containing ice slag [J]. Construction and Building Materials, 2019, 228: 116639. https://doi.org/10.1016/j.conbuildmat.2019.08.020.

LIU L, FANG Z, QI C, ZHANG B, GUO L, SONG Ki-il. Experimental investigation on the relationship between pore characteristics and unconfined compressive strength of CPB [J]. Construction and Building Materials, 2018, 179: 254–264. DOI: https://doi.org/10.1016/j.conbuildmat.2018.05.224.

OREJARENA L, FALL M. Artificial neural network based modeling of the coupled effect of sulphate and temperature on the strength of cemented paste backfill [J]. Canadian Journal of Civil Engineering, 2011, 38(1): 100–109. DOI: https://doi.org/10.1139/L10-109.

CHEN Q, ZHANG Q, QI C, FOURIE A, XIAO C. Recycling phosphogypsum and construction demolition waste for CPB and its environmental impact [J]. Journal of Cleaner Production, 2018, 186: 418–429. DOI: https://doi.org/10.1016/j.jclepro.2018.03.131.

SHENG Huang, KAI Wen-xia, LAN Qiao. Dynamic tests of cemented paste backfill: Effects of strain rate, curing time, and cement content on compressive strength [J]. Journal of Materials Science, 2011, 46(15): 5165–5170. DOI: https://doi.org/10.1007/s10853-011-5449-0.

YAO Zhi-quan, ZHANG Qin-li, HU Guan-yu. Experimental study on tension strength characteristics of backfilling [J]. Journal of University of South China, 2009, 23(3): 10–13.

WOLFGANG H, HU Ji-ping. Factors influencing the strength of fine cementing filler [J]. Foreign Metal Mining, 1983(4): 61–69. (in Chinese)

QI C, CHEN Q, FOURIE A, ZHANG Q. An intelligent modelling framework for mechanical properties of CPB [J]. Minerals Engineering, 2018, 123: 16–27. DOI: https://doi.org/10.1016/j.mineng.2018.04.010.

QI C, FOURIE A, CHEN Q. Neural network and particle swarm optimization for predicting the unconfined compressive strength of CPB [J]. Construction and Building Materials, 2018, 159: 473–478. DOI: https://doi.org/10.1016/j.conbuildmat.2017.11.006.

QI C, FOURIE A, CHEN Q, ZHANG Q. A strength prediction model using artificial intelligence for recycling waste tailings as CPB [J]. Journal of Cleaner Production, 2018, 183: 566–578. DOI: https://doi.org/10.1016/j.jclepro.2018.02.154.

CARLOS M, KESIMAL A, ERCIKDI B, YILMAZ E. The effect of desliming by sedimentation on paste backfill performance [J]. Minerals Engineering, 2003, 16(10): 1009–1011. DOI: https://doi.org/10.1016/S0892-6875(03)00267-X.

XU W B, DU J H, SONG W D, CHEN H Y. Experiment on the mechanism of consolidating backfill body of extra-fine grain unclassified tailings and cementitious materials [J]. Rock and Soil Mechanics, 2013, 34(8): 2295–2302. DOI: https://doi.org/10.16285/j.rsm.2013.08.013.

WANG Q, CHEN H E, CAI K Y. Quantitative evaluation of microstructure features of soil contained some cement [J]. Rock and Soil Mechanics, 2003(S1): 12–16. DOI: https://doi.org/10.16285/j.rsm.2003.s1.003.

XUE R, HU R L, MAO L T. Fractal study on the microstructur evariation of soft soils in consolidation process [J]. China Civil Engineering Journal, 2006(10): 87–91. DOI: https://doi.org/10.15951/j.tmgcxb.2006.10.014.

CHEN L, SONG W D, LU B Q, WANG S P. Experimental research on total tailings cemented filling function in Jinshandian iron mine [J]. Gold, 2011, 32(12): 31–35.

CAO Yang, ZHOU Jian, YAN Jia-jia. Study of microstructures of soft clay under dynamic loading considering effect of cyclic stress ratio and frequency [J]. Rock and Soil Mechanics, 2014, 35(3): 735–743. DOI: https://doi.org/10.16285/j.rsm.2014.03.041.

ZHOU J, DENG Y, CAO Y. Experimental study of microstructure of Hangzhou saturated soft soil during consolidation process [J]. Journal of Central South University: Science and Technology, 2014, 45(6): 1998–2005. (in Chinese)

ZHOU Hui, FANG Ying-guang, YU Chang-jiang. Micro-Structure observation and analysis of guangzhou soft soil during consolidation process [J]. Chinese Journal of Rock Mechanics and Engineering, 2009, 28(S2): 3830–3837.

CHEN Xin, SHI Xiu-zhi, ZHOU Jian, CHEN Qiu-song, LI En-ming, DU Xiang-hong. Compressive behavior and microstructural properties of tailings polypropylene fibre-reinforced CPB [J]. Construction and Building Materials, 2018, 190: 211–221. DOI: https://doi.org/10.1016/j.geotexmem.2015.03.003.

CHEN X, WU S, ZHOU J. Influence of porosity on compressive and tensile strength of cement mortar [J]. Construction and Building Materials, 2013, 40: 869–874. DOI: https://doi.org/10.1016/j.conbuildmat.2012.11.072.

LIU Z. Research and application of the microscopic pore structure characteristics of low permeability coal seam [D]. Xi’an, China: Xi’an University of Science and Technology, 2013.

LIU C, WANG B J, SHI B. Analytic method of morphological parameters of cracks for rock and soil based on image processing and recognition [J]. Chinese Journal of Geotechnical Engineering, 2008, 30(9): 1383–1388. (in Chinese)

ZENG C. Research on soft soil’s microstructure characteristic and their change along with process of consolidation [D]. Guangzhou, China: South China University of Technology, 2011. (in Chinese)

SHI Bin. Quantitative research on the orientation of microstructures of clayey soil [J]. Acta Geologica Sinica, 1997(1): 36–44.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Foundation item: Projects(51674188, 51874229, 51504182) supported by the National Natural Science Foundation of China; Project (2018KJXX-083) supported by Shaanxi Innovative Talents Cultivate Program-New-star Plan of Science and Technology, China

Rights and permissions

About this article

Cite this article

Liu, L., Zhou, P., Feng, Y. et al. Quantitative investigation on micro-parameters of cemented paste backfill and its sensitivity analysis. J. Cent. South Univ. 27, 267–276 (2020). https://doi.org/10.1007/s11771-020-4294-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-020-4294-1